Firewood Processing Machines: Boost Efficiency Today

Imagine sitting by a crackling fire, the warmth enveloping you as the chilly winds howl outside. To enjoy such moments, you need a reliable source of firewood, and that’s where firewood processing machines come into play.

Have you ever wondered how you could streamline the task of chopping and preparing firewood? These machines could be the game-changer you’ve been looking for. They promise efficiency, safety, and convenience, making the daunting task of firewood preparation almost effortless.

By harnessing the power of these innovative machines, you can turn a laborious chore into a quick and rewarding activity. Dive into this article to discover how firewood processing machines can transform your approach to wood preparation and enhance your overall experience. Your fireside moments await, so let’s unlock the secrets behind these powerful tools together.

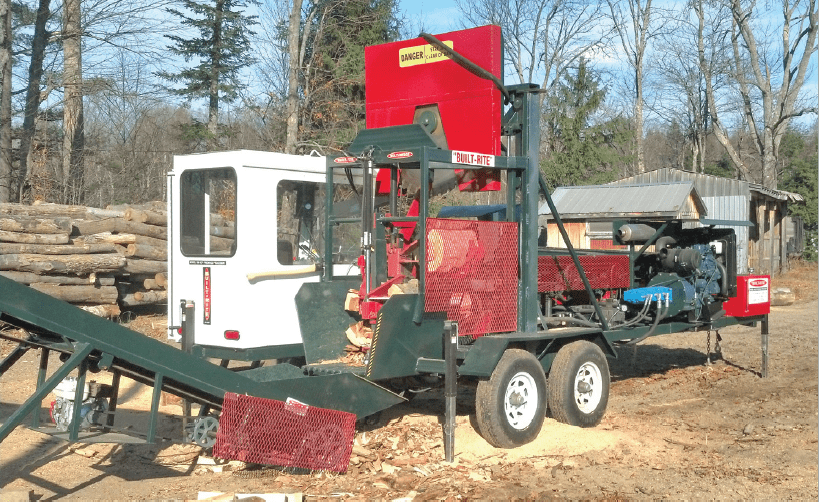

Credit: www.hud-son.com

Types Of Firewood Processing Machines

Log splitters are useful for cutting wood logs. They are simple to use. Push a button or pull a lever to start. The splitter uses a wedge to cut the wood. This makes the wood easier to burn. Some splitters run on gasoline. Others use electric power. Choose the right type for your needs.

Wood chippers break down branches and small logs. These machines have sharp blades. The blades cut the wood into small pieces. Chippers are great for making mulch. Mulch helps plants grow strong. Wood chippers come in different sizes. Some are small and easy to move. Others are large and stay in one place.

Firewood saws cut logs into smaller pieces. They are faster than axes. Saws can be electric or manual. Electric saws are very powerful. Manual saws need human strength. Use firewood saws safely. Always wear safety gear. Goggles and gloves are important. These tools make cutting wood easier.

Benefits Of Using Processing Machines

Processing machines make cutting wood fast. This means more wood in less time. Workers can do other tasks while machines work. This leads to more firewood each day. Machines help with heavy lifting. Less effort for humans. More wood means more sales and happy customers.

Using machines saves money. Fewer workers needed for the job. Less money spent on labor costs. Machines need less maintenance. They are durable and last long. Investing once saves money later. Fuel costs less than paying many workers. This keeps business profitable.

Machines make work safer. Workers stay away from sharp tools. Less risk of cuts and injuries. Machines handle dangerous tasks. Training for machines is easy. Safety gear is important, but machines do the hard work. This keeps everyone safe and sound.

Selecting The Right Machine

Understand what you need from the machine. Some machines cut wood fast. Others split big logs with ease. Choose based on your wood type and quantity. Think about how often you will use it. Frequent use needs a strong, reliable machine. Occasional use might need something simpler.

Space is important when buying a machine. Measure your storage area first. Ensure the machine fits well. Large machines need more room. Small machines can fit in tight spaces. Make sure you can move around it easily.

Money matters when choosing a machine. Set a clear budget before you shop. Compare prices of different models. Some machines are cheap but need more repairs. Others cost more but last longer. Balance cost with quality for the best choice.

Maintenance Tips

Inspect machines every week. Look for any loose bolts or worn parts. Check safety guards and ensure they are in place. Listen for any strange noises. They can signal trouble. Make sure all emergency stops work properly. Replace any broken switches.

Store machines in a dry place. Moisture can cause rust and damage. Cover them when not in use. Use a tarp or a cover. Keep them away from direct sunlight. Sunlight can harm the machine’s surface. Ensure the storage area is clean and tidy.

Lubricate moving parts often. This prevents wear and tear. Use the right type of oil. Clean the machines after every use. Remove any dust and debris. Use a soft cloth or brush. Avoid water on electric parts. Dry thoroughly if wet.

Innovations In Firewood Machinery

Machines now cut firewood on their own. These machines save time. They also help with safety. Workers do less manual labor. This makes work easier. Less chance of getting hurt. This is helpful in big operations. Many logs can be cut in one day. The machine does the hard work.

New machines use less energy. This is better for our planet. Some machines use solar power. Others are built with recycled materials. They make less noise and pollution. This helps the environment stay clean. People enjoy working with these machines. They feel good about helping the earth.

Smart machines can talk to computers. They adjust themselves. They know what size logs to cut. Workers can control them from far away. They use apps on phones or tablets. This makes the job easy. It also helps with precision. Logs are cut exactly right. This saves material and money.

Credit: www.dyna-products.com

Safety Measures

Wearing protective gear is very important. Always use gloves to protect hands. Goggles keep eyes safe from wood chips. Ear protection helps with loud machine noise. Sturdy boots protect feet from falling logs. Helmets shield the head from accidents.

Read machine manuals before use. Check machines for damage regularly. Keep work area clean to avoid trips. Use machines only in daylight. Do not rush. Focus on the task at hand. Stay alert and aware of surroundings.

Know emergency numbers for quick help. Keep a first aid kit nearby. Learn basic first aid for minor injuries. Practice fire drills to escape safely. Have a phone on hand for emergencies. Inform someone when workig alone. Plan escape routes in advance.

Credit: www.hahnmachinery.com

Frequently Asked Questions

What Are Firewood Processing Machines?

Firewood processing machines are specialized equipment used to cut, split, and stack logs into firewood. They enhance efficiency by automating the labor-intensive process. These machines come in various sizes and capabilities, catering to both small-scale users and commercial operations. Their use significantly reduces the time and effort required for firewood production.

How Do Firewood Processors Work?

Firewood processors operate by cutting and splitting logs into uniform pieces. Logs are fed into the machine, where they are cut to a specific length. The machine then splits the logs using hydraulic pressure. This process is efficient and quick, allowing users to produce large quantities of firewood with minimal manual labor.

Are Firewood Processing Machines Cost-effective?

Yes, firewood processing machines are cost-effective for regular users. They save time and reduce labor costs significantly. Although the initial investment might be high, the efficiency and productivity gains outweigh the costs. Businesses and individuals processing large volumes of firewood can see a quick return on investment.

What Safety Measures Are Needed When Using These Machines?

When using firewood processing machines, always wear protective gear like gloves, goggles, and steel-toed boots. Ensure the machine is on stable ground before operation. Regularly inspect the machine for any wear or damage. Follow the manufacturer’s guidelines for maintenance and operation.

Never operate the machine under the influence of alcohol or drugs.

Conclusion

Firewood processing machines make preparing wood easy and efficient. They save time and reduce labor. Choosing the right machine is crucial for your needs. Consider factors like size, power, and budget. These machines can handle different types of wood. This versatility is a key benefit.

Many users find them helpful and reliable. You can improve your firewood production significantly. Explore the options available. Choose a machine that fits your requirements best. With the right equipment, firewood processing becomes simple and effective. Enjoy warm fires with less effort and more time.