Silicon Carbide vs Aluminum Oxide Sandpaper: Abrasive Showdown

Choosing the right sandpaper can feel tricky, especially when you’re just starting out. The question of Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? often pops up. It’s a common area where many people get a little confused. Don’t worry, it’s simpler than you might think. We’ll break down the differences and help you pick the perfect sandpaper for your projects. Next, we’ll explore each type, so you can make a smart choice.

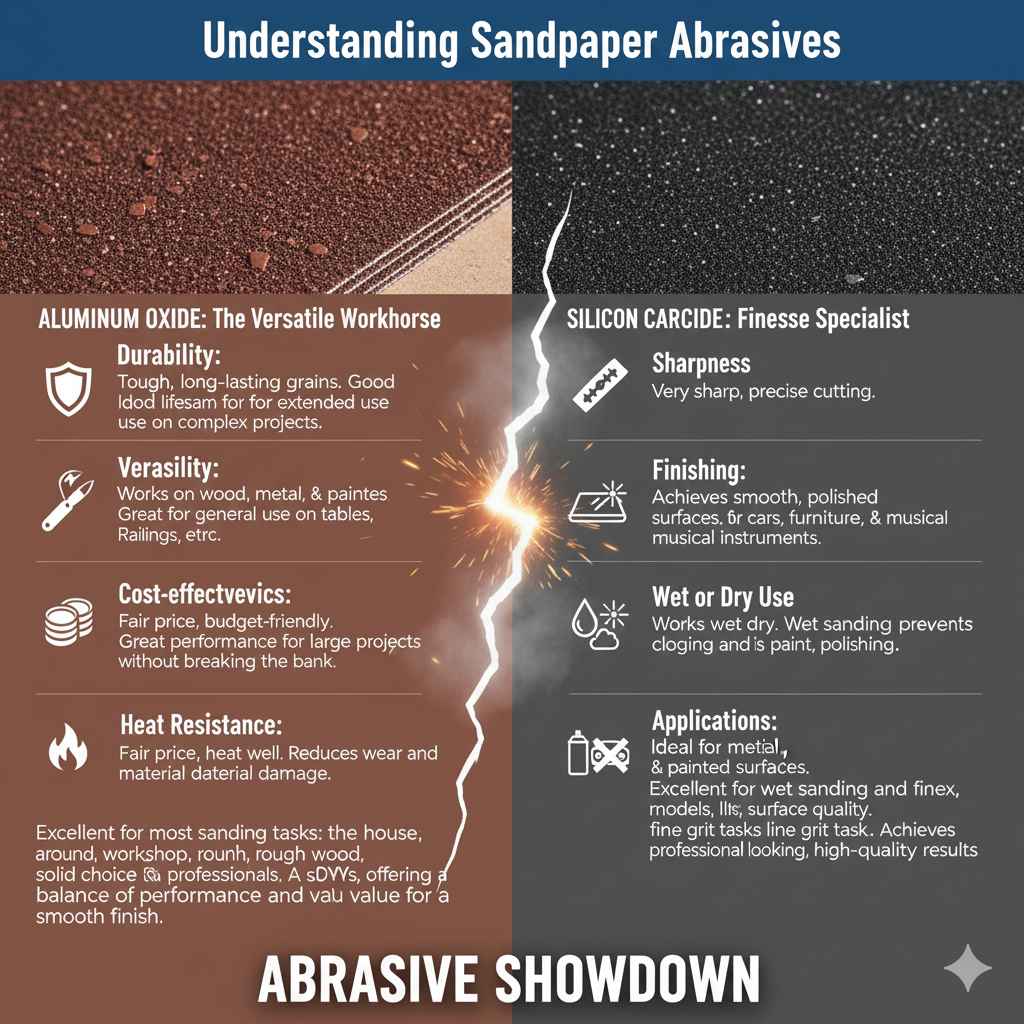

Understanding Sandpaper Abrasives

Before exploring the core differences of Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best?, it is helpful to grasp what sandpaper is made of. Sandpaper isn’t actually made of sand, but rather tiny, sharp particles glued onto a backing material, usually paper or cloth. These particles, called abrasive grains, are what do the work of removing material from a surface. Different types of abrasive grains are used, each with unique properties affecting the sandpaper’s performance.

The grain type, along with the grit size and backing material, determines what the sandpaper is best suited for. This means, the choice between different abrasives has a significant impact on how well the sandpaper works and what projects it’s best for. Exploring the materials is a good step towards making the correct decision.

Aluminum Oxide: The Versatile Workhorse

Aluminum oxide is one of the most common abrasives found in sandpaper. It’s a synthetic material known for its toughness and durability. Aluminum oxide grains are very hard and break down during use. This means, as the sandpaper wears down, fresh, sharp edges are exposed, providing a consistent cutting action.

It is also good at handling heat. This makes aluminum oxide sandpaper a great all-around option for many different applications. You’ll find it in sandpaper for wood, metal, and painted surfaces. It’s often favored for its balance of cost and performance.

- Durability: Aluminum oxide grains are tough and long-lasting, providing a good lifespan for the sandpaper. This means it can handle a lot of work before it needs to be replaced.

The sandpaper’s lifespan is also good for more complex projects. - Versatility: Aluminum oxide sandpaper works well on a variety of materials including wood, metal, and painted surfaces. This makes it a great choice for general use.

For instance, you might use it on a wooden table or a metal railing. - Cost-effectiveness: This type of sandpaper usually comes at a fair price. This makes it a good option if you have a tight budget, or if you’re working on larger projects.

It provides great performance without breaking the bank. - Heat Resistance: Aluminum oxide is good at handling heat generated from the sanding process. This reduces the chance of the sandpaper wearing down quickly or damaging the material you are sanding.

Aluminum oxide sandpaper is excellent for most sanding tasks. You can use it for projects around the house or in your workshop. It handles most materials effectively, from rough wood to removing paint. It is a solid choice for DIYers and professionals. Its toughness ensures it can withstand a variety of sanding tasks. This type of sandpaper provides a great balance of performance and value. It’s a reliable choice for achieving a smooth finish on a variety of surfaces. Aluminum oxide sandpaper is a trusted tool. It will help you get good results every time.

Silicon Carbide: The Finesse Specialist

Silicon carbide is another type of abrasive grain often used in sandpaper. It’s known for being very sharp, and is used for creating smooth finishes. Silicon carbide grains are more brittle than aluminum oxide. This means they break down more easily. The sharp edges are excellent for polishing, smoothing, and achieving a fine finish. It works well on materials like metal, plastic, and painted surfaces, especially for wet sanding. Wet sanding with silicon carbide helps prevent clogging and reduces the risk of scratches.

- Sharpness: Silicon carbide grains are very sharp. This allows for smooth, precise cutting. This is good for fine finishes and polishing. The results are much more refined.

- Finishing: This sandpaper excels at achieving smooth, polished surfaces. You can use it for projects where appearance matters. Think of cars, furniture, or musical instruments.

- Wet or Dry Use: This sandpaper works well whether you use it wet or dry. Wet sanding helps prevent clogging and reduces the amount of dust. This extends the sandpaper’s life.

- Applications: Silicon carbide is ideal for metal, plastic, and painted surfaces. It is excellent for tasks such as removing scratches, blending paint, or polishing.

Silicon carbide sandpaper is perfect for tasks requiring a smooth finish. It’s great for detailed work and projects. You’ll find it useful when working with cars, models, or any project where surface quality is important. It is useful for wet sanding, which helps achieve a flawless finish. The fine grit options are very useful for tasks like removing scratches or polishing surfaces.

Silicon carbide gives you the best results. It makes the surface look great. The results are professional-looking. It is a must-have for achieving a high-quality finish on your projects. This sandpaper will leave you with a smooth and polished surface.

Key Differences and Their Uses

Understanding the key differences between Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? means looking at their performance. Aluminum oxide is the workhorse, offering a balance of durability and versatility. Silicon carbide is designed for jobs where you need a fine finish. Choosing the right one depends on the project. Aluminum oxide usually works well for wood. Silicon carbide is better for metal or paint. In summary, knowing the different types helps you select the correct sandpaper for the job. This helps get good results.

Grit Sizes and Applications

The grit size of sandpaper plays a big role in the type of job it does. Grit size is the number of abrasive particles per square inch of the sandpaper. Lower grit numbers mean coarser sandpaper, which removes material quickly. Higher grit numbers mean finer sandpaper, which creates smoother surfaces.

When considering Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? for grit size, you’ll find different ranges for each type. Aluminum oxide is often available in a wider range of grits. Silicon carbide excels in fine grit applications for polishing. Understanding the grit sizes and which sandpaper to use can make a big difference in achieving your desired outcome.

- Coarse Grits (40-80): These grits are used for aggressive material removal, like taking off old paint or shaping wood. Aluminum oxide is often used for these tasks because of its durability.

- Medium Grits (100-180): Used for general sanding, smoothing surfaces, and preparing for finishing. Aluminum oxide works well here.

- Fine Grits (220-320): Used for creating a smooth surface before applying a finish. Silicon carbide is a good choice for this step.

- Very Fine Grits (400+): Used for polishing and achieving a mirror-like finish. Silicon carbide is preferred for these grits.

Selecting the right grit size is essential for a good finish. Start with a coarser grit to remove material quickly. Then, move to finer grits to smooth the surface. The number of grits you use and the smoothness will determine the look of your project. When choosing between Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best?, consider the grit sizes and the material you’re sanding. You’ll get the best results by choosing the right type of sandpaper. This means the job will be faster and it will also look better.

Wet Sanding vs. Dry Sanding

Another important factor when choosing sandpaper is whether to sand wet or dry. Wet sanding involves using water or a lubricant while sanding. This helps reduce dust and heat. It can also create a smoother finish. Dry sanding is done without any liquid. This works well for most jobs. When comparing Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best?, it’s good to know which type of sanding is suitable for each. Silicon carbide is well-suited for wet sanding. Aluminum oxide can also be used wet, but it’s often used dry.

- Wet Sanding with Silicon Carbide: Wet sanding with silicon carbide is common for automotive work and polishing. The water acts as a lubricant and removes dust. This helps prevent scratches and creates a smooth finish.

- Dry Sanding with Aluminum Oxide: Aluminum oxide is a great choice for dry sanding. It can handle the heat and dust generated during sanding. It’s good for most wood projects.

- Benefits of Wet Sanding: Wet sanding reduces dust and heat buildup. This reduces the risk of clogging the sandpaper and improves the finish. It’s often used for paint and metal.

- Benefits of Dry Sanding: Dry sanding is simpler and faster. It is suited for wood and general sanding tasks. This makes it a time-saving method for common projects.

Deciding between wet or dry sanding affects the outcome of your project. If you want a smooth, polished finish, wet sanding with silicon carbide can be a good choice. Dry sanding with aluminum oxide is great for basic tasks where you need to remove material quickly. You’ll get the best results by matching the sandpaper type with the sanding method and project requirements. It’s a combination of the right technique and sandpaper that determines the final result. Consider the material, finish requirements, and work environment. This helps you select the correct approach for each project. Proper methods will help you get the best outcome for your project.

Cost and Availability

When you’re trying to figure out Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best?, cost and availability are other things to think about. Aluminum oxide sandpaper is usually cheaper. It is easy to find in most stores. Silicon carbide is usually a little more expensive. It may not be available everywhere, depending on the store. However, the price difference is not so big. This may be affected by the amount of sandpaper you buy, or where you get it. Consider these things to pick the right option.

- Cost of Aluminum Oxide: Aluminum oxide sandpaper is generally cheaper. This makes it an affordable option for many projects. Its wide availability also helps.

- Cost of Silicon Carbide: Silicon carbide is sometimes a little more expensive, because of the production. However, it’s a good investment.

- Availability: Aluminum oxide sandpaper is found almost everywhere, in most hardware stores. Silicon carbide might be found in specialized stores.

- Choosing Based on Needs: Choose the sandpaper that works best for your project. Consider both performance and cost. Make a smart choice based on your budget and requirements.

Both types of sandpaper are available, although aluminum oxide is more widespread. Check prices and availability at different stores. You will get the best value by comparing prices. Buying in bulk may reduce the price per sheet. Choose the type of sandpaper that matches your budget and requirements. The best results come from choosing the right sandpaper for your project. Be sure to consider your budget and the types of materials. You will ensure you have the best value for your project.

| Feature | Aluminum Oxide | Silicon Carbide |

|---|---|---|

| Best For | Wood, metal, general use | Polishing, fine finishes, wet sanding |

| Durability | High | Medium |

| Grit Range | Wide | Fine to Very Fine |

| Cost | Lower | Higher |

Choosing the Right Sandpaper for Your Projects

Choosing the correct sandpaper can make a big difference in the quality of your project. The main factor when you are choosing between Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? is the material you’re working with. Then think about the finish you want to achieve. Aluminum oxide sandpaper is a good choice for general-purpose sanding tasks. Silicon carbide is great for smooth, polished surfaces. Using the right type of sandpaper ensures a great outcome.

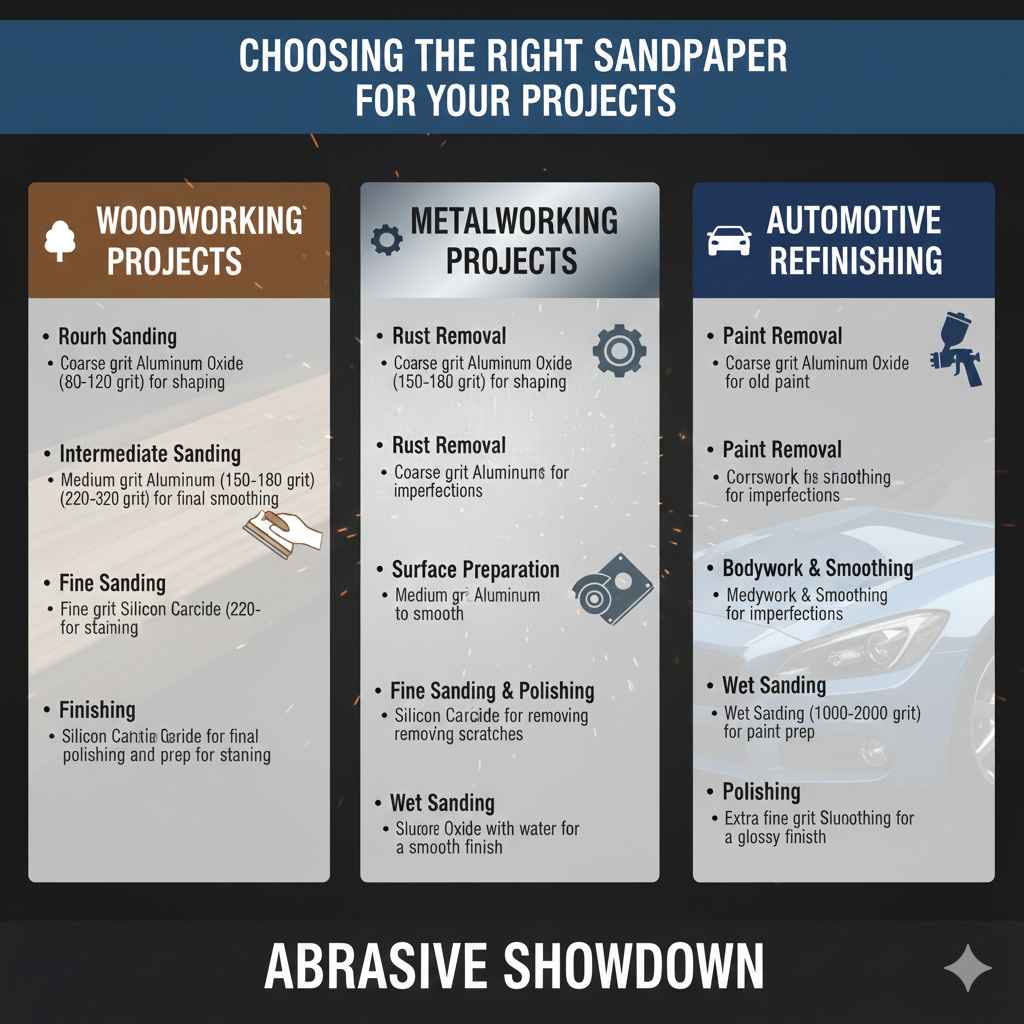

Woodworking Projects

Woodworking often involves sanding. You might have to sand rough wood, or you could need to prepare wood for a finish. The ideal sandpaper often depends on the type of wood and the project’s requirements. Aluminum oxide sandpaper is often a good choice. Silicon carbide is well-suited for the final touches. The choice between Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? is based on the project. You must think about the wood and finish.

- Rough Sanding: Start with aluminum oxide. Use a coarser grit (e.g., 80-120 grit) to remove material and shape the wood. This works well for taking out rough edges.

- Intermediate Sanding: Use a medium grit (e.g., 150-180 grit) aluminum oxide to smooth the surface. This prepares the wood for the finish.

- Fine Sanding: Use a fine grit silicon carbide (e.g., 220-320 grit) for the final smoothing. This provides a surface ready for staining or painting.

- Finishing: Use silicon carbide for the final polishing. This helps achieve a smooth, professional finish.

For woodworking projects, you should have both types of sandpaper. Aluminum oxide sandpaper is perfect for removing material, shaping, and smoothing. Silicon carbide works well for the fine details and the finishing touches. Always start with a coarser grit and switch to finer grits. This helps get a great outcome. This combination of sandpaper ensures you create a high-quality outcome. Choose the correct grit and type to meet your needs.

Metalworking Projects

Metalworking often needs sanding to remove rust, scratches, and prepare the metal for painting. The choice between Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? depends on your goals. Silicon carbide works great for these tasks. Aluminum oxide is another good choice if you’re working on bigger projects. The sanding process, and the result, will be better if you use the correct sandpaper.

- Rust Removal: Start with a coarse grit aluminum oxide to remove rust and other imperfections. This prepares the metal for sanding.

- Surface Preparation: Switch to a medium grit aluminum oxide to smooth the surface. This helps prepare the metal for the paint.

- Fine Sanding and Polishing: Use silicon carbide for the final sanding and polishing. This removes scratches and makes the metal look smooth.

- Wet Sanding: Use wet sanding. You can use silicon carbide with water or a lubricant. This prevents scratches and creates a smooth finish.

Using the right sandpaper is key for metalworking. Aluminum oxide is great for the tough tasks. Silicon carbide is great for polishing. Using the correct sandpaper, and knowing the right grit sizes, ensures a great finish. You will make the metal look better. Whether you are removing rust, smoothing surfaces, or preparing for paint, these two types of sandpaper provide a good outcome. Using the correct type of sandpaper helps achieve the outcome you want.

Automotive Refinishing

Automotive work involves paint removal, bodywork, and polishing. The choice between Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? affects the finish. Silicon carbide is usually preferred for automotive work, especially for wet sanding. Aluminum oxide can also be used, mainly for removing the initial paint. The sanding procedure, and the final outcome, will be improved if the proper sandpaper is used.

- Paint Removal: Use coarse grit aluminum oxide for removing old paint and shaping bodywork. This prepares the surface for the next steps.

- Bodywork and Smoothing: Medium grit aluminum oxide will help smooth out imperfections. This gets the surface ready for painting.

- Wet Sanding for Paint Prep: Use silicon carbide for wet sanding. Use grits from 1000 to 2000. Wet sanding reduces scratches and prepares the surface for paint.

- Polishing: Use extra fine grit silicon carbide for the final polishing. This gives a smooth, glossy finish.

For automotive work, select sandpaper that fits your needs. Aluminum oxide is useful for tough tasks, like removing the old paint. Silicon carbide is very useful for getting a great paint finish. Using both types of sandpaper, along with wet sanding, helps achieve a smooth finish. This guarantees a smooth, glossy outcome. Properly preparing the surface ensures the paint lasts. This creates a good outcome. The correct sanding procedure ensures a high-quality finish.

Frequently Asked Questions

Question: What is the main difference between aluminum oxide and silicon carbide sandpaper?

Answer: Aluminum oxide is more durable and is excellent for general-purpose sanding on wood, metal, and painted surfaces. Silicon carbide is sharper and best for achieving smooth finishes, particularly when wet sanding on paint or plastics.

Question: Which type of sandpaper is better for wet sanding?

Answer: Silicon carbide is the preferred choice for wet sanding because it is less likely to clog. This results in a smoother finish.

Question: Can I use aluminum oxide sandpaper for polishing?

Answer: Aluminum oxide can smooth surfaces. However, it’s not the best choice for polishing. Silicon carbide provides a smoother finish and is better suited for polishing.

Question: Is silicon carbide sandpaper suitable for woodworking?

Answer: Silicon carbide sandpaper can be used for finishing and polishing wood, but it’s not the best choice for heavy material removal. For woodworking, it works well in the finishing steps to get a smooth surface.

Question: How do I choose the right grit size for my project?

Answer: Start with a coarser grit to remove material quickly. Then, gradually switch to finer grits for smoothing the surface. Match the grit to the material and the desired finish.

Final Thoughts

Choosing between Silicon Carbide vs Aluminum Oxide Sandpaper: Which Works Best? means looking at the job you need to do. Aluminum oxide sandpaper is a sturdy option. It’s great for taking off old paint, shaping wood, and other general tasks. Silicon carbide is perfect for getting smooth finishes, especially for metal or paint, where a smooth surface is needed. These two types of sandpaper are very useful. They can handle any project.

Use aluminum oxide for its strength and silicon carbide when you need a smooth surface. This lets you get the results you want. Remember to think about what you are working on, and choose the correct sandpaper.