MDF Installation Guidelines: Nail Your Project’s Success!

For MDF installation, use wood glue or construction adhesive to join mitred ends easily and effectively. Always store MDF indoors in a clean, dry, well-ventilated area.

Installing MDF requires following specific guidelines and techniques to ensure a successful outcome. Whether you are a professional or a DIY enthusiast, understanding the best practices for MDF installation is crucial for achieving a durable and visually appealing result. Properly acclimating MDF and using the right tools and fastening systems are essential steps in the installation process.

By adhering to recommended installation instructions, you can create beautiful and long-lasting finishes with MDF in various applications such as baseboard trim, fire-rated installations, wall paneling, doors, and molding.

Before You Begin

Before you start installing MDF, it is important to follow some guidelines to ensure a successful installation. This section will provide you with important information on acclimating MDF to your environment and the required tools and materials you will need.

Acclimating MDF To Your Environment

Prior to installation, it is crucial to acclimate MDF to the environment in which it will be installed. This helps prevent any potential issues, such as warping or shrinking, that may occur due to changes in temperature and humidity. Follow these steps to properly acclimate MDF:

- Store the MDF boards in the room where they will be installed for at least 48 hours.

- Ensure the room is at the desired temperature and humidity levels that will be maintained after installation.

- Keep the MDF boards off the floor and away from any direct contact with walls or windows.

- Do not remove the packaging until you are ready to begin installation.

By allowing MDF to acclimate to its environment, you minimize the risk of any potential issues that may arise during or after installation.

Required Tools And Materials

Before starting the installation process, make sure you have the necessary tools and materials on hand. Here is a list of what you will need:

| Tools | Materials |

|

|

Having these tools and materials readily available will help make the installation process smoother and more efficient.

Preparation Steps

Before starting the installation of MDF (Medium Density Fiberboard), it is important to follow the proper preparation steps to ensure a successful and long-lasting result. This section will guide you through the essential steps of measuring and marking, as well as cutting MDF.

Measuring And Marking

Accurate measurements are crucial for a precise and professional MDF installation. Here are the steps to measure and mark the MDF boards:

- Start by measuring the dimensions of the area where the MDF will be installed, whether it’s a baseboard trim, fire-rated wall paneling, or a 3D wall molding. Use a tape measure to accurately determine the length and width.

- Transfer the measurements onto the MDF boards using a pencil or a marker. Make sure to mark the cutting lines clearly, ensuring they align with the dimensions of the installation area.

- For corner joints, use a square or a protractor to mark the appropriate angles on the MDF boards. This will ensure a precise fit when the boards are joined together.

Cutting MDF

Once the measurements and markings are complete, it’s time to cut the MDF boards. Follow these guidelines for a clean and accurate cut:

- Place the marked MDF board on a stable work surface, such as a sawhorse or a workbench.

- Use a circular saw or a table saw with a fine-toothed blade to cut along the marked lines. Make sure to wear safety goggles and gloves for protection.

- Move the saw smoothly and steadily through the MDF board, applying even pressure to ensure a clean and precise cut.

- For curved or intricate cuts, consider using a jigsaw or a scroll saw. These tools allow for more flexibility and precision when cutting MDF.

- After cutting the MDF boards, sand the edges with sandpaper to remove any roughness or splinters. This will result in a smooth and finished look.

By following these preparation steps of measuring, marking, and cutting MDF, you will set the foundation for a successful installation. Remember to always prioritize safety and accuracy to achieve the best results.

Joining MDF Panels

To join MDF panels, start by applying construction adhesive or wood glue to the edges, then press them firmly together. For corner joints, miter the edges and use the same adhesive for a secure bond. Additionally, reinforce the joints with screws or nails for added stability.

These MDF installation guidelines ensure a strong and durable result.

Joining MDF Panels is an essential part of any DIY project that requires the use of Medium Density Fiberboard. MDF is a popular material used in construction, furniture making, and interior design. However, to ensure a perfect finish, the joining process must be done right. In this section, we will discuss the best adhesives for MDF, creating strong corner joints, and how to ensure a seamless MDF installation process.

Best Adhesives For MDF

The easiest way to join MDF panels is by using wood glue or construction adhesive. Both adhesives are readily available and have excellent bonding properties. However, for a more robust and long-lasting joint, we recommend using construction adhesive. The bubbling of the glue during the hardening process will fill in unevennesses, resulting in a stronger bond. Additionally, it’s essential to choose an adhesive that’s suitable for indoor use and can withstand high humidity levels.

Creating Strong Corner Joints

Creating strong corner joints is crucial for any MDF installation project. To create a strong corner joint, we recommend using a combination of wood glue and screws or nails. First, apply a generous amount of glue to the joint and then clamp the two pieces together. Next, drill pilot holes and drive screws or nails through the joint. Finally, wipe off any excess glue and let the joint dry completely before sanding or painting.

Ensuring A Seamless MDF Installation Process

To ensure a seamless MDF installation process, it’s essential to follow the manufacturer’s installation guidelines. Different MDF products may have different installation instructions, so it’s crucial to read and understand the installation manual before starting the project. Additionally, it’s essential to acclimate the MDF panels in the installation area for at least 48 hours before installation. This will help prevent any warping or cracking of the panels after installation. Finally, always store MDF panels in a clean, dry, and well-ventilated area to prevent moisture damage.

In conclusion, joining MDF panels requires careful consideration of the type of adhesive used, corner joint strength, and proper installation guidelines. By following these guidelines, you can ensure a perfect finish and a long-lasting MDF installation project.

Installation Techniques

When it comes to MDF installation, following proper Installation Techniques is crucial for a successful outcome. Whether you are working on baseboard trim, fire-rated MDF, wall paneling, or molding, understanding the best practices is essential.

Nailing Vs. Screwing MDF

- Consider using nails for MDF installations where a seamless finish is a top priority.

- Screws are recommended for areas that require extra strength and durability.

Using Power Nailers Effectively

- When working with MDF, power nailers can significantly speed up the installation process.

- Ensure the correct nail size is selected to avoid damaging the MDF.

- Practice proper nailing techniques to prevent splitting or cracking of the material.

Special Considerations

When working with Medium Density Fiberboard (MDF), there are certain special considerations that need to be taken into account to ensure a successful installation. From fire rated MDF to high moisture areas, it’s important to understand the specific guidelines for these situations.

Dealing With Fire Rated MDF

Fire rated MDF requires special attention during installation to maintain its fire resistance properties. It’s crucial to use fire-rated adhesives and fasteners as specified by the manufacturer. Additionally, ensure that the surrounding materials and construction methods comply with fire safety regulations to maintain the integrity of the fire rated MDF.

Installing MDF In High Moisture Areas

MDF in high moisture areas demands extra precautions to prevent swelling and damage. Applying a moisture-resistant sealer or primer to all surfaces of the MDF can provide protection against moisture absorption. Proper ventilation and avoiding direct contact with water sources are also essential to safeguard the MDF from moisture-related issues.

Finishing Touches

Once the MDF installation is complete, it’s time to focus on the finishing touches to ensure a professional and polished look. This includes sanding, priming, and painting the MDF to achieve a seamless and refined appearance.

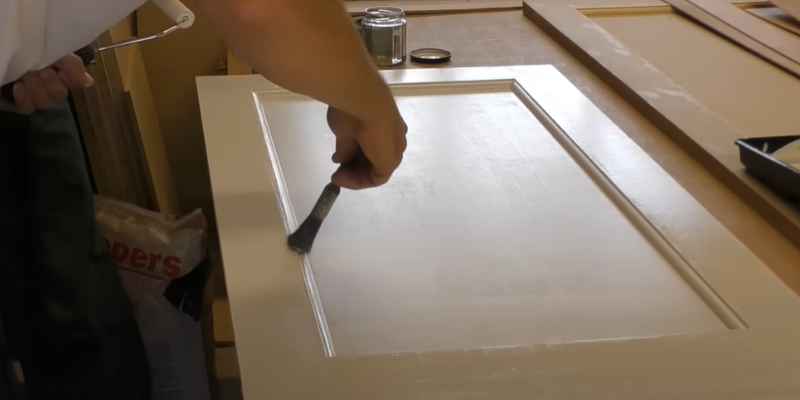

Sanding And Priming

Before painting, it’s crucial to sand the MDF surface to remove any rough spots or imperfections. Use a fine-grit sandpaper to smooth out the surface, paying special attention to the edges and corners. After sanding, wipe the MDF clean to remove any dust or debris. Next, apply a high-quality primer designed for MDF to create a smooth and even base for the paint.

Painting MDF For A Professional Finish

For a professional finish, it’s essential to use the right type of paint and technique when painting MDF. Choose a high-quality latex or acrylic paint for the best results. Apply the paint evenly using a brush or roller, ensuring full coverage and smooth strokes. Multiple thin coats are preferable to one thick coat to avoid drips and uneven coverage. Allow each coat to dry completely before applying the next.

Maintenance And Care

Proper maintenance and care are essential to ensure the longevity and durability of MDF installations. By following the guidelines for cleaning, repairing, and general upkeep, you can preserve the quality and appearance of MDF surfaces.

Cleaning MDF Surfaces

Regular cleaning is crucial to maintain the aesthetics of MDF surfaces. Use a soft, damp cloth to wipe the surface, and avoid abrasive cleaners that can cause damage. For stubborn stains, mild soap and water can be used, but ensure that the surface is dried immediately to prevent moisture absorption. Avoid prolonged exposure to liquids, and always use coasters or mats to protect MDF surfaces from spills and heat.

Repairing Damaged MDF

When MDF surfaces get damaged, prompt action can prevent further deterioration. For minor scratches or dents, a wood filler can be used to fill in the imperfections. Once filled, sand the area gently to ensure a smooth surface. For larger damages, consider consulting a professional to assess the extent of the damag and provide suitable repairs to restore the integrity of the MDF installation.

Frequently Asked Questions

What Is The Best Way To Attach MDF?

The best way to attach MDF is using wood glue or construction adhesive for joining. Construction adhesive is recommended for bonding two ends together, filling in unevenness for a better bond.

Should I Nail Or Screw MDF?

For MDF, it’s best to use screws instead of nails for a stronger hold. Pre-drill holes to prevent splitting.

How Is MDF Installed?

To install MDF, use wood glue or construction adhesive for joining mitred edges securely. Power nailers are commonly used for fastening MDF mouldings during installation. Store MDF indoors in a clean, dry area before installing to prevent damage. Aim to follow manufacturer’s guidelines for a successful installation process.

How Long Does Mdf Need To Acclimate?

MDF typically needs to acclimate for at least 48 hours before installation. This allows the MDF to adjust to the temperature and humidity of the installation area, which can prevent warping or cracking. It’s important to store the MDF in a clean, dry, and well-ventilated area during this time.

Conclusion

Following the MDF installation guidelines is crucial for a successful project. By using the right adhesives and fastening systems, and ensuring proper acclimatization of the material, you can achieve a durable and aesthetically pleasing result. Remember to store the MDF indoors and maintain a clean, dry environment for optimal installation.