How to Buy Lumber for Woodworking: Top Tips & Tricks

To buy lumber for woodworking, first determine the type and quantity of wood you need. Visit local suppliers or reputable online stores to compare prices and quality.

Buying lumber for woodworking can be a rewarding experience. Selecting the right wood affects the durability and appearance of your projects. Various types of lumber are available, each serving different purposes. Hardwoods, like oak and maple, offer strength and beauty, while softwoods, like pine and cedar, are cost-effective and easier to work with.

Understanding your project’s requirements is crucial for making informed choices. Consider factors like grain, moisture content, and treatment options. Taking the time to choose the right lumber ensures your woodworking projects turn out beautifully and last for years to come.

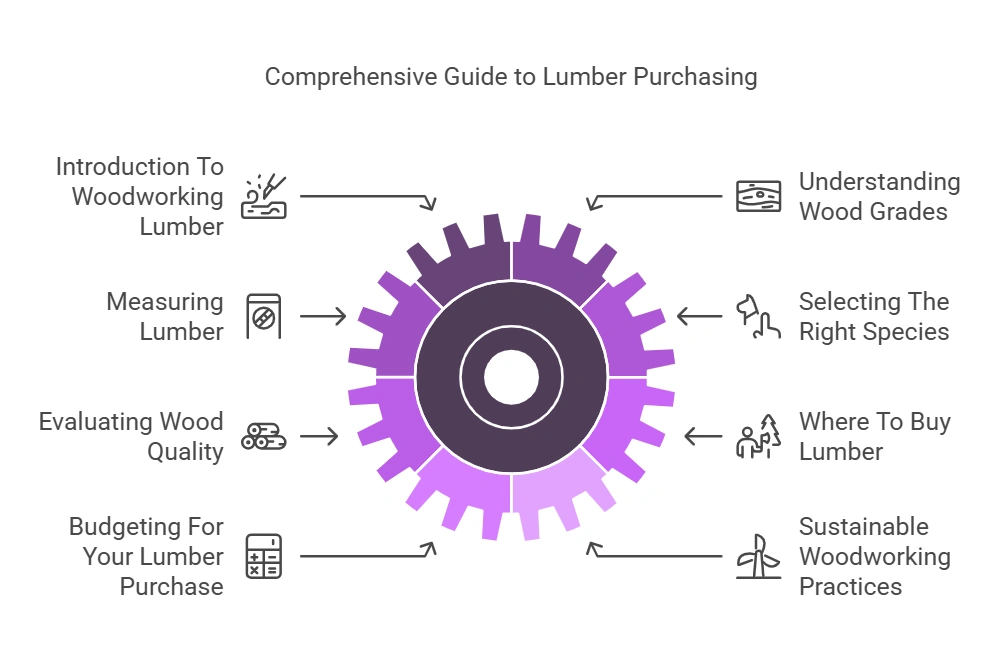

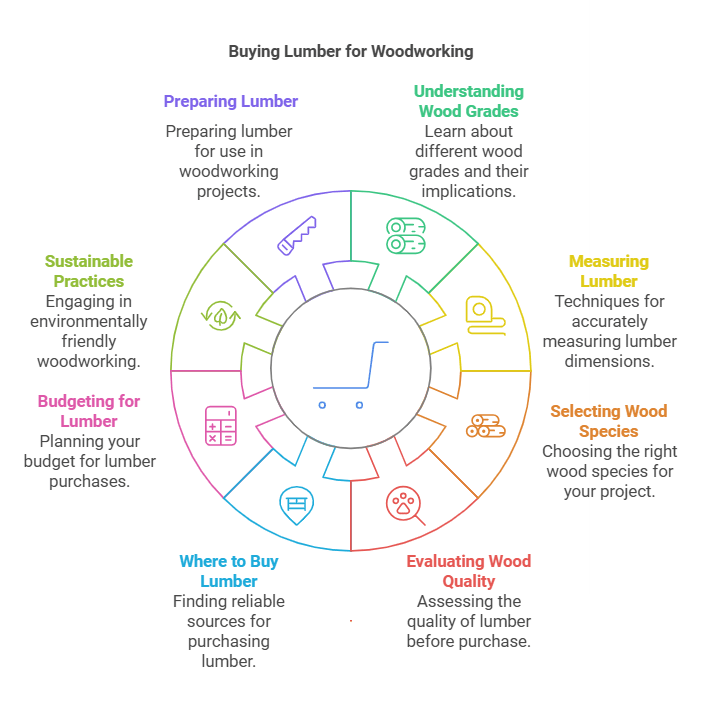

Introduction To Woodworking Lumber

Choosing quality wood is crucial for any woodworking project. High-quality lumber ensures durability and better results. Poor wood can lead to issues later on, such as warping or splitting.

Different projects require different types of wood. Here are some common types:

| Type of Wood | Best For |

|---|---|

| Softwood | Furniture and cabinetry |

| Hardwood | Flooring and fine furniture |

| Plywood | Shelves and structural projects |

| Particleboard | Low-cost furniture |

Consider the specific needs of your project. Different wood types offer unique strengths and aesthetics. Always inspect for knots, cracks, or other defects before purchasing.

Understanding Wood Grades

Understanding wood grades is essential for successful woodworking projects. Different grades indicate the quality and appearance of the lumber. Higher grades often have fewer knots and defects. This impacts how the wood will look and perform.

Lumber grading systems vary by region. Common systems include National Hardwood Lumber Association (NHLA) and American Softwood Lumber Standard. Each system uses specific criteria to evaluate wood. Knowing these can help you choose the right wood for your needs.

The impact of wood grades on projects is significant. Better grades typically lead to stronger and more attractive pieces. Choosing the right grade ensures durability and longevity in your work. Always consider the final use of the project when selecting lumber.

Measuring Lumber

Understanding lumber dimensions is key for woodworking projects. Lumber is measured in board feet. A board foot is a unit of measure for volume. One board foot equals a piece of wood that is 12 inches long, 12 inches wide, and 1 inch thick.

Common dimensions include:

| Dimension (inches) | Board Feet |

|---|---|

| 1 x 6 x 10 | 5 |

| 2 x 4 x 8 | 5.33 |

| 1 x 12 x 8 | 8 |

Knowing these measurements helps in calculating costs. Always check the grade and moisture content of the lumber. This ensures better quality for your projects.

Selecting The Right Species

Hardwoods and softwoods have different properties. Hardwoods come from deciduous trees. They are usually stronger and denser. Common examples include oak, maple, and cherry. Softwoods come from coniferous trees. They are lighter and easier to work with. Common examples include pine, cedar, and fir.

| Wood Species | Type | Characteristics |

|---|---|---|

| Oak | Hardwood | Strong and durable; great for furniture. |

| Pine | Softwood | Lightweight and affordable; easy to cut. |

| Maple | Hardwood | Dense and smooth; ideal for cabinetry. |

| Cedar | Softwood | Resistant to rot; perfect for outdoor projects. |

Evaluating Wood Quality

Evaluating wood quality is crucial for successful woodworking. Check for defects like cracks, knots, and warping. These can weaken your projects. Look closely at the wood grain. A straight grain is often stronger and more attractive.

Moisture content plays a big role in wood quality. Wood that is too wet can warp or crack as it dries. Aim for a moisture content around 6-8% for best results. You can use a moisture meter to check this easily.

| Defect | Impact on Woodworking |

|---|---|

| Knots | Weakens the structure |

| Cracks | May cause failure in projects |

| Warping | Affects fit and finish |

Where To Buy Lumber

Local lumber yards often offer a wider variety of specialty woods. They can provide expert advice on wood selection. Big box stores usually have a larger inventory of common lumber. Prices at big box stores may be more affordable, but quality can vary.

Shopping for lumber online can be convenient. Look for reputable suppliers with good reviews. Always check the shipping costs and delivery times. Request samples if possible to ensure quality. Compare prices across different sites to find the best deal.

Budgeting For Your Lumber Purchase

Planning is key for a successful lumber purchase. Start by knowing your budget. Set a limit to avoid overspending.

Use these cost-effective buying strategies:

- Buy in bulk for discounts.

- Look for sales or clearance items.

- Consider reclaimed wood options.

Calculating your project’s lumber needs is essential. Measure your project space accurately. Create a list of required materials.

| Material | Quantity | Estimated Cost |

|---|---|---|

| Pine Boards | 10 | $50 |

| Oak Boards | 5 | $75 |

Sustainable Woodworking Practices

Choosing eco-friendly lumber is vital for sustainable woodworking. Look for certifications that show responsible sourcing. These certifications help ensure the wood comes from well-managed forests.

| Certification | What It Indicates |

|---|---|

| FSC (Forest Stewardship Council) | Wood from well-managed forests, protecting wildlife and forests. |

| PEFC (Programme for the Endorsement of Forest Certification) | Promotes sustainable forest management and biodiversity. |

| SFI (Sustainable Forestry Initiative) | Encourages responsible forestry practices in North America. |

Understanding these certifications helps you make better choices. Always opt for wood that supports the environment and communities. Sustainable choices lead to a healthier planet.

Preparing Lumber For Use

Acclimating wood is very important before starting your woodworking project. Wood absorbs moisture from the air. It can expand or contract based on the environment.

Keep the wood in the same room where you will use it. Let it sit for at least 48 hours. This will help the wood adjust to the temperature and humidity.

Initial milling is the first step after acclimation. Start by cutting the wood to rough sizes. Use a table saw for straight cuts.

Next, plane the surfaces to make them smooth. This step is crucial for a nice finish. Use a jointer to ensure straight edges.

Finally, check for any defects. Remove knots or cracks as needed. Your lumber should be ready for your woodworking project.

Expert Tips For Lumber Shopping

Buying lumber requires some expert knowledge. First, always check the moisture content. Proper moisture helps prevent warping. Look for straight boards with no major defects. Knots can weaken the wood.

Understand the different types of wood. Softwoods are great for beginners. Hardwoods offer durability for advanced projects. Always ask about the wood’s origin. Sustainable practices are important for the environment.

Avoid common pitfalls while shopping. Don’t rush your decision. Take time to compare prices and quality. Always measure your space before buying. This prevents unnecessary waste.

| Common Pitfalls | Tips to Avoid |

|---|---|

| Rushing the purchase | Take your time comparing options |

| Ignoring defects | Inspect each board carefully |

| Not measuring space | Always measure before buying |

Final Thoughts On Lumber Purchase

Buying lumber for woodworking requires careful planning. A good checklist can help avoid mistakes. Here are some important points to remember:

- Choose the right type of wood for your project.

- Check for defects like knots or splits.

- Measure the dimensions you need carefully.

- Ask about the grade of the lumber.

- Compare prices from different suppliers.

- Consider sustainability and sourcing of the wood.

Planning for future projects can save money. Always buy a little extra wood. This helps with mistakes or changes. Store lumber in a dry area to prevent damage.

Frequently Asked Questions

What Types Of Lumber Are Best For Woodworking?

Softwoods like pine and cedar are great for beginners. They are easy to work with and readily available. Hardwoods such as oak or maple offer durability and beauty but are typically more expensive. Choose based on your project needs and budget for the best results.

How Do I Choose Quality Lumber?

Inspect the lumber for straightness, no visible defects, and moisture content. Look for wood that feels smooth to the touch without knots or cracks. A reliable lumber supplier can help guide you in selecting quality materials for your woodworking projects.

Where Can I Buy Lumber For Woodworking?

You can purchase lumber from local hardware stores, lumber yards, or specialty woodworking shops. Online retailers also provide a wide selection and convenient delivery options. Consider checking out reclaimed wood sources for unique pieces and sustainable options.

How Much Lumber Do I Need For My Project?

Calculate the dimensions of your project to determine the amount of lumber required. Consider the thickness, width, and length of each piece. It’s wise to buy a little extra to account for mistakes or adjustments during the woodworking process.

Conclusion

Buying lumber for woodworking can be a rewarding experience. Understanding types, grades, and sources is essential. Always consider your project needs and budget. Take your time to choose quality materials. With the right lumber, your woodworking projects will come to life beautifully.

Happy woodworking!