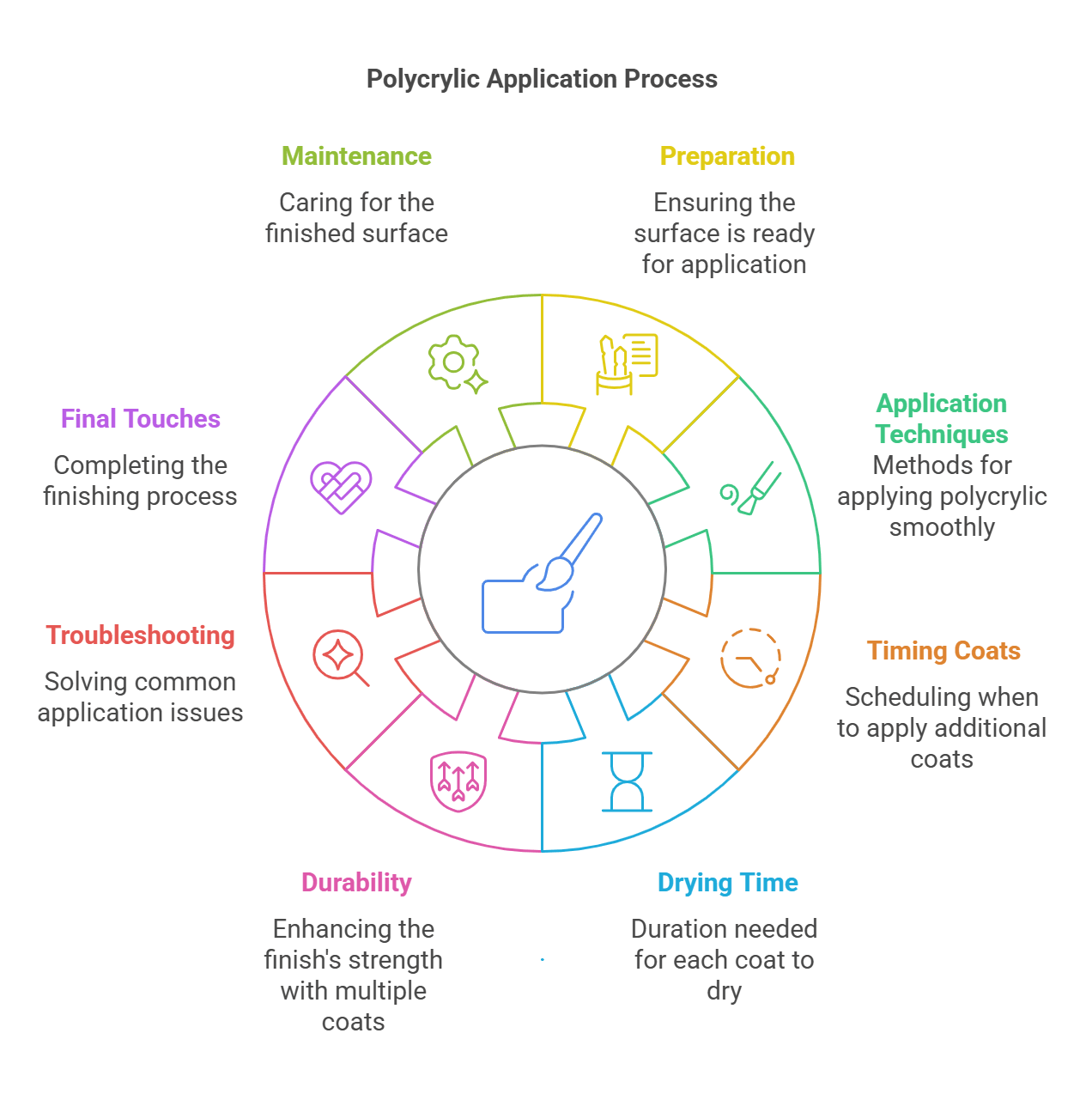

How Long Between Coats of Polycrylic: Quick Guide

Typically, you should wait 2 to 4 hours between coats of Polycrylic. Ensure the first coat is completely dry before applying the next.

Applying Polycrylic is an excellent way to protect and enhance the beauty of wood surfaces. This water-based finish dries quickly and offers a durable layer against scratches and stains. Homeowners often choose Polycrylic for furniture, cabinetry, and crafts due to its clear finish and ease of use.

Understanding the timing between coats is crucial for achieving the best results. Properly timed applications lead to a smooth, even finish that showcases the wood’s natural grain. With the right approach, Polycrylic can significantly improve the longevity and aesthetics of your wood projects.

Introduction To Polycrylic Finishes

Polycrylic is a popular finish used on wood surfaces. It provides a clear, durable coat that enhances the wood’s beauty. This finish is water-based, making it easy to clean up.

One major benefit is its fast drying time. This allows for quicker project completion. Polycrylic also resists yellowing, keeping colors vibrant. It is less toxic than oil-based finishes, ensuring safer application.

Applying Polycrylic can be done with a brush, roller, or spray. Always remember to apply thin coats for the best results. A smooth finish requires light sanding between coats.

Preparing For Application

Before applying Polycrylic, proper surface preparation is essential. Start by cleaning the surface thoroughly. Remove any dust, dirt, or grease. Use a damp cloth for better results.

Sanding the surface lightly helps the Polycrylic adhere better. Use fine-grit sandpaper for this task. Always sand in the direction of the wood grain.

Gather the necessary tools and materials. Here’s a simple list:

| Tools | Materials |

|---|---|

| Sandpaper (fine-grit) | Polycrylic |

| Brush or roller | Clean cloth |

| Paint tray | Water (for cleaning) |

Having these tools will make the application easier and more effective.

Application Techniques

Choosing between brush and spray for applying Polycrylic is important. A brush gives more control and detail. It works well for small projects. Spraying covers larger areas quickly. It can lead to a smoother finish.

After applying the first coat, allow it to dry completely. This usually takes about two hours. Check the manufacturer’s instructions for exact times. Once dry, lightly sand the surface. This helps the next coat stick better. Clean off any dust before applying the second coat.

Timing Your Coats

Drying time for Polycrylic can change based on several factors. Temperature plays a big role in how fast it dries. A warmer room speeds up drying. Humidity is also important; high humidity slows it down.

Good ventilation helps Polycrylic dry quicker. Open windows or use fans to improve air flow. The type of surface you apply it to matters too. Wood absorbs moisture, affecting drying time.

| Factor | Effect on Drying Time |

|---|---|

| Temperature | Higher temperatures = faster drying |

| Humidity | High humidity = slower drying |

| Ventilation | Better air flow = quicker drying |

| Surface Type | Absorbent surfaces = longer drying |

Drying Time Between Coats

The drying time between coats of Polycrylic is crucial for a smooth finish. Generally, a wait time of 2 to 4 hours is recommended. This allows the first coat to dry properly before applying the next one.

To check if your coat is dry, look for these signs:

- The surface feels dry to the touch.

- No sticky or tacky areas remain.

- The finish appears clear and smooth.

Always ensure proper ventilation to help speed up the drying process. High humidity can extend the wait time, so check the weather conditions.

Multiple Coats For Durability

Multiple coats of Polycrylic provide strong protection for your surfaces. Aim for at least two to three coats for the best results. Each coat helps to enhance durability and appearance.

Between each coat, allow adequate drying time. This typically ranges from one to two hours. After drying, sanding is essential. Use fine-grit sandpaper to smooth the surface. This helps the next coat adhere better.

Here’s a quick overview of the process:

| Step | Action |

|---|---|

| 1 | Apply first coat |

| 2 | Wait 1-2 hours |

| 3 | Sand the surface |

| 4 | Apply second coat |

| 5 | Repeat as needed |

Troubleshooting Common Issues

Dealing with bubbles and streaks can be frustrating. Start by using a high-quality brush. Apply the polycrylic in long, even strokes. Avoid over-brushing, as this can create bubbles. If bubbles form, use a foam roller for a smoother finish.

For fixing tacky or sticky surfaces, check the drying time. Wait at least two hours between coats. If it’s still tacky, the environment may be too humid. Increase air circulation by using a fan. Applying a thin coat can also help.

Final Touches And Curing

Applying the final coat of Polycrylic is essential for a smooth finish. Wait at least 2-4 hours between coats. This allows the previous coat to dry properly.

Make sure to sand lightly between coats. Use fine-grit sandpaper to avoid scratches. Clean the surface after sanding to ensure a good bond.

For the best results, allow the final coat to cure. Cure time is usually 24 hours for light use. Full strength may take up to 30 days. Avoid heavy items on the surface during this time.

Maintenance And Care

To keep surfaces clean, use a damp cloth. Avoid harsh chemicals that can damage the finish. For tough stains, a mild soap solution works well.

Regular maintenance helps in preserving the beauty of treated surfaces. Inspect for scratches or wear. Fix any issues promptly to avoid further damage.

Reapply Polycrylic every 3 to 5 years. Check the surface condition for signs of wear. High-traffic areas may need more frequent reapplication.

Frequently Asked Questions

How Long To Wait Between Polycrylic Coats?

Waiting time between coats of Polycrylic typically ranges from 1 to 2 hours. Ensure the first coat is dry to the touch before applying the next. Environmental factors like temperature and humidity can affect drying time, so always check the product label for specific recommendations.

Can I Apply Polycrylic In Humid Conditions?

Yes, you can apply Polycrylic in humid conditions, but it may take longer to dry. High humidity can extend the drying time significantly. It’s best to ensure proper ventilation and consider waiting longer between coats to achieve the best finish.

What If I Rush Between Polycrylic Coats?

Rushing between Polycrylic coats can lead to poor adhesion. This may result in bubbling or uneven surfaces. Always allow adequate drying time for each coat to ensure a smooth and durable finish on your project.

Is Sanding Necessary Between Polycrylic Coats?

Sanding between coats of Polycrylic is recommended for optimal results. Lightly sanding helps to improve adhesion and create a smoother surface. Use fine-grit sandpaper and wipe away dust before applying the next coat for the best finish.

Conclusion

Understanding the drying time between coats of polycrylic is essential for achieving a flawless finish. Patience is key; allow adequate time for each layer to cure properly. This will enhance durability and appearance. Follow the recommended drying times for the best results.

Your project will thank you with a beautiful, long-lasting finish.