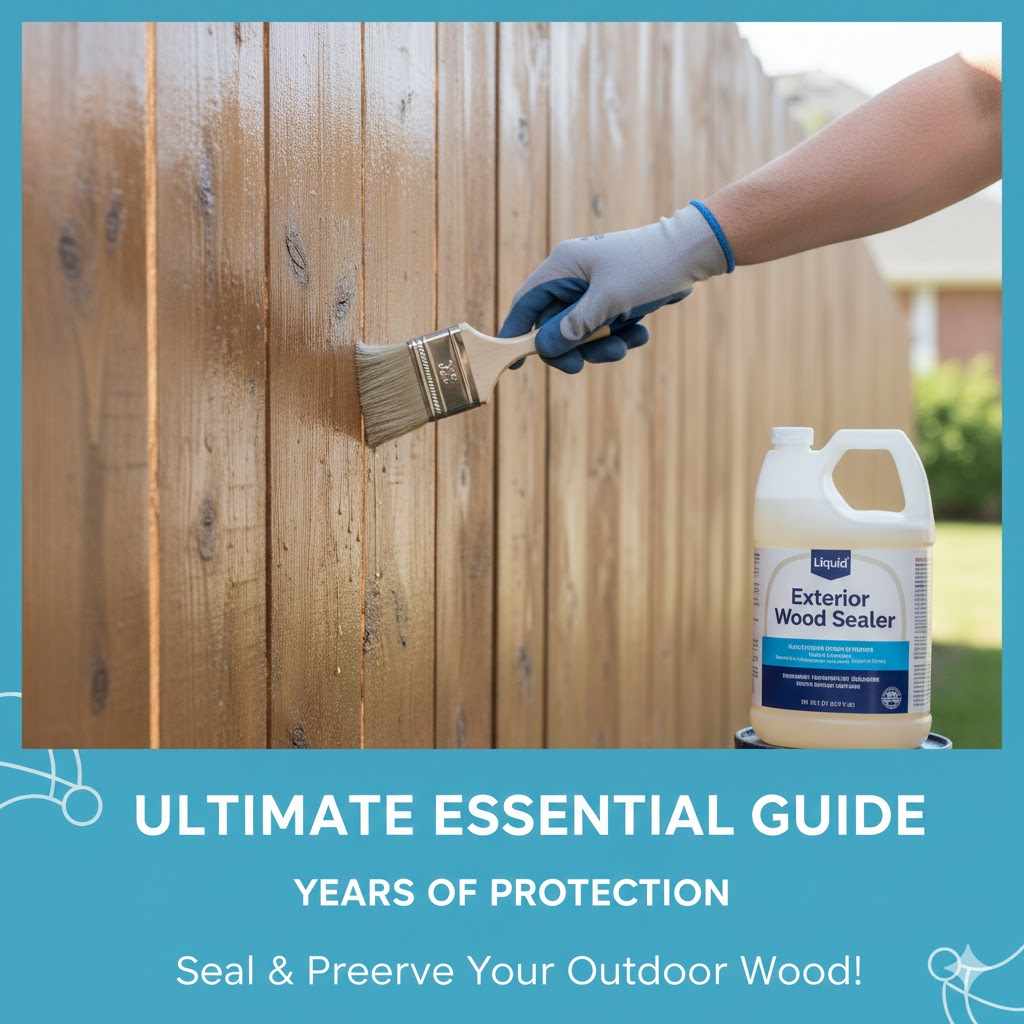

How to Seal Exterior Wood: The Ultimate Essential Guide

To seal exterior wood, first clean and sand the surface until it is smooth, dry, and free of debris. Choose a high-quality outdoor sealer suited for your climate. Apply a thin, even coat with a brush or roller, moving with the wood grain. Allow it to dry completely, apply a second coat if recommended, and let it fully cure before exposing it to weather.

Hello there, fellow maker! It’s Md Meraj, your friend in the workshop. There’s nothing quite like the pride you feel after building a beautiful new deck, a sturdy fence, or a charming garden bench. You step back, admire your handiwork, and then a little cloud of worry rolls in… literally. How will that gorgeous wood hold up against sun, rain, and snow?

It’s a common fear, but I’m here to tell you that protecting your project is easier than you think. Don’t let worries about weathering steal your joy. Together, we’ll walk through the simple, rewarding process of sealing your exterior wood. I’ll show you exactly how to give your project a tough, beautiful finish that lasts for years. Let’s get started!

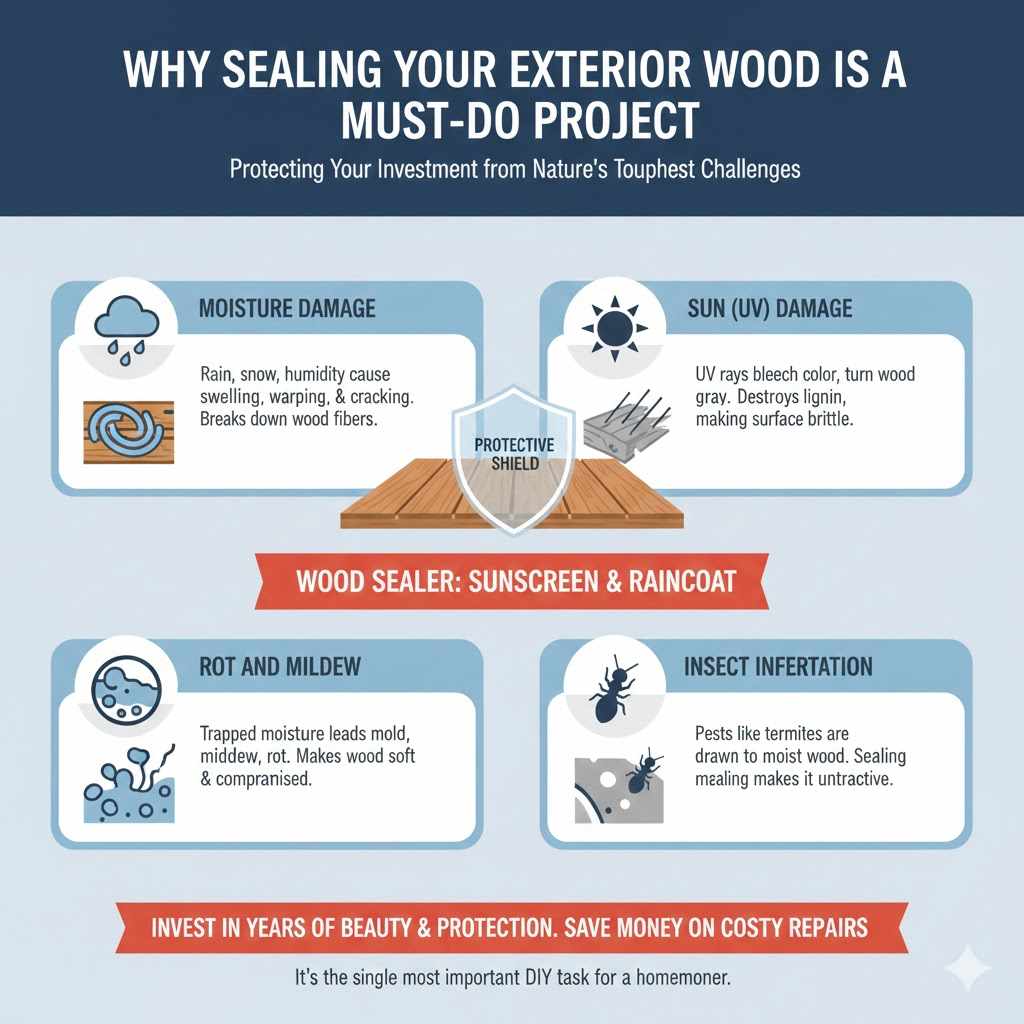

Why Sealing Your Exterior Wood is a Must-Do Project

Leaving exterior wood unfinished is like sending it into a storm without a jacket. Wood is a natural, porous material, and it’s vulnerable to the elements. When you take the time to seal it properly, you’re not just making it look good; you’re giving it a crucial shield against nature’s toughest challenges. Think of wood sealer as sunscreen and a raincoat, all in one can.

Here’s what you’re fighting against:

- Moisture Damage: Rain, snow, and even high humidity can soak into unprotected wood. This causes the wood to swell, warp, and crack as it dries out again. Over time, this constant cycle breaks down the wood fibers, weakening the entire structure.

- Sun (UV) Damage: The sun’s ultraviolet rays are brutal on wood. They bleach out the natural color, turning it into a dull, weathered gray. More importantly, UV rays destroy lignin, the natural glue that holds wood fibers together, making the surface brittle and prone to splintering.

- Rot and Mildew: Trapped moisture creates the perfect breeding ground for mold, mildew, and fungi that cause rot. These organisms feed on the wood, leading to soft, spongy spots that can compromise the safety of a deck or fence. A good sealer makes the wood inedible to these tiny invaders.

- Insect Infestation: Pests like termites and carpenter ants are drawn to soft, moist wood. Sealing your wood makes it a much less attractive home and food source for these destructive insects.

By investing a little time in sealing, you extend the life of your project by years, save money on costly repairs or replacements, and keep your hard work looking beautiful season after season. It’s one of the most rewarding and impactful DIY tasks a homeowner can do.

Choosing Your Armor: Understanding Different Types of Wood Sealers

Walking into the finish aisle at a hardware store can be overwhelming. You’ll see cans labeled stain, sealer, varnish, and more. Let’s simplify it. For exterior wood, your main choice will be between products that soak into the wood and products that form a protective film on top.

Penetrating vs. Film-Forming Sealers

First, understand the two main ways sealers work:

- Penetrating Sealers: These products, often oil-based or modified water-based formulas, dive deep into the wood’s pores. They protect from within, creating a water-repellent barrier that doesn’t form a thick layer on the surface. This allows the wood to have a more natural look and feel. They are less likely to peel or flake but may require more frequent reapplication.

- Film-Forming Sealers: Products like varnish, polyurethane, and solid-color stains create a durable, protective shell on the surface of the wood. This film provides excellent protection against moisture and physical wear. However, if the film is breached (scratched or cracked), moisture can get trapped underneath, leading to peeling and failure.

Oil-Based vs. Water-Based Sealers

The next big decision is the sealer’s formula. Both oil-based and water-based options have their strengths, and the right choice often depends on your project and preferences.

Here’s a simple table to help you decide:

| Feature | Oil-Based Sealers | Water-Based Sealers |

|---|---|---|

| Penetration | Excellent. Soaks deep into wood fibers for great water repellency. | Good. Forms more of a protective film on the surface. |

| Durability | Very durable against elements but can become brittle and crack over time. | More flexible and less prone to cracking. Excellent UV resistance. |

| Appearance | Enriches the wood grain, often adding a warm, amber tone. | Goes on milky but dries clear. Won’t significantly change wood color. |

| Drying Time | Slow. Often takes 24-48 hours to dry. | Fast. Can be dry to the touch in just a few hours. |

| Odor & VOCs | Strong odor and higher in Volatile Organic Compounds (VOCs). | Low odor and lower in VOCs, making them more environmentally friendly. |

| Cleanup | Requires mineral spirits or paint thinner. | Easy cleanup with simple soap and water. |

What About Stain and Sealer Combos?

Many exterior products are a “stain and sealer” in one. These are fantastic for beginners and save a lot of time. They add color while providing protection. They come in several transparencies:

- Clear: Offers protection with no color, letting the natural wood beauty show through. Provides the least UV protection.

- Toner: Adds just a hint of color to enhance the wood grain.

- Semi-Transparent: Adds rich color but still allows the wood grain and texture to be visible. A popular choice for decks and fences.

- Solid Color: Looks more like paint. It completely covers the wood grain but offers the maximum UV protection and durability. Ideal for older, weathered wood you want to restore.

Gather Your Supplies: The DIYer’s Toolkit

Having everything ready before you start makes the whole process smooth and enjoyable. You don’t need a professional workshop, just a few key items. Here is your shopping list:

- Wood Sealer: Choose the right type for your project (e.g., a semi-transparent, water-based deck stain and sealer).

- Applicators:

- High-Quality Paint Brush: Use a natural bristle brush for oil-based sealers and a synthetic (nylon/polyester) brush for water-based ones.

- Paint Roller or Pad Applicator: Excellent for covering large, flat surfaces like a deck floor quickly.

- Paint Tray: To hold your sealer while you work.

- Preparation Tools:

- Wood Cleaner: A specialized deck or wood cleaner works best to remove dirt, grime, and old finishes.

- Stiff-Bristled Brush or Broom: For scrubbing the wood clean.

- Garden Hose or Power Washer: For rinsing. Be gentle if using a power washer!

- Sandpaper or Orbital Sander: Medium-grit (80-120) for smoothing rough spots and fine-grit (150-220) for a final pass.

- Bucket: For mixing cleaner and holding water.

- Safety & Protection Gear:

- Drop Cloths or Plastic Sheeting: To protect plants, siding, and concrete from spills.

- Painter’s Tape: To tape off areas you don’t want sealer on, like trim or house siding.

- Safety Goggles: To protect your eyes from splashes and dust.

- Gloves: Waterproof gloves to keep your hands clean and protected.

- Dust Mask: Essential for sanding to avoid inhaling wood dust.

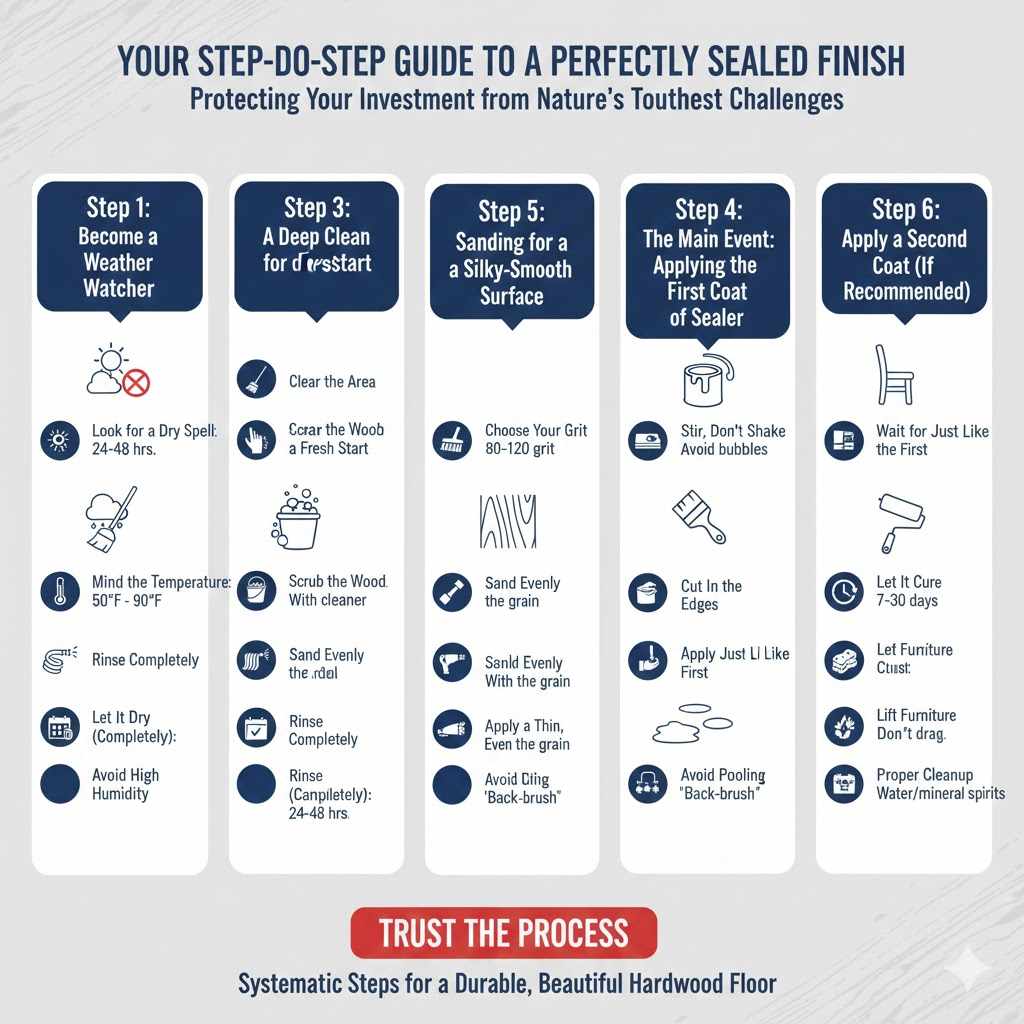

Your Step-by-Step Guide to a Perfectly Sealed Finish

Alright, you’ve chosen your sealer and gathered your tools. Now for the fun part! Follow these steps carefully, and you’ll achieve a professional-looking finish that protects your wood beautifully.

Step 1: Become a Weather Watcher

This is the most important first step, and it costs nothing! Your enemy is moisture and extreme temperatures. Sealer needs time to dry and cure properly.

- Look for a Dry Spell: Check the forecast. You need at least 24-48 hours of dry weather after application. Check the forecast on a reliable source like the National Weather Service.

- Mind the Temperature: Most sealers work best in temperatures between 50°F and 90°F (10°C to 32°C). Avoid sealing in the direct, blazing sun, as it can cause the sealer to dry too quickly and create a blotchy finish. Overcast, mild days are perfect.

- Avoid High Humidity: High humidity will significantly slow down drying times.

Step 2: A Deep Clean for a Fresh Start

You can’t apply a new coat over dirt and grime. Sealer needs to bond with clean wood fibers. A clean surface is the foundation of a lasting finish.

- Clear the Area: Remove all furniture, grills, planters, and decorations from the surface.

- Sweep Thoroughly: Sweep away all leaves, dirt, and loose debris.

- Scrub the Wood: Mix your wood cleaner according to the manufacturer’s instructions. Apply it to the wood and let it sit for a few minutes to loosen the grime. Then, scrub the surface with a stiff-bristled brush, moving with the grain of the wood.

- Rinse Completely: Use a garden hose with a spray nozzle to rinse all the cleaner and dirt away. Start at the highest point and work your way down. If you use a power washer, use a low-pressure setting and keep the nozzle moving to avoid gouging the wood.

- Let It Dry (Completely!): This is critical. Wood must be bone dry before you apply sealer. Wait at least 24-48 hours after cleaning before moving to the next step. Check a small area; if it looks dark, it’s still holding moisture.

Step 3: Sanding for a Silky-Smooth Surface

Sanding may seem like a chore, but it makes a huge difference. It removes any remaining fuzzy or splintered wood fibers raised during washing and opens up the wood’s pores to accept the sealer more evenly.

- Choose Your Grit: For most decks or fences, a medium-grit sandpaper (around 80-120 grit) is perfect for smoothing things out.

- Sand Evenly: Whether sanding by hand or with an orbital sander, always move with the grain of the wood. Your goal is a smooth, uniform surface, not a mirror finish.

- Remove the Dust: After sanding, the surface will be covered in fine dust. Use a leaf blower or a shop vacuum to remove most of it, then wipe the surface down with a clean, damp cloth. Let it dry one last time.

Step 4: The Main Event: Applying the First Coat of Sealer

The moment of truth! Your preparation is about to pay off.

- Read the Instructions: Every product is slightly different. Read the directions on the can for specific application tips and drying times.

- Stir, Don’t Shake: Gently but thoroughly stir your sealer with a paint stick. Shaking can create air bubbles that will leave bumps in your finish.

- Test in a Hidden Spot: Before you go all in, apply a small amount of sealer to an inconspicuous area (like behind a bush or on an inside board) to make sure you like the color and finish.

- Start with Edges and Details (“Cutting In”): Use your paintbrush to apply sealer to corners, railings, between boards, and any other tricky spots your roller can’t reach.

- Apply a Thin, Even Coat: Pour some sealer into your paint tray. Lightly load your roller or brush and apply the sealer in long, smooth strokes, following the wood grain. Work in small, manageable sections. Aim for a thin coat; thick coats don’t dry properly and can become sticky.

- Avoid Pooling: Watch for puddles of sealer forming in cracks or on knots. Use your brush to spread them out before they start to dry. This is called “back-brushing” and it ensures an even, beautiful coat.

Step 5: Apply a Second Coat (If Recommended)

Some woods and some sealers benefit from a second coat for added durability and a richer color. Check your product’s label.

- Wait for the Right Time: The can will tell you how long to wait between coats. Don’t rush this! Applying a second coat too soon can ruin the first one. It could be anywhere from 4 to 24 hours.

- Apply Just Like the First: Apply the second coat using the same technique: thin, even strokes, following the grain.

Step 6: The Final Stretch: Curing and Cleanup

You’re almost done! A little patience now ensures your hard work lasts.

- Let It Cure: “Dry time” is different from “cure time.” A sealer might be dry to the touch in a few hours, but it needs several days to fully harden and cure. Avoid heavy foot traffic or placing furniture on the surface for at least 48-72 hours, or as long as the can recommends.

- Proper Cleanup:

- For water-based sealers, clean your brushes and tools with warm, soapy water.

- For oil-based sealers, you’ll need mineral spirits or paint thinner.

- Important Safety Note: Rags soaked with oil-based products can spontaneously combust. Do not bunch them up. Lay them flat on a non-flammable surface to dry completely before disposal. For guidance on safe disposal, consult the EPA’s guidelines for household hazardous waste.

Frequently Asked Questions (FAQ)

1. How often should I seal my exterior wood?

This depends on your climate and the product used. A good rule of thumb is to inspect your wood annually. A simple test is to sprinkle some water on the surface. If it beads up, the sealer is still working. If it soaks in, it’s time to reapply. Generally, plan to re-seal every 1-3 years for horizontal surfaces like decks and every 3-5 years for vertical surfaces like fences.

2. Can I apply sealer over an old stain or paint?

It’s not recommended. For the sealer to penetrate and bond properly, it needs to reach the bare wood fibers. Applying it over a peeling, failing finish will just make the new coat fail too. You should always strip, clean, and sand off old finishes before applying a new coat of sealer.

3. What’s the difference between a wood sealer and a wood stain?

Traditionally, a “sealer” was a clear protective coat, while a “stain” was purely for color. However, modern products have blurred these lines. Most exterior “stains” today are combination products that both stain (color) and seal (protect) the wood in one step. A “clear sealer” provides protection with no color.

4. How long does wood sealer take to dry and fully cure?

Drying and curing times vary by product (oil vs. water-based) and weather conditions. It might be dry to the touch in 4-8 hours. However, it needs much longer to fully cure and achieve maximum hardness and durability. Wait at least 24-48 hours before walking on a deck and 72 hours or more before placing heavy furniture on it.

5. What happens if I don’t seal my exterior wood?

Unsealed wood will absorb moisture, leading to warping, cracking, and splitting. It will turn a silvery-gray due to sun damage, and it will be highly susceptible to rot, mildew, and insect damage. Neglecting to seal will drastically shorten the lifespan of your project and lead to expensive repairs.

6. Is it better to use a brush, roller, or sprayer to apply sealer?

Each has its place. A brush is best for details, edges, and cutting in. A roller or pad applicator is fastest for large, flat surfaces like deck floors. A sprayer is very fast for large, intricate projects like a lattice fence but requires careful masking to prevent overspray and often needs to be followed by a brush (back-brushing) to ensure an even coat.

7. Do I need to seal pressure-treated wood?

Yes, absolutely! Pressure-treating protects the wood from rot and insects, but it does not protect it from moisture and sun damage. You should allow new pressure-treated wood to dry out for a few months (do the water sprinkle test) and then seal it just like any other exterior wood to prevent it from cracking and graying.

Taking Pride in a Job Well Done

And there you have it! Sealing your exterior wood isn’t a complex, mysterious task—it’s a straightforward process of careful preparation and thoughtful application. By following these steps, you’ve done more than just add a coat of sealer. You’ve given your project a durable shield, ensuring that the time, effort, and care you put into building it will be preserved for many years to come.

Now, step back and admire that beautiful finish. Every time you enjoy your deck or look out at your fence, you can feel a deep sense of accomplishment, knowing you did the job right. You’ve protected your investment and added lasting beauty to your home. That’s what a good day’s work is all about. You’ve got this!