Marine Grade Plywood vs Pressure Treated: Comparison

Picking the right wood for outdoor projects can be confusing. Many people wonder about the differences between Marine Grade Plywood and Pressure Treated wood. This guide makes the Marine Grade Plywood vs Pressure Treated: Comparison simple.

We will walk through each option step-by-step so you can choose what’s best for your needs. Get ready to learn how to make smart choices for your next build.

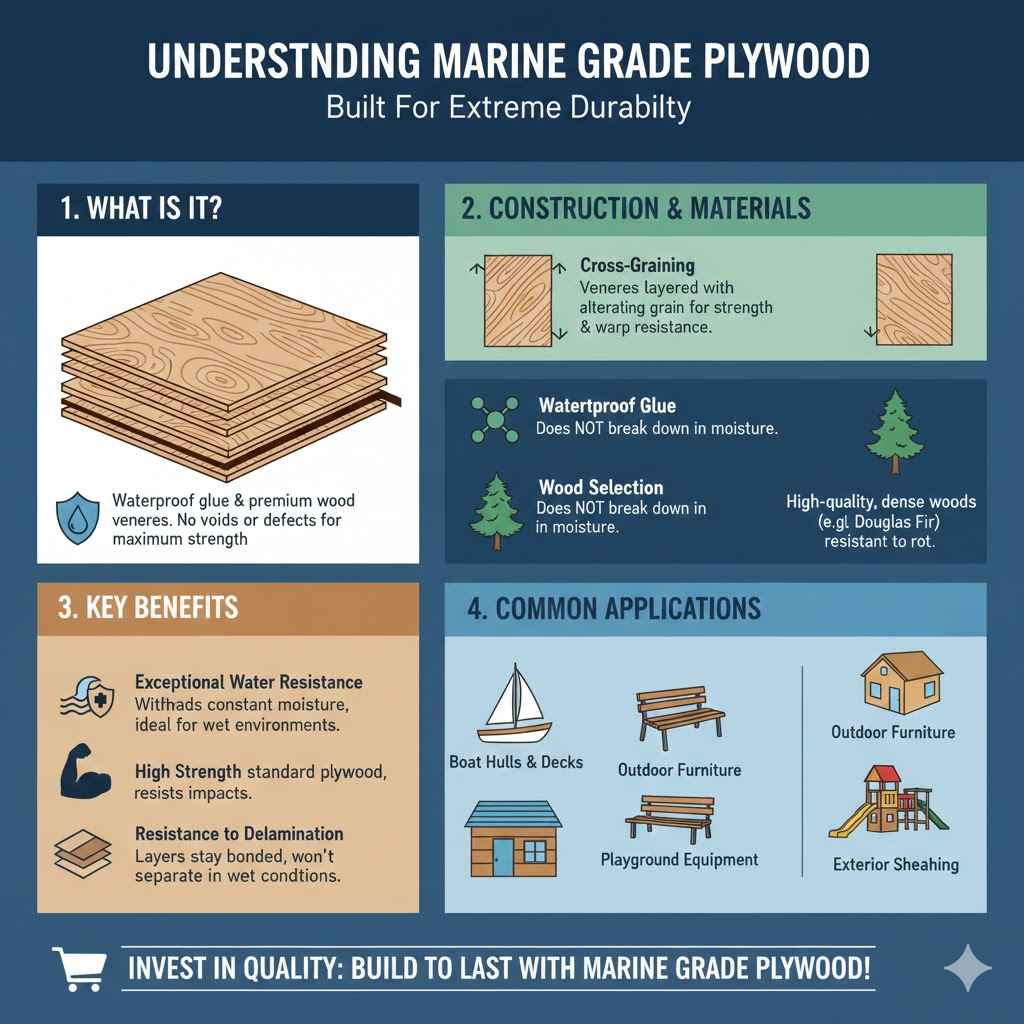

Understanding Marine Grade Plywood

Marine Grade Plywood is a top-tier wood product designed for serious durability, especially in wet environments. It’s not just any plywood; it’s built to last in tough conditions. This section explains what makes it special and why it’s a favorite for many boat builders and outdoor enthusiasts who need the best.

We will look at its construction, the glues it uses, and the types of wood that go into it.

What is Marine Grade Plywood

Marine Grade Plywood is made with waterproof glue and high-quality wood veneers. The glue used is typically a phenolic resin, which is incredibly strong and does not break down even when constantly exposed to water. This is a big difference from regular plywood, which uses glues that can dissolve in moisture.

The wood itself is usually made from Douglas Fir or other strong, stable wood species. Every layer, or veneer, is checked for defects like knots or core gaps. This means there are no weak spots where water can seep in and cause damage.

Think of it as a solid, tough panel with no hidden flaws.

Construction and Materials

The way marine grade plywood is put together is key to its strength. It has many thin layers of wood, called veneers. These veneers are glued together with their grain running in opposite directions.

This cross-graining makes the plywood very strong and helps prevent it from warping or splitting.

Manufacturers select the best wood for each veneer. They avoid large knots, splits, or voids. A void is a gap or empty space within the plywood.

In marine grade plywood, these voids are not allowed. This ensures a solid panel throughout. The waterproof glue is spread between each layer.

This is what makes it resistant to delamination, which is when the layers start to separate.

Waterproof Glue

The glue is the hero here. It’s not just water-resistant; it’s fully waterproof. This means it can handle being submerged or exposed to rain and humidity for years without failing.

This type of glue is often used in boat building and other projects where constant moisture is a problem. It forms a bond that is stronger than the wood itself.

Wood Selection

The types of wood used for marine grade plywood matter a lot. Douglas Fir is common because it is strong, stable, and naturally somewhat resistant to decay. Other woods might be used depending on the region and the specific product.

The important thing is that the wood is dense and can withstand exposure to water and the elements without rotting quickly.

Key Benefits of Marine Grade Plywood

Exceptional Water Resistance: Its primary advantage is its ability to withstand constant moisture without degrading. This makes it ideal for boat hulls, decks, and other applications where water is a major factor.

This means you can use it in areas where other wood products would quickly rot or fall apart. Imagine building a small boat or an outdoor kitchen counter that needs to handle spills and weather. Marine grade plywood is built for that kind of abuse.

High Strength and Durability: The cross-graining and quality materials make it very strong. It can hold heavy loads and resist damage from impacts.

This strength is crucial for structural components. Whether it’s a floor in a shed or a bench by the pool, you need wood that won’t sag or break easily. Marine grade plywood offers that peace of mind.

Resistance to Delamination: Unlike regular plywood, the waterproof glue prevents the layers from separating over time, even in wet conditions.

This is a key difference. Cheap plywood can puff up or fall apart when it gets wet. Marine grade plywood stays solid, maintaining its integrity and appearance for much longer.

Common Applications

Marine grade plywood is widely used in boat construction. This includes building boat hulls, decks, bulkheads, and cabins. Its ability to handle constant moisture and salt water is unmatched.

Beyond boats, it’s excellent for outdoor furniture, playground equipment, and any project exposed to harsh weather. It can also be used for exterior wall sheathing and roofing in very wet climates.

Exploring Pressure Treated Lumber

Pressure treated lumber is another popular choice for outdoor projects. It is wood that has been chemically treated to resist rot, decay, and insect infestation. This process makes it suitable for use in ground contact and other exposed conditions.

We will look at how it is treated, what chemicals are used, and where it works best.

The Pressure Treating Process

Pressure treating involves placing lumber in a sealed cylinder. Then, a vacuum is pulled to remove air from the wood cells. After that, a preservative solution is pumped into the cylinder under high pressure.

This forces the chemicals deep into the wood.

Once the cylinder is full and pressurized, the excess solution is removed, and a final vacuum is applied. This helps pull the solution deeper into the wood and cleans the surface. The result is wood that is protected from the inside out.

This makes it last much longer than untreated wood.

Preservative Chemicals

Older pressure treated lumber often used Chromated Copper Arsenate (CCA). However, CCA is no longer used for residential lumber due to health concerns. Today, the most common treatments use alkaline copper quaternary (ACQ) or copper azole (CA).

These are much safer for people and the environment.

These copper-based chemicals work by killing fungi and insects that would otherwise eat away at the wood. They are fixed into the wood fibers, meaning they do not leach out easily. This provides long-term protection.

Benefits of Pressure Treated Lumber

Rot and Insect Resistance: The main advantage is its ability to withstand decay and insect damage. This extends its lifespan significantly compared to untreated wood.

This makes it a cost-effective choice for many outdoor projects. You won’t have to replace decks, fences, or garden beds as often.

Ground Contact Suitability: Many types of pressure treated lumber are rated for ground contact. This means they can be buried in the soil or used in direct contact with the ground.

This is essential for things like fence posts, deck pilings, and retaining walls. The wood won’t rot from being in contact with damp soil.

Cost-Effectiveness: Generally, pressure treated lumber is more affordable than marine grade plywood for many applications.

This makes it a practical option for larger projects where budget is a key concern. You can achieve a similar level of durability for less money.

Common Applications

Pressure treated lumber is used for decks, fences, pergolas, and garden beds. It’s also common for building outdoor stairs, retaining walls, and structural framing for outdoor structures like sheds.

Because it’s strong and readily available, it’s a go-to for many DIY and professional building projects that need to stand up to the weather. It is often sold with warranties against rot and insect attack.

Marine Grade Plywood vs Pressure Treated Comparison

When you compare Marine Grade Plywood and Pressure Treated lumber, you are looking at two very different ways to achieve durability in outdoor settings. The Marine Grade Plywood vs Pressure Treated: Comparison highlights key differences in their properties, uses, and costs. Understanding these distinctions is vital for choosing the right material for your specific project.

This section breaks down how they measure up against each other.

Water Resistance and Durability

Marine Grade Plywood excels in constant water exposure. Its waterproof glue prevents delamination, meaning the layers won’t separate. It’s built for situations where wood is submerged or frequently wet, like boat building.

Pressure Treated lumber is resistant to rot and insects, making it durable outdoors. However, it is not designed for continuous submersion. While it can handle rain and humidity, prolonged exposure to standing water might eventually degrade it.

The wood itself is protected from decay, but the glue in standard construction can be affected.

Strength and Stability

Marine Grade Plywood offers excellent strength due to its cross-grained construction. It is less prone to warping or expanding and contracting with moisture changes than many other wood products. This stability is critical for applications where precise dimensions are needed.

Pressure Treated lumber is strong for structural purposes. However, it can sometimes twist or warp as it dries. While it holds fasteners well, its dimensional stability might not be as high as marine grade plywood, especially in fluctuating humidity.

Cost Considerations

Marine Grade Plywood is typically more expensive per sheet than pressure treated lumber. This is because of the higher quality materials and manufacturing process involved. Its cost reflects its superior performance in specific, demanding environments.

Pressure Treated lumber is generally more budget-friendly, especially for larger projects. It offers good value for its resistance to rot and insects, making it a popular choice for decks, fences, and other common outdoor structures where cost is a major factor.

Application Suitability

Marine Grade Plywood is best for boat building, exterior cabinetry, and any project that will be constantly wet or requires high stability. It’s also used for high-end outdoor furniture or structures that demand the utmost in longevity and resistance to water damage.

Pressure Treated lumber is ideal for decks, fences, pergolas, outdoor play structures, and garden beds. It’s perfect for applications that need protection from ground moisture and insects but are not constantly submerged.

| Feature | Marine Grade Plywood | Pressure Treated Lumber |

|---|---|---|

| Primary Protection | Waterproof glue, void-free construction | Chemical preservatives (rot & insect resistance) |

| Water Exposure | Excellent for constant immersion/wet conditions | Good for rain/humidity; not for constant submersion |

| Strength | High, stable, less prone to warping | Good structural strength, can warp |

| Cost | Higher per sheet | More affordable for general use |

| Typical Use | Boat building, marine applications, high-end exterior | Decks, fences, pergolas, ground contact structures |

Scenario: Building a Floating Dock

Let’s consider building a floating dock. This structure will be constantly in contact with water, and possibly submerged during high tides.

- Material Choice: For the main decking and structural components that will be in direct contact with water, Marine Grade Plywood would be the superior choice. Its waterproof glue and void-free construction ensure it won’t delaminate or rot from constant water exposure.

- Support Structure: For any framing members that might be in contact with the water but not constantly submerged, or for parts that need to resist insects, Pressure Treated lumber could be considered. However, for the critical flotation components and deck surface, marine grade is the reliable option.

- Fasteners: Regardless of the wood choice, using marine-grade stainless steel fasteners is crucial to prevent rust and corrosion in the water environment.

In this scenario, while pressure treated lumber offers protection against decay, the continuous water immersion makes marine grade plywood the much safer and longer-lasting option for the deck surface.

Scenario: Constructing a Raised Garden Bed

Now, imagine building a raised garden bed. This structure will hold soil and moisture from watering plants, and it will be in contact with the ground.

- Material Choice: Pressure Treated lumber is an excellent choice for this project. It is specifically designed to resist rot and insect damage, and it is rated for ground contact. This means it can sit directly on the soil without quickly deteriorating.

- Durability: The chemicals infused into the wood will protect it from the damp soil and the moisture from watering your plants. This ensures the garden bed will last for many years.

- Cost-Effectiveness: Pressure treated lumber is also more affordable, making it a practical choice for a project like a garden bed that might be relatively large.

Here, the need is for rot and insect resistance in a ground-contact scenario. Pressure treated lumber perfectly fits these requirements, offering durability without the higher cost of marine grade plywood.

Maintenance and Longevity

Ensuring your outdoor projects stand the test of time involves not just choosing the right materials but also caring for them. Both Marine Grade Plywood and Pressure Treated lumber offer excellent longevity, but their maintenance needs can differ. This section looks at how to keep your projects looking great and functioning well for years to come.

Caring for Marine Grade Plywood

Marine Grade Plywood, while incredibly durable, can benefit from regular care. For applications exposed to sunlight, a protective finish is recommended. This could be a marine-grade varnish, sealant, or exterior paint.

Regular cleaning with mild soap and water will remove dirt and grime. Inspect for any damage or wear and tear periodically. If the finish starts to wear, reapply it to maintain the protective barrier.

Proper installation, ensuring good drainage and ventilation, also plays a big role in its longevity.

Maintaining Pressure Treated Lumber

Pressure Treated lumber also benefits from a protective finish, especially if you want to maintain its appearance. Staining or sealing can add an extra layer of protection against UV rays and moisture, and it can also enhance the wood’s color.

Allow pressure treated lumber to dry for a few weeks before applying a finish. It will often look wet when first purchased. Regular cleaning will keep it looking good.

Unlike marine grade plywood, the core protection comes from the chemicals, so superficial wear on a finish is less critical for its structural integrity but important for aesthetics.

Lifespan Expectations

When properly installed and maintained, both materials can last for many years. Marine Grade Plywood, particularly in marine environments, can last for decades. Its resistance to water is its primary strength, meaning it won’t decay from moisture.

Pressure Treated lumber typically comes with a warranty against rot and insect infestation for 25 years or more. Its lifespan depends on the treatment retention and environmental conditions. In ground contact, it performs exceptionally well against decay.

Environmental Considerations

Both materials have environmental impacts. The production of plywood involves timber harvesting and manufacturing processes. Pressure treating involves chemicals, though modern treatments are designed to be safer.

For marine grade plywood, responsible forestry practices are important. For pressure treated lumber, proper disposal and handling are key. Newer treatments are generally considered to have a lower environmental impact than older formulations.

Frequently Asked Questions

Question: Is Marine Grade Plywood better than Pressure Treated for a deck?

Answer: For a deck surface exposed to constant rain or splash, marine grade plywood offers superior resistance to delamination. However, for a standard deck not constantly submerged, pressure treated lumber is usually more cost-effective and provides excellent rot and insect resistance.

Question: Can I use Marine Grade Plywood for a fence?

Answer: While marine grade plywood is very durable, pressure treated lumber is typically a more practical and cost-effective choice for fence posts and pickets. Marine grade plywood might be used for decorative fence panels in very wet areas.

Question: Does Pressure Treated wood last longer than Marine Grade Plywood?

Answer: It depends on the application. For constant water immersion, marine grade plywood will likely last longer without delaminating. For ground contact and general outdoor exposure, pressure treated lumber offers excellent longevity against rot and insects.

Question: What is the main difference in protection?

Answer: Marine grade plywood’s protection comes from its waterproof glue and void-free construction, making it resistant to water damage. Pressure treated lumber’s protection comes from chemicals infused into the wood to resist rot and insects.

Question: Which is better for boat building?

Answer: Marine Grade Plywood is the standard for boat building because it is specifically designed to withstand constant exposure to water and saltwater without breaking down.

Summary

Choosing between Marine Grade Plywood and Pressure Treated lumber depends on your project. Marine grade plywood offers unmatched water resistance for constant wetness. Pressure treated lumber provides cost-effective rot and insect protection for general outdoor use.

Both materials are durable but serve different needs. Select based on your project’s specific exposure to moisture and your budget.