How Does a Chainsaw Oiler Work: Essential Guide

A chainsaw oiler automatically lubricates the chain and bar to reduce friction, heat, and wear, ensuring smooth operation and extending the life of your saw. Understanding its simple mechanism helps maintain your tool effectively.

Have you ever looked at your chainsaw and wondered how that crucial chain stays slick and smooth, ready for action? It’s a common question for anyone starting with these powerful tools! Without proper lubrication, your chainsaw’s chain and bar can quickly overheat, leading to premature wear, constant sharpening, and even potential breakdowns. This can be frustrating and costly for any DIY enthusiast or homeowner. But don’t worry!

The system responsible for this vital job is surprisingly simple. I’m here to break down exactly how a chainsaw oiler works, making it easy for you to understand and maintain your saw for years of reliable use. Get ready to feel confident about this essential part of your chainsaw! We’ll cover everything from the basic mechanics to simple maintenance tips.

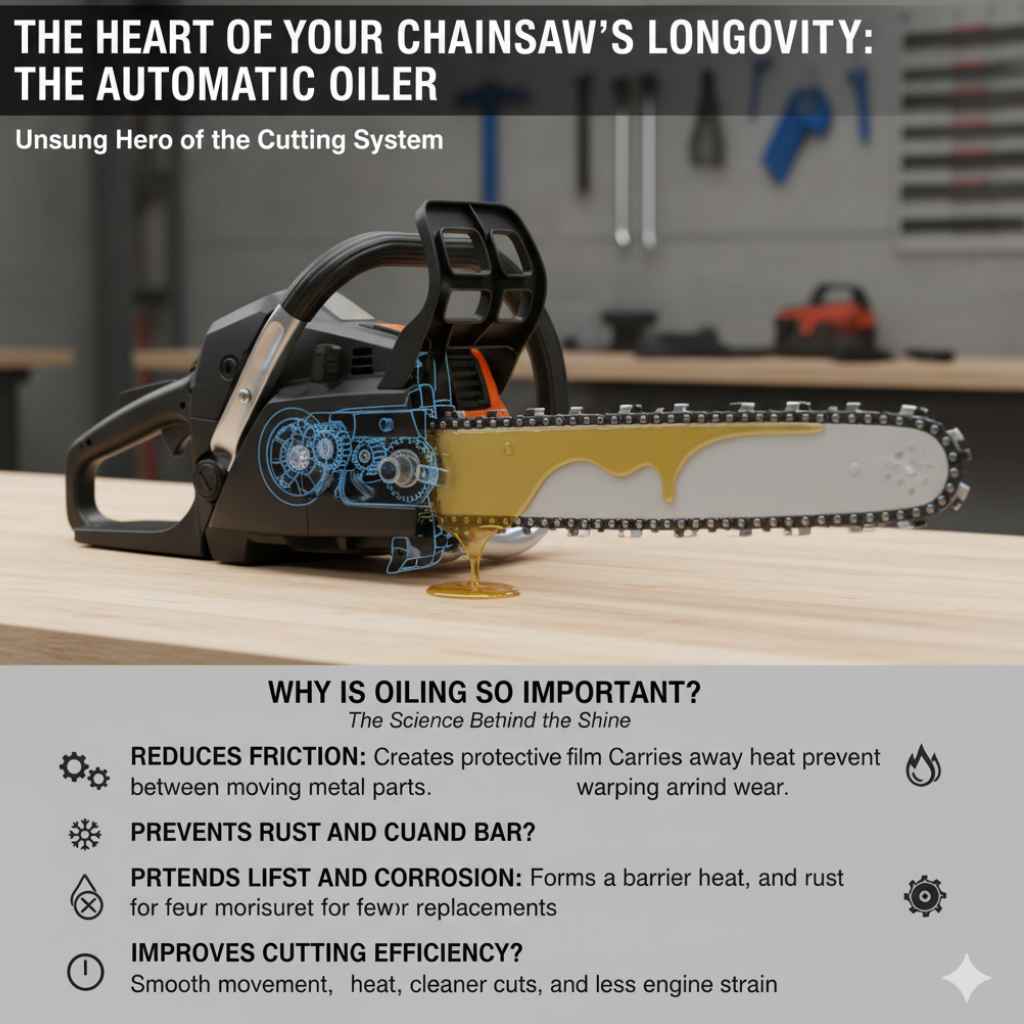

The Heart of Your Chainsaw’s Longevity: The Automatic Oiler

Your chainsaw isn’t just about the engine and the sharp chain; it’s a well-engineered system where every part plays a vital role. The automatic oiler is one of those unsung heroes. Its primary job is to keep the cutting chain and the guide bar properly lubricated. This isn’t just about making things look nice; it’s absolutely critical for performance and safety. When the chain moves at high speeds, friction occurs between the chain, the bar, and the wood. Without oil, this friction creates excessive heat. Heat is the enemy of metal parts; it causes them to expand, warp, and wear down much faster. This leads to a duller chain, a less efficient cut, and a higher chance of the chain binding or even breaking.

Why is Oiling So Important? The Science Behind the Shine

Let’s delve a bit deeper into why that oil is so indispensable. Think of it like the oil in your car’s engine. It’s not just there to make things move smoothly; it’s preventing catastrophic damage:

- Reduces Friction: The most obvious benefit. Oil creates a thin film between the moving parts of the chain and the guide bar. This film drastically reduces the metal-on-metal contact, which is the source of friction.

- Cools the Chain and Bar: As the chain cuts through wood, friction generates heat. The oil acts as a coolant, carrying away this heat. This prevents the metal from becoming too hot, which can lead to hardening, brittleness, and wear. For optimal performance and to maintain the integrity of your chain and bar, keeping them cool is key.

- Prevents Rust and Corrosion: Sawdust and moisture can quickly lead to rust on your metal components. The oil forms a protective barrier, keeping moisture and debris away from the chain and bar, thus preventing rust and corrosion. A rusty chain is a weak chain and won’t cut well.

- Extends Lifespan: By reducing wear, heat, and rust, proper lubrication significantly extends the life of your chainsaw’s chain, bar, and even the drive sprocket. This means fewer replacements and more time spent cutting, not fixing.

- Improves Cutting Efficiency: A well-oiled chain moves smoothly and cuts cleanly. Less friction means the engine doesn’t have to work as hard, leading to better fuel efficiency and a more satisfying cutting experience. You’ll notice a cleaner cut, less bogging down, and more power directed into actually slicing wood.

Without this continuous lubrication, your chainsaw would quickly grind to a halt, much like a car without oil running dry. It’s an essential part of the cutting ecosystem.

How a Chainsaw Oiler Works: The Mechanical Magic (Simplified!)

Most modern chainsaws use an automatic oiling system, and thankfully, they’re designed to be incredibly reliable. While there are slight variations between brands and models, the core principle is always the same: using the engine’s motion to pump oil from a reservoir to the chain. Let’s break it down into its main components and how they work together.

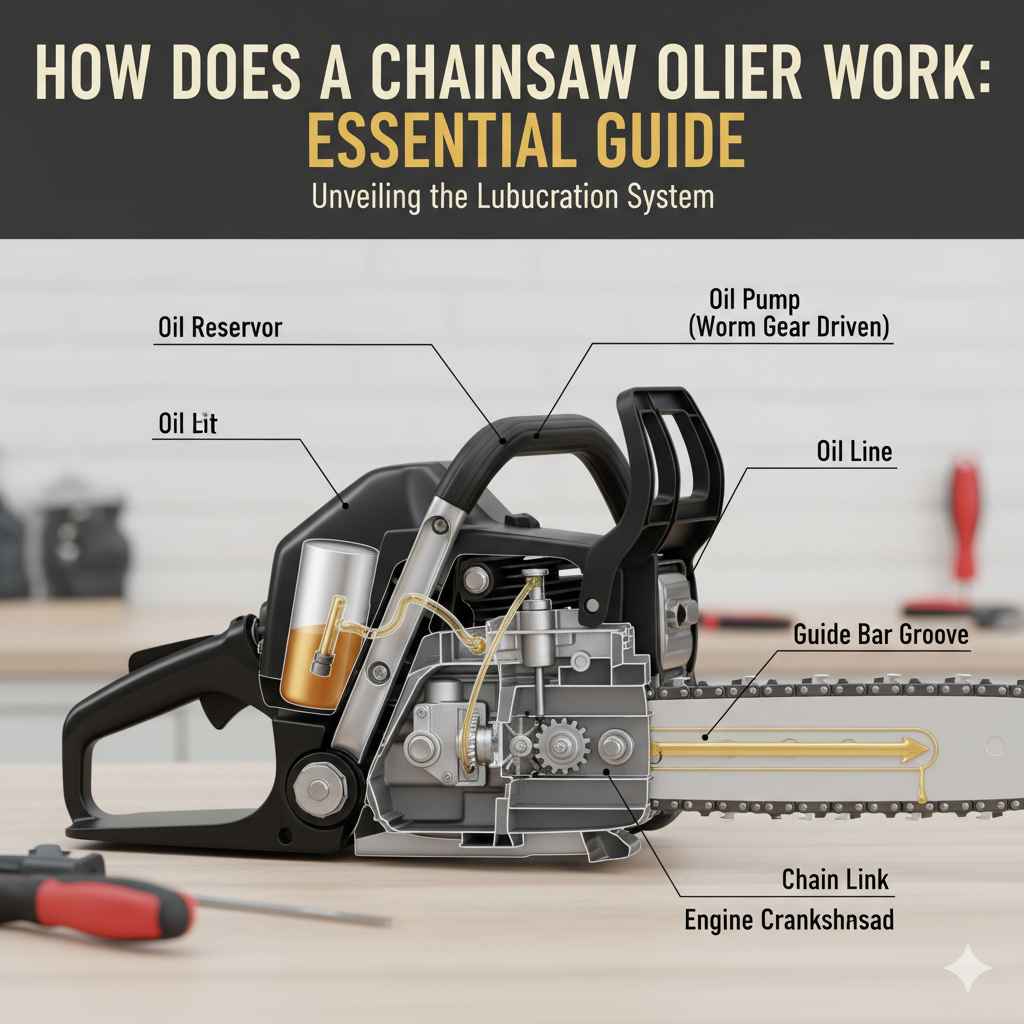

Key Components of a Chainsaw Oiler System

Here are the essential parts you’ll find in a typical automatic chainsaw oiler:

- Oil Reservoir: This is where the bar and chain oil is stored. It’s usually a transparent or translucent tank built into the chainsaw body, allowing you to easily see the oil level. Never use motor oil or other lubricants here; always use dedicated bar and chain oil.

- Oil Pump: This is the heart of the system. It’s usually a small, precision-engineered pump powered by the chainsaw’s engine.

- Oil Feed Line: A tube or channel that carries oil from the reservoir to the pump and then to the guide bar.

- Drive Mechanism (Worm Gear or Piston): This is how the engine powers the pump.

- Worm Gear Driven Pump: On many smaller to mid-sized saws, a small worm gear, often made of plastic, meshes with the chain drive sprocket. As the chain moves, it spins the worm gear, which in turn drives the oil pump. This is a clever system because the oil flow is directly proportional to the chain speed – the faster the chain spins, the more oil is pumped.

- Piston Pump: Larger or more professional saws might use a piston pump. This is typically connected to the crankshaft or another rotating part of the engine. As the engine runs, the piston moves back and forth, drawing oil from the reservoir and pushing it out through the feed lines.

- Metering System: Some pumps have adjustable flow rates, allowing you to control how much oil is delivered. This is usually a small screw or a dial accessible on the saw.

- Oil Delivery Port (on the Bar): A small hole or set of holes at the tip of the guide bar where the oil exits the feed line and is distributed along the bar’s groove.

- Bar Groove and Chain Channels: The guide bar has a precisely machined groove that the chain runs in. There are also small channels within this groove that help spread the oil along the entire length of the bar and onto the chain’s links and rollers.

The Step-by-Step Oil Flow

Here’s a simplified journey of the oil from the tank to your cutting chain:

- Filling the Reservoir: You fill the oil reservoir with appropriate bar and chain oil.

- Engaging the Pump: When you start the chainsaw and either engage the chain brake or pull the throttle, the engine begins to run. This rotation is transferred to the pump’s drive mechanism (worm gear or piston).

- Drawing Oil: The spinning worm gear or moving piston creates suction, drawing oil from the reservoir into the oil pump.

- Pumping Oil: The pump then pressurizes the oil and pushes it through the oil feed line.

- Reaching the Bar: The pressurized oil travels through the feed line up to the guide bar.

- Distribution: The oil exits the feed line at the base of the bar and enters the oil delivery port. From there, it flows into the bar’s groove. As the chain moves rapidly through the groove, it picks up the oil and distributes it along its entire length, lubricating the cutters, the side plates, and the rollers. The oil also lubricates the drive sprocket that engages the chain.

This constant, controlled flow ensures that the chain and bar are always adequately lubricated, even under heavy use. It’s a beautiful example of mechanical efficiency at work!

Manual Oilers: A Worthy Mention

While automatic oilers are standard on almost all modern gas and many electric chainsaws, it’s worth noting that older or very basic models (or some specialized electric/battery saws) might have a manual oiling system. This requires you to periodically press a button or squeeze a lever on the saw to manually pump oil onto the chain and bar. If your saw has this, you need to be diligent about lubricating it frequently, especially during demanding cuts. Failure to do so can lead to the same problems of overheating and wear as an automatic system that isn’t functioning correctly. Always check your saw’s manual to know what type of oiling system you have!

Common Oiler Problems and How to Fix Them

Even the best systems can encounter issues. Thankfully, most chainsaw oiler problems are straightforward to diagnose and fix, often without needing a professional. Knowing these common hiccups can save you a lot of frustration.

Troubleshooting: Why Isn’t My Chainsaw Oiling?

If you notice your chain isn’t getting oiled, here are the most common culprits:

- Empty Oil Reservoir: This sounds obvious, but it’s the most frequent reason! Always double-check your bar and chain oil level before each use.

- Clogged Oil Filter: The intake of the oil pump has a small filter to prevent debris from entering. This filter can get clogged with sawdust and oil residue. You’ll need to access the reservoir and clean or replace this filter.

- Blocked Oil Passage/Feed Line: Sawdust, dried oil, or debris can block the oil feed line from the pump to the bar, or the small ports in the guide bar itself. You’ll need to carefully clear these obstructions. Compressed air can be helpful, or a small, stiff wire or needle can be used to poke through the ports.

- Worn or Broken Worm Gear (for gear-driven pumps): The plastic worm gear that drives the pump can wear down or even break, especially if the chain is overtightened or runs dry for too long. This will stop the pump from turning. You’ll typically need to disassemble the clutch cover to inspect and replace it.

- Faulty Oil Pump: The internal mechanisms of the pump itself can fail due to wear or damage. This is a more complex repair and might require replacing the entire pump assembly.

- Incorrect Bar/Chain Setup: If the chain is too loose, it might not engage the worm gear properly. Conversely, if the chain is too tight or binding, it can put excessive strain on the drive mechanism. Ensure your chain is tensioned correctly according to your saw’s manual.

- Using the Wrong Oil: Using motor oil or other non-dedicated lubricants can gum up the system and clog passages. Always use a specific bar and chain oil.

Quick Fixes and Maintenance Tips for Your Oiler

Preventing problems is always easier than fixing them. Here are some simple tips:

- Regularly Check Oil Level: Before every use, glance at the oil reservoir.

- Clean the Oil Reservoir Opening: Before refilling, wipe away any debris around the oil cap.

- Inspect the Guide Bar: Look for blockages in the oil delivery port and the bar groove. Clean them out with a brush or a thin tool. You can find guides on cleaning chainsaw bars from reputable sources like the US Forest Service.

- Check the Worm Gear: Periodically, especially if you suspect an issue, remove the clutch cover and check the condition of the worm gear.

- Test the Oiling System: After starting the saw, point the tip of the bar at a light-colored surface (like a piece of cardboard or pale wood) and rev the engine slightly. You should see a thin line of oil flicked off the chain. Do this before you start a major cutting job.

- Clean Your Saw: Keep your chainsaw generally clean. Sawdust packed around the oiling components can cause issues.

- Use Quality Bar & Chain Oil: Invest in good quality, specifically formulated bar and chain oil. It’s designed to adhere to the chain and resist being thrown off at high speeds.

A little bit of attention goes a long way in keeping your oiler running smoothly and your chainsaw cutting efficiently.

When to Seek Professional Help

While many oiler issues are DIY-friendly, there are times when it’s best to consult a professional. If you’ve tried the basic troubleshooting steps and your saw still isn’t oiling, or if you’re uncomfortable disassembling parts of your chainsaw, it’s wise to take it to a qualified service center. Some problems, like a severely damaged pump or internal engine issues affecting the oiler drive, are best left to the experts. They have the tools, knowledge, and diagnostic equipment to pinpoint complex problems and repair them correctly, ensuring your saw’s safety and performance.

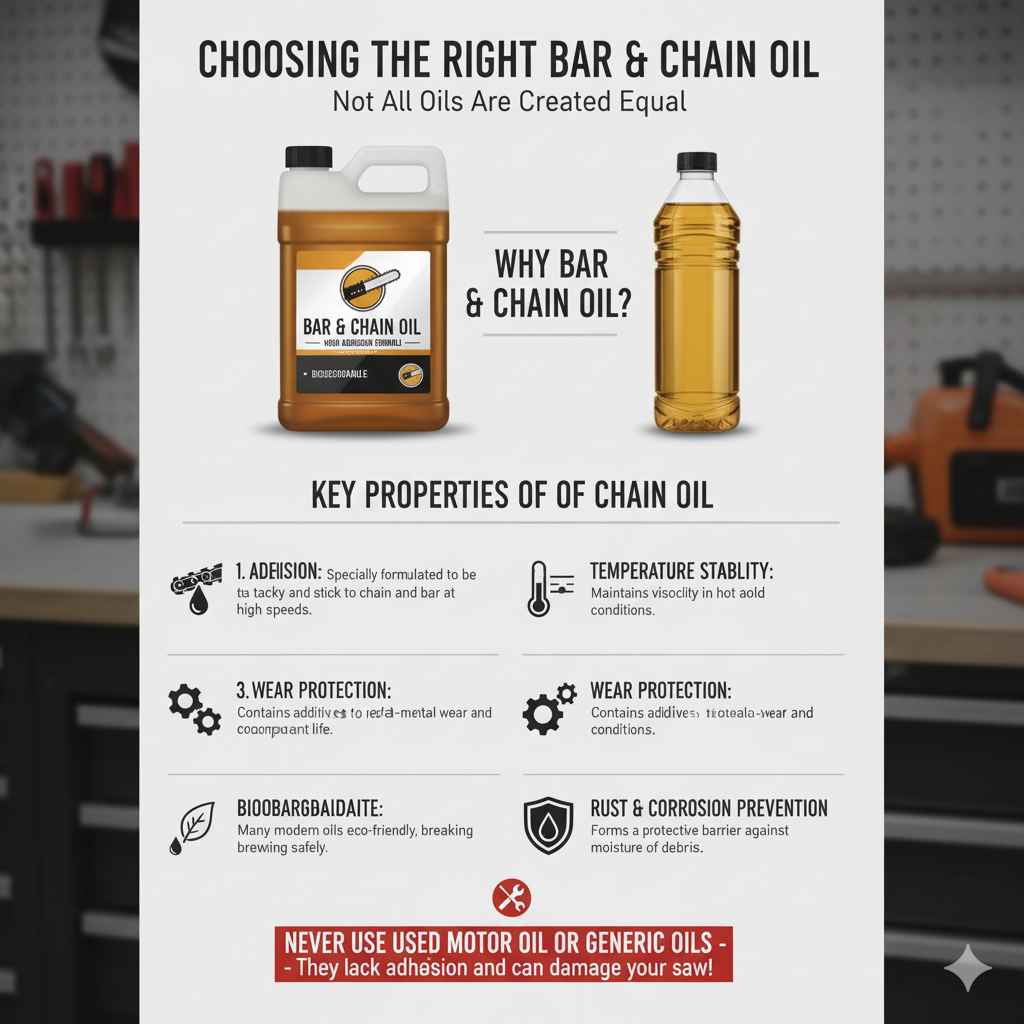

Choosing the Right Bar & Chain Oil

The oil you use is just as important as the oiling system itself. Not all oils are created equal when it comes to chainsaws. You must use ‘Bar and Chain Oil’. Here’s why:

- Adhesion: Bar and chain oil is formulated to be sticky. This means it stays on the chain and bar even at high speeds and under centrifugal force, ensuring continuous lubrication. Regular motor oil is too thin and will be flung off quickly.

- Temperature Stability: It’s designed to maintain its viscosity across a range of temperatures, from very cold to quite hot.

- Preventing Wear: It contains additives to protect against wear and tear on the metal components.

- Biodegradability: Many modern bar and chain oils are biodegradable, which is better for the environment, especially if you’re working in sensitive areas.

You can find bar and chain oil at most hardware stores and outdoor power equipment retailers. Always follow your chainsaw manufacturer’s recommendations for oil type.

Understanding Oiler Flow Rates

Different chainsaws and different cutting conditions might require different amounts of lubrication. Many chainsaws have an adjustable oiler, allowing you to fine-tune the flow rate. This is often a small screw or a dial, usually located near the oil reservoir cap or on the side of the saw.

Adjusting Your Oiler for Optimal Performance

Here’s a general guide to adjusting your oiler:

- When to Increase Flow:

- Cutting in hot weather.

- Bucking (cutting logs into smaller pieces) dry, hard wood can generate more heat and friction.

- Cutting larger diameter logs, which requires more sustained effort from the saw.

- If you notice the bar and chain are getting excessively hot to the touch after a short period of use.

- If your chain is dulling unusually quickly.

- When to Decrease Flow:

- Cutting in very cold weather, as oil can become too thick.

- Cutting soft, wet wood where less lubrication might be needed.

- If you notice excessive oil slinging off the chain onto the saw body or surrounding area (though some slinging is normal and desirable to ensure lubrication).

Important Note: Always consult your chainsaw owner’s manual for specific instructions on how to adjust your particular model’s oiler. Improper adjustment can lead to either insufficient lubrication (causing damage) or over-lubrication (causing mess and inefficiency).

Here’s a quick comparison table of oiler flow rates:

| Flow Setting | Condition | Result |

|---|---|---|

| Low | Cool weather, soft woods, light cutting | Minimal oil used, less mess, sufficient lubrication for easier tasks. |

| Medium | Average conditions, moderately hard woods | Balanced lubrication and oil usage, good for general use. |

| High | Hot weather, dry hardwoods, demanding cuts, prolonged use | Maximum lubrication provided, prevents overheating and wear, but uses more oil. |

A simple test to check your oiler is to hold the tip of the bar over a light-colored surface and briefly rev the engine. You should see a line of oil being thrown off the chain. This indicates the oiler is functioning. Remember, a little oil sling is normal and good; excessive amounts might indicate the flow is too high or the chain is too dull.

Conclusion: Your Chainsaw Will Thank You!

Understanding how your chainsaw’s oiler works is fundamental to keeping your tool in top condition. It’s a simple, yet incredibly important, mechanism that protects your investment and ensures safe, efficient operation. By regularly checking your oil levels, keeping the system clean, using the right kind of oil, and understanding when to adjust the flow, you’re actively preventing wear and tear.

This proactive maintenance isn’t just about saving money on repairs; it’s about ensuring your chainsaw is ready to perform when you need it most, whether you’re trimming branches, felling a small tree, or crafting something beautiful from wood. So, take a moment to appreciate the quiet efficiency of your chainsaw’s oiler – it’s truly the unsung hero that keeps the power flowing smoothly and safely. Happy sawing!

Frequently Asked Questions (FAQ)

Q1: How often should I refill my chainsaw’s oil reservoir?

You should refill your bar and chain oil reservoir every time you refill the fuel tank, or at least before each significant cutting session. Always check the oil level visually – it’s better to have a bit too much than too little.