How to Clean Sanding Belts: Quick & Effective Tips

To clean sanding belts, use a rubber cleaning stick or a specialized belt cleaner. Run the stick along the belt while it’s still on the machine to remove debris.

Sanding belts are essential tools for woodworking and metalworking, but they can accumulate dust and debris over time. Regular cleaning not only extends the life of your sanding belts but also enhances their performance. A clean belt provides better results, ensuring a smoother finish on your projects.

Understanding how to properly clean your sanding belts will save you money and improve efficiency. This guide will provide easy steps to maintain your sanding belts, allowing you to achieve optimal performance every time you work. Keep your tools in top shape, and enjoy the benefits of effective sanding.

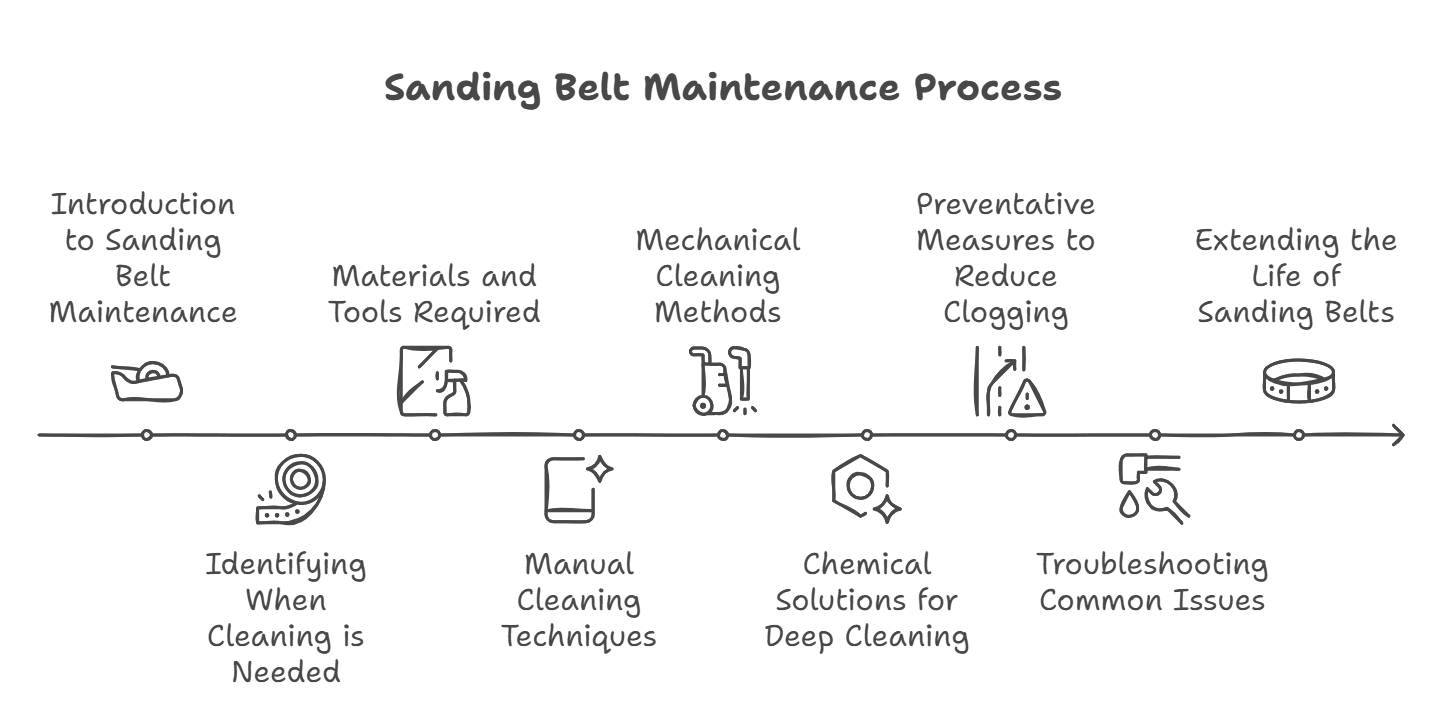

Introduction To Sanding Belt Maintenance

Keeping sanding belts clean is very important for their performance. Dirt can cause grinding and friction. This can lead to wear and tear. A clean belt works more efficiently. It helps to achieve better results on your projects.

Dirty belts may leave scratches on surfaces. They can also overheat and break down. Regular cleaning extends the life of the belt. It ensures that your tools work well. A well-maintained belt saves time and money.

Cleaning prevents the buildup of residue. This helps to maintain a smooth surface. Use a proper cleaning method for the best results. Keep your sanding belts in top condition!

Identifying When Your Sanding Belt Needs Cleaning

Visible signs of clogging on sanding belts are easy to spot. Look for a change in color. Dust and debris build up can lead to this change. If the belt appears darker, it needs cleaning.

Changes in sanding efficiency are another clear sign. If the belt takes longer to sand, it may be clogged. You might notice scratches or uneven surfaces on your workpiece. This indicates the belt isn’t working properly.

Regularly check your sanding belts. Keeping them clean will improve their performance. A clean belt also lasts longer. Always prioritize maintenance for better results.

Materials And Tools Required For Cleaning

Cleaning sanding belts requires some essential tools and materials. Here are the key items needed:

- Rubber cleaning stick – Removes dust and debris effectively.

- Soft brush – Helps clean the surface gently.

- Vacuum cleaner – Removes fine particles from the area.

- Protective gloves – Keeps hands safe during cleaning.

- Safety goggles – Protects eyes from dust and particles.

Using the right safety gear is also crucial. Recommendations include:

- Dust mask – Prevents inhalation of fine dust.

- Ear protection – Reduces noise from machinery.

Manual Cleaning Techniques

Brushing away surface debris is a simple method. Use a stiff brush to remove dirt. Make sure to clean the belt gently. This helps maintain its performance and longevity. Regular brushing keeps the sanding belt in good shape.

For stubborn residues, eraser sticks work wonders. These sticks easily lift off tough materials. Rub the eraser over the belt’s surface. This method is effective for sticky or gritty spots. Always follow up with a brush to ensure a thorough clean.

Mechanical Cleaning Methods

Using a Belt Sander Cleaning Stick is an effective way to maintain sanding belts. This stick helps remove debris and dust that accumulate on the belt surface. A cleaner belt works better and lasts longer. Simply hold the cleaning stick against the running belt. Move it gently to clear away particles.

Abrasive belt cleaners come in various materials. Most are made from rubber or similar substances. They provide excellent cleaning without damaging the belt. Regular use of these cleaners can improve sanding efficiency. It also reduces wear and tear on the belt.

Keep the cleaning stick handy for quick maintenance. This simple tool makes a big difference in your sanding projects. A clean belt ensures smooth and consistent results in your work.

Chemical Solutions For Deep Cleaning

Choosing the right solvent is key for deep cleaning sanding belts. Common solvents include mineral spirits and acetone. These can effectively remove buildup.

Always check the manufacturer’s recommendations before using any solvent. Test the solvent on a small area first. This ensures it won’t damage the belt.

Safety is important. Wear gloves and goggles to protect your skin and eyes. Work in a well-ventilated area to avoid inhaling fumes.

Keep solvents away from heat sources. Store them in a cool, dry place. Always follow local regulations for disposal.

Preventative Measures To Reduce Belt Clogging

Using the right sanding techniques can help avoid belt clogging. Always use the correct grit for your project. Start with a coarse grit and move to finer ones.

Keep the sanding surface clean. Remove dust and debris regularly. Use a vacuum attachment to reduce mess. This helps maintain the performance of the sanding belt.

Establish a routine maintenance schedule. Check belts for wear and replace them when needed. Regularly clean belts with a belt cleaner or a stiff brush. This prevents buildup and extends the life of the belt.

Troubleshooting Common Sanding Belt Issues

Uneven wear on sanding belts can lead to poor performance. Check the alignment of the machine. Misalignment often causes belts to wear unevenly. Also, inspect the tension of the belt. Too much or too little tension can affect wear.

Excessive heat build-up is another issue. It can damage both the belt and the material being sanded. To reduce heat, use slower speeds. This helps cool down the belt during use. Regularly clean the belt to remove dust and debris. A clean belt works more efficiently and generates less heat.

Extending The Life Of Your Sanding Belts

To extend the life of your sanding belts, proper storage is key. Keep them in a cool, dry place. Avoid hanging them where they can bend or warp. Store them flat to maintain their shape.

Regularly check for wear and tear. Replace your sanding belt if you notice fraying, tearing, or a loss of grit. A worn belt can damage your projects. Always use the right grit for your task.

| Signs to Replace | Actions |

|---|---|

| Fraying | Replace immediately |

| Tearing | Replace immediately |

| Loss of grit | Replace for best results |

Conclusion: Maximizing Sanding Belt Efficiency

Cleaning sanding belts helps maintain their performance. Regularly removing dust and debris is essential. This keeps the belt working effectively.

Key cleaning strategies include:

- Using a belt cleaner to remove built-up particles.

- Washing belts in warm, soapy water when heavily soiled.

- Allowing belts to dry completely before reuse.

Always inspect belts for wear. Replace any that show signs of damage. Proper maintenance extends the life of your sanding belts.

Following these steps leads to better results. A clean belt operates smoothly and efficiently. Enjoy the benefits of maximized sanding performance!

Frequently Asked Questions

How Often Should I Clean Sanding Belts?

Cleaning sanding belts should be done regularly. Depending on usage, aim for every few hours of operation. This helps maintain performance and extends belt life. Regular cleaning prevents clogging and ensures an even sanding finish, saving time and resources.

What Is The Best Way To Clean Sanding Belts?

The best way to clean sanding belts is to use a belt cleaning stick. Simply rub the stick against the belt while it’s running. This method removes debris effectively. It’s quick and maintains the belt’s texture, enhancing its efficiency for future projects.

Can I Wash Sanding Belts With Water?

No, washing sanding belts with water is not recommended. Water can damage the adhesive and reduce the belt’s effectiveness. Instead, use a specialized cleaning stick or compressed air. These methods keep the belts clean without compromising their integrity.

Why Do Sanding Belts Get Clogged?

Sanding belts get clogged due to dust and debris accumulation. This occurs during prolonged use or on certain materials. A clogged belt reduces efficiency and leads to poor sanding results. Regular cleaning can significantly mitigate this issue and extend the belt’s lifespan.

Conclusion

Cleaning sanding belts is essential for maintaining their efficiency and lifespan. Regular maintenance can improve performance and save you money. By following the simple steps outlined in this guide, you’ll ensure your sanding belts remain in top condition. Keep your workspace clean and enjoy better results in your projects.