How to Finish Metal Roof Edge: Seamless Tips & Tricks

To finish a metal roof edge, install a metal edge trim for protection and aesthetics. Secure it with screws along the roofline.

Completing the metal roof edge is essential for durability and a polished look. A well-finished edge prevents water infiltration and protects the underlying structure from the elements. Proper installation enhances your roof’s lifespan, offering peace of mind during harsh weather.

Metal edge trims come in various styles and colors, allowing you to match your home’s design. This finishing touch not only improves functionality but also adds to the visual appeal of your roof. Whether you’re a DIY enthusiast or hiring a professional, understanding the process can make a significant difference in the outcome. Follow these steps for a sleek, effective finish.

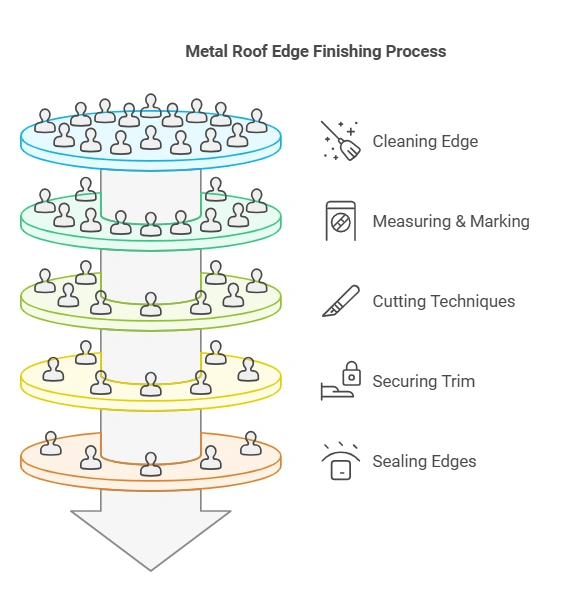

Introduction To Metal Roof Edge Finishing

Finishing the edges of a metal roof is crucial. Proper edge finishing protects the roof from water damage. It also enhances the overall look of the roof. This section covers the importance of proper edge finishing. It lists the tools and materials needed for the job.

Importance Of Proper Edge Finishing

Edge finishing plays a vital role in roof integrity. Here are key benefits of proper edge finishing:

- Waterproofing: Prevents leaks and water damage.

- Durability: Increases the lifespan of the roof.

- Aesthetics: Enhances the roof’s visual appeal.

- Wind Resistance: Helps the roof withstand strong winds.

Tools And Materials Needed

Gathering the right tools and materials is essential. Below is a list of what you need:

| Tools | Materials |

|---|---|

| Measuring Tape | Metal Trim |

| Snips | Sealant |

| Drill | Fasteners |

| Hammer | Underlayment |

| Screwdriver | Paint (optional) |

Having the correct tools and materials makes the job easier. Always prioritize safety by wearing protective gear.

Preparation Steps Before Starting

Preparing properly is vital for a successful metal roof edge finish. Follow these steps to ensure a smooth process and excellent results.

Cleaning The Roof Edge

Before starting any work, clean the roof edge thoroughly. A clean surface helps the materials adhere better. Follow these steps:

- Remove loose debris like leaves and twigs.

- Use a broom or blower for dust and dirt.

- Wash the area with water and mild soap.

- Rinse well and allow it to dry.

Check for any rust or damage. Address these issues before proceeding.

Measuring And Marking

Accurate measurements are crucial for a proper fit. Use the following steps for effective measuring:

- Gather necessary tools: tape measure, chalk line, and level.

- Measure the length of the roof edge.

- Mark each measurement clearly on the edge.

- Double-check measurements for accuracy.

Use a chalk line to create straight lines. This will guide your installation.

Proper preparation leads to a well-finished roof edge. Pay attention to details for the best results.

Cutting Techniques For Precision

Cutting metal roof edges requires skill and precision. Using the right tools ensures clean cuts. This section covers two effective cutting techniques.

Using Tin Snips For Straight Cuts

Tin snips are a popular choice for cutting metal. They come in different types:

- Straight-cut snips: Best for long, straight cuts.

- Left-cut snips: Ideal for cutting left curves.

- Right-cut snips: Perfect for cutting right curves.

Follow these steps for straight cuts:

- Measure and mark the cutting line.

- Clamp the metal sheet to keep it steady.

- Use straight-cut snips along the line.

- Apply even pressure for a clean cut.

Employing A Metal Brake For Angles

A metal brake is essential for creating angles. It bends metal sheets accurately. Here’s how to use it:

- Mark the desired angle on the metal.

- Place the metal sheet in the brake.

- Align the mark with the brake’s edge.

- Slowly lower the handle to bend the metal.

- Release the handle to finish the bend.

Using a metal brake provides clean, sharp angles. This tool enhances the overall look of the roof edge.

Securing The Metal Edge Trim

Securing the metal edge trim is essential for a durable roof. Proper fastening prevents leaks and damage. Follow these tips for effective installation.

Choosing The Right Fasteners

Selecting the correct fasteners is crucial. Use fasteners designed for metal roofing.

- Material: Choose stainless steel or galvanized options.

- Length: Fasteners should penetrate the substrate adequately.

- Head Type: Use flat heads to avoid water pooling.

Check manufacturer guidelines for specific recommendations. This ensures a secure and long-lasting fit.

Spacing And Placement Tips

Proper spacing and placement enhance stability. Follow these guidelines:

- Space fasteners every 12 to 24 inches along the trim.

- Position fasteners 1 inch from the edge of the trim.

- Align fasteners in a straight line for a neat appearance.

Use a measuring tape for accuracy. Double-check all placements before fastening.

| Fastener Type | Material | Recommended Use |

|---|---|---|

| Self-Drilling Screws | Stainless Steel | For metal-to-metal connections |

| Wood Screws | Galvanized Steel | For securing to wooden structures |

| Rivets | Aluminum | For permanent connections |

Follow these tips for a secure metal edge trim installation. A well-secured edge prevents future problems.

Sealing Edges For Waterproofing

Properly sealing the edges of a metal roof is crucial. It prevents leaks and protects the structure. Water can cause significant damage. Effective sealing ensures your roof lasts longer.

Selecting The Best Sealants

Choosing the right sealant is vital. Here are some factors to consider:

- Type of Sealant: Use silicone or polyurethane sealants.

- Weather Resistance: Sealants should withstand extreme conditions.

- Flexibility: Select sealants that can expand and contract.

- Application Ease: Look for user-friendly products.

| Sealant Type | Advantages | Disadvantages |

|---|---|---|

| Silicone | Excellent waterproofing, UV resistant | Poor adhesion on some metals |

| Polyurethane | Strong adhesion, flexible | Longer curing time |

Application Methods For Sealants

Applying sealants correctly ensures maximum protection. Follow these steps:

- Clean the area thoroughly.

- Apply a primer if necessary.

- Use a caulking gun for even application.

- Fill gaps generously.

- Tool the sealant for a smooth finish.

Ensure proper curing time as specified by the manufacturer. Regular inspections will help maintain the seal’s integrity.

Ensuring Aesthetic Appeal

Finishing the edges of a metal roof is crucial for visual appeal. Proper edge treatments enhance the overall look of your home. It also adds value and functionality. Focus on matching colors and maintaining clean lines.

Matching Trim With Roof Color

Choosing the right trim color matters. It creates harmony and balance. Here are some tips:

- Choose similar shades: Select trim colors close to your roof color.

- Use contrasting colors: A bold contrast can make your roof stand out.

- Consider the overall palette: Match trim with the home’s exterior colors.

Testing paint samples helps visualize the final look. A well-matched trim enhances the roof’s design.

Maintaining Clean Lines

Clean lines are essential for a polished appearance. Follow these steps to achieve them:

- Ensure proper alignment during installation.

- Use high-quality sealants for finishing edges.

- Trim excess materials for neat edges.

Regular maintenance is important. Inspect edges for wear and tear. Keeping edges clean improves the roof’s aesthetic.

Follow these guidelines to elevate your metal roof’s look. A well-finished roof edge contributes to the overall charm of your home.

Safety Considerations During Installation

Installing a metal roof edge involves various safety measures. Prioritizing safety protects you and your property. Understanding risks helps ensure a smooth installation process.

Personal Protective Equipment

Wearing the right personal protective equipment (PPE) is crucial. Here are essential items:

- Hard hats: Protect your head from falling objects.

- Safety goggles: Shield your eyes from debris.

- Gloves: Prevent cuts and injuries from sharp edges.

- Steel-toed boots: Protect your feet from heavy materials.

- High-visibility vests: Ensure you are seen by others.

Always inspect your PPE before starting work. Replace any damaged equipment immediately.

Working Safely At Heights

Working on roofs poses risks. Follow these safety tips:

- Use a sturdy ladder to access the roof.

- Secure the ladder properly before climbing.

- Wear a harness connected to a safety line.

- Ensure the roof is dry to prevent slips.

- Work with a buddy to improve safety.

Regularly assess the work area for hazards. Remove any obstacles that could cause accidents.

Troubleshooting Common Issues

Metal roofs are durable, but issues can arise. Knowing how to troubleshoot these problems is essential. This section covers two common issues: misaligned edges and leaks.

Dealing With Misaligned Edges

Misaligned edges can ruin the appearance of your roof. They may also lead to more serious problems. Here’s how to fix them:

- Inspect the Alignment: Check edges for unevenness.

- Loosen Fasteners: Carefully loosen screws along the misaligned edge.

- Adjust Panels: Move panels into the correct position.

- Tighten Fasteners: Secure screws once alignment is correct.

Always ensure the panels are flush against each other. This prevents water from seeping through the gaps.

Handling Leaks And Sealant Failures

Leaks can cause damage to your home. Identifying and fixing leaks early is crucial.

Follow these steps to handle leaks:

- Locate the Source: Inspect for water stains or damp areas.

- Check Sealants: Look for cracked or missing sealants.

- Remove Old Sealant: Use a putty knife to remove damaged areas.

- Apply New Sealant: Use high-quality sealant specifically for metal roofs.

Regular maintenance helps prevent leaks. Check your roof at least twice a year.

| Issue | Solution |

|---|---|

| Misaligned Edges | Inspect, loosen fasteners, adjust, and tighten. |

| Leaks | Locate, check sealants, remove old, and apply new sealant. |

Frequently Asked Questions

How Do I Finish The Edge Of A Metal Roof?

Finishing the edge of a metal roof involves proper trimming and sealing techniques. Start by cutting the metal panels to the desired length. Use closure strips to prevent water penetration. Finally, apply a quality sealant along the edges to enhance durability and weather resistance.

What Tools Do I Need For Metal Roof Edge Finishing?

Essential tools include a metal snip, tape measure, and power drill. A level ensures even alignment, while a caulking gun is vital for sealant application. Additionally, safety gear like gloves and goggles is important for protection during the process.

How Do I Prevent Rust On Metal Roof Edges?

To prevent rust, use galvanized or stainless steel materials for the edges. Regularly inspect and clean the edges to remove debris and moisture. Applying a protective coating can also help shield the metal from corrosion caused by environmental factors.

Can I Do Metal Roof Edge Finishing Myself?

Yes, finishing a metal roof edge can be a DIY project. However, it requires basic carpentry skills and safety precautions. Ensure you have the right tools and materials. If unsure, consult with a professional for guidance to achieve optimal results.

Conclusion

Finishing a metal roof edge enhances durability and aesthetics. Proper installation ensures protection against elements. Always choose quality materials for the best results. Regular maintenance will prolong the life of your roof. Follow these guidelines for a successful project, and enjoy the benefits of a well-finished metal roof edge for years to come.