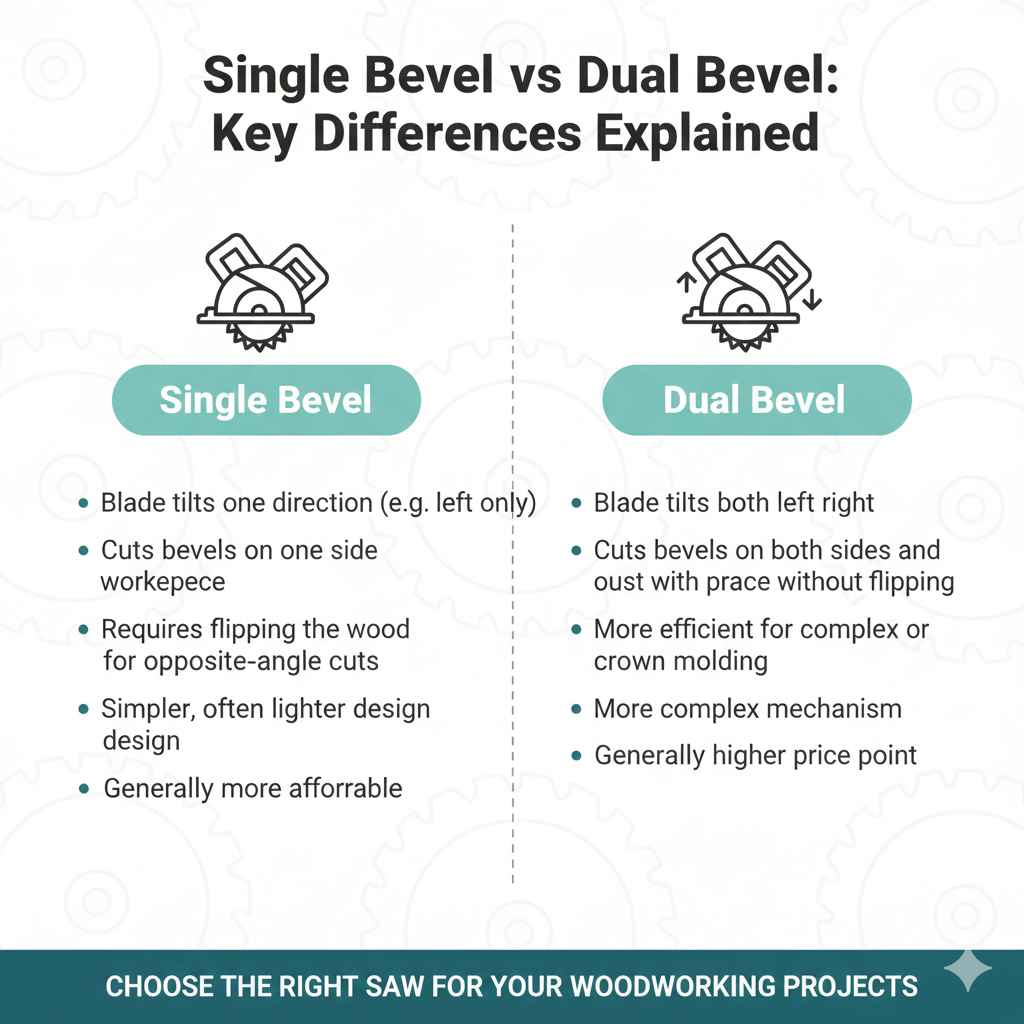

Single Bevel vs Dual Bevel: Key Differences Explained

Figuring out the Single Bevel vs Dual Bevel: Key Differences can feel tricky at first, especially when you’re starting out. There are lots of terms and details to learn! But don’t worry, it’s easier than it sounds. This post will break down everything in a simple way, step by step. We’ll explore what these terms mean and how they apply in real situations. Let’s get started and clear up any confusion you might have.

What Are Bevels and Why Do They Matter?

Bevels are angled edges on a tool or object. Think of them as slopes. They’re important because they affect how tools work, how things fit together, and how strong the resulting joints are. Understanding bevels helps you choose the right tool for the job. They’re used in a variety of crafts, from woodworking to metalworking, and even in everyday objects. Getting the bevel right can make a huge difference in the quality and durability of the finished product. Proper beveling also makes tools more effective and efficient, leading to better results. This section will explore the fundamental concept of bevels and show you why they are essential.

Single Bevel Defined

A single bevel has an angled edge on only one side. Imagine a knife where the sharp edge is created by grinding down one side, leaving the other side flat. This is a single bevel. It’s often easier to create and maintain than a dual bevel. Single bevels are commonly used in situations where a strong, sharp edge is needed. They are particularly effective when the goal is to cut or shape materials with precision. For instance, chisels and some types of plane blades often have a single bevel. The angle of the bevel determines how the tool cuts; a steeper angle creates a sharper, more delicate edge, while a shallower angle is more durable.

Sharpening: Single bevel tools are generally easier to sharpen. You only need to work on one side, which simplifies the process.

Edge Strength: The edge can be quite strong, especially with a steeper angle, making it suitable for tough materials.

Examples: Think of a Japanese chisel or a plane blade. The bevel angle is specific and designed for a particular use.

Uses: Single bevels are great for cutting, shaping, and removing material where precision is important.

When you look at a single-bevel tool, the flat side is the reference surface. This side sits flat against the material. This ensures that the bevel angle does the work of cutting. The angle dictates the sharpness and how the tool interacts with what you’re working on. Over time, the angle might need maintenance to keep the tool working well.

Dual Bevel Defined

A dual bevel has angled edges on both sides of the tool. Picture a knife with a symmetrical point, where both sides of the blade are ground to create the edge. This design offers a balance of strength and cutting ability. Dual bevels are often used when a tool needs to be versatile, handling different types of cuts and materials. The angle on each side can vary, depending on the tool’s intended purpose. The symmetry helps with tool balance, so it’s good for jobs where accuracy is important, but often the blades need to be precisely aligned. It also determines how the tool bites into the material.

Versatility: Dual bevels can be used for a wider range of tasks compared to single bevels.

Balance: The design helps balance the tool, making it easier to control during use.

Examples: Many Western-style knives and chisels have dual bevels.

Cutting Styles: The dual bevel allows for different cutting styles and techniques.

The angles on a dual bevel are typically the same on both sides, making the blade symmetrical. However, they don’t have to be. Some tools may have slightly different angles on each side for specific tasks. The user has more control. The tool’s effectiveness depends on the consistent angles on both sides. A well-maintained dual bevel edge will stay sharper longer because the cutting force is more evenly distributed.

Key Differences in Performance and Application

The performance of a tool with a single bevel versus a dual bevel really depends on what you want to achieve. Each design has benefits. Single bevels tend to excel in situations where precise cutting is required, while dual bevels are often more versatile. This section will compare the key differences in how these bevels function and how they’re applied in various scenarios. Understanding these differences allows you to choose the perfect tool for your project.

Cutting Action and Precision

Single bevels shine when precision is the main focus. Because the flat side acts as a guide, they provide extremely accurate cuts. Imagine you’re making a very small, angled cut; the flat side stays flat against the material, guiding the blade precisely. Dual bevels offer a more balanced cutting action. They can be easier to control when you want to make general cuts. However, they may not offer the same degree of accuracy as their single bevel counterparts. Single bevels require some practice to master, but once you do, they offer exceptional control. They are more effective at making consistent cuts.

Accuracy of Single Bevels: The flat side provides a reference surface, leading to greater accuracy. The cuts are often very clean.

Precision Cutting: Single bevels are ideal for tasks where you need to remove tiny amounts of material precisely.

Dual Bevel Control: Dual bevels offer a more neutral cutting action, which can be useful in various situations.

Precision Requires Practice: Both types of bevels need practice, but the angle and edge on single bevels is more sensitive.

The cutting action of single bevel tools is somewhat directional. It’s important to orient the tool correctly to achieve the desired cut. Dual bevels generally offer more freedom in terms of the direction of the cut. The user has more flexibility. The angle of the bevel affects the cutting action. The angle determines how easily the tool cuts through the material.

Material Suitability

The type of material you’re working with plays a big role in which bevel is best. Single bevels can be great for hardwoods and materials that need a fine edge, such as wood. Dual bevels work well with many materials, including softwoods, plastics, and metals. The choice often depends on the level of precision needed. Different materials call for different strategies. The tools will perform differently based on material type. The right tool depends on both the material and the job.

Hardwood vs. Softwood: Single bevels often perform well on hardwoods, creating very clean cuts.

Versatility of Dual Bevels: Dual bevels can handle a wider range of materials, including softwoods, plastics, and some metals.

Material Hardness: Softer materials tend to work well with both single and dual bevels.

Tool Durability: Both bevels hold up well, but the bevel angle and tool itself needs to match the material.

Some tools are better for specific jobs. The best type of bevel depends on the material’s properties and the desired outcome. The tool needs to match the material. Both blade types can get damaged. Choose the bevel that suits your job. The best choice is influenced by the characteristics of the material.

Ease of Use and Sharpening

Single bevel tools tend to be easier to sharpen, because you only need to work on one side. This can make them a great choice for beginners. However, it also means that the edge is very sensitive, and it can dull more quickly. Dual bevels require sharpening on both sides, which can be a bit more involved. Both bevels need regular maintenance, however. The choice of tool type often comes down to personal preference and the tasks that you regularly do.

Sharpening Simplicity: Single bevels are generally easier to sharpen because you focus on one side only.

Sharpening Complexity: Dual bevels require more careful attention because of the need to sharpen both sides.

Edge Durability: The durability of the edge depends on the material, the angle, and how you use it.

User Skill: Both require practice and skill for sharpening and upkeep.

Proper maintenance is important to keep tools sharp, safe, and effective. Regular sharpening is essential for both single and dual bevel tools. The process of sharpening both types can become easier with practice. Choosing the tool is influenced by the user’s skillset. The right tool makes the job easier.

Real-World Examples and Case Studies

To really see the difference between Single Bevel vs Dual Bevel: Key Differences, let’s explore some examples of how they are used. The examples highlight how each type of bevel works in real-world situations, showing their strengths. We’ll examine tasks, tools, and the results to help you understand which bevel is best for certain jobs.

Woodworking Projects

In woodworking, the right tool is key to a beautiful finish. Consider a cabinet maker, using chisels for intricate details. A single bevel chisel might be used for fine paring cuts. The flat side guides the cut with amazing precision, perfect for fitting joints. A dual bevel chisel is well suited for chopping out mortises because it offers a sturdy cutting edge, and it’s versatile. In this area, the tool of choice depends on the project’s details and the type of joint being created. The choice between a single and a dual bevel is influenced by the level of detail.

Case Study 1: A craftsman is building a fine wooden box, and he uses a single bevel chisel to clean up the corners of dovetail joints. The precise angle allows him to remove tiny amounts of wood with ease, resulting in a perfect fit.

Case Study 2: For building a dining table, a dual bevel chisel is used to remove wood when creating the mortise. It is then used for the clean-up work on the edges of the tenon.

Woodworkers often have sets of both single and dual bevel chisels to handle different tasks. They choose the tool best for the job. The projects showcase how the best tools help to produce quality work. The selection of tools directly impacts the outcome of the job.

Metalworking Applications

Metalworkers often use single-bevel tools, such as Japanese chisels, for precision work. Dual bevels are also common for tasks such as shaping and cutting. The best type of bevel for metalworking often depends on the type of metal and the cutting task. Proper sharpening is important. The tools can be used for shaping, cutting, and deburring. The choice between single and dual bevels helps to determine the outcome. The selection of tools directly impacts the outcome of the job.

Case Study 1: A metal worker is creating a decorative metal sculpture. A single bevel chisel is used to clean up the edges and remove small metal pieces for detail. The precision of the tool helps to form the desired shape.

Case Study 2: An engineer is preparing metal sheets for an industrial project, utilizing a dual bevel chisel to trim the metal. The dual bevel allows for a more general use.

Choosing between a single and dual bevel impacts the result. Both tool types have a place in metalworking. The choice depends on the details of the job and the materials involved. The appropriate choice of tool is key to success.

Cutting Tools

Many cutting tools also use different bevels. For example, a single-bevel knife, like a Japanese kitchen knife, is designed for precise slicing. The flat side of the blade helps the knife glide through the food. A dual-bevel knife, like a general-purpose chef’s knife, works well in a variety of situations. The tool depends on the user’s needs. The choice is influenced by the tasks.

In the kitchen, the right knife makes cooking easier. The best choice is determined by the tasks. Both types are useful. The tools help to create good food.

Choosing the Right Tool for the Job

Picking the best tool from the Single Bevel vs Dual Bevel: Key Differences involves thinking about the job’s needs. You have to consider the material, the level of precision needed, and your own skill. The right choice is the one that best suits the job you’re doing. Let’s explore how to make the best choice. This will ensure that you have the right tool to get the job done efficiently.

Assessing the Task

Before selecting a tool, consider the task. What are you going to do? Are you looking for detail, or do you need a tool that can do several things? Single bevels are the answer when you need precision and control, such as when doing detailed woodworking. Dual bevels are often better for general tasks, allowing you to cut with the tool more easily. Consider what needs to happen. The best tool choice will depend on the details of the job.

Detailed Work: If you need to remove small pieces, a single bevel is the better option.

Versatile Cuts: For different cuts and a wide range of tasks, choose a dual bevel.

Cutting Action: The best tool will depend on the action needed.

Project Type: Is it a detailed project or general? The best tool will depend on this.

The best tool depends on the job. The best tools have the correct bevel. The choice directly affects the results. The goal influences the decision.

Considering the Material

The type of material you’re working with helps determine the right tool. Softwoods may work well with both bevels. Hardwoods may need the precision of a single bevel. The goal is to work with the tool that cuts the material most efficiently. The right tool helps with the work. The choice is determined by the material. This will help you get the best outcomes.

Soft Materials: Dual bevels may work well with these.

Hard Materials: Single bevels are often the preferred choice.

Material Characteristics: What material are you using?

Tool Performance: The tool’s effectiveness will depend on this.

You can achieve the best result by making the right choice. Consider the material when selecting the tool. The best tool helps to get the outcome you desire. The best tool matches the job.

Skill Level and Maintenance

Your skill and the tool’s upkeep are important. Single bevels can be easier to sharpen, which makes them good for beginners. Dual bevels take more work but offer versatility. Knowing how to sharpen and care for your tools is essential. Your skill will influence your choice. Both tools require proper maintenance. The correct tool will help you to get the best outcomes.

Skill Level: Consider what you know before you start.

Sharpening Skills: Sharpening can impact your choice.

Regular Care: Both tools require care and sharpening.

Maintenance Tasks: What is required for proper tool care?

Proper care of a tool is essential. The right choice helps you get the results you want. The tool you choose /,,bsamust match your skill. You will achieve better results with good maintenance.

Frequently Asked Questions

Question: What is a single bevel?

Answer: A single bevel is an angled edge that is ground on only one side of a tool or blade. This design provides precision and is often used for tasks that require careful cuts.

Question: What is a dual bevel?

Answer: A dual bevel features angled edges on both sides of the tool or blade. This design helps the tool to perform different cutting tasks and offers more versatility.

Question: Are single bevel tools easier to sharpen?

Answer: Yes, single bevel tools are generally easier to sharpen because you only need to work on one side of the edge. This simplifies the sharpening process.

Question: Which type of bevel is better for beginners?

Answer: Single bevel tools are often easier for beginners, due to the simpler sharpening process. However, both types require practice and skill to use effectively.

Question: What are some examples of dual bevel tools?

Answer: Examples of dual bevel tools include many Western-style knives and chisels. These tools are designed for a variety of tasks where versatility is needed.

Final Thoughts

In this post, we explored the Single Bevel vs Dual Bevel: Key Differences and discovered the features of each. We saw that single bevels are great for precise work. Dual bevels provide versatility for cutting tasks. The best tool depends on the job. The key is to match the tool to the task, material, and your skill level. Now that you have this information, you can explore the world of tools with confidence. Consider your projects and choose the right tools. With practice, you’ll become more skilled in the craft of cutting!