How to Tell Grain Direction in Wood: Expert Tips

To determine grain direction in wood, observe the growth rings and the natural lines on the surface. The grain runs parallel to the growth rings and is typically more pronounced on one side.

Understanding grain direction is essential for woodworking, as it influences both aesthetics and functionality. Grain direction affects how wood reacts to tools, finishes, and environmental changes. Properly aligning cuts with the grain can enhance the strength and appearance of your projects.

Recognizing grain patterns can also help in selecting the right wood for specific applications. Whether you’re crafting furniture or simple decor, knowing how to tell grain direction will improve your results and ensure a polished finish. Mastering this skill will elevate your woodworking techniques significantly.

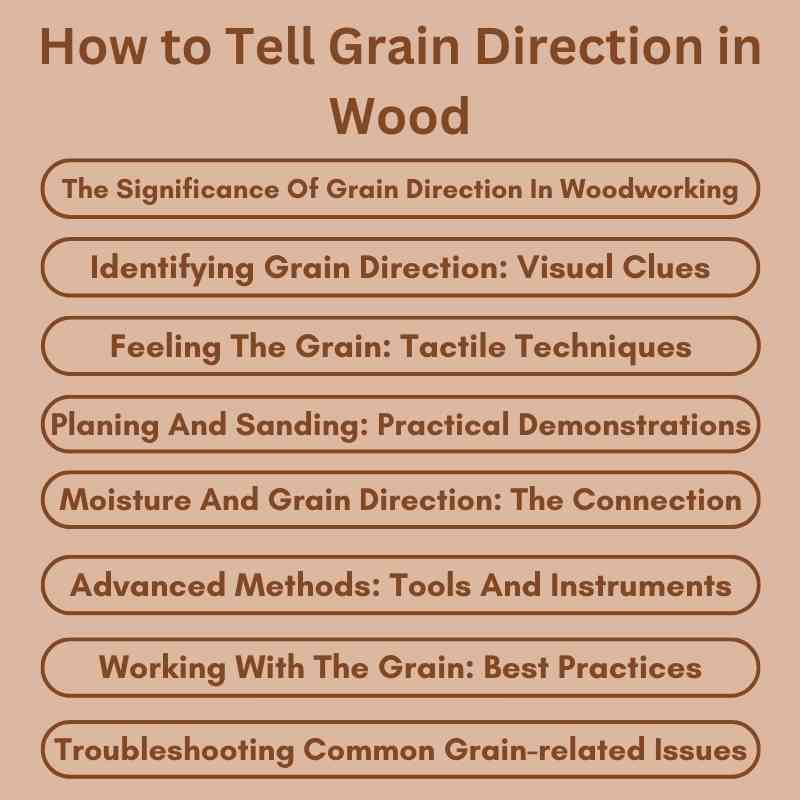

The Significance Of Grain Direction In Woodworking

Understanding grain direction is essential for woodworking. It affects both aesthetics and design. Wood grain can create different visual effects. A vertical grain offers a clean look. Horizontal grain adds a rustic feel.

Grain direction also influences the structural integrity of the wood. Wood is stronger along the grain. This helps in making sturdy furniture and structures. Cutting against the grain can lead to cracks and breaks. Knowing the grain direction ensures better performance and durability.

Identifying Grain Direction: Visual Clues

Identifying grain direction in wood is easy with careful observation. Start by examining the wood surface closely. Look for lines or patterns that indicate the grain’s flow. These lines often run in the same direction as the grain.

Next, focus on the growth rings. These rings can show how the tree grew. They often appear as curved lines. The distance between these rings can also give clues about grain direction.

Look for any color changes or texture variations. These can highlight the grain’s orientation. Remember, grain direction is important for woodworking and finishing tasks.

Feeling The Grain: Tactile Techniques

To find the grain direction in wood, use your fingertips. Run your fingers along the surface. Feel for smoothness and roughness. The grain usually feels smoother in the direction it runs.

Another method is the scratch test. Lightly scratch the wood with your fingernail. If it scratches easily, you are going against the grain. If it feels tough, you are going with the grain.

Practice these techniques on different types of wood. Each type has a unique texture and grain pattern. With time, you will get better at identifying grain direction.

Planing And Sanding: Practical Demonstrations

To determine grain direction, observe the shavings and sawdust produced during planing. Shavings that curl indicate the grain runs in a certain direction. If the shavings are long and continuous, the grain runs along the length of the board.

Resistance variations also help identify grain direction. Planing against the grain creates more friction. The tool feels harder to push, showing the grain is opposite to the cutting motion. Conversely, planing with the grain feels smoother and easier.

| Observation | Grain Direction |

|---|---|

| Curled Shavings | Grain runs along the board |

| Long Continuous Shavings | Grain runs with the length |

| High Resistance | Grain runs opposite to the cut |

| Smooth Cutting | Grain runs with the cut |

Moisture And Grain Direction: The Connection

Humidity affects wood fibers significantly. High humidity can make fibers swell, while low humidity can cause them to shrink. This change in size alters the grain direction. Understanding this helps in choosing the right wood for projects.

Warping occurs when wood fibers react to moisture changes. It leads to twisting or bending. Different grains respond uniquely to humidity. The direction of the grain can affect how much warping happens. Always consider the grain when selecting wood for stability.

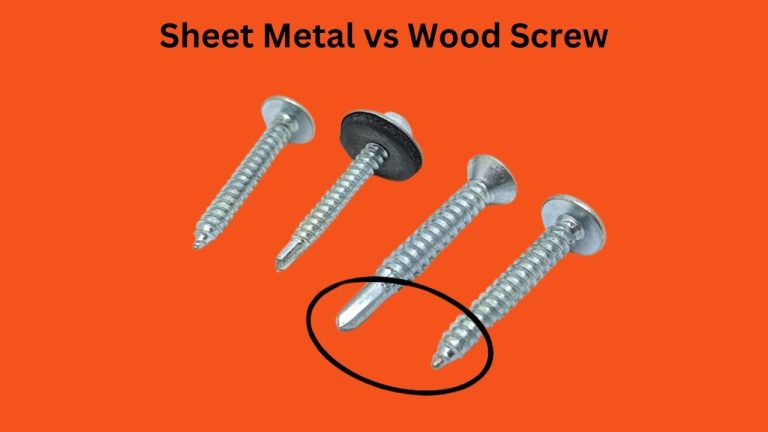

Advanced Methods: Tools And Instruments

Many tools help identify grain direction in wood. Grain direction indicators show how the wood fibers align. A moisture meter can also assist in detecting grain. This tool measures moisture levels in different areas.

Using a laser level provides clarity on wood grain. It highlights the direction of the fibers. Digital grain direction tools offer precise measurements for professionals. They ensure accuracy in every project.

Handheld magnifying glasses reveal fine details in the wood. A simple light source can enhance visibility. Observing how the light reflects helps in understanding grain direction.

Working With The Grain: Best Practices

To achieve clean edges in wood, cut along the grain. Use a sharp blade for best results. A dull blade can tear the fibers. Always make smooth, even cuts.

For gluing, apply adhesive along the grain direction. This helps the glue bond better. Clamp the pieces together for a strong hold. Allow sufficient drying time for the best results.

When finishing, sand with the grain. This avoids scratches and uneven surfaces. Start with coarse sandpaper and move to finer grits. Finish with a protective coat to enhance appearance.

Tearouts can be a common problem in woodworking. They occur when the wood fibers break away during cutting. To prevent this, always use a sharp tool. A sharp chisel or plane helps minimize damage.

Apply masking tape along the cut line. This tape holds fibers together and reduces tearouts. Make shallow cuts to avoid stress on the wood. Cross-cutting with the grain also helps.

For correcting planing mistakes, check the tool’s angle. An incorrect angle can cause unwanted marks. Adjust the blade depth for a smoother finish. Regularly clean the blades to keep them effective.

Practice on scrap wood before starting on your project. This way, you can identify and fix issues early.

Learning From The Masters: Case Studies

Many expert craftsman use simple methods to find grain direction. One popular technique involves examining the wood’s surface. Look for the natural lines that run along the wood. These lines indicate the grain direction.

Another method is to feel the texture of the wood. The grain feels different based on its direction. Running your fingers along the surface helps identify the flow of the grain.

Some craftsmen also use water or oil to enhance visibility. Applying a small amount can make the grain pop out. This technique helps in making more precise cuts.

Historical techniques often involve simple tools like a hand lens. Using a magnifying glass allows for a closer look at the grain. This method reveals patterns that are not visible to the naked eye.

Preserving The Grain: Maintenance And Longevity

Protecting wood from damage is very important for its longevity. Protective treatments can help maintain the wood’s beauty. Coatings like varnish or oil create a barrier against moisture.

Seasonal care is essential for wood. During winter, wood can dry out. Summer heat can cause it to swell. Regular checks for cracks or warping are necessary.

| Season | Care Tips |

|---|---|

| Winter | Apply a protective coat. |

| Spring | Inspect for moisture damage. |

| Summer | Keep wood shaded and cool. |

| Fall | Clean leaves and debris. |

Frequently Asked Questions

How Can I Identify Wood Grain Direction?

To identify wood grain direction, look for the pattern of lines and growth rings. The grain usually runs in the same direction as the tree’s growth. Checking the ends of the wood can also reveal grain patterns, helping you determine the correct orientation for cutting or finishing.

What Tools Help Determine Wood Grain Direction?

Several tools can assist in determining wood grain direction. A moisture meter can help, as it often reads differently across grain patterns. Additionally, a straight edge or a marking gauge can highlight inconsistencies in grain, making it easier to identify the direction clearly.

Why Is Knowing Grain Direction Important?

Knowing grain direction is crucial for woodworking projects. It affects how wood bends, splits, and finishes. Cutting against the grain can lead to splintering and poor finishes. Understanding grain direction ensures stronger joints and enhances the overall aesthetics of the finished product.

Can I See Grain Direction On Finished Wood?

Yes, you can see grain direction on finished wood. The finish often accentuates the natural lines and patterns of the wood. Light can also reveal subtle variations in grain direction. Observing these details helps in aligning pieces correctly for better visual appeal and structural integrity.

Conclusion

Understanding grain direction in wood is essential for any woodworking project. It influences the strength, appearance, and finish of your work. By using simple techniques, you can easily identify the grain direction. Mastering this skill will enhance your craftsmanship and lead to better results in your woodworking endeavors.

Happy crafting!