Polycrylic Spray vs Brush: Which Finish Is Smoother

Many DIYers wonder about the best way to apply polycrylic for a smooth finish. It’s a common question because getting that perfect, glass-like surface can feel tricky, especially when you’re just starting. You want your project to look professionally done, right?

Don’t worry, figuring out if Polycrylic Spray vs Brush: Which Finish Is Smoother? makes a big difference is simpler than you think. We’ll walk through it step by step, showing you exactly what works best.

Polycrylic Application Methods Compared

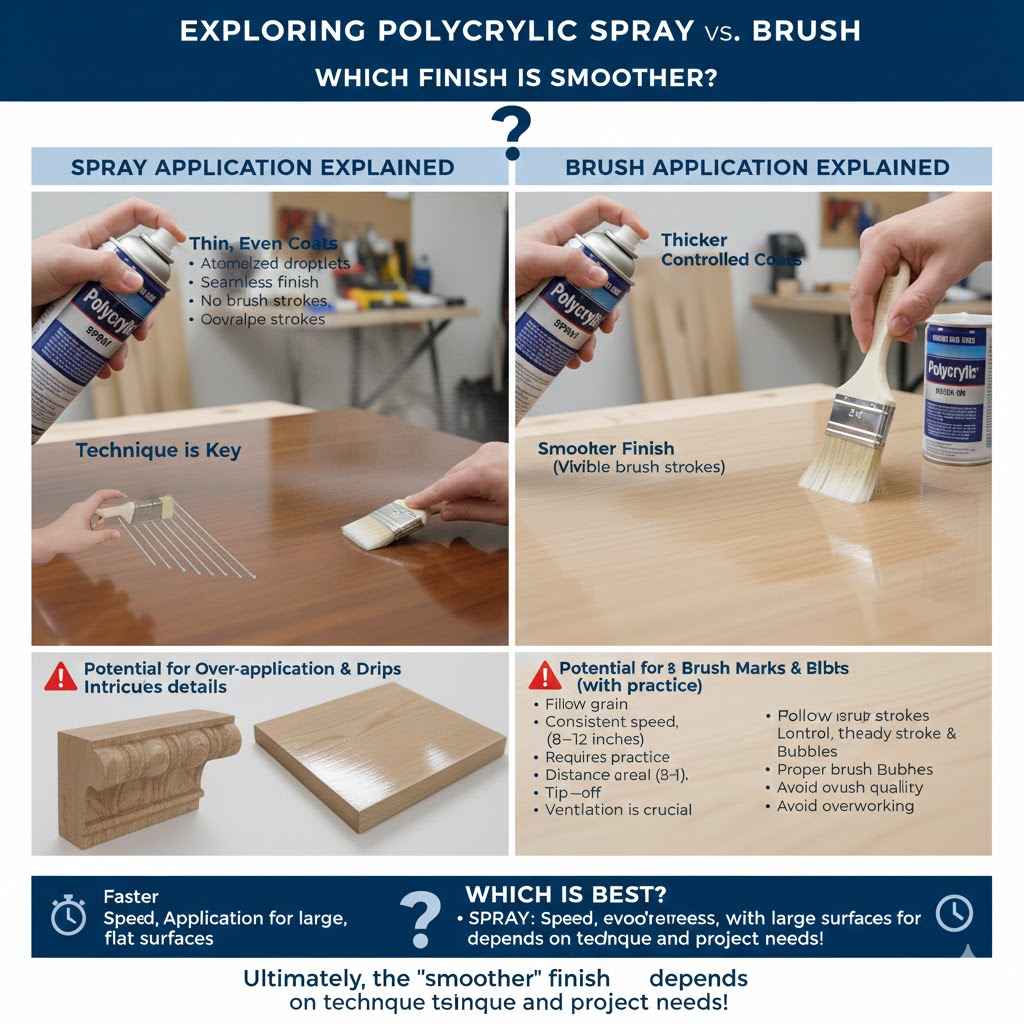

Exploring Polycrylic Spray vs Brush Which Finish Is Smoother

Choosing the right application method for polycrylic is key to achieving a beautiful, durable finish on your woodworking projects. For beginners and experienced crafters alike, the question often arises: what’s the difference between using a spray can and a brush, and which one will give me that coveted smooth look? This section will break down the core differences between these two popular application techniques.

We’ll look at what makes each method unique and how they impact the final outcome. Understanding these distinctions helps you pick the best approach for your specific project and desired results.

Spray Application Explained

Using polycrylic in a spray can offers a convenient way to apply a thin, even coat. The aerosol application atomizes the liquid into fine droplets, which then settle onto the surface. This method is particularly good for reaching intricate areas and creating a seamless finish without brush strokes.

The fine mist can be tricky to control, requiring careful technique to avoid drips or uneven coverage. Proper ventilation is also a significant consideration when working with spray cans.

The mechanics behind spray cans involve a propellant that pushes the product out of the can. As the propellant mixes with the air, it causes the liquid polycrylic to break into tiny particles. This atomization is what creates the fine mist.

The speed at which you move the can and the distance from the surface greatly influence the thickness of the coat. Overlapping your spray passes is essential for uniform coverage.

When you spray polycrylic, you’re essentially creating a cloud of finish that lands on your workpiece. The goal is to make this cloud as uniform as possible. If you spray too close, you risk runs and drips because too much liquid lands in one spot.

If you spray too far away, the droplets may dry before they hit the surface, leading to a rough, uneven texture. Finding that sweet spot takes practice.

Even Coats

Spraying allows for extremely thin and even coats of polycrylic to be applied. This is beneficial because it minimizes the chance of drips and runs, which are common issues with thicker applications. The fine mist ensures that the product distributes uniformly across the surface, creating a smooth foundation for subsequent coats. This evenness contributes significantly to the final polished appearance of your project.

Coverage of Complex Shapes

Spray cans excel at reaching corners, edges, and detailed carvings that are difficult to cover thoroughly with a brush. The aerosol can direct the spray into these tight spots, ensuring complete protection and a consistent finish. This makes spray polycrylic ideal for furniture with ornate details or small craft items where a brush might struggle to get into every nook and cranny without leaving visible marks.

Faster Application Times

For larger, flat surfaces, a spray can often cover the area more quickly than brushing. You can lay down a broad sweep of finish in one pass, significantly reducing the overall time spent on application. This speed is a major advantage when you need to complete a project efficiently or are working on multiple items simultaneously.

Potential for Over-application

One of the main challenges with spray cans is the risk of applying too much product. The ease of spraying can tempt users to apply heavier coats than recommended, leading to drips, runs, and an uneven finish. Controlling the amount of product dispensed requires a steady hand and proper technique, especially for beginners who might not yet have developed this skill.

Brush Application Explained

Applying polycrylic with a brush is a more traditional method. It involves using a high-quality synthetic brush to spread the protective coating. This technique gives you direct control over the thickness and placement of the finish.

While it can be more labor-intensive and requires careful brushwork to avoid strokes, it offers excellent precision for smaller projects or areas where overspray is a concern.

The brush method relies on the bristles to pick up and distribute the polycrylic. A good brush will have soft, synthetic bristles that are designed to hold the liquid without excessive dripping. The key to a smooth finish with a brush is to use long, even strokes and to maintain a wet edge – meaning you always brush into the previously applied wet area.

This prevents lap marks, which are visible lines where one coat of finish meets another that has already started to dry.

When brushing, the density of the bristles and the way you load the brush with polycrylic are important. Overloading can lead to drips, while not enough product can result in a streaky, thin coat. The angle at which you hold the brush and the pressure you apply also play a role.

Gentle pressure with long, smooth strokes is generally recommended to achieve the best results.

Precise Control

Brushing offers the most direct control over where the polycrylic is applied. You can meticulously guide the finish exactly where you want it, which is invaluable for detailed work or for protecting specific areas. This precision helps prevent accidental application to unwanted parts of your project, ensuring a clean and professional look, especially for furniture with intricate designs or when working close to other materials.

Avoiding Overspray Issues

Unlike spray cans, brushes do not produce overspray. This means you don’t have to worry about covering surrounding areas or dealing with the cleanup of a fine mist of finish that has settled on unintended surfaces. This makes brushing a safer choice when working in areas with limited ventilation or when masking adjacent surfaces is difficult or impractical.

Risk of Brush Strokes

The most common challenge with brushing is the potential for visible brush strokes. If the polycrylic is applied too thickly, or if the brush is not used with a smooth, consistent motion, the marks left by the bristles can be noticeable. This requires a careful technique, including using high-quality brushes and long, overlapping strokes, to achieve a smooth, even finish without unsightly lines.

Building Thickness Gradually

Brushing allows you to build up the finish layer by layer with deliberate control. You can apply thin coats and inspect them as you go, making adjustments as needed. This gradual buildup is excellent for achieving a substantial protective layer over time, ensuring durability without the risk of overwhelming the surface with too much liquid at once.

Key Differences and When to Choose Each

The choice between spray and brush application hinges on several factors, primarily the project’s complexity, your experience level, and the desired final look. Spraying is often faster for large, flat surfaces and offers an inherently smoother finish with less effort if done correctly. It’s ideal for large furniture pieces, cabinets, or anything with a lot of surface area where a flawless, factory-like finish is the goal.

The fine mist can leave a more uniform appearance than even the most skilled brushwork.

Brushing, on the other hand, provides superior control. It is better suited for smaller projects, intricate details, or when working in an area where overspray is a major concern. If you’re new to finishing and worried about drips from a spray can, brushing allows for a more deliberate pace.

You can see exactly where you are applying the product and correct mistakes as you go. It also requires less preparation regarding masking and ventilation.

Application Speed and Efficiency

When it comes to speed, spray cans generally win for large, open surfaces. You can cover a significant area in a short amount of time, making it efficient for big jobs like tabletops or cabinet doors. Brushing, while slower, allows for more detailed attention.

For small items or pieces with many edges and corners, the time saved by brushing might be negligible or even reversed if you factor in masking time for spraying.

Finish Quality and Smoothness

The ultimate goal is often a smooth, professional-looking finish. Spraying, with its atomized application, can achieve this very well, often resulting in fewer imperfections like dust nibs or brush marks. However, achieving this requires practice and the right technique to avoid runs.

Brushing can also yield a smooth finish, but it demands more skill and the right tools. Poor brushing technique is a common cause of noticeable strokes and an uneven feel.

Cost Considerations

Initially, spray cans might seem more expensive per can. However, if you consider the time saved and the potential need for extra sanding or fixing mistakes with brush application, the cost can balance out. High-quality brushes also represent an investment.

For frequent users, a good brush might be more economical in the long run than constantly buying spray cans.

Here’s a simple table to highlight the differences:

| Feature | Polycrylic Spray | Polycrylic Brush |

|---|---|---|

| Application Speed | Faster for large areas | Slower, more deliberate |

| Smoothness Potential | High, even finish; less risk of strokes | High, but requires skill to avoid strokes |

| Control | Lower; risk of overspray and drips | Higher; precise application possible |

| Best For | Large flat surfaces, complex shapes needing consistent coverage | Small projects, detailed work, areas where overspray is an issue |

| Learning Curve | Moderate; requires technique for evenness | Moderate to High; requires good brushing technique |

Achieving a Smoother Finish Regardless of Method

Whether you choose a spray can or a brush, several universal principles apply to achieving that incredibly smooth polycrylic finish. Preparation is paramount. Sanding your project to a fine grit, typically 220 or higher, is essential before applying any finish.

This creates a smooth surface for the polycrylic to adhere to and results in a better final feel.

Cleaning the surface thoroughly after sanding is also crucial. Dust particles are the enemy of a smooth finish. Use a tack cloth to remove every bit of dust.

This simple step can prevent many imperfections from marring your work. Applying thin coats is another critical factor for both methods. Thicker coats are more prone to runs, drips, and unevenness.

Allowing adequate drying time between coats is also vital. Rushing this process can lead to lifting or an uneven surface. Always follow the manufacturer’s recommendations for drying times.

Finally, light sanding between coats with a very fine grit sandpaper (320 or higher) or a fine-grit sanding sponge can knock down any minor imperfections or dust nibs. Wipe down with a tack cloth after each sanding session.

Surface Preparation Steps

Before you even think about applying polycrylic, the surface needs to be in pristine condition. This means smoothing out any imperfections from previous work, like saw marks or dents. Start with a medium grit sandpaper and gradually move to finer grits.

For a truly smooth finish, you should end with at least 220-grit sandpaper. The smoother the wood, the smoother the finish will be.

After sanding, it’s imperative to remove all dust. A shop vacuum with a brush attachment can get rid of the bulk of the dust. Then, use a tack cloth.

These are slightly sticky cloths designed to pick up fine dust particles that vacuums might miss. If you don’t have a tack cloth, a clean, lint-free rag dampened very slightly with mineral spirits can work in a pinch, but a tack cloth is preferred for best results.

Sanding Grit Progression

The importance of progressive sanding cannot be overstated. Starting with a coarse grit (e.g., 80 or 100) might be necessary to remove significant imperfections. However, each subsequent grit size removes the scratches left by the previous one. You must move systematically through grits like 120, 150, 180, and finally to 220 or even 320 for a silky-smooth surface ready for finishing.

Dust Removal Techniques

Dust is the arch-nemesis of a flawless finish. After sanding, compressed air can blow dust off larger surfaces. For finer dust and grooves, a soft brush attachment on a vacuum cleaner is effective. The final and most critical step is using a tack cloth. It adheres to and lifts microscopic dust particles, ensuring a clean canvas for your polycrylic application.

Surface Inspection

Before applying any finish, carefully inspect the prepared surface under good lighting. Run your hand over it; it should feel smooth to the touch. Look for any remaining scratches, dents, or imperfections. Address any issues found by re-sanding the affected area with the appropriate grit sandpaper. A truly smooth surface is the foundation for a smooth finish.

The Importance of Thin Coats

Applying polycrylic in thin coats is a golden rule for achieving a smooth finish, regardless of your chosen application method. Thick coats are much more likely to sag, drip, or pool, creating an uneven and undesirable texture. Thin coats allow the product to level out more effectively, reducing the risk of these imperfections.

They also dry faster, allowing for more coats in a shorter period.

With a spray can, this means using light, sweeping passes and maintaining a consistent distance from the surface. With a brush, it involves loading the brush with just enough product and using long, smooth strokes, avoiding pressing too hard. The idea is to lay down a light mist or a thin film of the finish rather than a thick layer.

Multiple thin coats are always superior to one or two thick coats. Each thin layer builds up to a durable finish, and the ability to sand lightly between coats helps ensure an exceptionally smooth final result. This layered approach is key to professional-looking results.

Minimizing Runs and Drips

When you apply polycrylic too thickly, gravity pulls it downwards, causing it to run and drip. Thin coats reduce the amount of liquid in any one spot, making it much harder for gravity to create these noticeable flaws. This is especially important on vertical surfaces or edges where drips are very common.

Better Leveling Properties

Polycrylic, like most finishes, has leveling properties, meaning it wants to spread out evenly. This works best when there isn’t an excessive amount of product. Thin coats give the polycrylic more time and space to flow out and level itself, filling in microscopic imperfections on the surface and creating a smoother appearance.

Faster Drying Times

A thinner layer of any liquid dries faster than a thicker layer because there is less material to evaporate. This is a significant advantage when applying multiple coats. You can re-coat sooner with thin layers, allowing you to complete your project more efficiently without compromising the quality of the finish.

Ease of Sanding Between Coats

Sanding between coats is crucial for smoothness. Thin coats are much easier to sand lightly without burning through to the wood. A light scuff with fine-grit sandpaper on a thin coat quickly removes minor imperfections, preparing the surface for the next layer without creating new problems.

Sanding Between Coats

This step is often overlooked by beginners but is absolutely critical for achieving that professional, ultra-smooth finish. After each coat of polycrylic has dried thoroughly, you’ll want to lightly sand the surface. The goal here isn’t to remove the coat of finish but to knock down any tiny imperfections that may have settled, such as dust nibs, or any slight roughness from the previous coat.

Use a very fine-grit sandpaper, like 320 or 400 grit, or a fine sanding sponge. You want to apply just enough pressure to smooth out any bumps without abrading the finish too aggressively. After sanding, always clean the surface again with a tack cloth to remove all dust before applying the next coat.

This process, repeated for each layer, builds up a remarkably smooth and even surface.

Removing Dust Nibs and Imperfections

Even in a clean environment, tiny dust particles can settle on your finish as it dries, creating small bumps called dust nibs. Light sanding with fine-grit paper gently removes these nibs and any other minor imperfections that have appeared, ensuring a flat surface for the next coat.

Improving Adhesion for Subsequent Coats

A light sanding creates a slightly rougher surface, which provides better adhesion for the next coat of polycrylic. This helps to ensure that each layer bonds well with the one below it, contributing to the overall durability and longevity of the finish.

Achieving a Perfectly Flat Surface

By repeatedly sanding between coats, you essentially build up a perfectly flat and level surface over time. This is how professionals achieve that deep, glassy look in their finishes, as there are no microscopic peaks and valleys to catch the light or feel rough to the touch.

Using the Right Tools

For sanding between coats, it’s best to use very fine-grit sandpaper (320-400 grit) or a fine-grit sanding sponge. These tools are less likely to scratch or damage the cured polycrylic. Avoid using coarse sandpaper, as it will create new scratches that will be difficult to remove with subsequent coats.

Polycrylic Spray vs Brush Which Finish Is Smoother Case Studies

To truly understand the difference between using a spray can and a brush for polycrylic application, let’s look at a couple of real-world scenarios. These examples highlight how different choices can lead to varying outcomes, giving you practical insight into what to expect.

Scenario 1 A Dining Table Refinish

Sarah decided to refinish her old dining table. The tabletop was a large, flat surface, and she wanted a mirror-like finish. She had some experience with painting furniture but was new to polycrylic.

She decided to use spray cans for the main tabletop surface, aiming for speed and an even coat.

Sarah began by thoroughly sanding the tabletop and cleaning it. She followed the spray can instructions, holding the can about 10-12 inches away and using steady, overlapping passes. She applied four thin coats, allowing adequate drying time between each.

She also lightly sanded between coats with 320-grit sandpaper and wiped with a tack cloth. The result was a very smooth, even finish across the entire tabletop, with no visible brush strokes. She was thrilled with how professional it looked.

However, she also had to apply polycrylic to the table legs, which had intricate carvings. For these areas, she found the spray can difficult to control, resulting in some overspray on the floor and uneven coverage in the carvings. She eventually switched to a high-quality synthetic brush for the legs, which allowed her to get into the detailed areas more precisely, though it took longer and required more careful brushwork to avoid pooling.

This scenario shows that for large, flat areas where an even, stroke-free finish is desired, polycrylic spray can be highly effective and efficient. However, for detailed work, a brush often offers better control and precision.

Scenario 2 A Small Jewelry Box Project

Mark was building a small, ornate jewelry box for his daughter. The box had delicate inlay work and several small compartments. He was concerned about getting polycrylic into all the nooks and crannies without creating a mess or leaving brush marks.

He decided to use a high-quality synthetic brush for the entire project.

Mark carefully sanded the box to a fine grit. He then used a small, artist-style brush to apply the polycrylic. He worked slowly and methodically, ensuring he applied thin, even coats.

He found that by using just enough polycrylic on the brush and employing short, controlled strokes, he could achieve a smooth finish without drips. He applied five thin coats, sanding lightly with 400-grit sandpaper between each.

The result was a beautifully smooth finish that highlighted the intricate details of the jewelry box. He had complete control over the application, and there was no overspray to clean up. While it took him longer than it might have with a spray can on a larger surface, the precision he achieved was exactly what he needed for this delicate project.

This case highlights the advantage of using a brush for smaller, more detailed projects. The direct control allows for meticulous application, minimizing waste and ensuring that every part of the object receives an even coat of finish.

Common Polycrylic Application Mistakes

Even with the best intentions, mistakes can happen when applying polycrylic. Understanding these common pitfalls can help you avoid them and ensure a smoother, more durable finish. Many issues stem from rushing the process, improper preparation, or incorrect application techniques.

Learning from the experiences of others can save you time and frustration.

Rushing the Drying and Curing Process

One of the most frequent errors is not allowing sufficient drying time between coats. Polycrylic needs to dry enough so that the surface is no longer tacky before the next coat is applied. Applying a new coat while the previous one is still wet can cause issues like lifting, bubbling, or an uneven texture because the solvents in the new layer can reactivate the layer beneath.

Furthermore, there’s a difference between drying and curing. While a coat might feel dry to the touch after a few hours, it can take days or even weeks for polycrylic to fully cure and reach its maximum hardness and durability. Applying heavy use or harsh cleaners to a piece before it’s fully cured can damage the finish.

Always check the product’s specific instructions for recommended drying and curing times.

Intercoat Contamination

When you apply a wet coat over a partially dry coat, the solvents from the fresh finish can soften and disturb the underlying layer. This can lead to a loss of gloss, a cloudy appearance, or even adhesion problems as the layers don’t bond properly. Proper drying allows the previous layer to form a stable film before the next is added.

Surface Tacky or Sticky

If the surface remains tacky after the recommended drying time, it indicates insufficient drying. This can be due to high humidity, low temperatures, or applying the coat too thickly. Continuing to apply more coats in this state will only worsen the problem, creating a soft, easily damaged finish.

Reduced Durability and Hardness

Curing is the process where the finish achieves its full hardness and chemical resistance. If a piece is put into heavy use before full cure, the finish can be scratched, dented, or stained much more easily than it would be if fully cured. Patience is rewarded with a long-lasting protective layer.

Improper Surface Preparation

As mentioned earlier, a smooth, clean surface is the bedrock of a smooth finish. Neglecting preparation is a recipe for disaster. This includes failing to sand adequately, not removing all sanding dust, or applying polycrylic over a greasy or dirty surface.

Using the wrong grit sandpaper can also be an issue. If you skip grits or use sandpaper that is too coarse, you’ll leave behind scratches that the polycrylic won’t be able to fill. Conversely, if you sand too aggressively between coats, you might remove too much of the previous layer, leading to an uneven finish.

Always follow a progressive sanding schedule and clean thoroughly after each sanding step.

Visible Scratches and Imperfections

If the wood surface isn’t sanded smoothly before the first coat, those imperfections will be magnified by the finish. The polycrylic will fill minor imperfections but won’t hide deep scratches or gouges. Ensuring a uniformly smooth surface from the start is essential.

Poor Adhesion and Peeling

If the surface is not clean or is contaminated with oil, wax, or grease, the polycrylic will not adhere properly. This can lead to peeling, flaking, or bubbling of the finish over time, compromising the protection and appearance of your project.

Dust Trapped in the Finish

Sanding creates fine dust. If this dust isn’t completely removed before application, it will be trapped in the wet polycrylic. These trapped particles will create a gritty texture, marring the smooth finish and requiring extensive sanding to fix, if it can be fixed at all.

Applying Coats That Are Too Thick

This is a mistake that applies to both spray and brush methods. It’s tempting to try and get good coverage with as few coats as possible by applying more product at once. However, this almost always leads to problems.

Thick coats are prone to sagging, dripping, and uneven drying, which results in a rough texture.

With spraying, this can happen if you hold the can too close or move too slowly. With brushing, it can occur from overloading the brush or applying heavy pressure. The key is to remember that multiple thin coats are always better than a few thick ones for achieving a smooth, durable, and attractive finish.

Thin coats allow the polycrylic to flow out properly and dry evenly.

Sagging and Dripping on Vertical Surfaces

When too much liquid polycrylic is applied to a vertical surface, gravity will cause it to sag and form drips as it tries to flow downwards. This creates unsightly lines and bulges in the finish that are difficult to correct without significant sanding.

Uneven Drying and Soft Spots

Thick coats take longer to dry, and the outer layers might appear dry while the inner layers remain wet. This uneven drying can create soft spots that are vulnerable to damage. It can also lead to a cloudy or hazy appearance in the finish.

Difficulty in Sanding Smoothly

Thick coats, especially if they have dried unevenly, are much harder to sand smooth without creating divots or burning through the finish. The goal of sanding between coats is to gently level the surface; this is significantly harder with thick, uneven layers.

Polycrylic Spray vs Brush Which Finish Is Smoother Frequently Asked Questions

Question: Is polycrylic spray easier to use than brushing for beginners?

Answer: For beginners, spray application can seem easier because it’s faster and can cover large areas quickly. However, achieving a truly smooth, even finish with spray cans requires practice to avoid drips and runs. Brushing offers more direct control, which some beginners find less intimidating for detailed work, even if it takes longer.

Question: Can I use a foam brush with polycrylic?

Answer: While you can use a foam brush, they are generally not recommended for achieving a smooth, professional finish with polycrylic. Foam brushes can sometimes leave a slightly bubbly texture and may not provide the fine control needed to avoid strokes or uneven coverage, especially compared to high-quality synthetic bristles.

Question: How many coats of polycrylic are usually needed for a good finish?

Answer: Typically, three to four thin coats of polycrylic are recommended for a durable and smooth finish on most projects. For high-traffic areas like tabletops or cabinets, five or more coats might be beneficial. The exact number depends on the desired level of protection and the specific product being used.

Question: Should I sand between every coat of polycrylic?

Answer: Yes, sanding lightly between coats is highly recommended for achieving the smoothest possible finish. Use a very fine-grit sandpaper (320-400 grit) or a fine sanding sponge. This step removes dust nibs and minor imperfections, ensuring each subsequent coat adheres well and contributes to a flat, glassy surface.

Question: Which method provides a more durable finish polycrylic spray or brush?

Answer: The durability of the finish primarily depends on the quality of the polycrylic product itself and the number of thin coats applied, not significantly on whether it was sprayed or brushed. Both methods, when done correctly with proper preparation and multiple thin coats, can yield a very durable finish.

Final Thoughts

The choice between polycrylic spray and brush application is about balancing speed, control, and desired outcome. Spraying excels for large, flat surfaces where a quick, even, stroke-free finish is paramount. Brushing offers superior control for intricate details and smaller projects.

Ultimately, a smooth finish hinges on meticulous surface preparation, applying thin coats, and light sanding between layers, regardless of the tool you choose.