Metal Mitre Saw Blade: Precision Cutting for Perfect Angles

A metal mitre saw blade is designed specifically for cutting metal materials. It offers precision and durability, ensuring clean cuts without excessive wear.

Metal mitre saw blades are essential tools for any metalworking project. They come in various sizes and tooth configurations to suit different applications. Made from high-quality materials, these blades can cut through steel, aluminum, and other metals with ease. Their design minimizes heat buildup and reduces the risk of blade warping.

Choosing the right blade enhances your saw’s efficiency and extends its lifespan. Proper maintenance and usage are crucial for optimal performance. Whether you’re a professional or a DIY enthusiast, investing in a quality metal mitre saw blade can significantly improve your cutting accuracy and project outcomes.

Introduction To Metal Mitre Saw Blades

Metal miter saw blades are essential for making precision cuts. They allow for accurate angles and clean edges. A quality blade ensures a smooth cutting experience. Some key features include:

- Material: High-speed steel or carbide-tipped for durability.

- Tooth Count: More teeth provide smoother cuts.

- Kerf Width: A thinner kerf means less material waste.

- Coating: Anti-friction coatings help reduce heat build-up.

Choosing the right blade improves both performance and safety. A well-maintained blade lasts longer and cuts better. Regular inspection is key to ensuring optimal performance.

Types Of Metal Mitre Saw Blades

Steel-toothed blades are common for cutting soft metals. They are affordable and easy to find. These blades work well on aluminum and copper. They do not last as long as carbide-tipped blades.

Carbide-tipped blades are more durable and last longer. They can cut through harder metals. These blades offer a smoother cut and less friction. They are a bit more expensive but worth the investment.

Selecting The Right Blade For Your Project

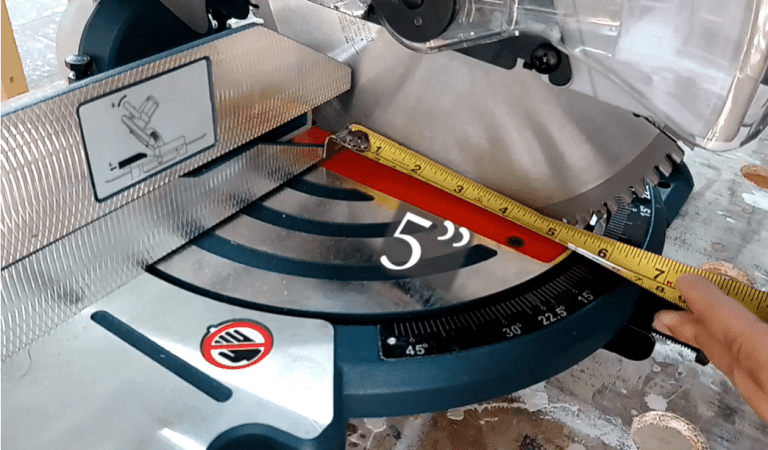

Choosing the right metal mitre saw blade is essential for your project. Consider the material you will cut. Different materials require specific blade types. For wood, a tooth count of 40-80 works best. For metal, use a blade with fewer teeth. Blade size also matters. Common sizes include 10-inch and 12-inch blades. Ensure your saw can handle the chosen size.

Check the blade compatibility with your mitre saw. Some blades fit only specific models. Always refer to the manufacturer’s guidelines. A compatible blade ensures safety and efficiency. The right blade can improve your cutting quality. It can also extend the life of your saw.

Blade Tooth Configuration

The tooth shape and angle of a mitre saw blade greatly affect its performance. Flat teeth create smooth cuts, while angled teeth help in faster cutting. Each shape has specific uses, making it important to choose wisely.

Tooth count impacts cutting speed and finish. A higher tooth count provides a smoother finish, ideal for fine work. Fewer teeth cut faster but leave a rougher edge. Finding the right balance is key for your project.

Maintenance For Longevity

To keep your metal mitre saw blade in great shape, regular cleaning is essential. Use a soft brush to remove sawdust and debris after each use. For tough buildup, a solution of water and vinegar works well. Soak the blade for a few minutes, then scrub gently.

Sharpening your blade improves cutting performance. Use a file or a specialized sharpening tool. Make sure to follow the original angle of the teeth. Check for any missing or damaged teeth before sharpening. Regular sharpening can extend the life of your blade significantly.

Safety Measures While Using Metal Mitre Saw Blades

Wearing the right Personal Protective Equipment is essential. Use safety goggles to protect your eyes. Ear protection can help reduce noise exposure. Gloves provide a good grip and protect your hands. A dust mask keeps harmful particles away from your lungs.

Proper handling and operation ensure safety. Always hold the saw firmly with both hands. Keep your hands clear of the blade while cutting. Make sure the blade is sharp and in good condition. A dull blade can cause accidents.

Check the work area for any obstructions. Ensure there is enough space around the saw. Always cut on a stable surface to avoid slipping. Follow the manufacturer’s instructions for best results.

Advanced Techniques For Perfect Angles

Mitre cuts and bevel cuts are both important for precise woodworking. Mitre cuts are angled cuts made across the width of the board. Use them for corners in frames or moldings. Bevel cuts, on the other hand, are angled cuts made along the thickness of the board. They are great for creating sloped edges on surfaces.

Achieving compound angles requires both mitre and bevel cuts. This technique is essential for items like crown molding. Start by measuring the angles accurately. Set your saw to the correct mitre and bevel angles. Make sure to double-check your settings before cutting.

Troubleshooting Common Cutting Issues

Blade wobble can cause uneven cuts. This usually happens due to a bent blade or loose parts. Check the blade for any signs of damage. Tighten all screws and ensure the blade is correctly installed.

Deflection occurs when the blade flexes during cutting. Use a thicker blade for stronger cuts. Keep the saw well-maintained to prevent this issue.

Dull blades lead to poor cutting performance. A dull blade can burn wood and create rough edges. Regularly sharpen or replace blades to ensure clean cuts. Use a sharpening tool suitable for your saw blade type.

Always keep your workspace clean. A clean area helps prevent accidents and improves cutting accuracy.

Innovations In Blade Technology

Innovations in blade technology have transformed metal cutting. Latest materials like carbide and diamond enhance durability. These materials provide longer life and better performance. Advanced coatings reduce friction and increase cutting efficiency.

Future trends in blade design focus on lightweight and strong structures. Manufacturers aim for blades that cut faster and last longer. Smart technology may also integrate sensors for real-time performance data. This can help users optimize their cutting tasks.

| Feature | Benefit |

|---|---|

| Carbide Material | Increased durability |

| Diamond Coating | Enhanced cutting efficiency |

| Lightweight Design | Easier handling |

| Smart Technology | Real-time performance tracking |

Conclusion: Achieving Precision With The Right Blade

Choosing the right metal mitre saw blade is essential for precision cuts. Consider the tooth count for smooth or fast cutting. Higher tooth counts offer cleaner cuts, while fewer teeth can cut faster. The blade material matters too. Carbide-tipped blades last longer and cut better. Pay attention to the kerf width for the desired cut size. A thin kerf blade removes less material, saving more of your workpiece.

Proper maintenance extends the blade’s life. Regularly clean the blade and check for wear. Replace blades when dull to maintain accuracy. Using the correct saw settings also impacts the quality of the cut.

Investing in a quality blade leads to better results. Remember these key points for mastering metal mitre saw blades. Achieving precision is possible with the right tools and knowledge.

Frequently Asked Questions

What Is A Metal Mitre Saw Blade?

A metal mitre saw blade is designed specifically for cutting metal materials. It features hardened teeth and unique coatings to enhance durability and performance. These blades can cut through various metals, including aluminum, steel, and other alloys, providing clean and precise cuts for your projects.

How Do I Choose The Right Blade?

Selecting the right blade depends on the material and thickness you plan to cut. Consider the tooth count and type; higher teeth count offers smoother finishes. Additionally, ensure the blade’s diameter matches your saw for optimal performance. Always check compatibility with your specific mitre saw model.

Can I Use A Wood Blade On Metal?

Using a wood blade on metal is not recommended. Wood blades are designed for softer materials, leading to poor cuts and potential blade damage. Metal blades have specific features, such as different tooth geometry, to handle the hardness of metals, ensuring safety and efficiency during cutting.

How Long Do Mitre Saw Blades Last?

The lifespan of mitre saw blades varies based on usage and material. Regular maintenance can extend their life significantly. Generally, high-quality blades can last for hundreds of cuts. However, inspect them regularly for wear and replace when necessary to maintain cutting accuracy and safety.

Conclusion

Choosing the right metal mitre saw blade is essential for precision and efficiency. The right blade can significantly enhance your cutting experience. Always consider factors like material, tooth count, and finish. Investing in a quality blade pays off in the long run, ensuring clean, accurate cuts for all your projects.