Is Teak A Hardwood? Essential Facts Revealed

Yes, teak is absolutely classified as a hardwood. It ranks high on the Janka hardness scale, meaning it is dense, incredibly durable, weather-resistant, and prized for everything from luxury furniture to boat decking. Understanding its properties makes choosing materials much easier.

Have you ever looked at a piece of gorgeous, honey-toned wood and wondered if it was strong enough for your next outdoor project? Figuring out if a wood like teak is truly a hardwood can feel like homework. You hear terms like “density” and “botany,” and it gets confusing fast! As a woodworker, I understand. You just want reliable material that lasts.

Don’t worry—we are going to clear up this confusion right now. We’ll look at exactly what makes teak special and why it earns that “hardwood” title. Get ready to build with confidence! Next, we dive into the science behind teak’s toughness and explore where it shines best.

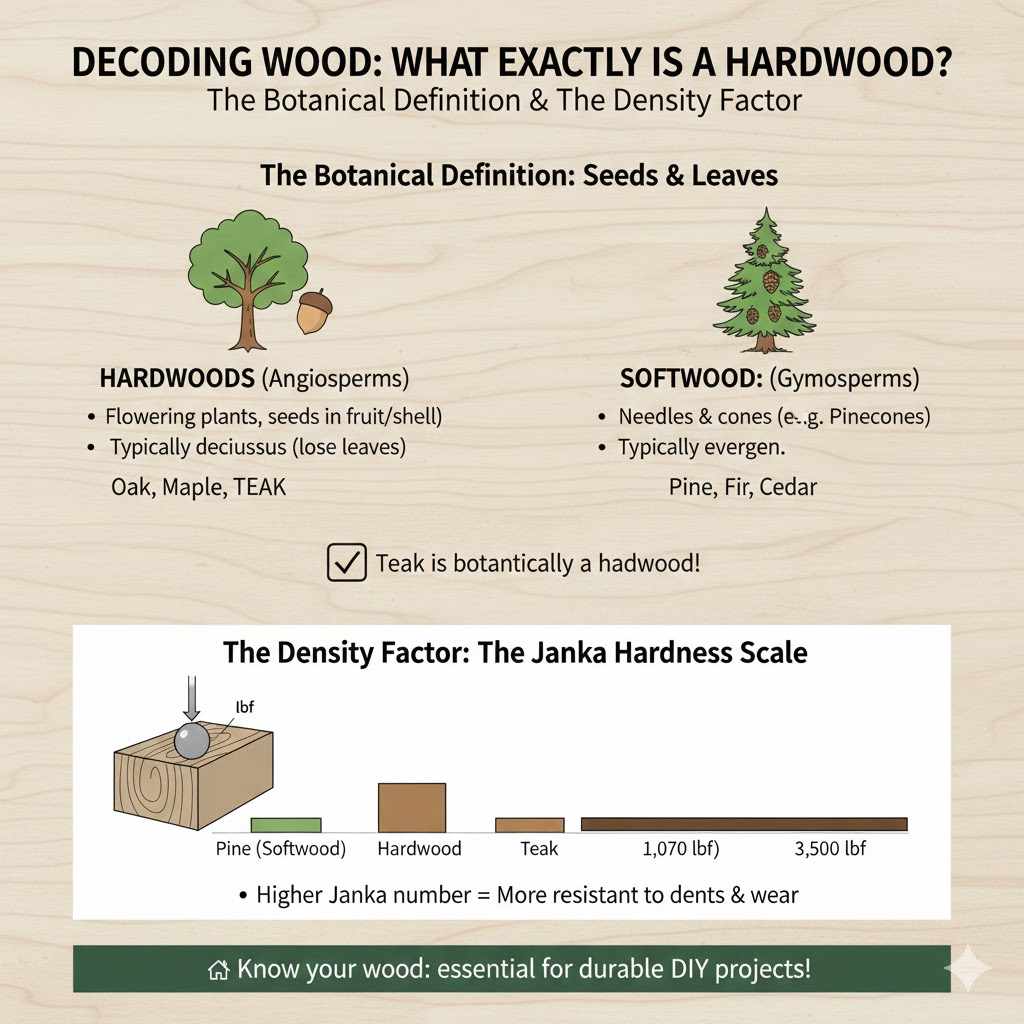

Decoding Wood: What Exactly is a Hardwood?

The confusion around wood types often starts because we think “hard” means “difficult to dent.” While density plays a role, the real difference between hardwoods and softwoods is biological—it all depends on how the tree grows! This is crucial information for any DIYer planning an outdoor bench or restoring some vintage furniture.

The Botanical Definition: Seeds and Leaves

Forget the Janka scale for a moment; the first rule is purely botanical.

Hardwoods come from Angiosperm trees. These trees are usually flowering plants that produce seeds inside a fruit or shell (think acorns or cherries). They are typically deciduous, meaning they lose their leaves in the fall. Examples include Oak, Maple, and, yes, Teak.

Softwoods come from Gymnosperm trees. These trees often have needles and produce seeds in cones (like pines or firs). They are usually evergreen.

Because teak fits the Angiosperm, flowering tree category, botanically speaking, it is a hardwood. This classification helps explain its superior strength.

The Density Factor: The Janka Hardness Scale

While the botanical definition confirms teak is a hardwood, its practical strength comes from its density. This is where the Janka Hardness Test comes in handy. This test measures the force required to embed a steel ball halfway into a piece of wood. The higher the number, the harder the wood.

Understanding this scale helps you predict how well a material will resist scratches, dents, and wear—perfect for high-traffic items.

Teak (Tectona grandis): The Undisputed Champion

Teak isn’t just a hardwood; it’s often considered the gold standard among hardwoods, especially for outdoor use. It possesses a unique combination of strength, density, and natural oils that make it exceptionally valuable.

Why Teak Earns Its High Rating

When you compare teak to common household hardwoods, you see its superiority clearly.

| Wood Type | Janka Hardness (Pounds-force) | Common Use |

|---|---|---|

| Red Oak (Reference Hardwood) | 1,290 lbf | Flooring, cabinetry |

| Maple | 1,450 lbf | Kitchen surfaces, cutting boards |

| Teak | 1,070 lbf | Outdoor furniture, boat decks |

| Southern Yellow Pine (Reference Softwood) | 690 lbf | Framing, budget decking |

Wait a second, Md Meraj! Why is teak’s Janka rating lower than Oak or Maple? That’s a great question and a common point of confusion!

The Nuance: Density vs. Oil Content

While Oak is structurally “harder” (more resistant to crushing forces), Teak’s real advantage lies in its natural chemical composition, particularly its high oil content.

1. Natural Oils: Teak is loaded with natural oils and silica. These oils act as a built-in sealant, repelling water, resisting rot, deterring insects, and preventing cracking.

2. Stability: This high oil content makes teak incredibly stable. It resists expansion and contraction much better than hardwoods lacking these oils, meaning it won’t warp easily, even with drastic temperature swings or high moisture.

So, even if a pure density test might place it slightly below some other woods, the combined resistance to external elements makes teak outperform them dramatically outdoors. This stability is a woodworking superpower!

Working With Teak: A Beginner’s Guide

Knowing that teak is a top-tier hardwood is one thing; actually buying and using it for a project is another. As a beginner, you need practical tips on handling this unique material safely and effectively.

Sourcing and Sustainability

Teak is expensive, and responsible sourcing is crucial. When buying teak, look for labels or assurances that the wood comes from sustainable, managed forests. Reputable suppliers will provide documentation. If a deal seems too good to be true for genuine teak, it might be lower-grade wood or, worse, illegally harvested. Check with resources like the Forest Stewardship Council (FSC) for guidance on sustainable wood purchasing.

Tools You Will Need for Teak Projects

Since teak is dense and oily, it requires sharp tools. Dull blades cause burning and tear-out, frustrating any new woodworker.

Cutting: A high-quality carbide-tipped blade for your table saw or circular saw is essential. Carbide stays sharp longer against hard woods.

Drilling: Use high-speed steel (HSS) or cobalt drill bits. Always drill a pilot hole before driving screws, as teak can split near edges.

Sanding: Start with a medium grit (around 100 or 120) and work your way up to 220. Since the natural oils repel moisture, sometimes a little sanding can feel slower than usual.

Fasteners: Only use stainless steel or high-quality brass screws. Regular steel screws will corrode due to the wood’s high natural oil and moisture content, staining the beautiful wood surface.

Step-by-Step: Cutting and Assembling Teak

When working with any hardwood, taking your time is key. Teak requires patience, but it rewards you tenfold in longevity.

- Measure Twice, Cut Once: Mark your cut lines clearly with a sharp pencil. Because of the cost, avoid waste!

- Secure the Material: Ensure the teak plank is clamped firmly to your workbench or saw guide. Vibration leads to inaccuracy.

- Cutting Slow and Steady: Feed the wood through the saw slowly. Do not rush the cut. Allow the blade to do the work. Pushing too hard can cause burning or bind the blade.

- Drill Pilot Holes: Measure where your screw needs to go. Use a drill bit slightly narrower than the screw shank. Drill just as deep as the screw needs to go.

- Countersink (Optional but Recommended): If you want the screw heads to sit flush or slightly below the surface (to hide them later), use a countersink bit. This prevents ugly dents when hammering the plug.

- Assembly: Apply a small bead of waterproof wood glue (like Titebond III) to the joint faces before screwing them together. Wipe away any excess glue immediately with a damp rag—oils can prevent glue adhesion if left on the surface.

Teak’s Best Features: Why It’s Worth the Investment

When beginners weigh the cost of teak against pine or cedar, they often hesitate. Here’s why stepping up to teak is an investment that saves you money and frustration in the long run, especially for outdoor applications.

Unmatched Durability and Weather Resistance

The core appeal of teak comes down to its performance in the elements.

Water Repellency: Teak is so water-resistant that it has been the preferred wood for shipbuilding and high-end marine decking for centuries. It resists swelling and rotting even when constantly saturated.

Pest Resistance: The natural silica and oils act as an internal defense system against wood-boring insects and termites. You usually don’t need harsh chemical treatments common for other exterior woods.

Temperature Tolerance: Teak holds up remarkably well through heat, sun, and cold without splintering or warping significantly.

The Aging Process: Silver Patina

One unique characteristic beginners need to know is how teak changes color when left unfinished outdoors.

Initial Color: Freshly cut or oiled teak shows a rich, golden-brown hue.

The Patina: If left exposed to sun and rain, the golden oils leach out slightly, and the surface oxidizes to a soft, silvery-gray color. This is completely normal and desirable for many people. It doesn’t reduce the structural integrity at all.

If you want to maintain that honey color, you must apply a teak sealer or oil regularly (once or twice a year). If you like the silver look, maintenance is minimal!

Comparing Teak to Other Popular Woods

To truly appreciate where teak sits, let’s compare it to two other common wood choices for exterior DIY projects: Cedar and Pressure-Treated Pine.

| Feature | Teak (Hardwood) | Cedar (Softwood) | Pressure-Treated Pine (Softwood) |

|---|---|---|---|

| Janka Hardness (Approx.) | 1,070 lbf | 350–900 lbf (varies) | 690 lbf (varies) |

| Natural Rot Resistance | Excellent (due to oils) | Good (natural preservatives) | Excellent (due to chemical treatment) |

| Finishing Needs (Outdoors) | None (to achieve patina) or light oiling | Requires sealing to prevent weathering | Must wait for wood to dry before painting/staining |

| Cost (Relative) | Highest | Medium | Lowest |

For longevity and pure elegance, teak wins. For budget builds where aesthetics are secondary, the treated pine offers good value. Cedar strikes a nice middle ground for things like pergolas or fencing where some density isn’t critical.

Tips for Finishing and Sealing Teak

One great benefit of working with teak is that you often don’t have to finish it, which is fantastic for beginners who might dread staining projects! However, if you love that rich color, a few pointers can make the process smoother.

Step 1: Preparation is Key (If Maintaining Color)

If your teak has turned silver or if you are working with new, oily teak, you need to prep the surface so any finish will stick properly.

1. Cleaning: Wash the surface with mild soap and water. For older, gray wood, use a commercial teak cleaner or a simple solution of 1 part white vinegar to 3 parts water. Scrub gently with a soft-bristle brush (not wire).

2. Brightening/Degreasing: Teak oils can prevent sealer penetration. You must “degrease” the surface. Many wood suppliers sell dedicated teak brighteners or degreasers. Alternatively, you can use mineral spirits sparingly, wiping thoroughly afterwards.

3. Drying: Let the wood dry completely—usually 24 to 48 hours depending on humidity. The surface must be bone dry.

Step 2: Applying Sealant or Oil

When buying sealers, look specifically for products designed for teak or exterior tropical hardwoods. Standard deck stains rarely bond well due to the oils.

Using Teak Oil: Teak oil isn’t pure oil; it’s usually a penetrating finish blended with resins and UV blockers. Apply sparingly with a clean rag. Work the oil into the grain. Let it sit for 15-20 minutes, then wipe off ALL excess. If you leave excess oil on the surface, it will become tacky and attract dirt.

* UV Protection Sealers: These products are best for maintaining that golden color. They often contain amber pigments and UV inhibitors. Apply according to the manufacturer’s directions, usually two thin coats are better than one thick coat.

Remember: finishing teak is often about upkeep rather than necessity. If you skip a year of oiling, the wood will simply turn gray—it will not rot! This forgiving nature is why I recommend it for new hobbyists.

Addressing Safety When Working With Teak

As your woodworking mentor, my first priority is always your safety. Even though teak is a hardwood, it presents a few unique challenges you should be prepared for in your workshop.

Inhalation and Skin Protection

1. Dust Control: Teak dust is notorious for causing respiratory irritation. Always wear a high-quality dust mask or, better yet, a respirator rated for fine particles. Connect your power tools (saws, sanders) to a dust collection system if possible.

2. Oil Contact: While the oils are natural, prolonged contact can cause skin irritation or allergic reactions in some sensitive individuals. Wear gloves (nitrile or heavy work gloves) during sanding and oil application.

Tool Maintenance Tip

The natural oils that make teak weather-resistant can gum up saw blades and sandpaper quickly. Plan to clean your blades with a commercial blade cleaner or mineral spirits after working on teak for an extended period. Clean sandpaper frequently by tapping it or using a sanding belt cleaner block. Sharp tools equal safer projects!

Frequently Asked Questions (FAQ) for Beginner Woodworkers

Q1: If I don’t oil my teak furniture, will it break down quickly?

A: No. Teak does not rely on its finish for structural integrity. The finish (oil or sealer) is only there to maintain the warm golden color against UV exposure. It will turn a beautiful silver-gray, but it will remain strong for decades.

Q2: Can I use standard exterior screws when building with teak?

A: Absolutely not. Standard zinc-coated or steel screws will react with the high silica and oil content in teak, causing black staining around the screw head very quickly. Always use 304-grade stainless steel or bronze fasteners for guaranteed results.

Q3: Is Teak heavy to work with compared to something like Oak?

A: Teak is dense, but generally, it is slightly lighter in actual weight than many high-density hardwoods like White Oak or Hickory. Its primary weight difference comes from its oiliness, which contributes to its dense “feel,” but it’s still easily manageable for a DIYer building simple frames.

Q4: Why does my new teak project look a little fuzzy after cutting?

A: That’s the “fuzzing” common to oily woods. The oils repel the smooth cut, leaving tiny fibers sticking up. Sanding lightly with 180 or 220 grit paper will smooth this out. Make sure your saw blade is extremely sharp!

Q5: Where does genuine teak wood primarily come from?

A: Traditionally, the highest quality teak (known for the best color and durability) comes from Myanmar (Burma) and India. However, large plantations in countries like Indonesia, Thailand, and Central American nations now supply much of the global market today, emphasizing sustainable harvesting.

Q6: Is reclaimed teak a good choice for a beginner project?

A: Yes, reclaimed teak is excellent! It is often older, already stable, and has already achieved that gorgeous silvery patina. It requires less prep work since the original finish is long gone, making it very beginner-friendly for items like garden edging or simple planter boxes.

Conclusion: Building with Confidence Using This Premium Hardwood

So, let’s bring it all home. Is teak a hardwood? Without a doubt, yes. Botanically, it is, and its superior performance in outdoor conditions certainly confirms its high status in the woodworking world. You are not just buying wood; you are investing in longevity, stability, and natural protection against rot and bugs.

As a beginner, selecting teak might feel like a leap due to the initial cost, but remember the hidden savings: you save time and money by not having to constantly seal, paint, or replace weather-damaged wood every few years.

Armed with the knowledge about pilot holes, stainless steel fasteners, and the beautiful patina it naturally develops, you are fully equipped to start that dream Adirondack chair or repair that weathered patio table. Don’t be intimidated by premium materials; approach teak with sharp tools and patience, and you will craft something truly heirloom-worthy. Happy building!