How Do Wooden Roller Coasters Stay on Track? Proven Secrets

Wooden roller coasters stay on track through a brilliant combination of gravity, physics, and clever engineering. Their unique design features, like the closely spaced, steel-capped wheels and the carefully shaped wooden track, create a stable, guiding system that keeps the train safely following its path, even at high speeds and sharp turns. It’s a testament to smart design and understanding how forces work.

Ever looked at a towering wooden roller coaster and wondered, “How in the world does that thing not just fly off the rails?” It’s a common question, and honestly, a bit of a marvel! These majestic wooden giants, with their creaks and groans, offer a thrilling ride that feels both classic and intense. But beneath all that excitement lies some seriously clever engineering designed to keep every car precisely on its wooden path. It might seem a little shaky, but rest assured, staying on track is their top priority, achieved through a fascinating interplay of forces and carefully crafted components. Let’s dive into the secrets that keep these wooden wonders safely guiding thrill-seekers on their exciting journeys.

The Magic of Motion: Gravity and Friction

At its heart, a roller coaster’s ability to stay on track is all about physics. Gravity is the primary force that pulls the train down each hill, giving it the speed it needs to climb the next. But it’s the clever design of the track and the train’s wheels that manage the sideways forces, keeping everything aligned. Friction between the wheels and the track also plays a role in controlling speed and stability. It’s like your bike staying upright while you ride – a balance of forces keeping things in place.

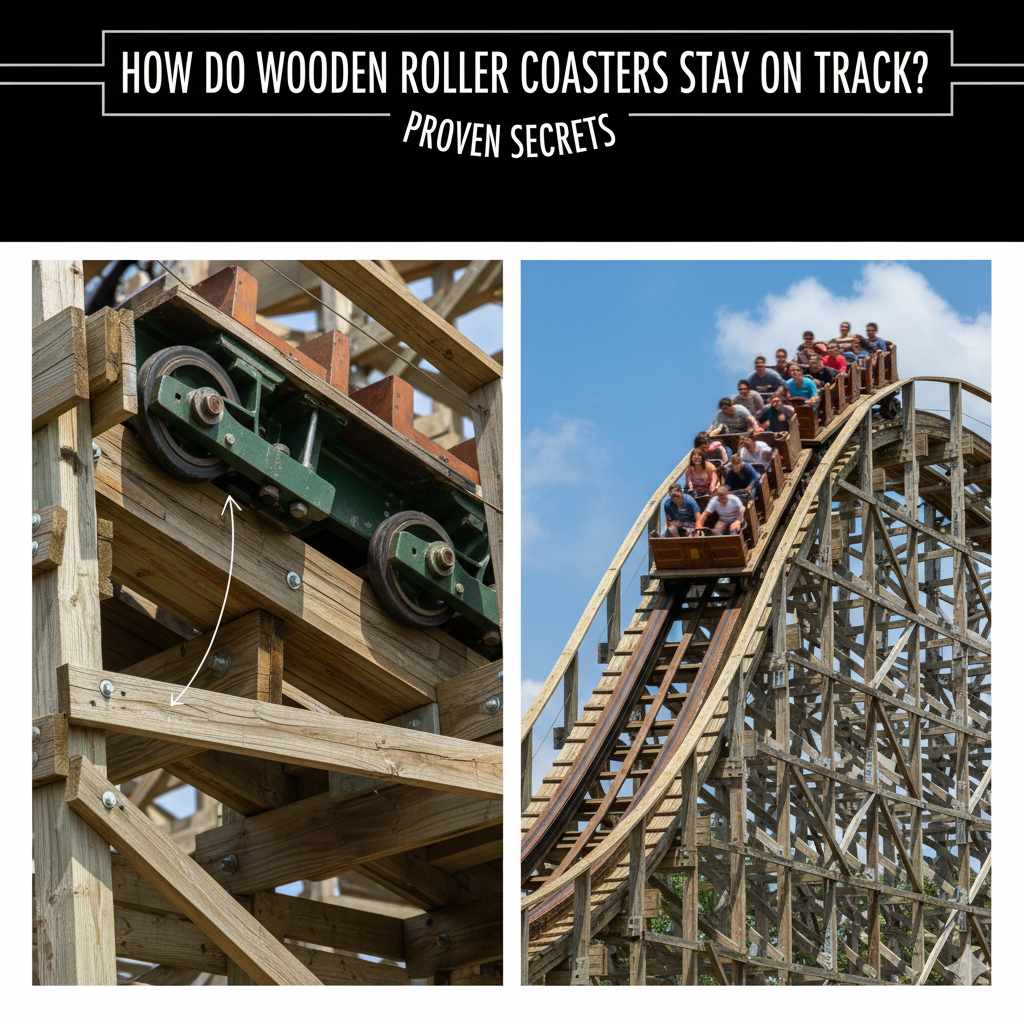

The Train: More Than Just Seats

When we think of a roller coaster, we usually picture the passenger cars. But the true heroes of staying on track are the wheels attached to the train’s undercarriage. These aren’t just simple wheels; they are a sophisticated system designed for control.

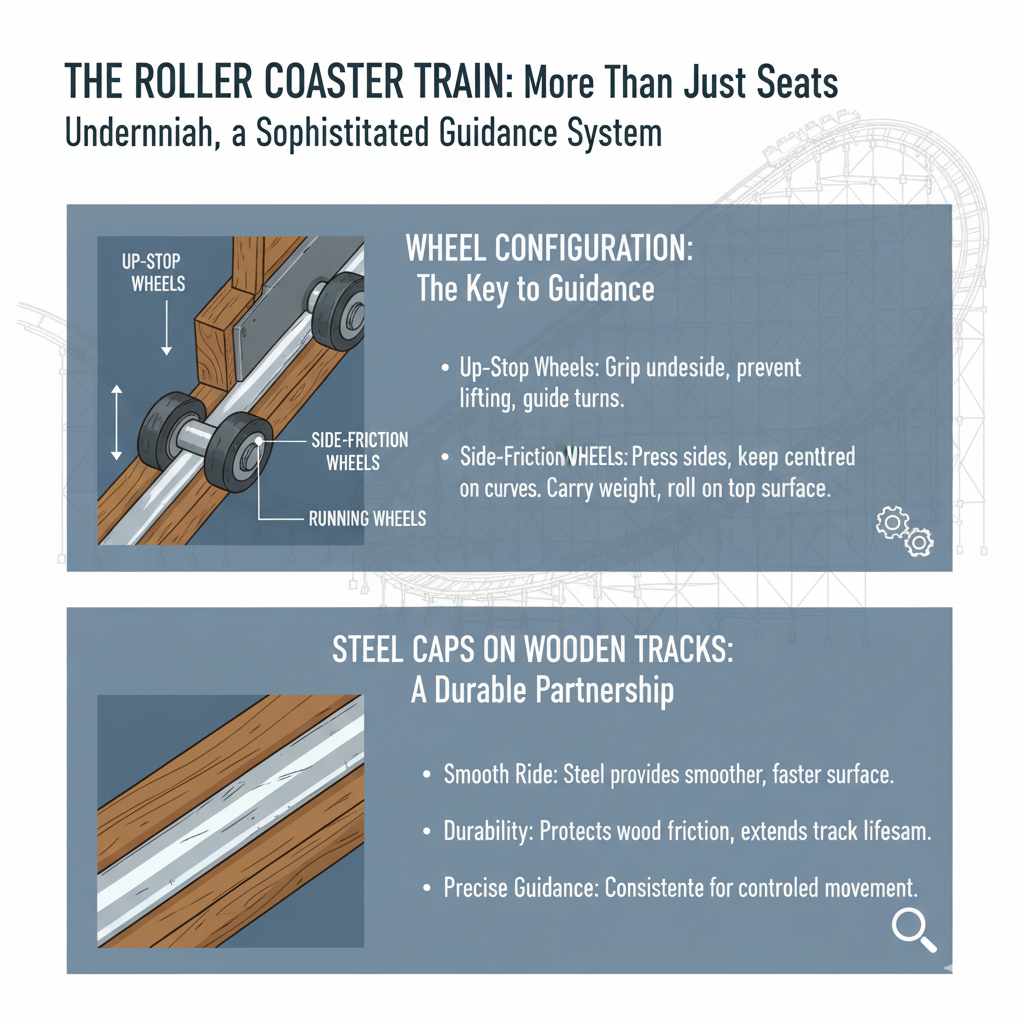

Wheel Configuration: The Key to Guidance

Most roller coaster trains have multiple sets of wheels designed to interact with the track in specific ways:

- Up-Stop Wheels: These are crucial. They are located on the underside of the track and are designed to grip the bottom edge of the wooden rails. Their main job is to prevent the train from lifting off the track, especially during moments of negative g-force where riders might feel like they’re floating. They are also angled slightly to help guide the train through turns.

- Side-Friction Wheels: Positioned on the sides of the train, these wheels press against the inner or outer sides of the wooden rails. They are essential for keeping the train centered on the track, particularly as it navigates curves. Their pressure helps to counteract lateral forces (sideways pushing).

- Running Wheels: These are the wheels that directly roll along the top surface of the track. While they carry the main weight of the train, they are supported and guided by the up-stop and side-friction wheels.

The combination of these wheels acting on the track creates a secure, almost locked-in feeling. It’s a multi-point system ensuring that no matter the movement, the train is constrained to follow the intended path.

Steel Caps on Wooden Tracks: A Durable Partnership

Wooden roller coasters don’t run on raw wood alone. You’ll notice the tracks are often capped with a steel band. This isn’t just for looks; it’s a critical component for both safety and longevity.

- Smooth Ride: Steel provides a much smoother rolling surface for the train’s wheels compared to wood, leading to a more comfortable and faster ride.

- Durability: Wood can wear down quickly under the intense friction and pressure of thousands of roller coaster cars. The steel cap protects the wood, significantly extending the track’s lifespan and reducing maintenance needs.

- Precise Guidance: The steel band creates a consistent surface for the wheels to interact with, ensuring predictable and controlled movement along the track. This consistency is vital for the wheel system to work effectively.

This partnership between wood and steel is a brilliant example of leveraging the strengths of different materials to create a superior and safer system.

The Track Design: Shaping the Journey

The shape of the wooden roller coaster track is as important as the wheels. It’s not just a straight line; it’s a carefully engineered canvas that directs the train’s energy.

Banking Turns: Leaning into the Curve

One of the most visually striking features of a wooden roller coaster is how the turns are “banked.” This means the track tilts inward as it curves. Think about how you lean your bicycle when you take a turn – a roller coaster does the same thing.

- Counteracting Centrifugal Force: As the train speeds through a turn, it experiences an outward force (often mistakenly called centrifugal force, though it’s a lack of centripetal force). Banking the turn redirects this force so that a proportion of the train’s weight pushes it into the curve, rather than trying to push it off.

- Comfort and Safety: Proper banking ensures a smoother, more comfortable ride and prevents extreme lateral forces that could dislodge the train or make the ride unpleasant. The degree of banking is calculated precisely based on the speed of the train and the radius of the turn.

This banking is a direct application of physics principles, ensuring the train remains stable and on its intended path during horizontal movements. You can see similar principles applied in race car tracks, where heavy banking helps cars navigate high-speed turns.

Airtime Hills: The Upside of Gravity

Wooden roller coasters are famous for their “airtime” hills – those moments when riders feel lifted out of their seats. These are not just for fun; they also play a role in guiding the train.

- Negative G-Forces: When a train crests a hill that’s shaped correctly, the vertical acceleration is designed to be less than the acceleration due to gravity. This results in a feeling of weightlessness, or negative g-force.

- Maintaining Wheel Contact: While it feels like you’re flying out of your seat, the up-stop wheels are still firmly engaged with the underside of the track, preventing the train from truly leaving its path. The precise parabolic shape of these hills is key to generating safe and exhilarating airtime.

The nuanced shaping of these hills ensures that the ride is thrilling but the train’s connection to the track remains secure.

Engineering and Maintenance: The Unsung Heroes

Beyond the materials and shape, the ongoing engineering and meticulous maintenance are what truly keep wooden roller coasters safe and on track.

Structural Integrity: The Foundation of Fun

Wooden roller coasters are massive structures. Their support systems are built with precision and often involve intricate latticework to distribute weight and stress effectively.

- Load Distribution: The entire structure is engineered to handle the immense forces exerted by the train, including gravity, acceleration, deceleration, and lateral forces.

- Wood Selection and Treatment: High-quality, durable lumber is chosen, and it’s often treated to withstand weather conditions, preventing rot and decay that could compromise the track’s integrity.

This robust construction is the bedrock of safety. To learn more about structural engineering principles that apply, you can explore resources from organizations like the American Institute of Steel Construction, which, while focusing on steel, outlines fundamental load-bearing and structural design concepts applicable to any large construction.

Regular Inspections and Upkeep

This is where the daily magic happens. Roller coasters, especially wooden ones, require constant vigilance.

- Daily Checks: Before the park opens each day, the entire coaster is inspected. This includes checking wheel assemblies for wear and tear, inspecting the track for any loose boards or fasteners, and ensuring all mechanical components are functioning smoothly.

- Wheel Wear: Friction causes wheels to wear down over time. They are regularly inspected and replaced to maintain the precise fit with the rails.

- Track Maintenance: The steel capping on the track is checked for damage, and individual wooden elements are inspected for signs of fatigue or damage. Minor repairs and adjustments are made continuously.

- Brake Systems: While not directly about staying on track, the brake systems are crucial for controlling speed and safely bringing the train to a stop, ensuring predictable operations.

This rigorous maintenance schedule, often overseen by specialized technicians, is vital for the enduring safety of these classic rides. The ASTM International Committee F24 on Amusement Rides and Devices provides standards that guide many aspects of amusement ride design, operation, and maintenance, underscoring the industry’s commitment to safety through established practices.

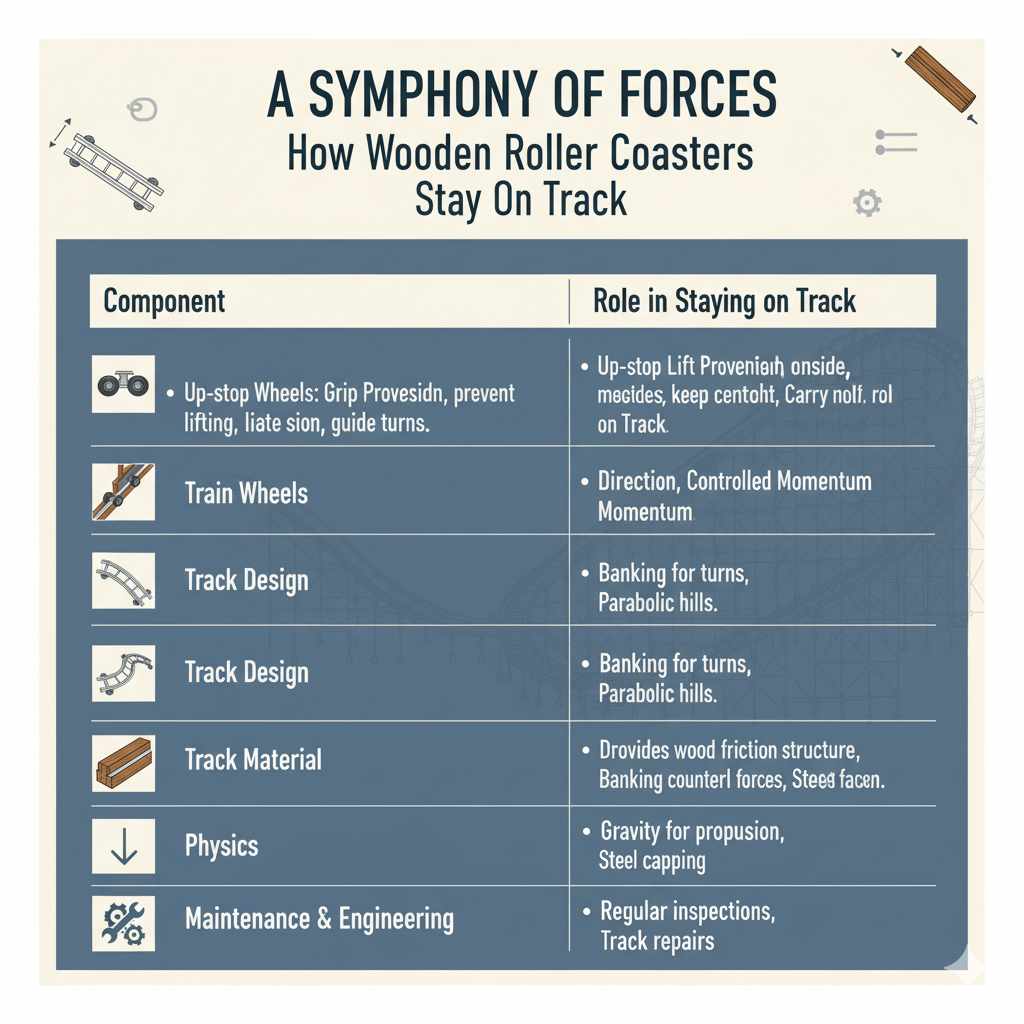

A Symphony of Forces

So, how do wooden roller coasters stay on track? It’s a beautiful, coordinated effort:

| Component | Role in Staying on Track | Key Features |

|---|---|---|

| Train Wheels | Guide, lift prevention, centering | Up-stop wheels; Side-friction wheels; Running wheels (all working in concert) |

| Track Design | Direction, controlled momentum | Banking for turns; Parabolic hills for airtime; Precise curves |

| Track Material | Provides a guide surface | Durable wood structure; Steel capping for smoothness and longevity |

| Physics | Underlying principles of motion | Gravity for propulsion; Banking counters lateral forces; Controlled speed management |

| Maintenance & Engineering | Ensures integrity and function | Structural soundness; Regular inspections; Wheel replacement; Track repairs |

It’s a complex system where each part plays a vital role. The wheels are like the hands gripping the rails, the track is the carefully drawn path, gravity provides the power, and constant care ensures everything works perfectly, ride after ride. It’s a testament to how well-understood engineering principles can be applied to create thrilling, yet safe, experiences.

Frequently Asked Questions (FAQ)

Q1: Are wooden roller coasters safe?

Yes, wooden roller coasters are designed and operated with a very high standard of safety. Like all amusement rides, they undergo rigorous inspections and regular maintenance to ensure they remain in excellent condition and adhere to safety regulations. The engineering principles discussed here are all focused on ensuring they stay safely on their tracks.

Q2: Why do wooden roller coasters feel different from steel ones?

The primary difference comes from the construction. Wooden coasters often have a more pronounced “clackety-clack” sound due to the structure and wheels interacting with the wooden track. They can also provide a more “floaty” sensation with significant airtime, and sometimes feel a bit more unpredictable due to the nature of wood. Steel coasters often offer smoother, more intense inversions and faster turns.

Q3: How is the speed of the roller coaster controlled on the track?

Speed is primarily controlled by gravity and track design. Hills are shaped to use momentum, and turns are banked to manage forces. Brakes, typically magnetic or friction-based, are strategically placed along the track to slow down or stop the train at various points, and especially at the end of the ride.

Q4: What happens if a wheel breaks on a wooden roller coaster?

Roller coaster trains are equipped with redundant systems. For example, if a set of running wheels were to fail, the up-stop wheels are designed to immediately engage and keep the train secured to the track. Maintenance crews also check wheel integrity extensively as part of daily inspections.

Q5: Is it true that wooden roller coasters are built “on-site”?

Historically, many wooden roller coasters were indeed built on-site, especially during the “golden age” of roller coasters. This allowed for custom designs to fit specific park layouts. While some custom wooden coasters are still built this way, modern manufacturing techniques also allow for pre-fabricated sections, though the overall construction and assembly still require significant on-site work.

Q6: How does weather affect a wooden roller coaster’s performance?

Weather can have an impact. Rain can make the track surface slippery, affecting braking and friction. Extreme temperatures can cause wood to expand or contract, though coasters are designed to accommodate this. High winds can also pose a risk, and rides may be temporarily closed during severe weather conditions for safety.

Conclusion: A Masterclass in Motion

So, the next time you find yourself gripping the safety bar, marveling at the wooden structure beneath you, remember the intricate dance of physics and engineering that keeps you safely on track. It’s a combination of strategically placed wheels, perfectly banked turns, precisely shaped hills, and a robust, well-maintained wooden structure, often enhanced with steel. These elements work in harmony, guided by gravity and controlled by friction, to provide an exhilarating, yet secure, adventure. It’s a testament to enduring design principles and the dedication to safety that makes wooden roller coasters a beloved staple of amusement parks everywhere. The creaking and groaning aren’t signs of instability, but the symphony of a well-oiled mechanical marvel doing exactly what it was built to do: provide thrills while staying perfectly on its course.