How to Make MDF Board: Step-by-Step Guide

Have you ever wondered how MDF board is made and why it’s such a popular choice for DIY projects and home renovations? MDF, or Medium Density Fiberboard, is a versatile and cost-effective material used in countless applications, from furniture making to interior design.

Understanding how it’s made can give you valuable insights into its unique properties and how you can use it in your own projects. Imagine having the ability to transform simple wood fibers into a robust and smooth board that can mimic the appearance of expensive wood.

With MDF, you can do just that, and more. By learning about its production process, you’ll discover why MDF is such a reliable and favored material among builders and crafters alike. You’ll uncover the secrets behind MDF board production, step by step. You’ll learn how simple wood fibers are transformed into a durable and versatile material that can elevate your projects to a whole new level. Whether you’re a seasoned DIY enthusiast or just getting started, understanding the making of MDF can open up a world of creative possibilities for you. So, are you ready to dive into the fascinating world of MDF and see how it can enhance your projects? Let’s get started!

Credit: www.linkedin.com

Materials Needed

Wood fibers are the main part of MDF boards. These fibers come from softwood. They are broken down into tiny pieces. The fibers are then cleaned and dried. This makes them ready for the next step.

Resin adhesives hold the fibers together. They are like glue. These adhesives make the board strong. They also help the board last longer. Without them, the board would fall apart.

Wax additives help the board resist water. They keep it from getting wet. This makes the board durable. Wax also gives the board a smooth finish. It looks nice and feels nice too.

Equipment Required

Chippers break wood into small pieces. Defibrators soften wood fibers. Both machines prepare the wood for mixing. They are important in the first step of making MDF board.

Mixers blend wood fibers with resin. Resin helps bind the fibers together. Blenders ensure even mixing. This step makes the board strong and uniform.

Pressing machines shape the mixed fibers. They press the fibers into thin sheets. Pressure and heat are used here. This step gives the board its final shape.

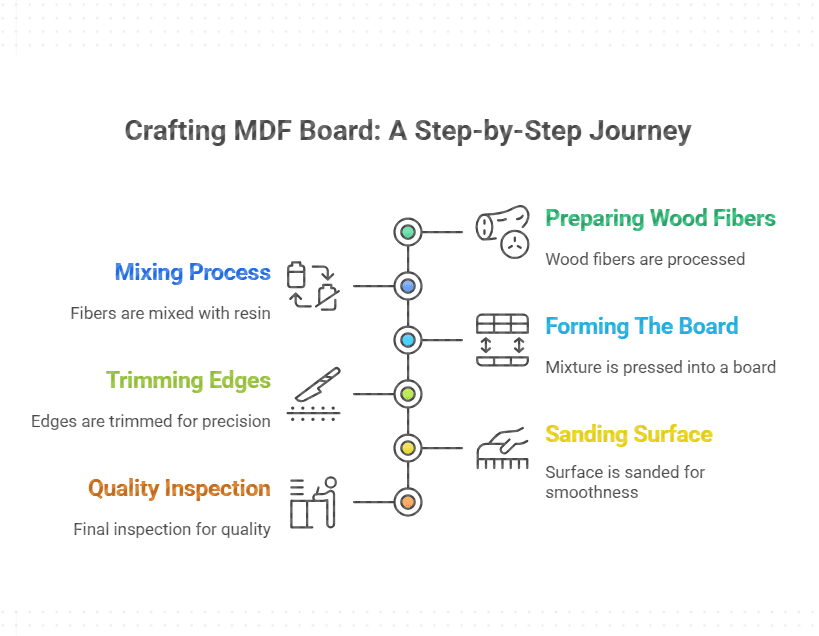

Preparing Wood Fibers

Select wood that is soft and easy to break. Pine and spruce are good choices. Avoid hardwoods. They are hard to process. Softwoods give smooth and even fibers. These make strong MDF boards. Quality of wood affects the board’s strength. Always choose the best wood for the job.

Wood must be broken into small pieces first. A chipping machine helps in this process. Chips are then ground into fibers. This grinding process is crucial. It makes the fibers uniform. Uniform fibers make better boards. Proper grinding ensures fewer defects in the final product.

Fibers need to be dry before use. Wet fibers can cause problems. They may lead to weak boards. Use a dryer to remove moisture. Dry fibers stick together well. They form a strong bond in the board. Ensure fibers are completely dry. This step is important for board quality.

Credit: www.esshelf.com

Mixing Process

Start by adding resin to the wood fibers. Resin helps the fibers stick together. Use just enough to cover all fibers. Next, add wax to the mix. Wax makes the board water-resistant. Stir well until all fibers are coated. The mix should look even.

Use a large mixer for blending. It should be strong enough to mix well. The mixture needs to be smooth. Check for lumps while mixing. Lumps can ruin the board. Make sure the mix is uniform before moving on.

Forming The Board

Small wood fibers are mixed with glue. This forms a thick mat. The mat needs to be even and smooth. Workers spread the mat on a large table. Machines help keep the mat flat. This step is important for strong boards.

The mat goes into a big press. The press is very hot. It uses heat and pressure to shape the board. The mat gets thinner and harder. This makes the MDF board strong. Workers watch the machines closely.

After pressing, the board needs to cool. It must cool slowly. This helps the board become solid. Curing makes the board strong and durable. It takes some time to finish. The board is now ready for use.

Finishing Touches

Creating MDF board involves compressing wood fibers with resin under high pressure. Ensure smooth edges and surfaces for a polished finish. Proper sanding enhances durability and appearance, giving it the perfect touch.

Trimming Edges

Cut the edges with care. Use a sharp blade for clean lines. Smooth edges look better. They also prevent splinters. Always wear gloves for safety. Trim slowly to avoid mistakes.

Sanding Surface

Sand the surface evenly. Smooth surfaces are important. Use fine sandpaper for best results. A rough surface will not look good. Sanding makes the board ready for paint. Dust off the board after sanding.

Quality Inspection

Check the board for flaws. Look for cracks or rough spots. Inspect the edges for splinters. Ensure the board is smooth and even. Quality is important for durability. A perfect board lasts longer.

Safety Precautions

Many chemicals are used in making MDF boards. Wear gloves when touching any chemical. Read labels before use. Never mix chemicals unless told. Keep chemicals away from children. Store in safe places. Use chemicals in ventilated areas. Wash hands after use.

Tools can be dangerous. Wear safety goggles to protect eyes. Keep fingers away from blades. Know how each tool works. Ask an adult for help if unsure. Unplug tools when not in use. Check cords for damage. Store tools safely.

Wear a mask to stop dust from entering lungs. Use earplugs to protect hearing. Wear strong shoes to guard feet. Put on a helmet for head safety. Wear long sleeves to protect arms. Choose gear that fits well. Keep gear in good condition.

Credit: www.esshelf.com

Frequently Asked Questions

How Do You Make Mdf Board?

MDF board is made by breaking down wood fibers, mixing them with wax and resin, and compressing under high heat.

How Are Mdf Boards Made?

MDF boards are made by combining wood fibers with resin, then compressing them under heat and pressure. This process creates a dense, smooth panel ideal for construction and furniture. The boards are then cut and finished to desired sizes for various applications.

What Is The Biggest Drawback Of Using Mdf?

MDF’s biggest drawback is its susceptibility to moisture, which can lead to swelling and damage. It’s not suitable for damp environments. Consider alternatives for wet spaces to ensure longevity and durability. Proper sealing can mitigate issues, but it’s not a foolproof solution.

Always assess environmental conditions before choosing MDF.

What Is The Raw Material Of Mdf?

MDF, or Medium Density Fiberboard, is made from wood fibers. These fibers come from softwood or hardwood, often sourced from sawmill residues. They are combined with wax and resin binders, then compressed under heat to form sheets. This process creates a dense, strong, and versatile material used in furniture and construction.

Conclusion

Creating MDF board is a simple process with basic steps. Start by gathering wood fibers. Then, mix them with resin under pressure and heat. This forms a sturdy board. Use the right tools for cutting and shaping. MDF is versatile and useful for many projects.

It’s an affordable option for furniture and decor. Remember to handle it with care. Wear protective gear when cutting to avoid dust. Follow these steps, and you can make your own MDF board. It’s rewarding and practical for DIY enthusiasts.

Happy crafting!