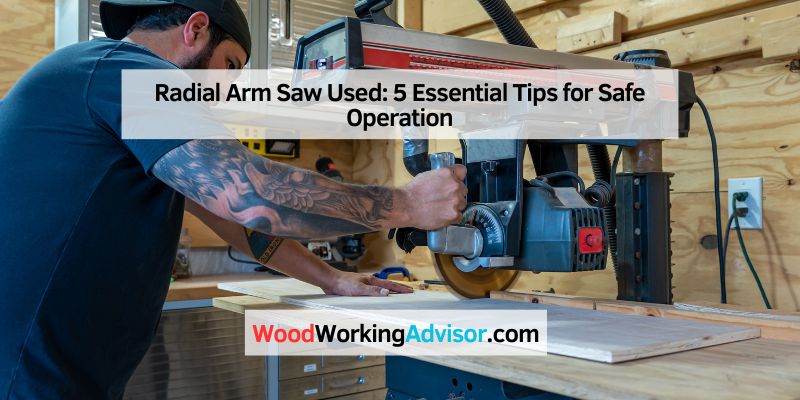

Radial Arm Saw Used: 5 Essential Tips for Safe Operation

A radial arm saw is a versatile woodworking tool used for making precise crosscuts and angled cuts. It features a circular saw blade mounted on a pivoting arm, allowing for flexibility in cutting.

Radial arm saws have gained popularity among woodworkers for their efficiency and accuracy. These tools excel in making repetitive cuts, saving time and effort. Their design allows users to manipulate the saw’s position easily, making it suitable for various projects, from cabinetry to framing.

Safety features and adjustable settings enhance usability, appealing to both novice and experienced craftsmen. Understanding the capabilities of a radial arm saw can significantly improve your woodworking skills, offering a reliable solution for achieving clean and precise cuts every time.

Introduction To Radial Arm Saws

Radial arm saws are powerful tools for woodworkers. They offer precision and versatility. This saw can make various cuts easily. From crosscuts to rip cuts, it handles them all. Understanding its features helps in maximizing its potential.

The Versatility Of Radial Arm Saws

Radial arm saws are known for their adaptability. Here are some common uses:

- Crosscuts: Perfect for cutting wide boards.

- Rip cuts: Can easily cut along the grain.

- Bevel cuts: Great for angled cuts.

- Dado cuts: Useful for making grooves.

Many woodworkers prefer radial arm saws. They can handle large pieces of wood. The adjustable arm allows for various cutting angles. This makes them ideal for both beginners and experts.

Safety First: A Primer

Safety is crucial when using a radial arm saw. Follow these safety tips:

- Always wear safety goggles.

- Keep hands away from the blade.

- Ensure the blade is sharp and properly aligned.

- Use a push stick for small pieces.

- Check that the saw is stable before starting.

Understanding these safety measures helps prevent accidents. Always prioritize safety for a better woodworking experience.

Personal Protective Equipment (PPE)

Using a radial arm saw can be dangerous. Proper Personal Protective Equipment (PPE) is essential. It protects you from injuries. Always wear the right gear before starting any project.

Essential Gear For Protection

Choosing the right PPE is crucial. Here’s a list of essential gear:

- Safety goggles

- Hearing protection

- Dust mask

- Cut-resistant gloves

- Steel-toed boots

Each item plays a key role in keeping you safe. Never skip any of these items. Always prioritize your safety.

Eye And Ear Safety

Protecting your eyes and ears is vital. Here’s how:

| Protection Type | Description |

|---|---|

| Safety goggles | Prevents wood chips and dust from entering your eyes. |

| Hearing protection | Reduces noise from the saw. Prevents hearing loss. |

Always wear safety goggles. They shield your eyes from debris. Use ear protection to guard against loud sounds. Protecting your hearing is just as important as eye safety.

Preparing The Work Area

Preparing the work area is crucial for safe and effective use of a radial arm saw. A well-organized space enhances focus and minimizes risks. Follow these steps to ensure a safe environment.

Clutter-free Environment

A clutter-free workspace is essential. Remove any unnecessary items from your area. Here are some tips:

- Clear off tables and surfaces.

- Store tools in designated places.

- Keep the floor free of debris.

Make sure materials are within reach. This helps avoid distractions and accidents. A tidy space promotes better workflow.

Proper Lighting And Space

Good lighting is vital for precision. Ensure your work area is well-lit. Here are some lighting tips:

- Use bright, even lighting.

- Avoid shadows on the work surface.

- Consider task lights for detailed work.

Space is equally important. Provide enough room to maneuver around the saw. Follow these guidelines:

- Maintain at least 3 feet of clearance around the saw.

- Position the saw on a stable surface.

- Ensure ventilation to avoid dust buildup.

A well-lit and spacious area enhances safety and accuracy. Take these steps seriously for a better woodworking experience.

Inspecting The Radial Arm Saw

Regular inspections keep your radial arm saw in top condition. This ensures safety and accuracy during your projects. A well-maintained saw can last for years.

Routine Check-ups

Routine check-ups are essential for the saw’s performance. Follow these steps for effective inspections:

- Clean the saw after every use.

- Check for any loose parts.

- Inspect the power cord for damage.

- Make sure the saw is properly calibrated.

Schedule a monthly detailed inspection. This helps catch issues before they worsen. Use the following checklist:

| Inspection Item | Status |

|---|---|

| Blade Alignment | ✅ Good / ❌ Needs Adjustment |

| Motor Functionality | ✅ Good / |

Setting Up For The Cut

Proper setup is crucial for a successful cut with a radial arm saw.

Attention to detail ensures safety and accuracy. Follow these steps

to achieve the best results.

Correct Blade Positioning

Positioning the blade correctly affects cut quality.

Follow these steps to set the blade:

- Ensure the saw is unplugged.

- Adjust the blade height to match the workpiece thickness.

- Align the blade with the cut line.

- Check that the blade is parallel to the fence.

Always use the right blade for your material.

A sharp blade reduces friction and improves cuts.

Regular maintenance keeps the blade effective.

Workpiece Alignment And Clamping

Proper alignment ensures accurate cuts.

Here’s how to align and clamp your workpiece:

- Place the workpiece against the fence.

- Check that it is squared to the blade.

- Use clamps to secure the workpiece.

- Double-check alignment before cutting.

Clamping prevents movement during the cut.

Always use appropriate clamps for your workpiece size.

This enhances safety and accuracy during operation.

The Cutting Process

The cutting process with a radial arm saw is both precise and efficient. This tool excels in various tasks, from crosscuts to bevels. Understanding how to control the saw enhances safety and accuracy.

Control And Stability

Control and stability are vital for effective cutting. Follow these tips to maintain control:

- Firmly grip the handle with both hands.

- Stand with feet shoulder-width apart.

- Keep the material secured against the table.

Use a stable surface for the radial arm saw. Ensure the table is level and free of debris. This helps in achieving clean cuts. Regularly check the saw’s alignment. Misalignment can lead to inaccurate cuts.

Avoiding Kickback

Kickback can be dangerous. Prevent it by following these steps:

- Always use a push stick for narrow pieces.

- Make sure the blade is sharp and properly installed.

- Adjust the depth of cut to suit the material.

- Cut with the grain of the wood.

Watch for signs of kickback during cutting. Stay alert and maintain focus. Proper setup and technique reduce risks significantly.

Post-operation Procedures

After using a radial arm saw, follow proper procedures. This ensures safety and keeps the saw in good condition. Two main areas to focus on are cleaning and maintenance, and securing the saw.

Cleaning And Maintenance

Proper cleaning is crucial after each use. It helps extend the life of your saw. Here are some cleaning steps:

- Unplug the saw before cleaning.

- Remove any sawdust and debris.

- Wipe down the table and arm with a damp cloth.

- Check the blade for any damage or build-up.

- Lubricate moving parts as needed.

Regular maintenance is important. Schedule it at least once a month. Here’s a quick maintenance checklist:

| Task | Frequency |

|---|---|

| Inspect blade condition | Monthly |

| Check alignment | Monthly |

| Lubricate parts | Monthly |

| Test safety features | Monthly |

Secure The Saw When Not In Use

Safety is key when the saw is not in use. Always secure it properly. Here are steps to follow:

- Unplug the saw to prevent accidental startup.

- Lower the arm and blade to the table.

- Cover the saw with a protective cover.

- Store the saw in a dry place.

- Keep the area around the saw clean and organized.

By following these procedures, you maintain a safe working environment. Proper care ensures your radial arm saw lasts longer.

Advanced Safety Measures

Using a radial arm saw can be safe with proper precautions. Advanced safety measures protect users from potential hazards. Understanding these measures is crucial for any woodworking project.

Using Blade Guards

Blade guards are essential for safety while using a radial arm saw. They prevent accidental contact with the blade. Here are some key points about blade guards:

- Always check the guard before use.

- Ensure the guard moves freely.

- Keep the guard in place at all times.

Blade guards can be adjustable. They should cover the blade as much as possible. This reduces the risk of injury significantly.

Dust Collection And Management

Dust collection systems are vital for a safe workspace. They keep the area clean and reduce fire hazards. Effective dust management improves visibility and air quality.

| Dust Management Techniques | Benefits |

|---|---|

| Use a Dust Collection System | Minimizes airborne particles |

| Regularly Clean Work Area | Prevents slip hazards |

| Wear a Dust Mask | Protects respiratory health |

Implement these dust management practices. They ensure a safer and cleaner environment. Always prioritize safety while working with a radial arm saw.

Frequently Asked Questions

What Is A Radial Arm Saw Used For?

A radial arm saw is primarily used for cross-cutting and ripping wood. It offers versatility in making precise cuts at various angles. This tool is ideal for woodworking projects, allowing users to cut large pieces easily. It’s especially useful for repetitive cuts, enhancing efficiency in a workshop.

How Does A Radial Arm Saw Work?

The radial arm saw consists of a saw blade mounted on a sliding arm. Users can adjust the blade’s height and angle for different cuts. The arm moves along a track, allowing for smooth and controlled motion. This design enables accurate cuts, making it a favorite among woodworkers.

Is A Radial Arm Saw Safe To Use?

While a radial arm saw can be safe, proper precautions are essential. Always wear protective gear, such as goggles and ear protection. Ensure the blade is sharp and in good condition. Familiarize yourself with the tool’s features to minimize risks and promote safe operation.

What Materials Can Be Cut With A Radial Arm Saw?

A radial arm saw is designed primarily for cutting wood. It can handle softwoods and hardwoods effectively. Additionally, it can cut plywood and composite materials with ease. However, always check the manufacturer’s guidelines for cutting other materials like plastics or metals.

Conclusion

A radial arm saw is a versatile tool that enhances woodworking efficiency. Its ability to make precise cuts is invaluable for both beginners and experts. Embracing this tool can elevate your craftsmanship and save time. Invest in quality blades for optimal performance and enjoy the creative possibilities it offers.