How to Make a Hole Smaller in Metal: Quick DIY Guide

To make a hole smaller in metal, use a metal filler or welding to close the existing hole. Afterward, drill a new hole of the desired size.

Creating a precise hole in metal is essential for various projects, from crafting to mechanical repairs. Sometimes, a hole may need resizing for improved functionality or aesthetics. Whether the goal is to enhance structural integrity or to fit specific components, knowing how to effectively reduce the size of a hole is crucial.

This process involves techniques such as welding, using fillers, or even reshaping the surrounding metal. Understanding the tools and methods required ensures a seamless and professional finish, making your project successful. By following the right steps, you can achieve a clean, accurate result every time.

Introduction To Metalwork

Metalwork is a fascinating craft. It involves shaping and manipulating metal. Many projects require precise adjustments, such as making a hole smaller. Understanding metalwork basics helps achieve excellent results.

The Art Of Finishing

Finishing is vital in metalwork. It enhances the appearance and functionality of your project. Here are some popular finishing techniques:

- Sanding: Smooths surfaces and edges.

- Polishing: Adds shine and removes imperfections.

- Painting: Protects metal and provides color.

- Coating: Prevents rust and corrosion.

Choose the right technique based on your project needs. A well-finished piece looks professional and lasts longer.

Safety First: Precautions To Take

Safety is crucial in metalwork. Follow these precautions to ensure a safe working environment:

- Wear safety glasses to protect your eyes.

- Use gloves to avoid cuts and scrapes.

- Work in a well-ventilated area.

- Keep flammable materials away from your workspace.

- Have a first aid kit nearby for emergencies.

By following these guidelines, you can enjoy metalwork safely.

Assessing The Metal And Hole Size

Understanding the type of metal and the size of the hole is crucial. This assessment helps determine the best method to make the hole smaller. Follow these steps to ensure effective results.

Identifying Metal Type

Different metals require different approaches. Start by identifying the metal type. Here are common types of metals:

| Metal Type | Characteristics |

|---|---|

| Steel | Strong, durable, often used in construction. |

| Aluminum | Lightweight, resistant to corrosion. |

| Copper | Good conductor, malleable, used in electrical work. |

Use a magnet to help identify some metals. If it sticks, it’s likely steel. Non-magnetic metals include aluminum and copper.

Measuring The Existing Hole

Accurate measurements are essential. Use a caliper or ruler to measure the hole.

- Measure the diameter of the hole.

- Record the measurement.

- Check for any irregularities in shape.

Ensure your measurement is clear and precise. A small error can lead to problems later. Use these steps to measure:

- Place the caliper at the widest point.

- Read the measurement carefully.

- Double-check your reading for accuracy.

Keep this information handy. It will guide you in selecting the right tools and techniques for reducing the hole size.

Tools And Materials Needed

To make a hole smaller in metal, gather the right tools and materials. Using the correct equipment ensures a smooth process. Below are essential tools and the right filler materials for your project.

Essential Equipment

- Drill: A power drill for precision.

- Drill Bits: Choose bits that fit your metal type.

- Tape Measure: Measure accurately before starting.

- Marker: Mark the area to fill clearly.

- File or Grinder: Smooth out edges after filling.

| Tool | Purpose |

|---|---|

| Drill | Drill new holes or reshape existing ones. |

| Drill Bits | Fit the specific metal type and hole size. |

| Tape Measure | Ensures precise measurements for accuracy. |

| Marker | Helps in marking areas before drilling. |

| File or Grinder | Smoothens rough edges after filling. |

Choosing The Right Filler Material

Selecting the correct filler material is crucial. It ensures a strong bond and proper sealing. Here are common filler materials:

- Epoxy Putty: Strong and durable for metal surfaces.

- Welding Rods: Perfect for metal-on-metal repairs.

- Metal Patch Kits: Easy to use for small repairs.

- JB Weld: A popular choice for metal bonding.

Always consider the type of metal and the size of the hole. This choice impacts the final result. Properly mixing the filler material is key for success.

Preparation Steps

Before attempting to make a hole smaller in metal, proper preparation is essential. This ensures safety, accuracy, and a successful outcome. Follow these steps carefully.

Cleaning The Area

Start with a clean workspace. Remove dirt and grease from the metal. Use these methods:

- Wipe with a cloth soaked in solvent.

- Use a wire brush for tough spots.

- Rinse with water and let it dry.

A clean surface helps tools work better. It also prevents contamination during the process.

Securing The Metal

Next, secure the metal firmly. This step is crucial to avoid accidents. Use the following tools:

- Clamps to hold the metal in place.

- A vise for extra grip.

Check that the metal is stable. This ensures you can work safely and precisely.

| Tool | Purpose |

|---|---|

| Clamps | Hold the metal securely. |

| Vise | Provide extra grip. |

Securing the metal prevents movement. This makes the process easier and safer.

Technique 1: Using Fillers

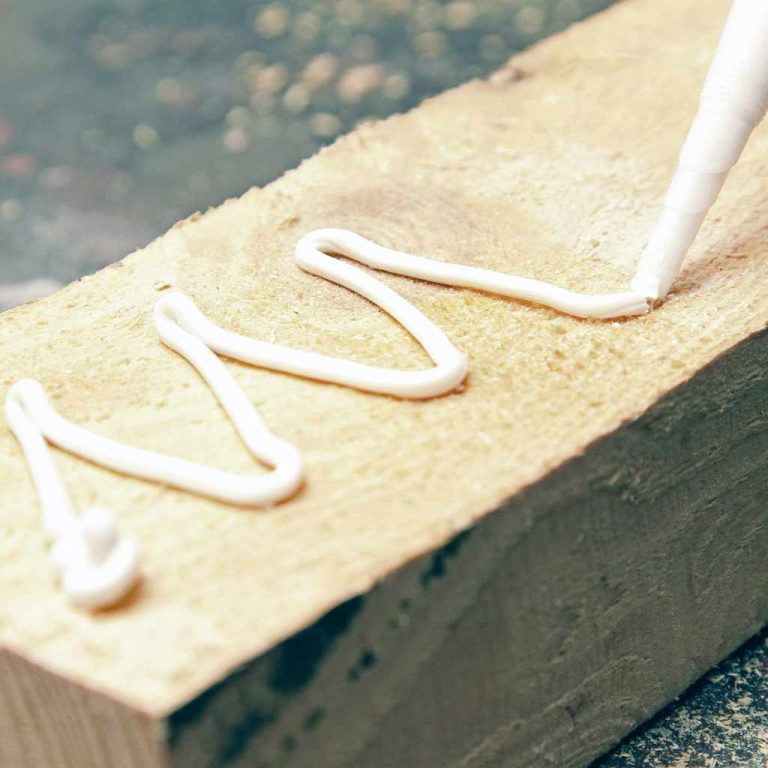

Using fillers is a simple way to make a hole smaller in metal. This method works well for small holes. Fillers can create a smooth finish. They bond well with metal surfaces. Follow these steps for the best results.

Mixing The Filler

Start by choosing the right filler. Common options include:

- Epoxy fillers

- Metal putty

- Welding rods

Follow these steps to mix the filler:

- Read the manufacturer’s instructions carefully.

- Measure the required amount of filler.

- Mix the filler and hardener in a clean container.

- Stir until you achieve a uniform texture.

Use the filler quickly after mixing. It sets fast, so work efficiently.

Applying And Shaping The Filler

Prepare the area before applying the filler:

- Clean the hole and surrounding metal.

- Remove rust or dirt for a better bond.

Now, apply the filler:

- Use a putty knife to spread the filler.

- Fill the hole completely, pressing firmly.

- Shape the filler to match the metal surface.

For a smooth finish, follow these tips:

- Use a damp sponge to smooth the surface.

- Allow the filler to cure as per instructions.

- Sand the area once cured for an even surface.

Using fillers effectively can greatly improve your metal work.

Technique 2: Welding To Reduce Hole Size

Welding is an effective method to reduce the size of a hole in metal. This technique fills the hole with molten metal, creating a solid patch. It is suitable for various metals like steel and aluminum. Proper execution ensures strength and durability.

Selecting The Welding Method

Choosing the right welding method is crucial. Here are some common methods:

- MIG Welding: Good for thin metals.

- TIG Welding: Offers precision for thicker materials.

- Stick Welding: Ideal for outdoor projects.

Consider the following factors:

- Metal type.

- Thickness of the material.

- Welding environment.

Welding Process Explained

The welding process involves several steps:

- Prepare the Area: Clean the metal surface around the hole.

- Choose Filler Material: Match the filler to the base metal.

- Heat the Metal: Use a welder to melt the filler material.

- Fill the Hole: Add the molten metal to the hole.

- Cool Down: Let the welded area cool slowly.

Follow safety precautions:

- Wear protective gear.

- Work in a well-ventilated area.

- Keep a fire extinguisher nearby.

Properly executed welding restores the integrity of the metal. It ensures the metal remains strong and usable.

Finishing Touches

After resizing a hole in metal, finishing touches are essential. These steps enhance the hole’s quality and ensure a smooth finish. Let’s explore two important processes: sanding and checking for uniformity.

Sanding For Smoothness

Sanding is crucial for a polished edge. It removes sharp edges and burrs. Use the following steps for effective sanding:

- Choose sandpaper: Start with coarse grit, then move to finer grit.

- Sand in a circular motion: This helps even out the surface.

- Check your progress: Feel the edge frequently to ensure smoothness.

Sand until you achieve a nice, smooth finish. Remember, patience pays off!

Checking For Uniformity

Uniformity ensures the hole looks professional. Follow these simple steps:

- Use a caliper: Measure the hole’s diameter at multiple points.

- Inspect visually: Look for any irregularities.

- Adjust as necessary: If the hole isn’t uniform, repeat sanding.

Ensuring uniformity improves the overall quality of your work. Small details matter!

Protecting And Sealing The Metal

After making a hole smaller in metal, protection is vital. Proper sealing stops moisture and rust. This ensures the metal lasts longer and remains strong.

Coating Options

Choosing the right coating is essential. Various options are available to protect metal surfaces:

- Paint: A simple and effective choice. It creates a barrier against moisture.

- Epoxy Coating: Durable and resistant to chemicals. Best for heavy-duty applications.

- Galvanizing: Coating with zinc. Provides long-lasting protection against rust.

- Powder Coating: A dry powder applied electrostatically. Offers a smooth, tough finish.

Preventing Future Corrosion

Corrosion can damage metal over time. Take these steps to prevent it:

- Regular Cleaning: Remove dirt and grime. Use soap and water.

- Apply Protective Coating: Follow the coating options listed above.

- Use Rust Inhibitors: These chemicals slow down rust formation.

- Store Properly: Keep metal items in a dry place. Avoid exposure to moisture.

| Coating Type | Durability | Best Use |

|---|---|---|

| Paint | Medium | General use |

| Epoxy Coating | High | Heavy-duty |

| Galvanizing | Very High | Outdoor use |

| Powder Coating | High | Aesthetics and protection |

Troubleshooting Common Issues

Making a hole smaller in metal can sometimes lead to unexpected problems. Knowing how to handle these issues is crucial for achieving the best results. Below are solutions to common problems you might face.

Dealing With Shrinkage

Shrinkage can occur during the metalworking process. This leads to a smaller hole than desired. Here are some tips to manage shrinkage:

- Choose the right metal: Some metals shrink more than others.

- Use a proper cooling method: Slow cooling reduces shrinkage.

- Monitor temperature: Keep the metal at a consistent temperature.

Always check the dimensions after cooling. Measure the hole accurately. Adjust your approach based on these measurements.

Correcting Imperfections

Imperfections may appear after resizing a hole. These can affect the overall quality. Follow these steps to fix them:

- Inspect the hole: Look for rough edges or uneven surfaces.

- File down rough edges: Use a metal file for a smoother finish.

- Use a reamer: This tool can help achieve the desired shape.

- Sand the area: Fine sandpaper can help smooth imperfections.

Regular checks during the process help catch mistakes early. This keeps your project on track.

Maintenance And Care Tips

Proper maintenance ensures your metalwork lasts long. Regular care keeps holes small and prevents further damage. Follow these tips to maintain your metal pieces effectively.

Routine Checks

Perform routine checks to catch issues early. Regular inspections help maintain the integrity of your metalwork.

- Inspect for rust or corrosion.

- Check for cracks around the hole.

- Look for signs of wear on surrounding areas.

Here are some steps for routine checks:

- Use a flashlight for better visibility.

- Feel for rough edges or sharp points.

- Document any findings for future reference.

Long-term Preservation

Long-term care keeps your metal projects in top shape. Follow these tips for preservation:

| Action | Frequency | Purpose |

|---|---|---|

| Clean with mild detergent | Monthly | Remove dirt and prevent corrosion |

| Apply protective coating | Annually | Shield against moisture and rust |

| Store in a dry place | Always | Prevent environmental damage |

Use these tips for long-lasting metalwork:

- Keep away from extreme temperatures.

- Avoid contact with harsh chemicals.

- Regularly check storage conditions.

Implementing these maintenance and care tips ensures your metal remains durable and reliable.

DIY Vs. Professional Services

Deciding whether to tackle a project yourself or hire a professional can be tough. Both options have their benefits and drawbacks. Understanding these can help you make the right choice.

When To Call The Experts

Some situations require expert help. Here are signs that you should call a professional:

- Complexity: The project is too complicated.

- Tools: You lack the necessary tools.

- Experience: You lack experience in metalworking.

- Safety: The task poses safety risks.

Cost-benefit Analysis

Consider these factors when analyzing costs:

| Factor | DIY | Professional |

|---|---|---|

| Initial Cost | Low, if tools are available | Higher upfront cost |

| Time | More time-consuming | Quick and efficient |

| Quality | Varies based on skill | Consistent, high quality |

| Learning Opportunity | Great for skill-building | Less hands-on experience |

Weigh these factors carefully. Sometimes, spending a little more saves time and effort.

Frequently Asked Questions

How Can I Reduce A Metal Hole Size?

To reduce a metal hole size, you can use a metal filler or a plug. This involves inserting a piece of metal into the hole and securing it. Once set, you can grind or file the surface to ensure it’s smooth and flush with the surrounding material.

What Tools Do I Need To Make A Hole Smaller?

You’ll need tools such as a drill, metal filler, and a grinder. A drill helps create the initial hole if needed. A grinder or file smooths the surface after filling. Additionally, a caliper can assist in measuring the hole size accurately before and after modification.

Is It Possible To Resize A Hole In Steel?

Yes, resizing a hole in steel is possible using fillers or plugs. Steel is a durable material, but you can use epoxy or welding for a strong bond. After applying the filler, finish with grinding to achieve a seamless appearance.

Always ensure safety measures during the process.

Can I Use Epoxy To Make A Hole Smaller?

Yes, epoxy is effective for making a hole smaller in metal. It fills the gap and hardens to create a solid surface. Ensure the area is clean before application for better adhesion. Once cured, sand or grind the surface to achieve the desired finish and size.

Conclusion

Making a hole smaller in metal is a straightforward process. With the right tools and techniques, anyone can achieve precise results. Always remember to prioritize safety and take your time. Mastering this skill can enhance your projects and save materials.

Happy crafting, and enjoy your newfound expertise in metalworking!