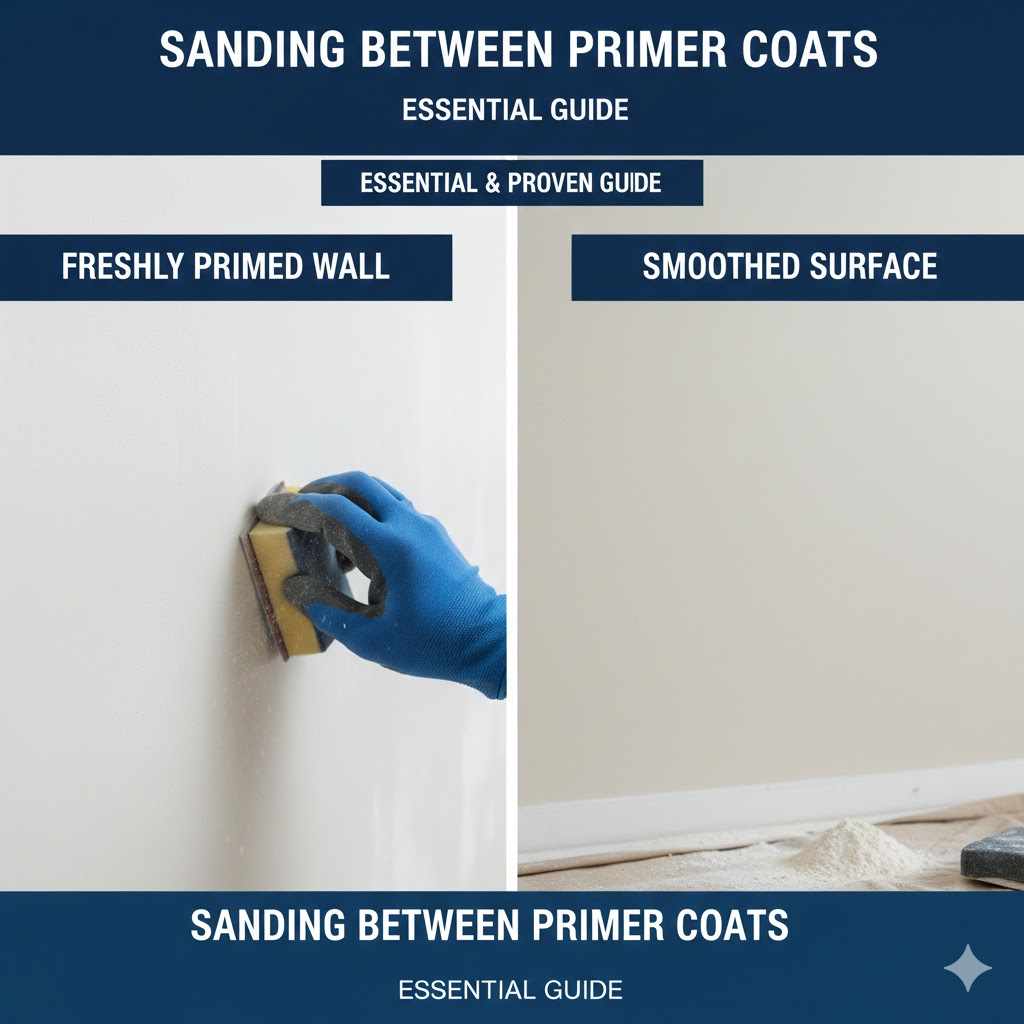

Sanding Between Primer Coats: Essential & Proven

Sanding between primer coats is essential for a professional, smooth finish; it removes surface imperfections left by the first coat, ensures superior adhesion for the topcoat, and leads to a durable, flawless result on your woodworking project.

Welcome to the shop! Have you ever noticed those tiny bumps, drips, or fuzzy bits appearing after you apply the first layer of primer? It can be frustrating when you are chasing that smooth, factory-like finish on your cabinets or furniture. Many beginners wonder if they can skip sanding between primer coats. The short answer is: please don’t!

Sanding between coats is the secret handshake of quality finishing. It isn’t complicated, but doing it right makes all the difference. Today, we will walk through this crucial step, making sure your next painting project looks fantastic and lasts for years. Let’s get started!

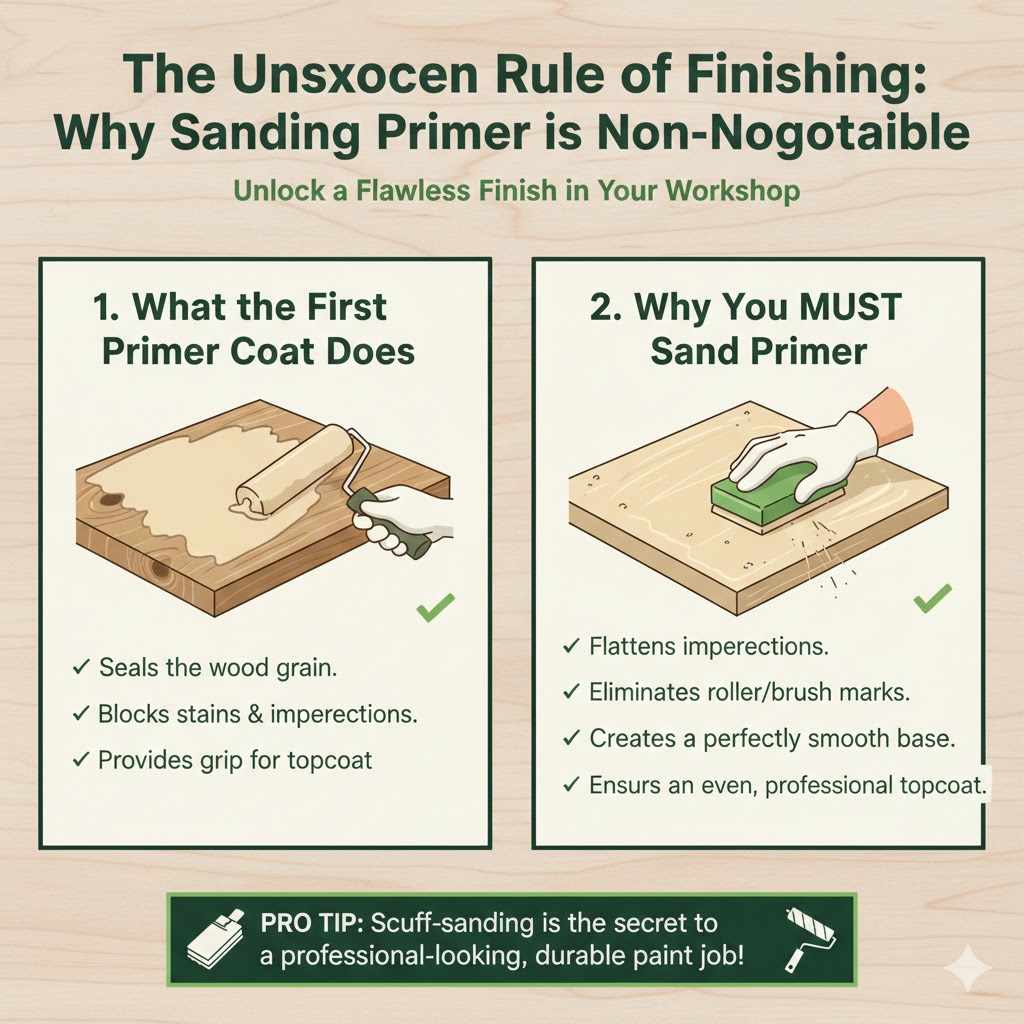

The Unspoken Rule of Finishing: Why Sanding Primer is Non-Negotiable

Think of primer as the glue and the foundation for your final color coat. The first coat of primer does the heavy lifting—it seals the wood, blocks stains, and provides a consistent surface for the paint to grab onto. However, primer rarely goes on perfectly flat, especially when applied with a brush or roller.

This is where the crucial step of sanding comes in. We call this process “scuffing” or “inter-coat sanding.” It’s not about removing all the primer; it’s about flattening the tiny imperfections so your beautiful topcoat lays down evenly. Skipping this means every little bump, roller mark, or dust mote trapped in the first coat becomes permanently magnified under the glossy topcoat.

What Exactly Are We Sanding Away?

When you apply any coating—be it oil-based or water-based primer—a few common issues arise:

- Telegraphing of the Substrate: Even sanded wood has tiny fibers that the primer soaks up, causing them to stand up like stiff hairs (called “grain raising”). Sanding knocks these down.

- Roller Stipple or Brush Marks: Rollers leave a texture, and brushes leave tiny valleys. Sanding levels these high points.

- Dust and Debris: Even in a clean shop, airborne dust settles into the wet primer. These become hard little pimples after drying.

- Overspray or Drips: Minor runs or slightly thicker spots need to be carefully leveled.

Properly sanding between primer coats ensures your final finish achieves maximum durability and a deep, glass-like sheen. High-quality results rely on a flat canvas, and that flat canvas starts here.

Gathering Your Essential Sanding Supplies

You don’t need fancy power tools for this job. In fact, simple hand sanding is often safer and more effective between coats because it helps prevent you from accidentally sanding through the primer into the bare wood beneath. Here are the go-to tools for sanding between primer coats:

Required Sanding Gear

| Tool/Material | Why You Need It |

|---|---|

| Abrasive Grit (Sandpaper) | Fine grit is key. Aim for 180 to 220 grit for general leveling. |

| Sanding Block or Pad | Ensures even pressure across the surface; prevents fingers from digging in. |

| Tack Cloth or Microfiber Towel | Crucial for removing fine sanding dust without adding moisture. |

| Respirator or Dust Mask (N95) | Always protect your lungs from fine sanding dust, even when wet-sanding primer. |

| Personal Protective Equipment (PPE) | Safety glasses are a must. |

Pro Tip on Grit Selection: Never start aggressive. If you use sandpaper finer than 150 grit, it won’t cut imperfections effectively. If you use paper coarser than 220 grit, you might scratch the primer too deeply, requiring more primer on the next coat to hide the scratches. 180 to 220 grit strikes the perfect balance for smoothness and speed.

Choosing Between Dry Sanding and Wet Sanding Primer

The choice between dry sanding (using standard sandpaper) and wet sanding (using very fine, waterproof paper and water) depends on the type of primer you used and how much leveling you need to do.

- Dry Sanding: Best for general leveling, knocking down dust nibs, and smoothing minor roller texture on oil-based or older latex primers. It’s faster but creates more airborne dust.

- Wet Sanding: Excellent for achieving ultra-smooth results, particularly on high-build automotive or epoxy primers, or when using modern, water-based primers. It keeps dust down significantly. You will need waterproof sandpaper (usually marked with P-grade or silicone carbide paper) and a spray bottle of water mixed with a drop of dish soap.

For most beginners tackling furniture or cabinets, a simple dry sanding with 220 grit is the standard, proven method for sanding between primer coats.

Step-by-Step Guide: How to Sand Between Primer Coats Like a Pro

Follow these simple steps meticulously. Remember, slow and controlled movements lead to the best finish. We are aiming for perfection here!

Step 1: Ensure Complete Dryness

This is the most common mistake beginners make: sanding primer that isn’t fully cured. Sanding wet or gummy primer leads to clumping, deep scratches, and peeling. Check the manufacturer’s specifications on the can for recoat times.

As a general rule of thumb, unless the can says otherwise, allow the primer to dry for at least 4 to 6 hours in a temperate environment (around 70°F / 21°C). If you feel any tackiness or sponginess when you press lightly, walk away and come back later!

Step 2: Prepare Your Area and Yourself

Even though we are aiming for smoothness, sanding always produces dust. You want this dust out of the air and off your piece.

- Close nearby doors and turn off fans to minimize airflow carrying dust.

- Put on your N95 mask and safety glasses. This step is crucial for your long-term health!

- Wipe down the surface lightly with a barely damp cloth to remove large debris, but ensure the surface dries completely again before you start sanding.

Step 3: Sanding with the Grain (Always!)

Using your sanding block wrapped with 180 or 220 grit paper, begin lightly sanding the entire surface. The key word here is lightly. We are feathering the high spots, not stripping the primer.

- Use gentle, consistent pressure. Let the grit of the paper do the work.

- Always sand in the direction of the wood grain. If you sand across the grain, you will leave visible scratches that will show up under your final topcoat.

- For rounded edges or complex profiles, lightly “roll” the sanding block around the curves to maintain consistent pressure.

How long do I sand? Keep sanding until the entire surface feels uniform, smooth, and all the shiny spots (the higher texture marks) have turned uniformly dull grey.

Step 4: Inspect and Stop When Ready

It’s easy to over-sand. You are done sanding that section when the surface feels silky smooth to your hand, and the primer color looks flat and matte across the entire area. If you accidentally sand through to the bare wood (called a “burn-through”), don’t panic! This happens to everyone.

If you have a few small burn-throughs on flat areas, use a clean, dry cloth to remove the dust, and then apply a very thin, spot coat of primer just to those areas. Let that spot dry completely (maybe an hour or two), lightly scuff it with the same grit paper, and then proceed to the final cleaning step.

Step 5: The Critical Cleaning Step (Dust Removal)

If there is any residual sanding dust remaining on the surface when you apply your next coat, you’ve essentially just glued tiny rocks onto your project. This is where the tack cloth comes in. Tack cloths are slightly tacky rags treated with a resin that grabs dust.

- Gently wipe the entire surface with a used, slightly less tacky section of the cloth first.

- Use the very tacky center of the cloth last, moving slowly and lifting the dust as you go. Avoid pressing hard, as the resin can transfer.

- After using the tack cloth, immediately inspect your hands and wear a fresh pair of nitrile gloves before handling the piece. The oils on your hands can prevent the next coat from sticking properly.

Once the piece is dust-free, you are ready for your second coat of primer or your first coat of topcoat. Because you followed these steps, the second coat will glide on effortlessly, resulting in a superior professional finish. If you plan on applying a third coat, repeat Steps 1 through 5 using finer sandpaper (around 320 or 400 grit) for this final smoothing pass.

Troubleshooting Common Primer Sanding Issues

Even experienced woodworkers run into roadblocks. Here are solutions for the most common problems encountered when sanding between primer coats.

The Primer Is Soft or Smears

This means the primer wasn’t fully cured (see Step 1). If you notice the primer gathering up in sticky little balls or smearing rather than turning into a fine powder when sanded, STOP IMMEDIATELY.

The Fix: Wait. Allow more time for solvent evaporation. This is often slower in cool or humid environments. If you are using heavy-build primer, it might take up to 24 hours to harden completely. Patience is your best tool here.

I Sanded Through to the Bare Wood (Burn-Through)

This is especially easy on edges and corners where primer tends to build up thin.

The Fix: Address the spot immediately with a small amount of primer applied with a small artist’s brush, just enough to cover the bare spot. Let it dry completely, gently scuff (using 220 grit), clean with a tack cloth, and then apply your full coat of paint or next primer coat.

My Finish Looks Like Orange Peel

While the sanding step fixes texture in the primer, if the primer was too thick initially, it can dry like orange peel (bumpy texture). Sanding a thick layer requires great care.

The Fix: If the orange peel is minimal, 180-grit sanding followed by a subsequent thinner primer coat should fix it. If the texture is severe, you may need to wipe off that whole section with thinner (if using oil-based) or a harsh detergent solution (for water-based), wipe clean, and re-prime thinly.

Dust Sticks to the Tack Cloth

If the dust seems glued to the surface, your tack cloth might be too aggressive or too old.

The Fix: Before touching the project, ‘condition’ your tack cloth by dabbing it onto a scrap piece of wood or tape it gently to your workbench a few times. This slightly reduces its extreme tackiness, allowing it to pick up dust without pulling up too much primer dust.

Best Practices for Primer Adhesion

Sanding between coats serves two vital functions: smoothing the surface and improving adhesion. Adhesion is how strongly the new coating sticks to the underlying layer. When you dry sand the primer with 180 or 220 grit, you create millions of microscopic anchor points—tiny scratches—for the next coat to grip onto. This mechanical bond is critical for long-term durability, especially on pieces that will see heavy use, like kitchen cabinets or high-traffic doors.

When painting over any slick surface—even cured primer—the paint may want to slide off. The purpose of the sanding pass is to “de-gloss” the primer surface, turning a slick surface into a slightly rough, “tooth-ready” surface.

Understanding High-Build vs. Standard Primer

The type of primer you select also impacts your sanding routine. High-build primers are designed to fill minor surface defects (like the scratches left by rough machine sanding on bare wood) much more aggressively than standard primers.

Primer Comparison for Inter-Coat Sanding

| Primer Type | Sanding Goal | Recommended Grit (After Coat 1) |

|---|---|---|

| Standard Latex/Alkyd Primer | Level texture and remove dust nibs. | 220 Grit (Dry Sanding) |

| High-Build/Surfacer Primer | Flatten deep imperfections; aggressive filling. | 180 or 220 Grit (Dry Sanding) |

| Automotive Primer | Achieve glass-like flatness for show-quality sheen. | 320 to 400 Grit (Wet Sanding) |

If you use a heavy-build primer, be extra careful not to sand through the thick coating. Even professionals often refer to online guides from organizations like the National Park Service regarding the preservation of historic finishes, which emphasizes careful surface preparation to protect the substrate below the finish layer.

Final Primer Application Notes

After successfully sanding and cleaning the first coat, your second coat of primer will lay down significantly flatter, consuming less material overall. A successful two-coat prime job often looks better than a poorly executed three-coat job.

When applying the second coat, aim to apply it thinner than the first coat. This prevents the buildup of too many layers between coats, which can lead to a finish that is too thick, causing edges to look rounded or soft. Thin coats dry faster and sand easier!

Expert Tips for Beginner Success

As your mentor in the workshop, Md Meraj wants to share a few secrets that have saved me hours of frustration over the years:

- Work Small Sections: If you are tackling a large bookcase or several doors, focus on sanding one section completely (sand, clean, inspect) before moving to the next. This prevents dust migration across large, freshly sanded areas.

- Use a Dedicated Light Source: Overhead shop lights often hide surface imperfections. Get low, or use an angled shop light. Shine the light across the surface parallel to the wood grain; this angle will immediately highlight every tiny scratch, bump, or dull spot you missed.

- Never Skip the Tack Cloth: I know it seems dusty and messy, but a good tack cloth wipe-down after sanding is what separates hobby work from craftsmanship. Don’t rely on a quick puff of air—dust hangs in the air for longer than you think!

- Don’t Fear the Grit Change: If your final primer coat will be followed by a spray lacquer or a very high-gloss topcoat, use 320 or even 400 grit on that final primer pass. This fine sanding provides maximum smoothness necessary for that mirror-like shine.

Remember, woodworking is a skill built one small, correct step at a time. Sanding between primer coats might feel like an extra chore, but mastering it eliminates the most common finishing frustration beginners face. You are building durability and beauty with every smooth stroke!

Frequently Asked Questions (FAQ) about Sanding Primer

Q1: What grit sandpaper should I use to sand the first coat of primer?

A: For most standard latex or oil-based primers, 180 or 220 grit sandpaper used with a sanding block is ideal. This is coarse enough to level surface defects but fine enough not to leave noticeable scratches.

Q2: Can I sand the primer if it’s still slightly tacky?

A: No. If the primer is tacky, it is not fully cured. Sanding a tacky primer will result in it smearing, clumping up on your sandpaper, and creating deep gouges or peels that you cannot easily fix later.

Q3: Do I really need a tack cloth after sanding?

A: Yes, absolutely! While a brush might remove large clumps, the finest sanding dust remains airborne or settled on the surface. The tack cloth is specifically designed to attract and hold this fine dust, ensuring a clean, contamination-free surface for the next coat.

Q4: What should I do if I sand through the primer down to the bare wood?

A: Don’t worry; this is fixable! Stop sanding immediately. Lightly clean the area, spot-prime the exposed wood only, allow it to dry, very lightly scuff it again with the same grit, and then wipe clean before continuing with your next full coat.

Q5: Is wet sanding mandatory between primer coats?

A: Wet sanding is optional and depends on the primer type and desired finish. It works very well for modern water-based primers or when aiming for an extremely flat, high-gloss final coat (using very fine paper, 400 grit or higher). For general home projects, dry sanding with 220 grit is usually sufficient.

Q6: How much pressure should I use when sanding the primer?

A: Use very light, consistent pressure. You are not trying to remove the primer layer; you are only aiming to flatten the high spots. Too much pressure causes burn-throughs, especially on edges.

Conclusion: The Path to a Professional, Lasting Finish

There you have it! Sanding between primer coats is truly the lynchpin holding a great finish together. It’s the patient, intentional step that elevates your project from looking “home-painted” to looking “professionally finished.” By selecting the right tools—specifically that reliable 180 or 220 grit paper and a trusty sanding block—and meticulously following the process of curing, sanding lightly with the grain, and achieving dust-free cleanliness with a tack cloth, you’ve set yourself up for guaranteed success.

The effort you invest now by carefully sanding between primer coats saves you double the frustration later when trying to hide flaws under that expensive, beautiful topcoat color. Keep practicing patience, respect the drying times, and always remember to wear your mask. With these proven techniques under your belt, you are ready to achieve a finish that is smooth, durable, and something you can be truly proud of. Happy building!