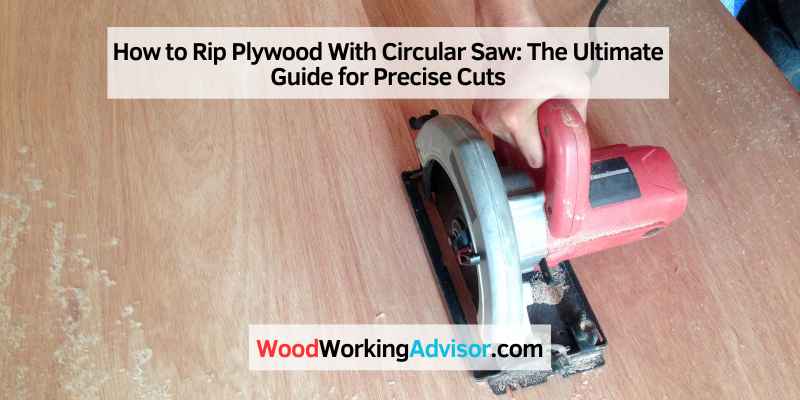

How to Rip Plywood With Circular Saw: The Ultimate Guide for Precise Cuts

To rip plywood with a circular saw, adjust the blade depth to slightly deeper than the thickness of the plywood, position the plywood on a stable work surface, and cut along the marked line with the circular saw while keeping a steady hand and following a straight line. Ripping plywood with a circular saw is a straightforward process that can be easily done with proper technique and safety precautions.

By following these steps, you can accurately and efficiently rip plywood to the desired size for your woodworking or construction projects.

Choosing The Right Circular Saw

When it comes to woodworking, choosing the right circular saw is essential for achieving precise and efficient cuts, especially when ripping plywood. Selecting the appropriate tool can make a significant difference in the quality of your project. Before delving into the process of ripping plywood with a circular saw, let’s explore the key considerations for choosing the right one.

Considerations For Plywood Ripping

Before you start ripping plywood with a circular saw, it’s crucial to consider a few factors to ensure a smooth and precise cutting process. Here are some essential considerations:

Blade Selection

When it comes to ripping plywood with a circular saw, the type of blade you use can greatly impact the quality of your cuts. It’s important to select the appropriate blade for the job. Here are some key factors to consider when choosing a blade:

Preparing The Plywood

Before you can start ripping plywood with a circular saw, it’s important to properly prepare the plywood. This involves measuring and marking the plywood and securing it in place for a safe and accurate cut.

Measuring And Marking

Measure twice, cut once – a golden rule for any woodworking project! To ensure an accurate and precise cut, start by measuring the desired dimensions of the plywood. Use a tape measure or ruler to carefully measure the length and width that you want the plywood to be ripped to.

Once you have your measurements, use a pencil to mark the lines on the plywood. It’s important to make clear and visible marks using a straight edge, such as a carpenter’s square, to ensure straight cuts. This will serve as a guide for your circular saw, making it easier to follow the exact line and prevent any potential mistakes.

Securing The Plywood

Securing the plywood before making your cut is crucial for safety and accuracy. Unsecured plywood can shift or move while cutting, leading to an uneven or dangerous cut. There are several methods you can use to secure the plywood:

- Clamps: Use clamps to firmly hold the plywood in place on a stable work surface. This will prevent it from shifting or vibrating during the cutting process.

- Weighted objects: If clamps are not available, you can use heavy objects like bricks or sandbags to weigh down the plywood. Place them strategically along the edges of the plywood to keep it stable.

- Sawhorses: Another option is to use sawhorses to elevate and support the plywood. Make sure the sawhorses are sturdy and properly positioned to provide a stable base for the plywood.

Regardless of the method you choose, ensure that the plywood is secured tightly and won’t move during the cutting process. This will not only improve safety but also help you achieve cleaner and more accurate cuts.

Setting Up The Circular Saw

Before you start ripping plywood with your circular saw, it’s important to set it up properly. By following these simple steps, you can ensure that your cuts are precise and your woodworking projects turn out great.

Adjusting The Blade Depth

To begin, you’ll need to adjust the blade depth on your circular saw. Start by unplugging the saw for safety. Then, locate the blade depth adjustment lever or knob on the saw. Loosen it and adjust the blade so that it extends no more than half an inch below the plywood you’re cutting. This will help prevent any splintering or tear-outs during the cutting process.

Aligning The Guide

Next, you’ll want to align the guide or fence on your circular saw. The guide is a straight edge that helps keep your cuts straight and accurate. Place the guide parallel to the cutting line on the plywood, making sure it’s securely attached to the saw’s base. You can use clamps or the built-in guide feature on your saw to hold it in place.

| Steps | Description |

|---|---|

| 1 | Unplug the saw and adjust the blade depth to prevent splintering. |

| 2 | Align the guide parallel to the cutting line to ensure accurate cuts. |

Now that you have set up your circular saw, you’re ready to start ripping plywood. By adjusting the blade depth and aligning the guide properly, you can ensure clean, precise cuts that will enhance the quality of your woodworking projects.

Techniques For Rip Cutting

Plywood is a versatile material commonly used in construction and woodworking projects. Rip cutting plywood can be a demanding task, but with the right techniques and tools, it can be efficiently and accurately accomplished using a circular saw. Below, we’ll explore the essential techniques for rip cutting plywood with a circular saw, focusing on the subheading: Techniques for Rip Cutting.

Using A Straight Edge Guide

A straight edge guide is a vital tool when it comes to achieving clean and precise rip cuts in plywood. It ensures that the saw follows a straight path along the length of the board, resulting in accurate cuts. Here’s how to use a straight edge guide:

- Place the plywood on a stable work surface and mark the desired cut line using a straightedge and pencil.

- Position the straight edge guide parallel to the cut line and secure it in place using clamps. Ensure that the saw’s blade will run alongside the guide.

- Adjust the depth of the saw blade to slightly exceed the thickness of the plywood, allowing for a clean cut without cutting into the work surface.

- Carefully position the circular saw against the straight edge guide and start the saw before gently pushing it along the guide to make the rip cut.

- After completing the cut, carefully remove the straight edge guide and finish any remaining clean-up work.

Making Multiple Passes

Making multiple passes can be a valuable technique when cutting through thicker plywood or when a cleaner cut is desired. Here’s how to make multiple passes when ripping plywood with a circular saw:

- Set the saw blade depth to around half the thickness of the plywood for the initial pass.

- Carefully guide the saw along the cut line, ensuring a steady and consistent pace to maintain accuracy.

- After the initial pass, reset the saw blade depth to complete the cut in subsequent passes, ensuring the blade doesn’t bind or splinter the plywood.

- Repeat the process, gradually deepening the blade with each pass until the desired depth is achieved, producing a clean and precise rip cut in the plywood.

Tips For Achieving Precise Cuts

When it comes to ripping plywood with a circular saw, achieving precise cuts is essential for a professional and polished result. The following tips will help you ensure your cuts are accurate and clean, giving you the confidence to tackle any woodworking project with ease.

Maintaining A Steady Pace

To achieve precise cuts when ripping plywood with a circular saw, it is crucial to maintain a steady pace throughout the process. Rushing the cut can lead to mistakes and uneven edges. Conversely, going too slowly can cause burn marks and tear-outs.

When starting the cut, set a comfortable speed that allows the blade to steadily glide through the plywood. Taking your time and maintaining a steady pace will lead to cleaner cuts and reduce the risk of accidents.

Supporting The Plywood

Supporting the plywood properly is essential for achieving precise cuts. When ripping plywood, it can sag or splinter if it is not adequately supported, resulting in uneven edges.

Start by placing the plywood on a sturdy work surface, ensuring it is entirely flat and stable. If possible, use sawhorses or a workbench to provide additional support. To prevent tear-outs and splintering, place a sacrificial board or a piece of scrap plywood under the cut line. This will provide support and help protect the surface from damage.

Furthermore, using clamps to secure the plywood in place will prevent it from shifting during the cut, resulting in more accurate and precise cuts.

Remember, supporting the plywood effectively is crucial for achieving smooth and clean cuts when using a circular saw.

Safety Precautions

When it comes to ripping plywood with a circular saw, ensuring your safety should be a top priority. Taking a few simple precautions can help prevent accidents and protect yourself from potential injuries. In this section, we will discuss some essential safety measures you should follow before you start the cutting process.

Wearing Protective Gear

Wearing appropriate protective gear is crucial to safeguard yourself while working with power tools like a circular saw. Here’s a list of essential protective equipment you should always wear:

- Safety goggles or a face shield: These protect your eyes from any flying debris or dust.

- Ear protection: Using earplugs or earmuffs helps minimize the impact of the noise generated by the circular saw.

- Dust mask: Prevent inhalation of harmful plywood dust particles by using a suitable respirator mask.

- Gloves: Choose gloves that provide a good grip and protect your hands from cuts or other injuries.

- Appropriate clothing: Wear long sleeves and long pants to minimize the exposure of your skin to potential hazards.

Using Clamps And Sawhorses

Using clamps and sawhorses correctly is essential to maintain stability and control over the plywood when cutting. Here are some tips for using them effectively:

- Clamping the plywood: Before starting, secure the plywood firmly using clamps. This prevents it from moving or vibrating during the cutting process.

- Proper positioning of sawhorses: Place the sawhorses at an appropriate distance to support the entire length of the plywood. This ensures stability and prevents any sagging or bending.

- Leveling the plywood: Use a level to ensure the plywood is flat and even on the sawhorses. This helps to maintain accuracy and control while cutting.

By adhering to these safety precautions, you can significantly reduce the risk of accidents and injuries when ripping plywood with a circular saw. Remember to always prioritize your safety and work in a well-lit and well-ventilated environment for optimal results.

Troubleshooting Common Issues

Troubleshooting common issues when ripping plywood with a circular saw can help ensure a smooth and accurate cut. Addressing problems such as tear-out and blade binding are essential for achieving high-quality results. By understanding these common issues and how to prevent and resolve them, you can improve your woodworking skills and produce cleaner cuts with your circular saw.

Preventing Tear-out

When cutting plywood with a circular saw, tear-out can occur on the bottom surface of the wood, resulting in a rough and splintered edge. To prevent tear-out, you can:

- Use a sharp, fine-toothed blade specifically designed for plywood.

- Apply masking tape along the cut line to stabilize the wood fibers.

- Support the plywood with sacrificial backing such as scrap wood to minimize splintering.

Addressing Blade Binding

Blade binding can lead to uneven cuts and increased risk of kickback. To address this issue, consider the following:

- Ensure the blade is properly aligned and securely tightened on the saw.

- Adjust the cutting depth to avoid overloading the blade and causing it to bind.

- Clear away debris and any obstructions from the cutting path before making the cut.

Conclusion

Ripping plywood with a circular saw can be a straightforward process when approached with the right technique. By following the step-by-step guide and practicing safety measures, you can achieve precise cuts for your woodworking projects. With the knowledge and confidence gained from this article, you’re now ready to take on plywood cutting with ease.