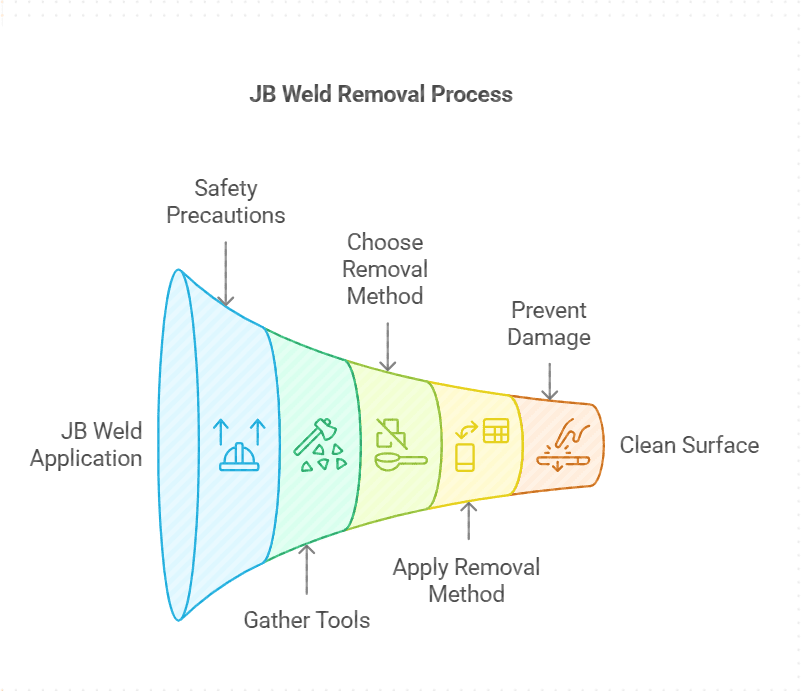

How to Remove JB Weld: Easy and Effective Methods

Removing JB Weld can be tricky. It requires the right approach and tools.

JB Weld is a strong adhesive used for bonding metals and other surfaces. It’s known for its durability, but sometimes you need to remove it. Maybe you made a mistake during application. Or perhaps it’s time for a repair. Understanding how to remove it effectively is crucial.

In this guide, you will learn simple steps to safely remove JB Weld. Whether you’re working on a car, a household item, or a DIY project, the methods discussed here will help. Proper removal ensures that your surfaces remain intact and ready for future use. Let’s explore the best ways to tackle this tough adhesive.

Introduction To Jb Weld

JB Weld is a strong adhesive. It binds metal, plastic, and other materials. It is popular for repairs. It comes in two parts. You mix them before use. It hardens quickly and is very strong. People trust it for tough jobs.

JB Weld fixes broken car parts. It repairs pipes and leaks. It is useful for household fixes. It mends broken tools and equipment. Many people use it for DIY projects. It is handy for hobbyists and professionals alike.

Credit: www.gripclean.com

Safety Precautions

Wear protective gloves and goggles while removing JB Weld. Ensure good ventilation and avoid direct skin contact.

Necessary Safety Gear

Always wear safety gloves to protect your hands. Use safety goggles to shield your eyes from debris. A mask helps avoid inhaling harmful fumes. Long sleeves and pants can protect your skin from contact. Closed-toe shoes are also essential. Keep a fire extinguisher nearby for emergencies.

Proper Ventilation

Ensure the room has good air flow. Open windows to let fresh air in. Use fans to move air around. Avoid closed spaces. Good ventilation prevents fume buildup. It keeps you safe while working. Never work in a confined space without fresh air. Always prioritize your health and safety.

Tools And Materials Needed

A few tools will make the job easier. A heat gun is very helpful. Use a putty knife to scrape off the JB Weld. A wire brush can clean up the residue. Keep a pair of protective gloves handy. You will also need some sandpaper for final touches.

It is good to have some acetone on hand. This can help dissolve JB Weld. A clean cloth can be useful for wiping surfaces. You might also need a bucket of water for cooling down hot areas. Keep some soap nearby for washing your hands after the job.

Credit: www.reddit.com

Mechanical Removal Methods

A chisel can be very effective. Choose a flat chisel. Place the chisel at the edge of the JB Weld. Tap it gently with a hammer. The JB Weld will start to chip away. Work slowly and carefully. Avoid damaging the surface underneath. Keep tapping until the JB Weld is gone.

Sandpaper helps remove JB Weld. Use coarse sandpaper first. Rub it over the JB Weld. This will wear down the JB Weld. Switch to fine sandpaper. This smooths the surface. Rub gently to avoid scratches. Repeat if needed. Sandpaper can be messy, but it works well.

Chemical Removal Methods

To remove JB Weld, acetone is a popular choice. It can dissolve the bond. Vinegar also works but is less strong. Citrus-based solvents are safer but slower. Isopropyl alcohol can help too. Always use gloves and ventilation with these solvents. Safety first!

Apply solvent with a cotton ball or cloth. Rub gently on the JB Weld. Let it sit for a few minutes. Check if the bond softens. Use a scraper to peel off the loosened material. Repeat if needed. Be patient. Don’t rush the process.

Heat Removal Methods

Removing JB Weld can be done through heat application. Use a heat gun to soften the JB Weld, then scrape it off gently. Avoid excessive force to prevent damage to the surface.

Using A Heat Gun

A heat gun can soften Jb Weld for easier removal. Hold the heat gun close to the Jb Weld. Move it in circles to heat the area evenly. Keep heating until the Jb Weld becomes soft. Use a scraper to peel off the softened Jb Weld. Be careful not to overheat the surface.

Safety Tips For Heat Application

Wear gloves to protect your hands. Use goggles to protect your eyes from debris. Keep a fire extinguisher nearby in case of an accident. Work in a ventilated area to avoid inhaling fumes. Do not touch the hot surface until it cools down. Keep kids and pets away from the work area.

Preventing Damage To Surfaces

Use plastic sheets or drop cloths to cover surfaces. This helps keep surfaces safe. Keep a wet cloth nearby. It is useful for quick clean-ups. Wear gloves to protect your hands. Keep surfaces free of unwanted marks.

Test on a small area before using it on the whole surface. This helps to see if it is safe. Use a tiny bit and wait. Look for any damage or changes. If it is safe, proceed. If not, choose another method.

Post-removal Cleanup

After removing JB Weld, some residue may remain. Use a clean cloth with a small amount of acetone. This helps to dissolve the sticky parts. Gently rub the area until it’s clean. Be careful not to damage the surface.

Once the residue is gone, check the surface. It might need some fixing. Sand the area gently to smooth it out. Make sure it’s even. After sanding, wipe the area with a damp cloth. This removes any dust. Finally, let the surface dry completely before using it again.

Tips And Tricks

Removing Jb Weld can be tricky. Use a grinder to remove large chunks. Apply heat to soften the bond. Be careful with the heat. Use a chisel to scrape off the residue. Solvents can help break down Jb Weld. Choose the right solvent for the job. Be patient. Take your time. Safety is very important. Wear gloves and goggles.

Do not rush. Rushing can lead to damage. Avoid using too much heat. Excessive heat can harm the surface. Do not skip safety gear. Skipping gloves and goggles is risky. Avoid using the wrong tools. Wrong tools can make the job harder. Be careful with solvents. Some solvents can damage materials. Do not ignore instructions. Follow guidelines carefully for best results.

Credit: www.reddit.com

Frequently Asked Questions

How Do You Remove Dried J-b Weld?

To remove dried J-B Weld, use a combination of grinding, sanding, or filing. Apply heat to soften it.

Is J-b Weld Permanent?

Yes, J-B Weld creates a strong, permanent bond. It resists water, chemicals, and extreme temperatures, ensuring durability.

How To Get J-b Weld Off Of A Car?

Remove J-B Weld by applying acetone or a similar solvent. Use a scraper or abrasive pad to gently scrub.

Can You Tap Out J-b Weld?

Yes, you can tap out J-B Weld once it fully cures. It becomes hard and can be drilled or tapped.

Conclusion

Removing JB Weld can be tricky, but it’s not impossible. You need patience and the right tools. Start with a heat source. Soften the JB Weld. Then, scrape it off gently. If needed, use a solvent. Always work in a well-ventilated area.

Safety first. Protect your hands and eyes. Follow these steps, and you’ll get the job done. Removing JB Weld takes time, but you can do it. Stay safe and good luck with your project.