How To Oil Chainsaw Bar: Essential Guide

Oiling your chainsaw bar is quick and easy! Simply fill the oil reservoir, ensure the oiler is working, and regularly check your chain for lubrication. This prevents premature wear and keeps your saw running smoothly.

Hey there, woodworking friends! Md Meraj here. Ever stared at your chainsaw, ready to tackle that next project, only to wonder about a simple but crucial step: how to oil the chainsaw bar? It’s a common question for many of us just starting out or even those of us who have been around the block a few times. A properly oiled bar and chain are the unsung heroes of a smooth cut, preventing frustrating snags and, more importantly, saving your precious equipment from damage. We’ve all been there, right? That feeling of uncertainty can slow you down.

But don’t you worry! Today, we’re going to break down exactly how to oil your chainsaw bar in a way that’s easy to understand and safe to do. We’ll cover everything from choosing the right oil to spotting the signs that your chain is getting the lubrication it needs. Get ready to feel more confident and make your chainsaw purr with satisfaction!

This guide will walk you through a simple, step-by-step process. We’ll look at the tools you need, the oils you can use, and what to do if things aren’t quite working as they should. By the end, you’ll be an expert in keeping your chainsaw’s cutting system in top shape!

Why Oiling Your Chainsaw Bar is Non-Negotiable

Think of the chainsaw bar and chain as the heart and lungs of your saw. They do all the hard work! The bar, that metallic guide the chain runs along, and the chain itself, with its sharp teeth, work together at high speed. Without proper lubrication, this dynamic duo faces some serious challenges.

Here’s why keeping that oil flowing is so important:

- Reduces Friction: Metal rubbing against metal at high speeds creates a lot of heat and friction. Oil acts as a lubricant, creating a slippery barrier that dramatically reduces this friction.

- Prevents Wear and Tear: Friction leads to heat, and heat is the enemy of metal. Without oil, the chain and bar can overheat, leading to premature wear, dulling of the chain, and even warping or damage to the bar itself.

- Keeps Things Cool: Lubrication also helps dissipate heat generated during cutting. This keeps the components at a more stable temperature, extending their lifespan.

- Ensures Smooth Cutting: A well-oiled chain glides effortlessly through wood. This means less strain on you and your saw, making your cutting experience more efficient and enjoyable.

- Prevents Rust and Corrosion: Chainsaw bars and chains are often made of metal that can rust, especially if exposed to moisture. The oil forms a protective layer that helps prevent this.

Ignoring this simple maintenance can lead to costly repairs or the need to replace expensive parts like the bar, chain, or even the drive sprocket much sooner than expected. For anyone serious about their woodworking or even just tackling occasional outdoor chores, understanding how to oil your chainsaw bar is a fundamental skill.

What You’ll Need: Tools and Materials for Bar Oiling

Before you start, it’s good to have everything ready. This makes the job quick and hassle-free.

Essential Items:

- Chainsaw: Of course! Make sure it’s clean and in good working order.

- Chainsaw Bar and Chain Oil: This is crucial. We’ll talk more about what kind to use in a bit.

- Funnel: A small funnel makes filling the oil reservoir easy and prevents spills.

- Rags or Paper Towels: For wiping up any drips and keeping things clean.

- Gloves (Optional but Recommended): To keep your hands from getting greasy.

- Safety Glasses: Always good practice when working with tools.

Choosing the Right Chainsaw Bar and Chain Oil

This is where many beginners get a bit confused. Can you just use any old oil? Nope! Chainsaw bar and chain oil is specifically formulated for this job. Here’s what to look for:

- Viscosity: It needs to be thick enough to cling to the chain and bar, even when spinning at high speeds. Standard motor oils are often too thin and will fly off.

- Adhesiveness: The oil should stick to the chain and not be flung off immediately.

- Temperature Performance: Good bar oil is designed to perform well across a range of temperatures. Some are all-season, while others might be formulated for colder or warmer conditions.

Types of Bar and Chain Oil:

- Petroleum-Based: These are the most common and cost-effective. They offer excellent lubrication and protection.

- Biodegradable/Vegetable-Based: If you’re working in sensitive environments where oil spills could be an issue (like near water bodies or in parks), these are the way to go. They break down more easily in nature but can sometimes be more expensive and may require more frequent application in very hot conditions, as they can be less viscous.

What to AVOID:

Never use:

- Used motor oil

- New motor oil (unless specifically stated by the manufacturer for your saw and application)

- Hydraulic fluid

- Any other household lubricant

Using the wrong type of oil can degrade rubber parts in your chainsaw, cause clogs, and offer insufficient lubrication, leading to the very problems you’re trying to prevent.

Step-by-Step: How to Oil Your Chainsaw Bar

Alright, let’s get down to business. Oiling your chainsaw bar is a straightforward process that should be part of your regular pre-operation check. Make sure your chainsaw is turned off and cool before you begin.

Step 1: Locate the Oil Reservoir

Your chainsaw has a separate reservoir for bar and chain oil. It’s usually distinguishable from the fuel tank. Often, it’s marked with an oil can symbol or the word “Bar Oil” or “Chain Oil.” The fuel tank is typically marked with a gas pump symbol or “Fuel.”

- Fuel Tank: For gasoline and 2-stroke oil mixture (if applicable).

- Bar Oil Reservoir: For specialized bar and chain oil.

Consult your chainsaw’s owner’s manual if you’re unsure where these are located on your specific model. A quick search on the manufacturer’s website for your chainsaw model’s manual can also be very helpful. For example, a manual for a Stihl chainsaw will clearly show the location of its fill caps.

Step 2: Prepare to Fill

Before opening the cap, clean around it with a rag. This prevents dirt and debris from falling into the oil reservoir, which could clog the oiler system.

Step 3: Open the Reservoir Cap

Carefully unscrew or unlatch the cap for the bar oil reservoir. Some caps have a tether, while others are completely removable.

Step 4: Add Chainsaw Bar and Chain Oil

Insert your funnel into the fill hole. Slowly pour the bar and chain oil into the reservoir. Fill it almost to the top, but leave a little room to avoid overflow when you replace the cap.

Tip: It’s a good practice to fill the bar oil reservoir every time you refuel your chainsaw. This way, you’re less likely to run out of oil mid-cut.

Step 5: Replace the Reservoir Cap

Once filled, carefully screw or latch the cap back on. Make sure it’s secure to prevent leaks. Wipe away any drips with a rag.

Step 6: Check for Oil Flow (The Crucial Test!)

This is a vital step to ensure your automatic oiler is working correctly. Once you’ve filled the reservoir and secured the cap, you need to check if the oil is actually reaching the bar and chain.

How to Test:

- Start your chainsaw.

- Hold the tip of the chainsaw bar about 6 inches above a light-colored surface, like a piece of cardboard, a newspaper, or a clean, light-colored piece of wood. Be extremely careful and ensure no one is in the path of the saw or debris.

- Run the chainsaw at a moderate throttle for about 10-15 seconds.

- Turn off the chainsaw.

- Examine the surface below the bar. You should see a line of oil. The faster the chain, the more noticeable the line will be. This indicates that oil is being pumped onto the chain and slung outwards.

If you don’t see an oil line, don’t panic! We’ll cover troubleshooting common issues next.

Troubleshooting Common Oiling Problems

What if you perform the oil flow test and see nothing? Don’t worry, it’s usually a fixable problem. Here are some common reasons why your chainsaw bar might not be getting oiled and how to address them:

Problem 1: No Oil Line Visible

- Cause A: Empty Reservoir: Double-check that you actually filled the correct reservoir. It sounds simple, but it happens!

- Cause B: Clogged Oil Filter: The oil line from the reservoir to the pump can get clogged with sawdust and gunk. You might need to remove the bar and chain and clean out the oiler hole on the powerhead.

- Cause C: Clogged Oil Passage: Similarly, the small passageway in the bar itself where the oil enters can get blocked. Look for the oiler hole on the bar (usually at the drive sprocket end) and carefully clean it out with a thin wire or pick.

- Cause D: Faulty Oil Pump: In some cases, the internal oil pump might have failed. This is a more complex repair, and you may need to consult your owner’s manual or a professional service center. Many modern saws have a small adjustable oil pump, which might need to be set to a higher flow rate if adjustable.

- Cause E: Ice or Cold Conditions: In very cold weather, the oil can become sluggish or freeze, especially if there’s any moisture in the reservoir. Try warming the saw or using a bar oil formulated for cold temperatures. Ensure your fuel mix doesn’t have excessive water.

Problem 2: Oil Leaking from the Reservoir

- Cause A: Loose Cap: The reservoir cap might not be screwed on tightly.

- Cause B: Damaged Seal: The O-ring or seal on the reservoir cap could be damaged or missing, preventing a tight seal.

- Cause C: Cracked Reservoir: Less common, but the plastic reservoir itself might have a crack.

Problem 3: Oil Slinging Excessively

- Cause A: Overfilling: If you overfill the reservoir, there might be too much oil for the system to handle, leading to excess slinging.

- Cause B: High Speed: Running the saw at full throttle for extended periods without cutting can cause more oil to be slung off.

- Cause C: Incorrect Oil Viscosity: Using an oil that is too thin (especially in hot weather) can cause it to be slung off more readily.

Important Note on Cleaning: When cleaning the oiler hole on the bar or the powerhead, be gentle. Use a thin piece of wire that’s smaller than the hole, or a toothpick. Avoid forcing anything, as you could damage the passages.

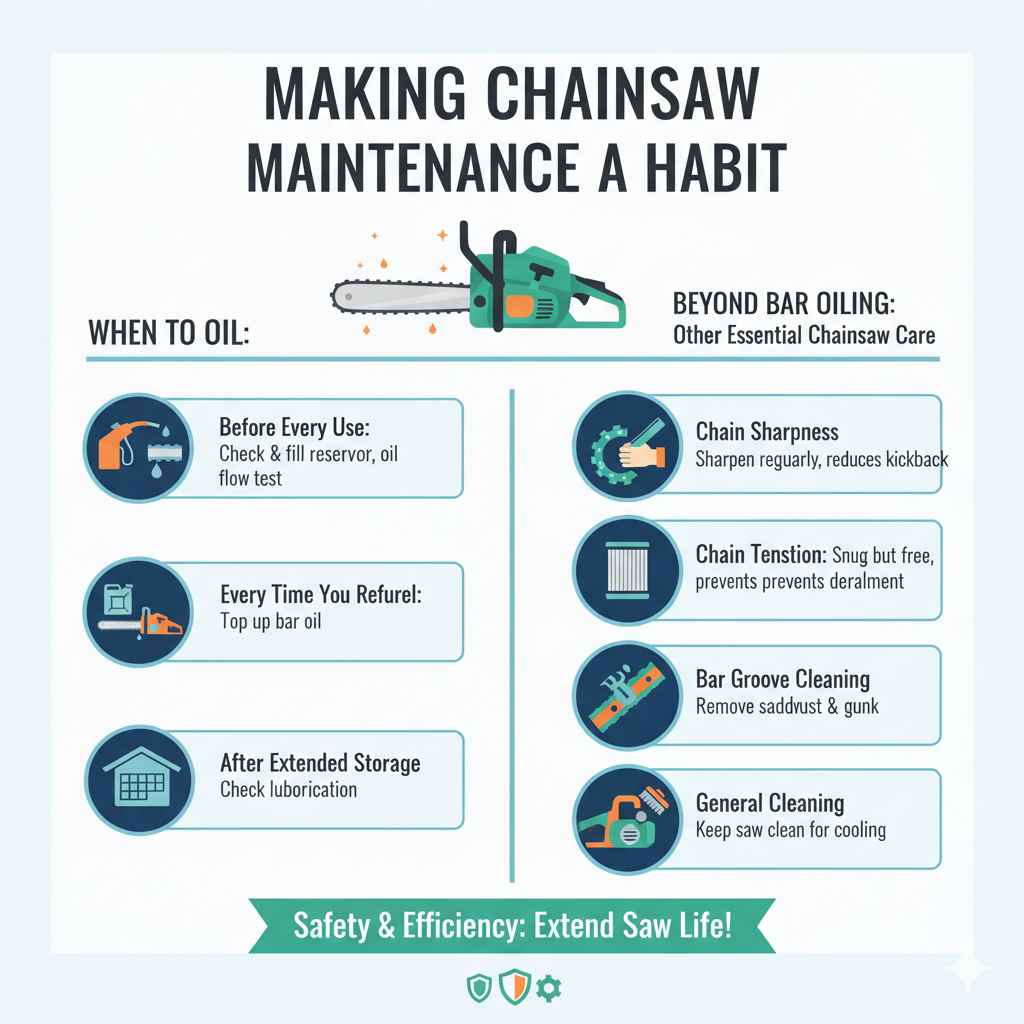

Making Chainsaw Maintenance a Habit

Oiling your chainsaw bar isn’t a one-time task; it’s part of a routine maintenance schedule. Making it a habit ensures your saw is always ready to go and lasts for years.

When to Oil:

- Before Every Use: This is the golden rule. Check and fill the reservoir, and perform the oil flow test.

- Every Time You Refuel: If you’re doing a lot of cutting, it’s easy to run through a tank of fuel quickly. Top up your bar oil at the same time.

- After Extended Storage: If your saw has been sitting for a while, check lubrication before starting.

Beyond Bar Oiling: Other Essential Chainsaw Care

While bar oiling is critical, a well-maintained chainsaw involves a few other simple checks:

- Chain Sharpness: A dull chain requires more effort, puts more strain on the saw, and increases the risk of kickback. Sharpen your chain regularly using a file jig or a professional service. Learn how to check if your chain is dull.

- Chain Tension: The chain should be snug but still be able to move freely by hand. Too loose, and it can derail; too tight, and it will cause excessive wear. Check your owner’s manual for specific tensioning instructions.

- Air Filter: A clogged air filter restricts airflow, impacting engine performance and fuel efficiency. Clean or replace it regularly. Reference guidelines from organizations like the Occupational Safety and Health Administration (OSHA) for general safe tool usage, though specific maintenance is in your saw’s manual.

- Bar Groove Cleaning: Periodically, remove the chain and bar and clean out any sawdust and gunk from the bar groove and around the drive sprocket.

- General Cleaning: Keep your chainsaw clean, especially around the engine cylinder fins, to allow for proper cooling.

By integrating these simple maintenance steps into your workflow, you’re not just extending the life of your chainsaw; you’re also ensuring your safety and efficiency when you’re out in the workshop or the woods.

Chainsaw Bar Oil vs. Motor Oil: A Clear Distinction

It’s worth reiterating why using dedicated chainsaw bar and chain oil is so important by comparing it to motor oil. Many people wonder if they can just use leftover motor oil. The short answer is almost always no.

| Feature | Chainsaw Bar & Chain Oil | Motor Oil (e.g., 10W-30) |

|---|---|---|

| Adhesion | High. Designed to cling to the chain and bar. | Low. Designed to flow through engine components. |

| Viscosity | Thicker, especially at operating temperatures, to stay put. | Formulated for engine temps and flow, often thinner at high external temps. |

| Additives | Contains tackifiers and anti-wear agents specific to chain/bar lubrication. | Contains detergents, dispersants, and other additives for engine protection, which can harm some chainsaw components. |

| Temperature Range | Often formulated for stable performance across different outdoor temperatures. | Optimized for engine internal temperatures, can be too thin or too thick for bar application. |

| Environmental Impact | Available in biodegradable formulas for ecological sensitivity. | Not suitable for environmental release. |

Motor oil’s primary job is to lubricate moving parts inside an engine. It’s designed to flow, cool, and clean engine internals. Chainsaw bar oil’s job is to stick to external moving parts (the chain and bar) and resist being flung off by centrifugal force while holding up under friction and heat. The additives in motor oil aren’t optimized for this and can actually gum up the oil pump or passages over time.

Think of it this way: you wouldn’t use cooking oil to lubricate the wheel bearings on your car, and similarly, you shouldn’t use motor oil on your chainsaw bar and chain. Using the right product ensures your tool performs optimally and safely.

Frequently Asked Questions (FAQ)

Here are some common questions beginners have about oiling their chainsaw bars:

Q1: How often should I check my chainsaw’s bar oil level?

You should check and top up your bar oil reservoir before every single use. It’s a small step that takes seconds but is crucial for preventing damage. It’s often easiest to do this every time you refuel your chainsaw.

Q2: Can I use regular motor oil if I’m in a pinch?

It’s strongly discouraged. Regular motor oil is too thin and will be thrown off the chain quickly, offering little protection. It can also contain detergents that can damage your saw’s oiling system or seals. It’s best to invest in proper bar and chain oil.