Skill Saw Vs Table Saw: Cutting-Edge Comparison

A skill saw is a handheld circular saw, while a table saw is a stationary tool for precise cuts. Each has distinct advantages for different woodworking tasks.

Choosing the right saw can significantly impact your woodworking projects. Skill saws offer portability and versatility, making them ideal for on-site cuts. They are great for quick, rough cuts and can easily handle various materials. On the other hand, table saws provide stability and precision, perfect for making straight cuts on larger pieces.

Their design allows for consistent results and intricate work, such as dados and bevels. Understanding the unique features of each saw helps you select the best tool for your specific needs, enhancing both efficiency and quality in your woodworking endeavors.

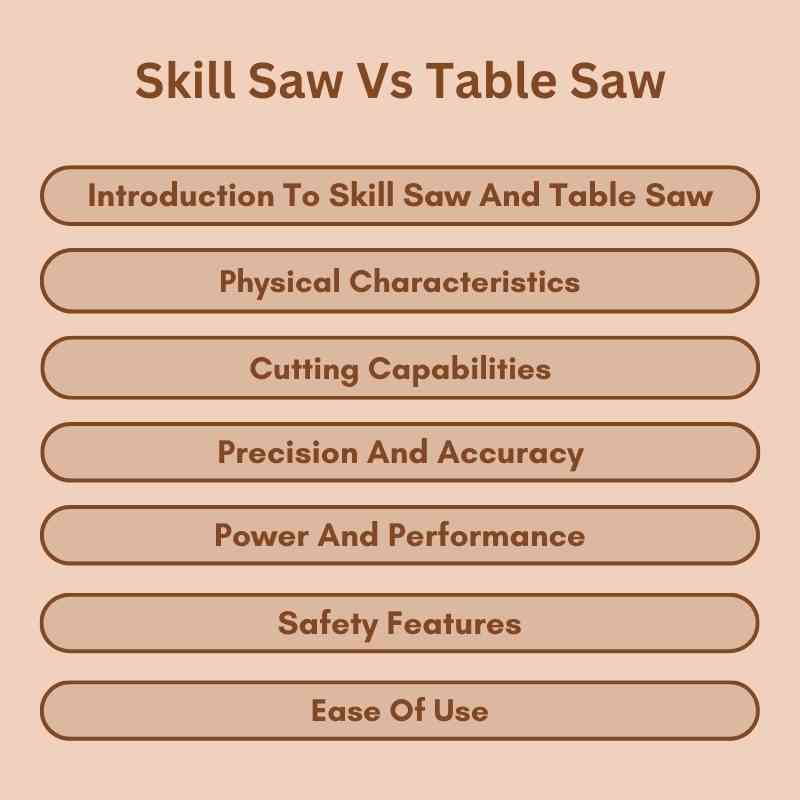

Introduction To Skill Saw And Table Saw

The world of woodworking features two essential tools: the Skill Saw and the Table Saw. Each tool serves a unique purpose. Understanding their differences helps in choosing the right one for your projects. Let’s explore their primary functions and historical development.

Primary Functions

The Skill Saw and Table Saw excel in different tasks. Here’s a quick comparison:

| Tool | Primary Function |

|---|---|

| Skill Saw | Portable cutting tool for various materials |

| Table Saw | Stationary tool for precise, straight cuts |

- Skill Saw: Ideal for cutting plywood and lumber.

- Table Saw: Best for making repeat cuts and precise angles.

The Skill Saw is lightweight. It can be easily moved. The Table Saw is heavier and stays in one place. Users can set the height and angle of the blade on a Table Saw for accuracy.

Historical Development

The Skill Saw has roots dating back to the early 20th century. It was designed for portability and efficiency. The first Skill Saw was invented in 1923 by Edwin P. Holmes. It changed how carpenters approached cutting tasks.

The Table Saw has a longer history. It evolved from hand saws used in workshops. The first known Table Saw appeared in the 18th century. Craftsmen used it for accurate woodworking tasks.

Both tools have improved over time. Modern technology has made them safer and more efficient.

Physical Characteristics

Understanding the physical characteristics of a Skill Saw and a Table Saw is crucial. Each tool has unique features that affect its use. This section will explore the design, build, portability, and space requirements of both tools.

Design And Build

The design and build of both saws vary significantly:

| Feature | Skill Saw | Table Saw |

|---|---|---|

| Type | Handheld | Stationary |

| Blade Type | Circular Blade | Table Mounted Blade |

| Cutting Capacity | Limited Depth | Greater Depth |

| Material | Lightweight | Heavy-Duty |

The Skill Saw is lightweight and portable. It’s perfect for cutting at various angles. The Table Saw is sturdy and designed for precision cuts. It excels in woodwork projects requiring high accuracy.

Portability And Space Requirements

Portability and space are key factors in choosing a saw:

- Skill Saw

- Lightweight design

- Easy to carry

- Ideal for job sites

- Table Saw

- Requires a dedicated workspace

- Heavier and less portable

- Need a stable table or stand

The Skill Saw easily fits in small spaces. It’s perfect for mobile projects. The Table Saw needs more room. It’s best for workshops with ample space.

Cutting Capabilities

Understanding the cutting capabilities of a Skill Saw and a Table Saw is essential for woodworkers. Each tool has unique strengths. Knowing how they differ helps in choosing the right one for your project.

Types Of Cuts

Both saws offer different cutting options. Here’s a breakdown:

| Type of Cut | Skill Saw | Table Saw |

|---|---|---|

| Cross Cuts | Yes | Yes |

| Rip Cuts | Yes | Yes |

| Miter Cuts | Limited | Yes |

| Bevel Cuts | Yes | Yes |

| Compound Cuts | Limited | Yes |

The Skill Saw excels in portability and versatility. It’s great for quick cuts. The Table Saw shines in precision and stability. It’s perfect for complex cuts.

Material Compatibility

Both saws handle various materials, but there are differences.

- Skill Saw:

- Wood

- Plywood

- Composite materials

- Table Saw:

- Hardwood

- Softwood

- Melamine

- Thin sheets

The Skill Saw is ideal for construction sites. It works well in tight spaces. The Table Saw is better for workshop settings. It provides clean and accurate cuts.

Precision And Accuracy

Precision and accuracy are vital in woodworking. They ensure clean cuts and perfect fits. Choosing between a skill saw and a table saw impacts these factors. Understanding their differences can elevate your projects.

Measurement And Guides

Accurate measurements are essential for great results. Both saws have unique methods for guiding cuts.

- Table Saw: Features a fence system for straight cuts.

- Skill Saw: Relies on user’s hand for guiding.

Table saws often come with a built-in ruler. This allows for easy and quick measurements. Skill saws require measuring tapes for accuracy.

Using a guide with a skill saw can help. A straight edge or clamp can enhance precision. This method ensures straight cuts but needs practice.

Consistency Across Cuts

Consistency is key in woodworking. Table saws excel in making repeated cuts.

| Feature | Table Saw | Skill Saw |

|---|---|---|

| Repetitive Cuts | High | Moderate |

| Adjustability | Easy | Requires skill |

| Setup Time | Quick | Longer |

Table saws maintain consistent depth and width. This makes them ideal for larger projects. Skill saws can produce consistent cuts but require practice.

Mastering a skill saw takes time. Users must learn to control the tool well. With experience, you can achieve great accuracy.

Power And Performance

Power and performance are crucial factors in choosing between a skill saw and a table saw. Each tool has unique strengths that impact your projects. Understanding their motor strength and efficiency can help you make the best choice.

Motor Strength

The motor strength of a tool determines its cutting ability. Here’s a quick comparison:

| Tool | Motor Power | Best Use |

|---|---|---|

| Skill Saw | 15 Amps | Cutting through thick materials |

| Table Saw | 1.5 – 5 HP | Precision cuts on larger sheets |

Skill saws excel in portability. They are great for outdoor jobs. Table saws provide more power for larger projects. Choose based on your specific needs.

Speed And Efficiency

Speed affects how quickly you complete your work. Efficiency ensures you use your time wisely.

- Skill Saw:

- Fast and agile for quick cuts.

- Great for moving from one spot to another.

- Table Saw:

- Offers consistent speed for repetitive cuts.

- Ideal for cutting multiple pieces accurately.

Both tools have their speed advantages. Skill saws offer mobility. Table saws provide stability for complex tasks.

Safety Features

Safety is crucial when using any power tool. Both the Skill Saw and Table Saw have unique safety features. Understanding these can help prevent accidents and injuries.

Built-in Safety Mechanisms

Both tools come with built-in safety mechanisms. Here’s a quick overview of their features:

| Tool | Safety Feature |

|---|---|

| Skill Saw |

|

| Table Saw |

|

Recommended Safety Gear

Using the right safety gear enhances protection. Here’s a list of essential equipment:

- Safety Glasses: Protect eyes from debris.

- Hearing Protection: Shields ears from noise.

- Dust Mask: Prevents inhalation of dust particles.

- Work Gloves: Offers grip and protects hands.

- Steel-Toed Boots: Safeguards feet from falling objects.

Choose appropriate gear for your task. Always prioritize your safety while working with power tools.

Ease Of Use

Understanding the ease of use is vital for both beginners and experts. Skill saws and table saws offer unique benefits. Knowing how each tool operates helps you choose the right one.

Learning Curve

The learning curve differs for skill saws and table saws. Here’s a quick overview:

| Tool | Learning Curve | Best For |

|---|---|---|

| Skill Saw | Short and straightforward | Cutting angles and curves |

| Table Saw | Longer, requires practice | Making straight cuts |

Skill saws are easier to handle. They allow for quick cuts. Table saws need more setup time. Learning to adjust the blade takes practice. Choose based on your project needs.

Maintenance And Cleaning

Maintenance and cleaning are crucial for both tools. Regular care keeps them running smoothly. Here’s how each fares:

- Skill Saw:

- Clean the blade after each use.

- Inspect the motor for dust buildup.

- Store it in a dry place.

- Table Saw:

- Wipe down the surface regularly.

- Check the alignment of the blade.

- Keep the area free of debris.

Both tools require attention. Proper maintenance prolongs their lifespan. Choose a tool that fits your cleaning routine.

Cost Considerations

Understanding the costs of a Skill Saw and a Table Saw is essential. Prices can vary widely. This section covers the price range and long-term value of each tool.

Price Range

Both Skill Saws and Table Saws offer different price points. Here’s a quick overview:

| Tool Type | Price Range |

|---|---|

| Skill Saw | $50 – $300 |

| Table Saw | $200 – $2,500 |

Skill Saws are more affordable. They fit tight budgets well. Table Saws are pricier but offer more features. Consider your needs before deciding.

Long-term Value

Long-term value matters for any investment. Here’s how both tools compare:

- Skill Saw:

- Portable and easy to store.

- Good for small projects.

- Lower maintenance costs.

- Table Saw:

- More accurate cuts.

- Ideal for larger projects.

- Higher resale value.

Choosing between the two depends on your needs and budget. A Skill Saw saves money upfront. A Table Saw can save time and effort long-term.

User Recommendations

Choosing between a Skill Saw and a Table Saw can be tough. User recommendations help guide choices. Different tasks may favor one tool over the other. Here’s what users say about each saw.

Professional Vs DIY Projects

Professionals and DIY enthusiasts have different needs. Here’s how they compare:

| User Type | Recommended Tool | Reasons |

|---|---|---|

| Professional | Table Saw |

|

| DIY Enthusiast | Skill Saw |

|

User Testimonials

Users have shared their experiences with both saws. Here are some standout comments:

- Mike, a contractor: “My table saw is my best friend on the job.”

- Sarah, a DIYer: “The Skill Saw fits perfectly in my garage.”

- John, a woodworker: “I trust my table saw for accuracy.”

- Lisa, a hobbyist: “The Skill Saw is easy to maneuver.”

Users emphasize the importance of choosing the right tool for their projects. Think about your needs before deciding.

Final Thoughts

Choosing between a Skill Saw and a Table Saw can be challenging. Each tool has unique advantages. Understanding your needs is crucial for making the right choice.

Choosing The Right Tool

Selecting the right tool depends on your project type. Here are key factors to consider:

- Portability: Skill saws are easy to carry. Table saws are usually stationary.

- Precision: Table saws offer more accuracy. Skill saws are better for rough cuts.

- Material: Both tools can cut wood. Table saws handle thicker materials better.

- Budget: Skill saws are generally cheaper. Table saws can be more expensive.

| Feature | Skill Saw | Table Saw |

|---|---|---|

| Portability | High | Low |

| Precision | Moderate | High |

| Material Thickness | Low | High |

| Cost | Low | High |

Future Of Carpentry Tools

The future of carpentry tools looks bright. Technology continues to evolve. Here are some trends to watch:

- Smart Tools: Expect tools with sensors and automation.

- Battery Technology: Battery life will improve. More powerful cordless tools will emerge.

- Sustainability: Eco-friendly materials will gain popularity.

- Virtual Reality: VR will enhance tool training and design planning.

Innovations will make tools safer and more efficient. Stay updated to choose the best equipment for your projects.

Frequently Asked Questions

Skill Saw Vs Table Saw: Which Is Better?

A table saw is ideal for precise cuts and large sheets of material. It’s stationary and offers stability. A skill saw, or circular saw, is portable and versatile for various tasks. Your choice depends on the project type and workspace requirements.

What Are The Main Differences Between Them?

The main difference lies in their design and usage. A table saw is fixed and excels at straight cuts. A skill saw is handheld, making it suitable for cutting on-site. Each tool serves different needs, making them complementary in a workshop.

Can I Use A Skill Saw For Table Saw Tasks?

Yes, a skill saw can perform some table saw tasks. However, it may lack the precision of a table saw. For accurate and repeatable cuts, a table saw is preferable. Use a skill saw for flexibility and portability, but expect trade-offs in accuracy.

Which One Is Safer To Use?

Table saws are generally considered safer due to their stability. They have built-in guards and anti-kickback features. Skill saws require more caution, as they are handheld and more prone to accidents. Always prioritize safety measures regardless of the tool you choose.

Conclusion

Choosing between a skill saw and a table saw depends on your specific needs. Skill saws offer portability and versatility for various projects. Table saws provide precision and stability for larger cuts. Consider your workspace and the types of cuts you frequently make.

Make an informed choice to enhance your woodworking experience.