How to Make Your Own Plywood: DIY Mastery!

To make your own plywood, start by gluing together thin sheets of wood veneer. Then, press them under high pressure to bond the layers.

Creating your own plywood can be a rewarding DIY project. It allows for customization in size, thickness, and wood types. Whether you’re building furniture or crafting decorative items, homemade plywood offers versatility. The process involves selecting quality wood veneers, applying adhesive, and using a press for bonding.

This method not only saves money but also provides a chance to experiment with different wood grains and finishes. With the right tools and materials, you can achieve professional results at home. Embrace this creative endeavor and enhance your woodworking skills while producing unique plywood tailored to your needs.

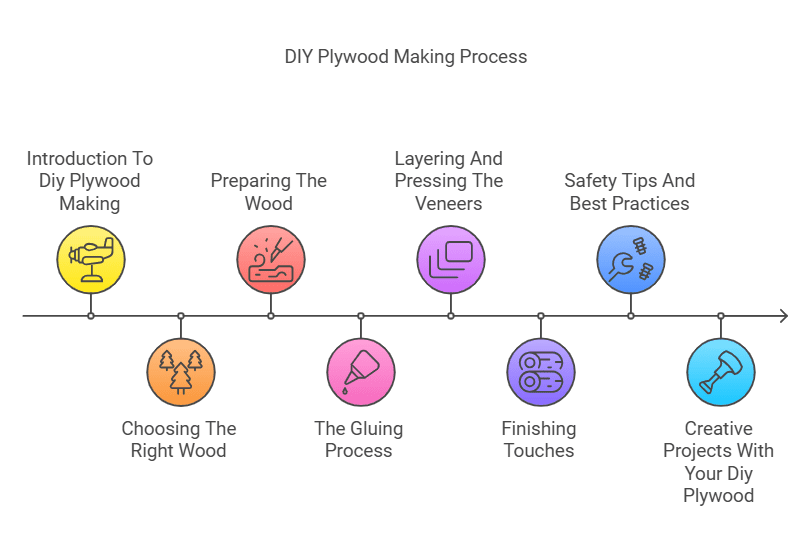

Introduction To Diy Plywood Making

Making your own plywood can be fun and rewarding. It allows for customization and savings. You can choose the size and thickness that suits your needs. This process also gives you control over the quality of the wood.

Gathering the right materials is essential. You will need sheets of wood veneer, glue, and a clamp. A saw and sander are also important tools. Don’t forget safety gear like gloves and goggles.

Making plywood at home is a great way to learn new skills. It’s also a chance to create something unique. Start your DIY journey and enjoy the process!

Choosing The Right Wood

Choosing the right wood is important for making plywood. Different types of wood work well.

| Type of Wood | Features |

|---|---|

| Pine | Lightweight and easy to work with. |

| Birch | Strong and durable, great for furniture. |

| Maple | Hardwood that resists scratches. |

| Oak | Heavy and very sturdy. |

Sourcing quality wood is key for good plywood. Check local lumber yards and suppliers.

Look for wood that is straight and free of defects. Inspect for knots and warping.

Buying in bulk can save money. Always ask for samples before making a large purchase.

Preparing The Wood

Start by cutting logs into thin veneers. Use a sharp saw to make clean cuts. Aim for uniform thickness to ensure even drying. Measure carefully to avoid waste. Each veneer should be consistent in size.

Next, the drying process is crucial. Place veneers in a dry, warm area. This helps remove moisture effectively. Use a fan or dehumidifier for faster drying. Ensure they are completely dry before moving on.

After drying, focus on smoothing the veneers. Use sandpaper with a fine grit for best results. This step removes any rough spots. Smooth surfaces help when gluing the veneers together. Always check for flatness and consistency.

The Gluing Process

Choosing the right glue is crucial for strong plywood. Use polyurethane glue for water resistance. PVA glue works well for indoor projects. Ensure the glue is suitable for the materials.

Apply glue evenly to avoid weak spots. Use a brush or a roller for a smooth layer. Make sure to cover the entire surface. Press the pieces together firmly for good adhesion. Wipe away any excess glue with a damp cloth.

Layering And Pressing The Veneers

To create strong plywood, arranging veneers correctly is key. Start with a sturdy base layer. Place the thicker veneers on the bottom. This adds strength to the plywood.

Next, use thinner veneers on top. They help create a smooth finish. Make sure to alternate the grain direction of each layer. This technique increases flexibility and strength.

For DIY pressing, you can use weights or clamps. Make sure the pressure is even across all layers. This will ensure a strong bond between the veneers.

Another option is to build a homemade press using wood and screws. This allows for uniform pressure. Check the layers regularly while pressing.

Finishing Touches

Trimming the edges of your plywood creates a clean and neat look. Use a sharp saw for precise cuts. Always wear safety gear while cutting. After trimming, inspect the edges for rough spots.

Sanding smooths the edges and surface of the plywood. Start with coarse sandpaper, then use finer grit. Sand in the direction of the grain to avoid scratches. After sanding, wipe away dust with a damp cloth.

Sealing the plywood protects it from moisture and damage. Choose a high-quality wood sealant for best results. Apply the sealant evenly with a brush or roller. Allow it to dry completely before using the plywood.

Safety Tips And Best Practices

Wearing Personal Protective Equipment (PPE) is very important. Always wear safety goggles to protect your eyes. Use ear protection when using loud tools. Dust masks help keep your lungs safe from harmful dust.

Wear gloves to protect your hands from splinters and chemicals. Choose the right gloves for the job. Steel-toed boots can protect your feet from heavy objects. Aprons can shield your clothes and skin.

Working safely with tools is key. Always read the instruction manual before using any tool. Make sure tools are in good condition. Keep your workspace clean and organized.

Use ventilation when working with chemicals. Avoid mixing different chemicals. Store chemicals in labeled containers away from children. Always have a first aid kit nearby for emergencies.

Creative Projects With Your Diy Plywood

Creating furniture from your own plywood can be very fun. Start with a simple table. Use a flat piece of plywood and add legs. You can also make a bookshelf. Cut the plywood into shelves and attach them to a sturdy frame.

For decorative items, think about making a picture frame. Just cut the plywood into the shape you want. Another idea is a lamp base. Cut and paint the plywood to match your room style.

DIY plywood projects can also include storage boxes. These can help organize your space. Use your creativity to design unique shapes. Making your own plywood projects is rewarding and fun!

Frequently Asked Questions

How Can I Make Plywood At Home?

Making plywood at home involves layering thin sheets of wood and gluing them together. Start with selecting suitable wood types. Cut them into thin veneers, apply adhesive, and stack them. Use clamps to secure the layers while drying. Once dried, trim the edges to your desired size.

What Materials Do I Need For Homemade Plywood?

To make plywood, you’ll need thin wood sheets, adhesive, clamps, and a cutting tool. Choose high-quality wood for durability. Additionally, you may require sandpaper for smoothing edges and a protective finish to enhance longevity. Proper materials ensure better strength and appearance of your final product.

Is Making Plywood Difficult For Beginners?

Making plywood can be challenging for beginners but is manageable. Start with simple projects to build your confidence. Following a detailed guide will help you understand the process. With practice, you’ll improve your skills and produce quality plywood. Patience and attention to detail are key.

How Long Does It Take To Make Plywood?

The time to make plywood varies based on your process. Preparing the wood and applying adhesive may take a few hours. Allow the glue to dry completely, which could take up to 24 hours. Overall, plan for at least a day from start to finish for best results.

Conclusion

Creating your own plywood is both rewarding and practical. With the right materials and techniques, you can achieve great results. This skill not only saves money but also allows for customization in your projects. Embrace the process, and enjoy the satisfaction of crafting plywood tailored to your needs.

Happy building!