How to Cut IPE Wood: Tips for Smooth & Precise Cuts

To cut Ipe wood, use a carbide-tipped circular saw blade for clean cuts. Always wear protective gear to ensure safety.

Ipe wood, known for its durability and resistance to decay, is a popular choice for outdoor projects. It’s dense and hard, making it crucial to use the right tools for cutting. Proper cutting techniques will help you achieve smooth edges and prevent damage.

Understanding the characteristics of Ipe wood will enhance your woodworking experience. Whether you’re building a deck, furniture, or decorative elements, knowing how to cut this tough material is essential. This guide will provide you with the best practices for cutting Ipe wood efficiently and safely. Follow these steps to ensure your project turns out beautifully and lasts for years.

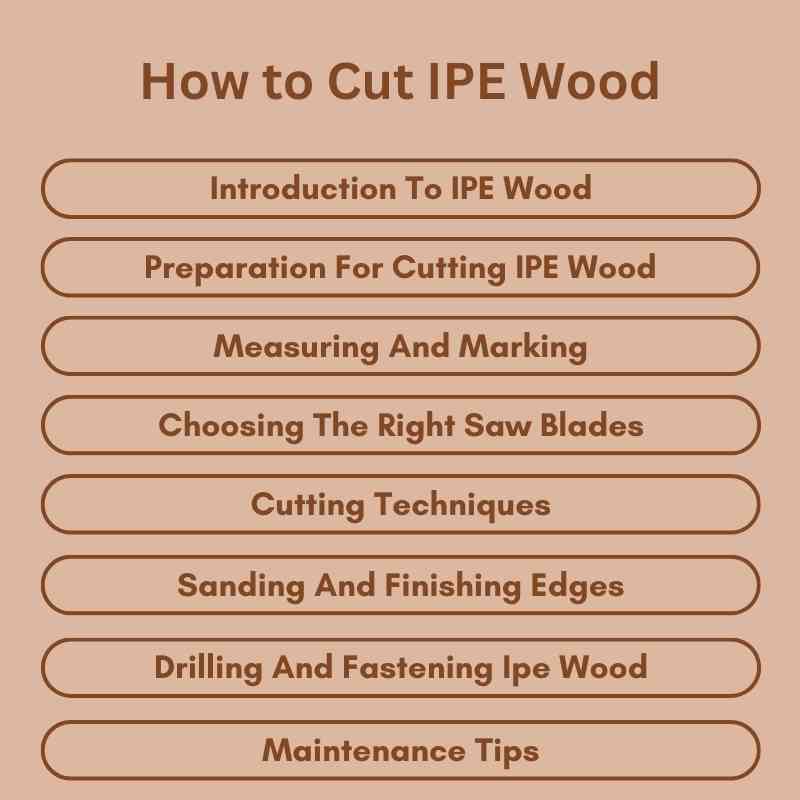

Introduction To IPE Wood

Ipe wood is a popular choice due to its unique properties. It is very dense and durable, making it resistant to wear. This wood can last for many years, even in harsh conditions.

The natural oils in Ipe wood protect it from insects and rot. Its beautiful rich brown color enhances any project. Ipe wood also has a high fire resistance rating, adding to its safety.

| Common Uses | Description |

|---|---|

| Decking | Ideal for outdoor decks, providing strength and beauty. |

| Furniture | Used for both indoor and outdoor furniture. |

| Flooring | Perfect for high-traffic areas due to its durability. |

Preparation For Cutting IPE Wood

Cutting Ipe wood requires the right tools. Start with a circular saw or a miter saw. A table saw can also work well. Use a sharp blade designed for hardwood. This helps ensure clean cuts.

Always wear safety goggles to protect your eyes. Ear protection is important due to loud noise. Wear a dust mask to avoid inhaling wood particles. Having gloves on will protect your hands.

| Tool | Purpose |

|---|---|

| Circular Saw | For straight cuts. |

| Miter Saw | For angled cuts. |

| Table Saw | For ripping wide boards. |

Measuring And Marking

Measuring and marking Ipe wood requires precision. Start by using a tape measure for accurate lengths. Always double-check your measurements before marking.

Use a pencil or marker to make clear lines. This helps avoid mistakes during cutting. Make sure the marks are visible and easy to follow.

For straight cuts, use a square to ensure the lines are perpendicular. A level can help check that everything is even. These tools make a big difference in the final result.

Choosing The Right Saw Blades

Choosing the right saw blade is crucial for cutting Ipe wood. Blade characteristics greatly affect the quality of the cut. Look for blades with high tooth counts. They create smoother cuts and reduce splintering.

Material type is also important. Carbide-tipped blades last longer and cut better. Thickness of the blade should match the Ipe wood’s density. A thicker blade is more effective for heavy-duty cuts.

Ensure the blade has sharp teeth. Dull blades can cause tear-out and rough edges. Regularly check the blade’s condition for optimal performance. Remember, the right blade makes cutting Ipe wood easy and efficient.

Cutting Techniques

To make straight cuts on ipe wood, use a circular saw or a table saw. Ensure the blade is sharp for a clean finish. Measure and mark your line clearly before cutting.

For angled cuts, a miter saw works best. Set the angle to your desired degree. Always secure the wood tightly to prevent slipping during the cut.

For curved cuts, use a jigsaw. Start by drilling a hole at the curve’s start. Then, guide the jigsaw slowly along the line for a smooth curve.

Sanding And Finishing Edges

Sanding Ipe wood makes it smooth and ready for finishing. Start with coarse sandpaper to remove rough spots. Use finer sandpaper for a sleek surface. Always sand with the grain to avoid scratches.

For the best results, sand in a well-ventilated area. Wear a mask to protect against dust. Clean the surface after sanding to ensure a good finish.

Finishing Ipe wood enhances its beauty and protects it. Use a high-quality oil or sealant for long-lasting results. Apply several coats for better protection against moisture and UV rays.

Regular maintenance will keep the wood looking new. Reapply finish as needed, especially in harsh weather. This helps maintain the natural color and grain of the wood.

Drilling And Fastening Ipe Wood

Ipe wood is very dense and strong. Pre-drilling holes is essential before fastening. This prevents the wood from splitting. Use a drill bit that is slightly smaller than the fastener. This ensures a tight fit and stability.

Choosing the right fasteners is crucial for your project. Stainless steel or brass screws work best with Ipe wood. They resist corrosion and last longer. Avoid using regular steel fasteners. They can rust and damage the wood over time.

| Fastener Type | Benefits |

|---|---|

| Stainless Steel | Corrosion-resistant, durable |

| Brass Screws | Long-lasting, attractive finish |

| Regular Steel | Not recommended |

Maintenance Tips

Cleaning cuts and surfaces of Ipe wood is essential for its beauty. Use a soft brush or cloth to remove dirt. For stubborn stains, mix mild soap with water. Avoid harsh chemicals that may damage the wood. Rinse the surface well after cleaning. Let it dry completely before applying any finish.

Long-term care keeps Ipe wood looking great. Regularly check for scratches or dents. Sand any rough areas lightly with fine-grit sandpaper. Apply a quality wood oil or sealer every year. This helps maintain the rich color and protects against moisture.

Keep Ipe wood away from extreme weather. Store it in a cool, dry place. Preventing exposure to direct sunlight will help preserve its quality.

Troubleshooting Common Issues

Splitting and cracking can happen with Ipe wood due to its density. Keep wood dry to prevent damage. Use a moisture meter to check levels before cutting.

Blunt blades lead to poor cuts and more splitting. Always use sharp tools for better results. Regularly sharpen blades to maintain efficiency. This saves time and effort.

Check blades for any chips or dullness before starting. A good cut reduces the risk of cracking. Choose the right blade type for Ipe wood, as this is important.

Sustainable Practices

Sourcing Ipe wood should focus on sustainable practices. Choose suppliers that follow responsible forestry methods. Look for certifications like FSC (Forest Stewardship Council). This ensures the wood comes from well-managed forests.

Minimizing waste is essential in the cutting process. Always measure before cutting to avoid mistakes. Use every piece of wood, even small scraps, for other projects. Proper planning can lead to efficient use of resources. Regularly check tools to ensure clean cuts. Clean cuts reduce the chance of excess waste.

Frequently Asked Questions

How Do You Cut Ipe Wood Effectively?

To cut Ipe wood effectively, use a carbide-tipped saw blade. This type of blade handles the density of Ipe better than standard blades. Ensure you secure the wood firmly to prevent movement during cutting. Always wear protective gear, including goggles and a dust mask, as Ipe dust can irritate.

What Tools Are Best For Cutting Ipe Wood?

The best tools for cutting Ipe wood include a circular saw, miter saw, or table saw. A jigsaw may work for curved cuts, but it’s less efficient. Always use a high-quality, sharp blade designed for hardwood. These tools will provide cleaner cuts and minimize splintering.

Is Cutting Ipe Wood Difficult?

Cutting Ipe wood can be challenging due to its density. It requires specialized tools and blades to cut effectively. However, with the right equipment and techniques, it becomes manageable. Patience and practice will help you achieve clean and precise cuts.

What Safety Precautions To Take When Cutting Ipe Wood?

When cutting Ipe wood, always wear safety goggles and a dust mask. The wood generates fine dust that can irritate your lungs. Ensure your work area is clear and well-ventilated. Secure the wood properly to avoid accidents, and never rush the cutting process.

Conclusion

Cutting Ipe wood can be a rewarding project. With the right tools and techniques, you can achieve clean, precise cuts. Remember to prioritize safety and take your time. Following these guidelines will help ensure your success. Enjoy your woodworking journey and the beauty that Ipe adds to your space!