How Often Sharpen Chainsaw: Essential Maintenance Tips

To keep a chainsaw in optimal condition, it should be sharpened after every 4-5 hours of use. Neglecting to sharpen the chain can lead to dullness, which can cause the chainsaw to work harder than necessary, resulting in slower cutting and potential safety issues.

A chainsaw is a powerful tool that can make quick work of even the toughest jobs. However, like any tool, it requires regular maintenance to function properly. One of the most important parts to maintain on a chainsaw is the chain.

Over time, the chain can become dull and less efficient, making it more difficult to cut through wood. In order to keep the chainsaw working as it should, it is important to sharpen the chain regularly. We will discuss how often you should sharpen your chainsaw, as well as some tips for doing it effectively.

The Importance Of Sharp Chainsaws

The Importance of Sharp Chainsaws cannot be overstated. A dull chainsaw blade can lead to safety risks, poor performance, and decreased efficiency. It is essential to sharpen your chainsaw regularly to maintain its optimal performance and ensure your safety.

Safety First: Risks Of A Dull Blade

A dull chainsaw blade can cause several safety risks, including:

- Kickbacks: A dull blade can cause the chainsaw to kick back, which can lead to serious injury or even death.

- Slower cutting: A dull blade can slow down the cutting process, which can cause the chainsaw to get stuck, leading to potential accidents.

- Increased fatigue: Using a dull chainsaw can cause increased fatigue, leading to reduced focus and potential accidents.

Therefore, it is crucial to sharpen your chainsaw regularly to prevent these safety risks.

Efficiency And Performance Considerations

Aside from safety risks, a dull chainsaw blade can also lead to decreased efficiency and poor performance. Some of the consequences of using a dull chainsaw blade include:

- Decreased cutting speed: A dull blade can cause slower cutting, leading to decreased productivity.

- Poor cutting quality: A dull blade can cause rough and uneven cuts, leading to poor quality work.

- Inefficient fuel consumption: A dull blade can cause the chainsaw to consume more fuel, leading to increased costs.

To ensure optimal efficiency and performance, it is recommended to sharpen your chainsaw blade after every 5 hours of use.

Identifying A Dull Chainsaw

Identifying a dull chainsaw can be challenging, but a clear sign is when it struggles to cut smoothly through wood. It is recommended to sharpen your chainsaw after every 3-5 hours of use to maintain optimal cutting performance and prevent damage to the chainsaw.

Regular maintenance ensures efficient cutting and prolongs the lifespan of your chainsaw.

Visual Inspection: What To Look For

When identifying a dull chainsaw, visual inspection is crucial.

- Look for blunt or uneven cutting teeth on the chain.

- Check for chips or damage on the chain links.

- Inspect for excessive heat marks on the bar.

Performance Clues: Slower Cuts And Excessive Strain

If your chainsaw is dull, performance clues will be evident.

- Notice slower cutting speed than usual.

- Observe the chainsaw pulling to one side during cuts.

- Feel excessive vibration or strain while operating the chainsaw.

Ideal Frequency For Sharpening

The ideal frequency for sharpening your chainsaw chain is crucial to maintaining its performance and longevity. By understanding the factors affecting sharpening intervals and following general guidelines, you can keep your chainsaw in top condition for efficient cutting and safety.

General Guidelines For Regular Users

- Inspect the chain after every use for visible damage or dullness.

- Sharpen the chain when you notice reduced cutting efficiency.

- Regularly check the depth gauges to ensure safe and effective cutting.

- Consider professional sharpening if you use the chainsaw frequently.

Factors Affecting Sharpening Intervals

Several factors can influence the frequency of sharpening your chainsaw chain, including the type of wood being cut, the cutting techniques employed, and the cleanliness of the working environment. Additionally, the chain’s exposure to dirt, rocks, and other abrasive materials can accelerate wear and necessitate more frequent sharpening.

Professional Vs. DIY Sharpening

When it comes to keeping your chainsaw in optimal condition, sharpening the chain is crucial. A sharp chain ensures efficient cutting, reduces the risk of kickback, and prolongs the life of your chainsaw. While you have the option to either call in the professionals or take the DIY route for sharpening, it’s essential to understand the differences and determine which approach suits your needs best.

When To Call In The Experts

While DIY sharpening can be cost-effective and convenient, there are certain situations where it is wise to seek the expertise of professionals:

- If you are a beginner or lack experience in chainsaw maintenance, it’s recommended to consult a professional. They have the knowledge and skills to ensure proper sharpening without causing any damage to the chain.

- If your chainsaw has a damaged or severely worn chain, it’s best to have it examined by professionals. They can assess the extent of the damage and determine if the chain needs repair or replacement.

- If you rely heavily on your chainsaw for professional use or extensive cutting tasks, professional sharpening ensures precision and consistency, allowing you to work efficiently and safely.

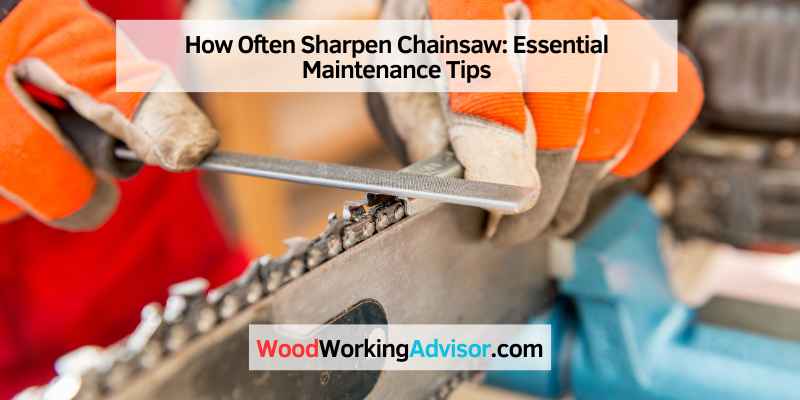

Getting Started With DIY Sharpening

For those who prefer the do-it-yourself approach, sharpening your chainsaw chain can be a rewarding and cost-saving task. Here are some steps to help you get started:

- Begin by wearing protective gear, including gloves and safety glasses, to ensure your safety throughout the sharpening process.

- Inspect the chain for any damaged or excessively worn parts. If you notice any issues, it’s best to consult a professional.

- Secure the chainsaw in a vice or a sturdy surface to provide stability while sharpening.

- Using a round file or a chainsaw-specific sharpening tool, follow the manufacturer’s recommended angle and file the cutting teeth using smooth, consistent strokes.

- Rotate the chainsaw to access all the teeth and repeat the filing process. Ensure each tooth receives equal attention.

- Once you’ve sharpened all the teeth, use a depth gauge tool to ensure the proper height of the depth gauges. This helps maintain the correct cutting depth and prevents the chain from digging too deep into the wood.

- Finally, lubricate the chain and test it on a small piece of wood to ensure it cuts smoothly and efficiently.

Remember, regular maintenance and sharpening of your chainsaw chain will significantly improve its performance and lifespan. Whether you choose professional sharpening or decide to tackle it yourself, the key is to prioritize safety and ensure that the chain is sharpened accurately and consistently.

Choosing The Right Tools For Sharpening

When it comes to maintaining your chainsaw, choosing the right tools for sharpening is crucial. Properly sharpening your chainsaw not only ensures clean and efficient cutting but also extends the life of the chain and reduces the risk of accidents. Let’s explore the essential tools and techniques for keeping your chainsaw sharp and ready for action.

Files

Using a file is a traditional and cost-effective method for sharpening chainsaw chains. Round files are commonly used for this purpose and are available in different diameters to match various chain sizes. The size of the file should correspond to the manufacturer’s recommendations for your chainsaw model.

Guides

File guides are essential for maintaining the correct filing angles and depths when sharpening chainsaw chains. These guides help ensure consistent and precise sharpening, preventing the risk of uneven cutting and premature chain wear. Depth gauge guides are also crucial for maintaining the proper depth settings for the chain’s teeth.

Electric Sharpeners

Electric sharpeners offer a convenient and efficient way to sharpen chainsaw chains, especially for those who frequently use their chainsaw. These sharpeners feature built-in angle guides and provide consistent results with minimal effort. Some models even offer automatic chain clamping for added convenience and precision.

Selecting The Proper Size And Type

When selecting files and guides for sharpening your chainsaw, it’s important to choose the proper size and type that align with your chainsaw’s specifications. Refer to your chainsaw’s manual or the manufacturer’s recommendations to ensure you select the correct tools for the job. Using the wrong size or type of file or guide can result in improper sharpening and potential damage to the chain.

Step-by-step Guide To Sharpening

Sharpening your chainsaw regularly is crucial for maintaining its performance and ensuring safe operation. In this step-by-step guide, we will walk you through the process of sharpening your chainsaw to help you keep it in optimal working condition. Let’s get started!

Preparing Your Chainsaw

Before diving into the sharpening process, it’s important to properly prepare your chainsaw. Follow these steps:

- 1. Safety first: Put on protective gear, including gloves and safety goggles, to shield yourself from any potential hazards.

- 2. Clean the chainsaw: Remove any debris, dirt, or sawdust from the chainsaw using a brush or compressed air. This will allow you to have a clear view of the chain while sharpening.

- 3. Secure the chainsaw: Place the chainsaw on a stable surface or secure it in a vice to prevent any accidental movements during the sharpening process.

- 4. Measure the chain tension: Check the chain tension and adjust it if necessary. A properly tensioned chain is essential for effective sharpening.

The Sharpening Process: A Detailed Walkthrough

Now that your chainsaw is prepared, let’s dive into the step-by-step process of sharpening:

- 1. Find the starting point: Locate the starting point of the cutting tooth on the chain. This is where you will begin the sharpening process.

- 2. Use a file guide: Attach a file guide to the chainsaw bar to ensure consistent and accurate sharpening angles. The file guide will help maintain the correct depth and angle while filing.

- 3. Sharpen the cutting tooth: With the file guide in place, position the file against the cutting tooth at the correct angle (usually 30 degrees). Use smooth and steady strokes to file the tooth in a downward motion, away from your body. Repeat this process for each cutting tooth, ensuring equal filing for all teeth.

- 4. File the depth gauges: The depth gauges control how deep the cutting tooth digs into the wood. Use a flat file or depth gauge tool to file down the depth gauges to the correct height. This step is crucial for maintaining safe and efficient cutting performance.

- 5. Check for balance: After sharpening all the teeth, check the balance of the chain. A well-balanced chain ensures smooth operation and reduces the risk of accidents. If needed, file off a small amount from the opposite side of the cutting teeth to achieve balance.

- 6. Lubricate the chain: Apply lubricating oil to the chain to reduce friction and keep it running smoothly. This will also help prevent premature wear and tear.

Following these step-by-step instructions will help you maintain a sharp and efficient chainsaw that is ready for any cutting task. Remember to regularly inspect and sharpen your chainsaw to ensure optimal performance and extend its lifespan. Stay safe and happy cutting!

Testing Your Chainsaw After Sharpening

After sharpening your chainsaw, it’s important to test it to ensure optimal performance. Regularly sharpening your chainsaw is essential for maintaining its cutting efficiency and preventing accidents. Testing it after sharpening will help you identify any issues and make necessary adjustments for safe and effective operation.

Performing A Test Cut

After sharpening, performing a test cut is crucial.

This step ensures the chainsaw is functioning optimally.

Start by selecting a small log or branch.

Observe the chainsaw’s performance during the cut.

Adjustments And Fine-tuning

Make any necessary adjustments post-test cut.

Check tension, lubrication, and chain alignment.

Fine-tune the chainsaw for smooth operation.

Performing a Test Cut

– Select a small log or branch.

– Observe the chainsaw’s performance.

Adjustments and Fine-Tuning

1. Check tension, lubrication, alignment.

2. Fine-tune for smooth operation.

Maintenance Tips To Prolong Sharpness

Proper Chainsaw Storage

Store chainsaw in a dry place away from humidity and direct sunlight.

Routine Cleaning And Care

Clean chain after each use with a brush and a mild degreaser.

Inspect chain for damage and tension, adjust as needed to ensure proper alignment.

Apply lubricant to the chain regularly to reduce friction and wear.

When To Replace Instead Of Sharpen

It’s important to know when it’s time to replace your chainsaw chain instead of sharpening it to ensure optimal performance and safety.

Signs Of Chain Wear And Damage

- Dull blade that struggles to cut

- Uneven cutting or pulling to one side

- Excessive vibration while in use

- Visible cracks or breaks in the chain

Upgrading To A New Chain

If your chainsaw chain exhibits any of these signs, it’s time to consider upgrading to a new chain:

- Frequent sharpening doesn’t improve cutting performance

- Chain is worn past safe limits for sharpening

- Safety concerns due to chain damage

Frequently Asked Questions

How Often Should I Sharpen My Chainsaw?

It is recommended to sharpen your chainsaw after every 5-10 hours of use or whenever you notice a decrease in cutting performance. Regular sharpening ensures optimal cutting efficiency and prevents damage to the chainsaw.

What Are The Signs That My Chainsaw Needs Sharpening?

Look out for signs such as increased effort required to cut, the chainsaw pulling to one side, or producing fine sawdust instead of wood chips. These indicate a dull chain that needs sharpening. Regular inspection and maintenance will help identify when sharpening is necessary.

Can I Sharpen The Chainsaw Chain Myself?

Yes, you can sharpen the chainsaw chain yourself using a round file and a filing guide. However, it requires proper technique and knowledge. If you are unsure, it is recommended to seek professional assistance or attend a chainsaw sharpening workshop to learn the correct method.

How Long Does It Take To Sharpen A Chainsaw?

Sharpening a chainsaw typically takes around 10-15 minutes, depending on the condition of the chain and your experience. It may take longer if the chain is severely worn or damaged. Taking the time to properly sharpen the chain ensures better cutting performance and extends the life of your chainsaw.

Conclusion

Regular chainsaw sharpening is crucial for optimal performance and safety. By following the recommended frequency and techniques, you can extend the life of your chainsaw and ensure efficient cutting. Remember to prioritize safety and invest in quality sharpening tools for the best results.

Keep your chainsaw sharp and ready for action!