How MDF Wood is Made: Uncover the Craftsmanship

Have you ever stopped to wonder about the materials that make up your furniture, cabinets, or that beautiful wall paneling? If you’re curious, you’re in the right place.

Medium Density Fiberboard, or MDF, is a fascinating product that plays a key role in countless items around your home. You might be surprised to learn about the intricate process that turns simple wood fibers into a versatile, durable material.

Understanding how MDF wood is made can give you a new appreciation for the furniture and fixtures you use every day. Plus, knowing more about MDF can help you make informed choices when selecting materials for your next DIY project or renovation. So, let’s dive in and uncover the secrets behind the making of MDF wood.

Origins Of MDF Wood

MDF wood started in the early 20th century. Woodworkers wanted better materials. They mixed wood fibers. They used heat and pressure. This made strong boards. These boards were smooth and easy to shape.

Early MDF was not very good. It was weak and crumbly. Improvements came in the 1960s. Glue made MDF stronger. New machines helped make more MDF. MDF became popular for furniture and building.

Innovators tried new ideas. They added chemicals to the mix. This made MDF fire-resistant. MDF was safer to use. Different colors were added. MDF looked nicer. Recycling began. Old wood was used again. MDF helped save trees.

Materials Used In MDF Production

MDF uses tiny wood fibers to create strong boards. These fibers are often from leftover wood pieces. Trees like pine and spruce provide these fibers. They are chopped into tiny bits. This makes them easy to press into sheets.

Resins and adhesives hold the wood fibers together. They create a strong bond. Urea-formaldehyde is a common resin used. It helps the board stay solid and durable. These chemicals ensure the board doesn’t fall apart. They also make the board smooth.

Manufacturing Process

MDF wood is crafted by breaking down hardwood and softwood into fibers. These fibers are mixed with wax and resin. The mixture is then pressed into panels under high temperature and pressure, forming sturdy boards used in furniture and construction.

Fiber Preparation

Wood chips are the starting point. They are broken down into small fibers. This process uses machines. These machines grind the wood into pulp. The pulp must be smooth. Smooth pulp makes better MDF. Water is added to make the pulp wet. Wet pulp is easier to work with.

Blending And Mixing

The wet pulp gets mixed with glue. Glue helps the fibers stick together. A machine does the mixing. It blends the glue evenly. Uniform blending is key. It makes the MDF strong. Sometimes, wax is added too. Wax helps resist moisture.

Forming Panels

The mixed pulp is spread out. It forms a thin layer. This layer is called a mat. Mats are layered on top of each other. Layering is crucial. It gives thickness to the MDF. The layers must be even. Uneven layers make weak MDF.

Pressing And Heating

A big press squeezes the layers. Pressure binds them tightly. Heat is applied during pressing. High heat dries the glue. Dry glue makes the MDF hard. The process takes time. Time ensures the MDF is well-made.

Credit: blog.plyco.com.au

Finishing Techniques

MDF wood is crafted from fine wood fibers bonded with resin under heat and pressure. This process results in a dense, smooth, and versatile material. Ideal for furniture and cabinetry, MDF offers a reliable surface for various finishing techniques.

Sanding And Surface Treatment

Sanding makes MDF wood smooth. It removes rough spots. A smooth surface is easier to paint. Fine sandpaper is best for this job. It leaves the surface clean. After sanding, the wood feels soft. A good surface treatment can protect the wood. It can also make it look nice. Sometimes, people use a special liquid. This liquid fills small holes. It helps the paint stick better.

Coating And Laminating

Coating adds a protective layer to MDF. It can be shiny or matte. This layer keeps the wood safe from water. Laminating is another method. A thin sheet is glued on top. This sheet can look like wood or any design. Laminating makes MDF stronger. It also adds beauty. Both methods make MDF last longer.

Quality Control Measures

MDF wood must be strong. Testing makes sure it can handle pressure. Machines press on the wood to check its strength. If the wood breaks, it fails. The wood must pass this test. It must be safe for use in homes.

Every piece of MDF wood should look the same. Workers check the wood’s color and size. They make sure each piece is smooth. No rough edges allowed. Machines help measure the thickness. Uniformity means better quality. Customers trust uniform products.

Credit: www.esshelf.com

Environmental Considerations

MDF wood is made with care for the planet. Factories use sustainable practices to save trees. They plant new trees for each one cut. This helps forests stay healthy. Sustainable practices also help animals and plants.

Recycling is important in making MDF wood. Factories use recycled wood pieces. This means less waste and more use of old wood. Waste management keeps the earth clean. It helps people and animals live better.

Applications Of MDF Wood

MDF wood, crafted by binding wood fibers with resin, finds use in furniture, cabinets, and interior paneling. Its smooth surface and easy workability make it popular for detailed designs. Ideal for painting or veneering, MDF offers versatility in home and office decor projects.

Furniture And Interior Design

MDF wood is popular for making furniture. It is strong and smooth. Designers love its clean finish. Cabinets and shelves often use MDF. It can be painted easily. This gives many color choices. MDF also creates stylish wall panels. These panels add beauty to rooms. MDF is budget-friendly. It is cheaper than solid wood. This makes it a good choice for homes.

Construction And Architecture

Builders use MDF in construction. It works well for doors and window frames. MDF is easy to shape. Architects use it for detailed designs. It is perfect for skirting boards and moldings. MDF resists warping. This makes it durable. It is also soundproof. This helps keep rooms quiet. MDF is a smart choice for modern buildings.

Credit: www.daiken-ad.com

Frequently Asked Questions

How Is MDF Wood Produced?

MDF wood is made by breaking down hardwood or softwood into fibers. Resin and wax bind the fibers together. The mixture is then formed into panels using heat and pressure, creating a dense, smooth surface ideal for furniture and construction.

What Are The Disadvantages Of MDF Wood?

MDF wood easily absorbs water and can swell. It’s less durable than solid wood and prone to cracking. It also produces harmful dust when cut. MDF can’t hold screws well and may sag under heavy weight. The material lacks natural wood grain, making it less aesthetically appealing.

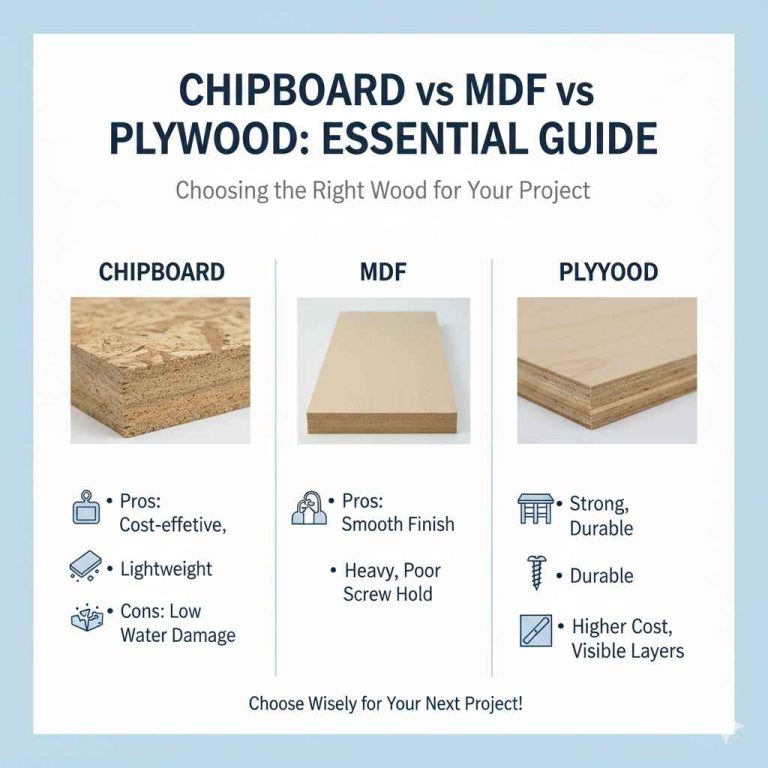

Is MDF Stronger Than Plywood?

MDF is denser but less strong than plywood. Plywood’s layered construction offers higher strength and durability. MDF is better for smooth finishes, while plywood excels in structural applications. Choose MDF for indoor furniture and plywood for projects requiring strength, like shelves or outdoor structures.

Is MDF A Natural Wood?

MDF is not natural wood; it’s engineered from wood fibers and resin. It offers a smooth surface and is cost-effective, widely used in furniture and cabinetry due to its versatility. MDF is denser than plywood, providing stability for various applications.

It’s a popular choice for interior projects.

Conclusion

MDF wood creation is a fascinating process. It involves mixing wood fibers. These fibers are combined with resin and wax. Then, they are pressed into sheets. The result? A smooth and durable board. MDF is versatile and cost-effective. It’s widely used in furniture and construction.

Understanding its production helps in choosing the right material. Next time you see MDF, remember its journey. From wood fibers to a finished board. Simple materials transformed with precision and care. A key player in modern woodworking.