How to Round Edges on Plywood: A DIY Guide

To round edges on plywood, use a router with a round-over bit or a sanding block. Both methods create smooth, rounded edges effectively.

Rounding edges on plywood enhances its aesthetics and safety, making it ideal for various projects. Sharp edges can pose risks, especially in furniture and children’s toys. Softening these edges not only improves the look but also increases durability. Whether you are a seasoned woodworker or a DIY enthusiast, mastering this simple technique adds a professional touch to your work.

Tools like routers, sanders, or even manual methods can help achieve the desired finish. This guide will walk you through the best practices for rounding edges on plywood, ensuring your projects are both visually appealing and safe to use.

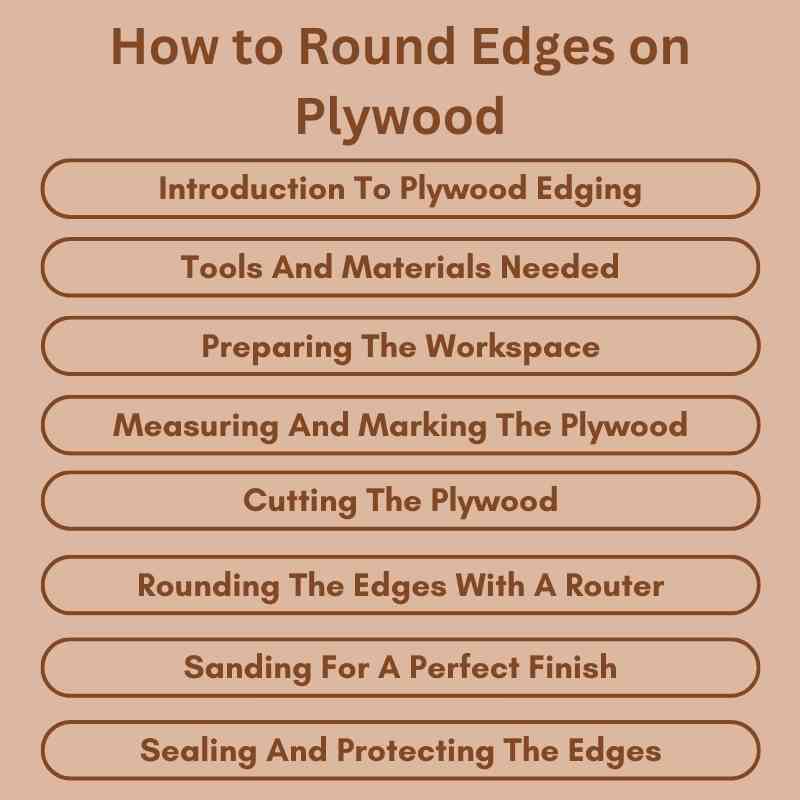

Introduction To Plywood Edging

Plywood is a popular choice for many projects. Smooth edges add a professional touch. They also improve safety by reducing sharp corners. Rounding edges helps avoid splinters and injuries.

Safety is key before starting any edging project. Always wear safety goggles to protect your eyes. Use a dust mask to avoid inhaling wood dust. Keep fingers clear of tools and blades. Always follow the manufacturer’s instructions for tools.

Planning the project ahead of time is important. Gather all necessary tools and materials. This includes sandpaper, routers, and safety gear. Having everything ready makes the process smoother.

Tools And Materials Needed

Choosing the right sandpaper is key for rounding edges on plywood. Use a medium grit like 120 for initial sanding. Follow with a finer grit, such as 220, for a smooth finish.

The router plays a major role in edging. It shapes the plywood edges quickly and evenly. With the right bit, you can create different profiles.

Alternative tools for rounding edges include file and sanding block. A jigsaw can also round corners effectively. Each tool has its unique benefits.

Preparing The Workspace

Start by choosing a stable work surface. A flat table or workbench works best. Ensure that it is clean and free from clutter. This helps to avoid accidents.

Next, gather all your tools. Keep them organized for easy access. Use a toolbox or a small cart. This makes finding tools quick and simple. Include items like a router, sandpaper, and clamps.

Check your lighting. Good lighting makes it easier to see your work. Position your work surface near a window or use bright lamps. Proper lighting helps you avoid mistakes.

Measuring And Marking The Plywood

Begin by deciding the radius for the edge curve. Use a compass to draw a circle on the plywood. Mark the center point clearly. This point helps keep the curve consistent.

For accurate marking, use a straightedge to connect points. This helps avoid mistakes. Double-check your measurements before cutting. Use a pencil for easy corrections.

Consider using templates for larger curves. Cut a piece of cardboard into the desired shape. Trace around the template on the plywood. This method ensures a perfect curve every time.

Cutting The Plywood

Cutting plywood requires careful techniques for the best results. Use a sharp saw blade to make clean cuts. A table saw or a circular saw works well. Always cut with the good side down to prevent splintering.

To prevent splintering, use masking tape on the cut line. This helps hold the wood fibers together. A slower feed rate also reduces splintering. Make sure the blade is set to the correct depth.

Keep the plywood secured with clamps while cutting. This prevents movement and improves accuracy. Measure twice before cutting to ensure precision. Following these tips will give you smooth, clean edges.

Rounding The Edges With A Router

Setting up the router bit is simple. Start by choosing the right bit for rounding edges. A round-over bit is a great choice. Make sure to adjust the depth of the cut properly. This ensures an even finish on the edges.

Before using the router, secure the plywood firmly. Use clamps to hold it in place. This prevents any movement while working. Always wear safety goggles to protect your eyes.

When routing, keep a steady hand. Move the router along the edge smoothly. This helps achieve a smooth finish without any bumps. Check the edge frequently to ensure the desired shape.

Sanding For A Perfect Finish

Proper sanding is key for a smooth finish on plywood edges. Grain direction plays a big role in sanding. Always sand along the grain to avoid scratches. Power sanding can save time and effort. It is great for large areas. Use a random orbital sander for best results.

Manual sanding gives more control. It works well for small, detailed areas. Use sandpaper with a grit of 120 for initial sanding. For a finer finish, switch to 220 grit. Keep checking the edge to ensure a smooth surface.

Both methods have their benefits. Choose the one that fits your project. Experiment with both to see what works best for you.

Sealing And Protecting The Edges

Choosing the right sealant is crucial for protecting plywood edges. Polyurethane sealants provide strong protection and are water-resistant. Acrylic sealants are easy to apply and clean up with water.

For even coverage, apply sealant using a foam brush or a roller. Start at one edge and work across smoothly. Avoid overloading the brush to prevent drips. Let each coat dry before applying the next one.

Remember to sand the edges lightly before sealing. This helps the sealant stick better. Always wear gloves to protect your hands while working.

Advanced Techniques

Creating beveled edges on plywood adds a stylish touch. Use a router with a beveled bit for this. Start by securing the plywood to a stable surface. Move the router slowly along the edge for even results.

For decorative edge treatments, consider using laminate or veneer. These materials provide a smooth, finished look. They come in various colors and patterns. Choose one that matches your project design.

Another option is to use sandpaper for a softer edge. Start with coarse grit and finish with fine grit. This technique enhances the wood’s natural beauty.

Troubleshooting Common Issues

Edge tear-out can ruin a clean cut on plywood. Use a sharp blade for smoother edges. Tape the edge with masking tape before cutting. This helps prevent tear-out during the process.

For uneven edge profiles, check the saw alignment. Ensure the blade is straight and sharp. Use a router to smooth out rough edges. A sanding block can also help in achieving a flat surface.

Consider using a jig or guide. This keeps the cuts precise and straight. Always wear safety gear like goggles and a mask for protection.

Maintenance And Care For Plywood Edges

Regular maintenance is key to extending the life of plywood edges. Inspect edges for signs of damage often. Clean them with a soft cloth to remove dirt. Use a mild soap if needed. Avoid harsh chemicals that can harm the surface.

For damaged edges, repair promptly to prevent further issues. Sand rough areas gently with fine-grit sandpaper. Apply wood filler to deep cracks. Once dry, sand the area smooth. Finish with a protective sealant to keep edges safe from moisture.

Frequently Asked Questions

How Do You Round Edges On Plywood?

Rounding edges on plywood can be done using a router with a round-over bit. Start by securing the plywood on a stable surface. Then, run the router along the edges, applying even pressure. This method provides a smooth, professional finish, enhancing both aesthetics and safety.

What Tools Are Needed To Round Plywood Edges?

To round plywood edges, you’ll need a router, round-over bit, and clamps. A sander can also be helpful for finishing touches. Ensure you have safety gear, like goggles and a dust mask, to protect yourself during the process. Proper tools will make your project easier and more efficient.

Can I Round Edges Without A Router?

Yes, you can round edges without a router. Use a hand sander or a block plane for this purpose. Begin with coarse grit sandpaper, then move to finer grits for a smooth finish. It may take longer, but you can achieve satisfactory results with patience and practice.

Is Rounding Edges Necessary For Plywood Projects?

Rounding edges is not strictly necessary, but it is beneficial. It reduces the risk of splintering and provides a more polished look. Rounded edges also make handling safer, especially in furniture projects. Overall, it enhances both functionality and visual appeal in your woodworking.

Conclusion

Rounding edges on plywood enhances both safety and aesthetics. By using simple tools and techniques, anyone can achieve professional results. Remember to take your time and practice on scrap pieces. With these tips, your projects will not only look better but also feel more polished.

Enjoy your woodworking journey!