Homemade Wood Flatbed: Ultimate DIY Truck Transformation

You can build a homemade wood flatbed by designing a frame and attaching wooden planks securely. This can be a cost-effective and customizable option for your truck.

Adding a protective sealant can help increase the durability of the wood and prevent rotting. Consider the weight capacity and dimensions needed for your specific truck model. By following safety guidelines and using quality materials, you can create a sturdy and functional wood flatbed for your truck.

This DIY project allows you to tailor the design to your preferences and offers a unique alternative to traditional metal flatbeds. With careful planning and construction, a homemade wood flatbed can be a practical and visually appealing addition to your vehicle.

Introduction To DIY Truck Bed Projects

Are you looking to add functionality and a personal touch to your truck? DIY truck bed projects offer an excellent solution. One popular option is a homemade wood flatbed, which not only provides a practical hauling surface but also adds a rustic charm to your vehicle. In this blog post, we will explore the benefits of a homemade wood flatbed and discuss the essential tools and materials you’ll need to get started.

Benefits Of A Homemade Wood Flatbed

Building your own wood flatbed for your truck comes with several advantages:

- Cost-effective: Creating a homemade wood flatbed is generally more affordable compared to purchasing a pre-made one.

- Customization: With a DIY project, you have the freedom to design the flatbed according to your specific needs and preferences. Whether you require additional storage compartments, tie-down points, or a unique aesthetic, you can tailor the flatbed to suit your requirements.

- Durability: When constructed properly using high-quality materials, a homemade wood flatbed can be just as durable as a commercially available option. Plus, you can easily repair or replace individual components if needed.

- Personal satisfaction: Building something with your own hands brings a sense of accomplishment and pride. Every time you use your homemade wood flatbed, you’ll be reminded of the effort you put into creating it.

Essential Tools And Materials

To embark on your DIY wood flatbed project, you’ll need the following tools and materials:

| Tools | Materials |

|---|---|

|

|

With these tools and materials at your disposal, you’ll be well-equipped to begin your homemade wood flatbed project.

Designing Your Wood Flatbed

Designing Your Wood Flatbed is an exciting and crucial step in the process of creating a custom flatbed for your truck. Taking the time to carefully plan and sketch out your design, calculate the dimensions and required materials, and consider the functionality and aesthetics of the flatbed will ensure a successful and satisfying end result.

Sketching Your Design

Before embarking on the construction of your wood flatbed, it’s essential to create a detailed sketch of your design. Consider the specific requirements for your truck and the intended use of the flatbed. Incorporate storage compartments, tie-down points, and any other features that will enhance its practicality. A well-thought-out sketch will serve as a roadmap for the construction phase.

Calculating Dimensions And Materials

Accurate calculations are paramount in ensuring the structural integrity and functionality of your wood flatbed. Determine the dimensions based on your truck’s specifications and the intended payload capacity. Once the dimensions are established, calculate the quantity and dimensions of the wood and any additional materials required for the construction. Prioritize sturdy, durable lumber and appropriate fasteners to guarantee the longevity of your flatbed.

Selecting The Right Wood

Choosing the right wood is crucial when building a homemade wood flatbed. Opt for durable and sturdy wood varieties such as oak, cedar, or redwood that can withstand heavy loads and weather conditions.

Types Of Wood For Durability

When selecting wood for your homemade wood flatbed, consider durability. Opt for hardwoods like oak or maple for long-lasting results.

Treating And Preparing Your Wood

Treating the wood is essential for longevity. Prep the wood by sanding and sealing to prevent rot and enhance appearance.

Building The Frame

Building a homemade wood flatbed is a great way to save money and customize your truck. One of the most important parts of building a flatbed is constructing the frame. In this post, we will discuss the process of building the frame, including cutting and assembling the base frame, reinforcing the structure, and adding finishing touches.

Cutting And Assembling The Base Frame

The first step in building the frame is to cut the lumber to the appropriate length. Measure the truck bed to determine the size of the frame and cut the lumber accordingly. It’s important to make precise cuts to ensure the frame fits snugly on the truck bed.

Next, assemble the base frame by attaching the cross members to the side rails. Use wood screws or bolts to secure the pieces together. It’s important to ensure that the frame is square and level, as this will affect the final product’s stability.

Reinforcing The Structure

Once the base frame is assembled, it’s time to reinforce the structure. This involves adding additional cross members and diagonal braces to provide additional support. The number of cross members and braces needed will depend on the size of the flatbed and the weight it will carry.

When attaching the cross members and braces, it’s important to use the appropriate hardware. Bolts and nuts are recommended over wood screws, as they provide a stronger connection. It’s also important to ensure that the hardware is tightened securely.

Finally, add finishing touches such as sanding and painting the frame to protect it from the elements.

Building a homemade wood flatbed can be a challenging but rewarding project. By following the steps outlined in this post, you can build a sturdy and functional flatbed that will last for years to come.

Installing The Flatbed Onto Your Truck

When it comes to installing the homemade wood flatbed onto your truck, it’s important to follow the right steps to ensure a secure and stable setup.

Preparing The Truck Bed

Before installing the flatbed, clean the truck bed thoroughly to ensure a smooth and flat surface.

- Remove any debris or loose material from the truck bed.

- Inspect the truck bed for any damage or rust that may affect the installation.

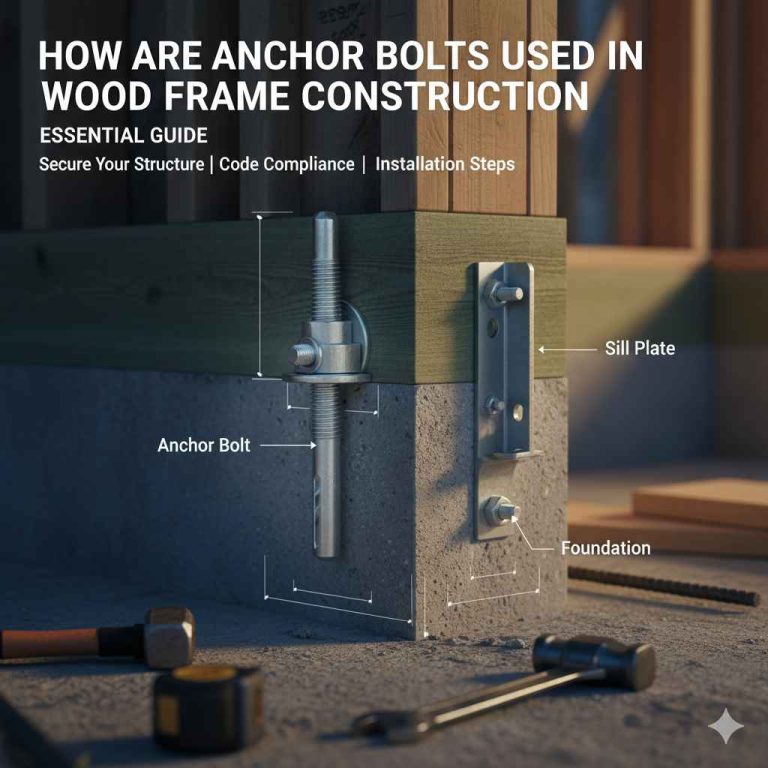

Securing The Flatbed

Properly securing the flatbed onto your truck is crucial for safety and stability during transportation.

- Position the flatbed carefully over the truck bed, ensuring proper alignment.

- Secure the flatbed to the truck bed using heavy-duty bolts and nuts.

- Check the tightness of the bolts to prevent any movement during transit.

Finishing Touches

After building your own wood flatbed, the last step is to add some finishing touches to make it look professional and unique. Below are some ideas to help you sand and seal your wood flatbed, as well as some customization options.

Sanding And Sealing The Wood

Before you can add any customizations, you’ll need to sand and seal the wood to protect it from weather and wear and tear. Start by sanding the entire surface of the flatbed with fine-grit sandpaper until it’s smooth to the touch. Then, apply a wood sealer to protect the wood from moisture and UV rays. You can choose between a clear sealer or a tinted one to add some color to your flatbed.

Customization Ideas

Now that your wood flatbed is sanded and sealed, it’s time to add some personal touches. Here are some ideas:

|

|

These customizations will not only make your wood flatbed unique but also more functional for your specific needs.

Maintenance Tips

For homemade wood flatbed maintenance, regularly check for cracks and splinters, sand down rough areas, apply a protective sealant, and store in a dry place to prevent warping. Clean with a damp cloth and mild soap to preserve the wood’s natural beauty.

Regular Inspection And Care

Regular inspection and care are crucial for maintaining the longevity and performance of your homemade wood flatbed. By following these maintenance tips, you can ensure that your flatbed stays in optimal condition for years to come.

Dealing With Wear And Tear

Over time, your homemade wood flatbed may experience wear and tear due to constant use and exposure to the elements. Here are some tips to help you deal with common issues:

- Check for loose or damaged wood: Inspect the flatbed regularly for any loose or damaged wood components. If you notice any, secure them or replace them promptly to prevent further damage.

- Reinforce weak spots: Identify any weak spots in the flatbed structure and reinforce them with additional supports or braces. This will help distribute the weight evenly and prevent further damage.

- Address rust and corrosion: If your flatbed has metal components, check them regularly for signs of rust or corrosion. Use a wire brush to remove any rust, and apply a rust-resistant coating to protect the metal from further damage.

- Keep the flatbed clean: Regularly clean the flatbed to remove dirt, debris, and other substances that can cause damage. Use a mild detergent and water to scrub the surface, and rinse thoroughly.

By following these maintenance tips and addressing any wear and tear promptly, you can extend the lifespan of your homemade wood flatbed and ensure its optimal performance. Remember to prioritize regular inspections and care to keep your flatbed in top shape.

Real-life DIY Success Stories

When it comes to DIY projects, there’s nothing more satisfying than seeing your hard work pay off. Real-life DIY success stories not only inspire others to take on their own projects, but they also showcase the creativity and resourcefulness of individuals who are willing to think outside the box. In this section, we’ll explore some inspiring transformations, as well as the lessons learned and tips shared by those who have successfully built their own homemade wood flatbeds.

Inspiring Transformations

These real-life DIY success stories will leave you inspired and motivated to tackle your own wood flatbed project. From turning a basic pickup truck into a versatile workhorse to customizing a flatbed to suit specific needs, these transformations demonstrate the endless possibilities of homemade wood flatbeds.

- Transforming a rusty old pickup truck into a functional and stylish wood flatbed.

- Creating a custom wood flatbed with built-in storage compartments for tools and equipment.

- Converting a standard truck bed into a wood flatbed to accommodate larger loads.

- Building a removable wood flatbed that can be easily installed or removed as needed.

Lessons Learned And Tips

Embarking on a homemade wood flatbed project can be daunting, but learning from those who have already gone through the process can save you time, money, and frustration. These DIY enthusiasts have shared their valuable lessons learned and useful tips that can help you avoid common pitfalls and make your own wood flatbed project a success.

- Measure twice, cut once: Accurate measurements are crucial to ensure a proper fit and functionality.

- Choose the right wood: Select a sturdy and weather-resistant wood that can withstand heavy loads.

- Secure the flatbed properly: Use strong bolts and brackets to ensure stability and prevent shifting during transportation.

- Consider weight distribution: Distribute the weight evenly to maintain balance and prevent strain on the vehicle.

- Don’t forget about safety: Install proper lighting and reflective markers to ensure visibility on the road.

These real-life DIY success stories and the lessons learned from them prove that with determination, creativity, and a little bit of know-how, anyone can build their own homemade wood flatbed. So, if you’re ready to take on the challenge, roll up your sleeves and get started on your own DIY project today!

Frequently Asked Questions

What Are The Benefits Of A Homemade Wood Flatbed?

A homemade wood flatbed offers customization, cost savings, and durability. You can tailor it to your specific needs, save money compared to purchasing a premade flatbed, and benefit from the strength and resilience of wood.

How Can I Build A Homemade Wood Flatbed?

To build a homemade wood flatbed, start by gathering the necessary materials and tools. Then, create a design plan, measure and cut the wood to fit, assemble the frame, and secure the bed to the truck. Finally, add any finishing touches and protective coatings.

What Type Of Wood Is Best For A Homemade Flatbed?

The best wood for a homemade flatbed is pressure-treated lumber or hardwoods like oak, maple, or cherry. These woods offer excellent strength, durability, and resistance to rot and decay, making them ideal for outdoor and heavy-duty applications.

Conclusion

In crafting a homemade wood flatbed, creativity and practicality converge beautifully. This DIY project offers a cost-effective and customizable solution for truck owners. By following these steps, you can enhance your vehicle’s functionality while adding a personal touch. Embrace the satisfaction of creating something unique and useful.