How Tight Should a Bandsaw Blade Be: Expert Tips & Guidelines

A bandsaw is a versatile tool in any woodworker’s shop. But, one common question is: how tight should the bandsaw blade be?

The correct blade tension is crucial for efficient and safe cutting. If the blade is too loose, it can wander during cuts and produce rough edges. On the other hand, too much tension can strain the bandsaw and reduce its lifespan.

Striking the perfect balance ensures smooth and precise cuts. This guide will help you understand the importance of proper tension and how to achieve it. By learning the right tension, you can improve your projects and extend the life of your bandsaw. Read on to discover the best practices for setting the ideal blade tension.

Credit: www.youtube.com

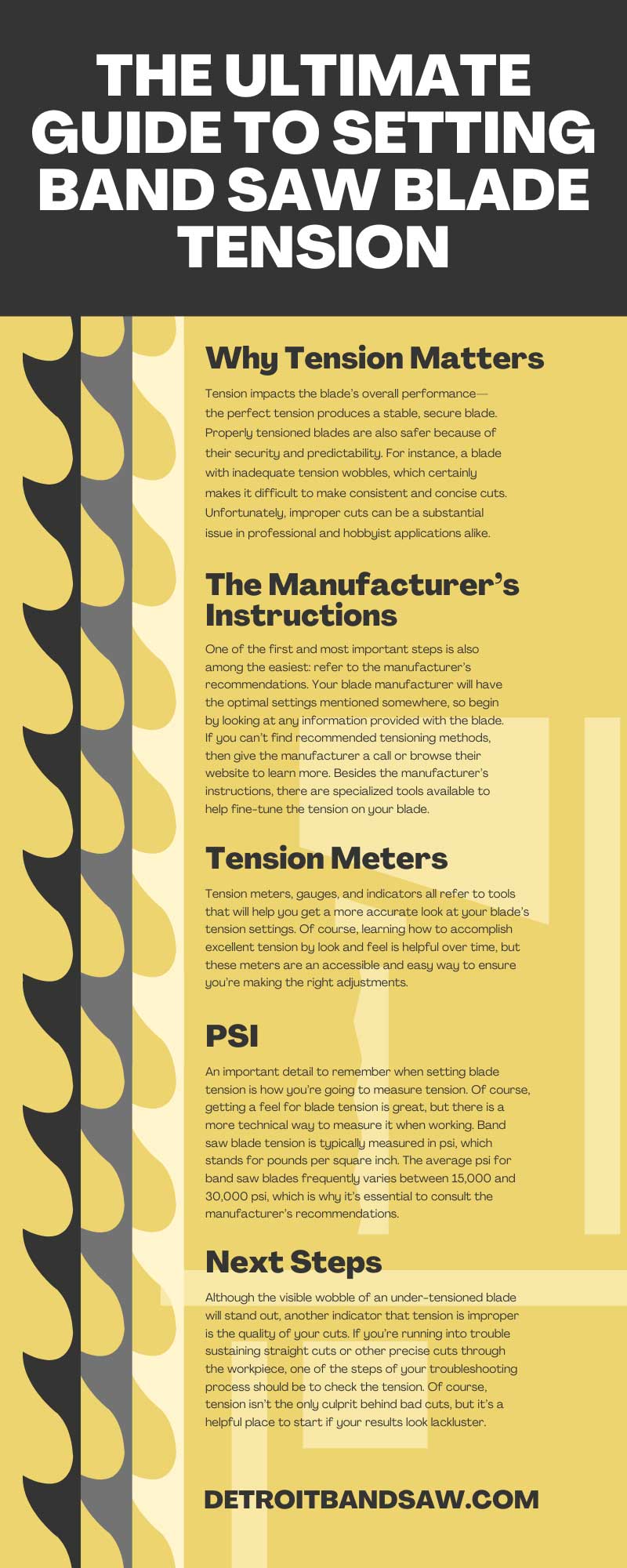

Ideal Bandsaw Blade Tension

Proper tension is key for smooth cuts. Too tight and the blade might break. Too loose and the blade can wander. Both situations can be dangerous. It also affects the life of your blade. Proper tension also ensures accurate and clean cuts. Safety is improved with correct tension.

Many think tighter is always better. This is not true. Some believe any tension is fine. This is also incorrect. Proper tension is specific for each blade. Always check the manual for your bandsaw. Some think they can feel the correct tension. This is risky and not reliable. Tools exist to measure the tension accurately. Use them for best results.

Credit: www.jlconline.com

Factors Affecting Blade Tension

The material of the blade impacts the tension needed. Harder materials like carbide need more tension. Softer materials like carbon steel need less tension. Each material type has a specific tension range. Always check the manufacturer’s recommendations for each blade type. Incorrect tension can lead to blade damage or poor cuts.

The width of the blade also affects tension. Wider blades need more tension to stay straight. Narrow blades need less tension but must still be tight enough. Proper tension keeps the blade from wandering while cutting. Always ensure the blade is secure and stable before use.

Signs Of Incorrect Blade Tension

Incorrect blade tension can cause various issues. A loose blade may wander or produce rough cuts. A too tight blade might snap or damage the bandsaw. Proper tension ensures smooth, accurate cutting and prolongs blade life.

Symptoms Of Loose Blades

A loose bandsaw blade can cause many problems. It may wander during cuts, making your work inaccurate. The blade can also jump off the wheels. You might hear a thumping sound. Cuts will be rough and uneven. Loose blades can damage your saw and increase wear on parts. It is important to check blade tension often.

Symptoms Of Tight Blades

A blade that is too tight can also cause issues. You might see cracks on the blade. The saw may have excessive noise. You might notice vibration. Overly tight blades can break more easily. The saw’s bearings and wheels could wear out faster. Proper tension helps your saw work well and lasts longer.

Adjusting Blade Tension

Tension gauges help measure the tightness of the bandsaw blade. These gauges are easy to use and provide accurate readings. Place the gauge on the blade. Read the measurement. Adjust the tension until it falls within the recommended range. This ensures the blade is neither too tight nor too loose. Proper tension prevents blade damage and ensures clean cuts.

Manual adjustment requires hands-on effort. First, turn off the saw. Loosen the blade slightly. Next, use your fingers to press the blade. It should move a bit but not too much. Tighten the blade if it moves too easily. If it is too stiff, loosen it. Check the blade often while adjusting. Proper tension helps the saw work well.

Maintaining Blade Tension

Regular inspection is key for proper blade tension. Check your bandsaw blade before each use. Look for wear and tear. Make sure there are no cracks or damage. Tighten the blade if it feels loose. Loosely fitting blades can reduce cutting accuracy. Tight blades can break easily. Always find the right balance.

Preventive maintenance keeps your bandsaw blade in top shape. Clean the blade often. Remove dust and debris. Lubricate the blade regularly. This helps avoid rust and keeps it sharp. Replace the blade when it gets old. New blades ensure smooth cuts. Always follow the manufacturer’s guidelines. This will help in keeping your bandsaw safe and efficient.

Safety Tips

Always wear safety glasses and ear protection. Keep your hands away from the blade. Use gloves if needed. Ensure the workspace is well-lit. Avoid loose clothing that can get caught. Tie back long hair. Proper footwear is essential to avoid slips.

Too much tension can damage the blade. It may also stress the machine. Check the blade’s manual for the correct tension. Use a tension gauge if available. Listen for unusual sounds while cutting. Adjust the tension if the blade wanders. A properly tight blade improves cuts and extends blade life.

Expert Recommendations

A bandsaw blade needs proper tension. Too loose, it won’t cut well. Too tight, it can snap. Experts suggest using a tension gauge. This helps find the right tension.

For general cutting, keep the tension at 15,000 PSI. For resawing, use 20,000 PSI. Using the correct tension improves blade life. Also, it gives cleaner cuts.

| Brand | Recommended Tension |

|---|---|

| Jet | 15,000 PSI |

| Grizzly | 16,000 PSI |

| Delta | 15,000 PSI |

| Rikon | 17,000 PSI |

Troubleshooting Tension Issues

Ensuring your bandsaw blade is tight enough is crucial. Proper tension prevents blade drift and ensures smooth cuts. Adjust until the blade feels firm without over-tightening.

Identifying Common Problems

Bandsaw blades can have many tension problems. A loose blade may drift and cut poorly. A too tight blade can break. If the blade makes noise or vibrates, tension might be wrong. Check for uneven cuts or worn-out teeth. These signs help spot tension issues quickly.

Quick Fixes

To fix tension issues, first, turn off the bandsaw. Release the tension and then re-tension the blade. Follow the manufacturer’s guide. Use a tension gauge if available. For a quick test, press the blade with your finger. It should move slightly but feel firm. Also, check the guides and bearings. Adjust them if needed.

Credit: nutechbandsaw.com

Frequently Asked Questions

How Tight Should A Bandsaw Blade Be?

A bandsaw blade should be tight enough to prevent slipping. It must be taut but not overly tight. Follow your manufacturer’s tension guidelines for best results.

What Happens If Bandsaw Blade Is Too Tight?

If a bandsaw blade is too tight, it can damage the blade and the machine. This can lead to unnecessary wear and tear.

Can A Loose Bandsaw Blade Cause Problems?

Yes, a loose bandsaw blade can cause inaccurate cuts and potential safety hazards. It may also slip off the wheels.

How Do I Check Bandsaw Blade Tension?

To check bandsaw blade tension, use a tension gauge or follow the flutter test method. Always refer to your manufacturer’s guidelines.

Conclusion

Finding the right tension for a bandsaw blade is crucial. Proper tension ensures clean cuts and extends blade life. Too tight, it can break; too loose, it can wander. Always check the manufacturer’s guidelines. Use a tension gauge for accuracy.

Regularly inspect your blade for wear. Practice and experience will help you get it right. Remember, safety first. Happy cutting!