Super Glue Metal to Metal: Ultimate Bonding Secrets

Super glue can effectively bond metal to metal. It forms a strong, durable connection suitable for various applications.

Super glue, known for its quick-drying properties, is a popular adhesive for metal repairs. It works by creating a chemical bond between surfaces, making it ideal for small projects or intricate repairs. Many people prefer super glue due to its ease of use and versatility.

Whether fixing a broken metal item or completing a DIY project, super glue offers a reliable solution. It’s essential to prepare the surfaces properly for the best adhesion. Clean and dry surfaces ensure the strongest bond. This adhesive is perfect for non-structural applications where high strength is not critical. Understanding its limitations will help you achieve the best results.

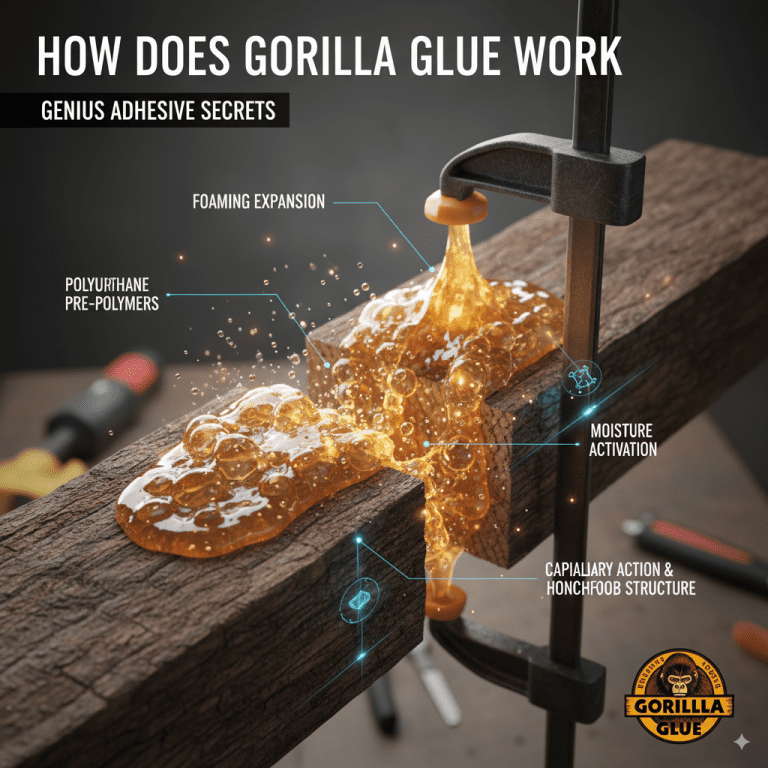

The Science Of Super Glue

Super glue, known as cyanoacrylate, is a powerful adhesive. Its chemical composition allows it to bond quickly. This glue works best on clean, dry surfaces. When applied, it forms strong bonds through a process called polymerization.

Super glue is effective on metal surfaces due to its ability to fill gaps. It cures quickly in the presence of moisture. Once cured, it creates a durable bond that can withstand stress. Using it on metal requires careful surface preparation for the best results.

Preparation For Metal Bonding

Surface cleaning is the first step for strong metal bonding. Remove any dirt, grease, or oil. Use a clean cloth with a suitable cleaner. Ensure the surface is completely dry before applying glue.

Abrading the metal helps create a rough texture. This texture increases the bond strength. Use sandpaper or a file for this process. Lightly sand the surfaces that will be glued. After sanding, wipe away any dust.

Following these steps ensures a better bond. Proper preparation is key to successful metal adhesion.

Choosing The Right Super Glue

Choosing the right super glue for metal is important. Different types of metal glues are available. Each type has its own strengths and weaknesses. Here are some common types:

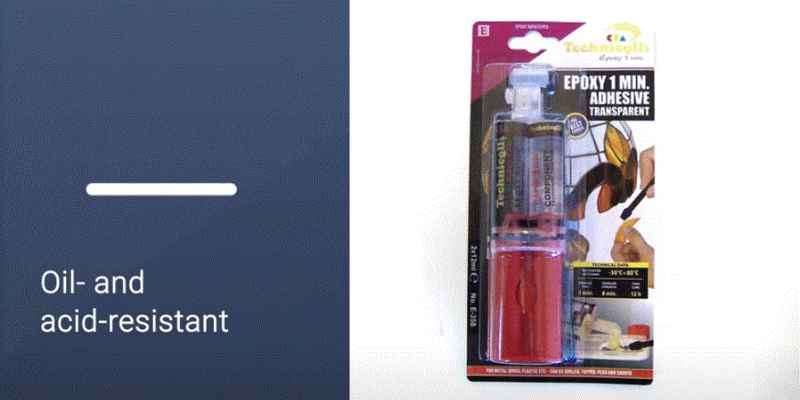

- Epoxy: Great for heavy-duty bonding and chemical resistance.

- Cyanoacrylate: Fast-setting and ideal for small repairs.

- Polyurethane: Works well on various surfaces and resists moisture.

Temperature and chemical resistance matter. Some glues can handle extreme heat. Others resist oils and solvents. Always check the product label for specific limits. This ensures a strong, lasting bond.

Application Techniques

Start by cleaning both metal surfaces. Use a cloth to remove dirt and oil. Apply a small amount of super glue evenly on one surface. Press the two pieces together quickly. Hold them firmly for a few seconds.

For a strong bond, use clamps. Clamping keeps the pieces together while the glue dries. Make sure the clamp is not too tight. Too much pressure can damage the metal.

Wait for the glue to dry completely. This may take a few hours. Check the instructions on the glue for exact drying times.

Curing Time And Conditions

The ideal curing environment for super glue involves a dry and warm space. Room temperature between 65°F and 75°F works best. Humidity levels should be low to ensure strong bonds. Avoid any wet areas that can slow curing.

To speed up the curing process, consider using a heat gun or hair dryer. Direct heat can help the glue set faster. Make sure not to overheat the metal parts. This may damage the surface or the glue.

Using a clamp can also help. Applying pressure ensures a tighter bond. Keep the parts together for the recommended time. This improves the overall strength of the bond.

Testing The Bond Strength

Testing the bond strength of super glue on metal surfaces is essential. Two main tests are used: tension and shear tests.

Tension tests pull the glued metal apart. They measure how much force the bond can withstand. Shear tests push the metal sideways. This checks the bond’s ability to resist sliding.

Long-term durability is also crucial. Over time, temperature changes and moisture can weaken the bond. Regularly checking the bond helps ensure it remains strong.

Using the right super glue is important for strong results. Always follow the manufacturer’s instructions for best outcomes.

Safety And Precautions

Always wear gloves and goggles when using super glue. This protects your skin and eyes from harmful chemicals. Use super glue in a well-ventilated area to avoid inhaling fumes.

Keep super glue away from children and pets. Store it in a cool, dry place. Avoid contact with skin and eyes. If glue gets on your skin, use acetone to remove it safely.

| Disposal Method | Description |

|---|---|

| Sealed Container | Place unused glue in a sealed container before disposal. |

| Local Regulations | Check local waste guidelines for proper disposal methods. |

| Do Not Pour | Avoid pouring glue down the sink or toilet. |

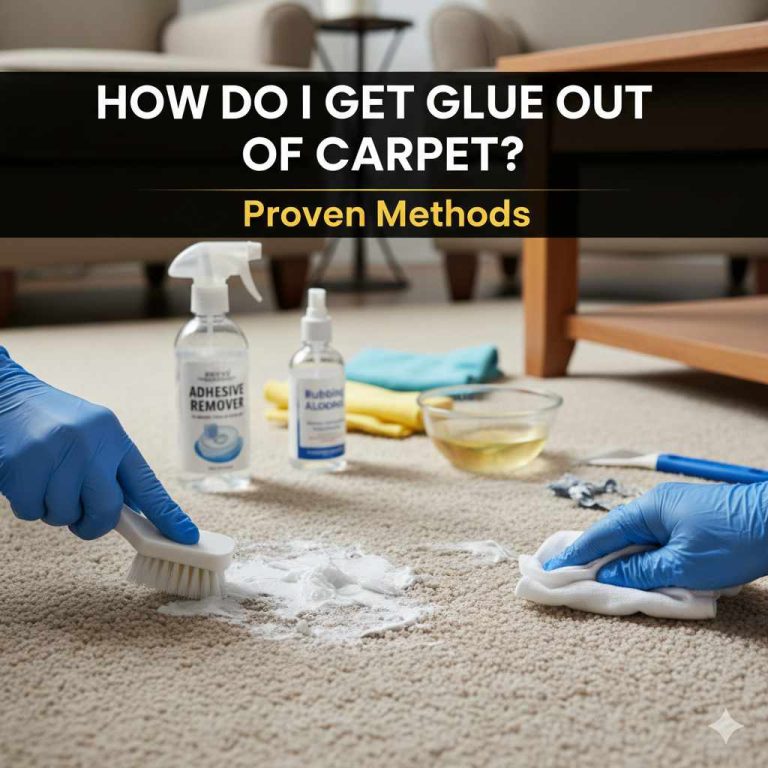

Troubleshooting Common Issues

Weak bonding can happen with super glue on metal surfaces. This issue often arises from dirty or oily surfaces. Always clean the metal before applying glue. Use rubbing alcohol or soap and water for cleaning. Let the surfaces dry completely.

To fix a weak bond, try applying more glue. Press the pieces together firmly for a few seconds. Use a clamp if needed to hold them in place.

Removing excess glue is important for a clean finish. Wait for the glue to dry slightly. Use a razor blade or a fine sandpaper to scrape it off. Be careful not to damage the metal surface. For stubborn spots, a little acetone can help dissolve the glue.

Advanced Bonding Techniques

Using primers and accelerators can greatly improve the strength of your bond. Primers prepare the surface, making it easier for super glue to stick. Accelerators speed up the drying time, allowing for quicker repairs.

Layering the glue can also provide better reinforcement. Apply a thin layer of super glue first. Wait for it to dry, then add another layer. This technique helps create a stronger bond between the metal pieces.

Always ensure both surfaces are clean and dry. Dirt and moisture can weaken the bond. For best results, use a clamp to hold the pieces together while the glue cures.

Creative Uses For Metal-to-metal Bonding

Super glue is great for metal-to-metal bonding. Many DIY projects benefit from this strong adhesive. Use it to fix metal parts in toys, tools, or furniture. It creates a strong bond quickly, making repairs easy.

In industrial applications, super glue helps join metal components. It is used in machinery and automotive repairs. This glue withstands heat and stress well. It is a reliable choice for manufacturers needing quick fixes.

| Application | Benefits |

|---|---|

| DIY Projects | Quick repairs, strong hold, easy to use |

| Industrial Use | Durable, heat resistant, efficient |

Frequently Asked Questions

Can Super Glue Bond Metal To Metal Effectively?

Yes, super glue can effectively bond metal to metal. It forms a strong, durable bond suitable for various metal types. However, ensure the surfaces are clean and dry for optimal adhesion. Also, consider using a specialized metal adhesive for heavy-duty applications.

How Long Does Super Glue Take To Dry On Metal?

Super glue typically dries within 10 to 30 seconds on metal. However, full strength may take up to 24 hours. Factors like temperature and humidity can influence drying time. Always check the manufacturer’s instructions for specific guidelines to ensure the best results.

Is Super Glue Waterproof For Metal Repairs?

Most super glues are water-resistant but not entirely waterproof. They may withstand brief exposure to water but can weaken over time. For long-lasting, waterproof bonds, consider using epoxy or other specialized adhesives designed for wet environments. Always test the bond if water exposure is expected.

Can Super Glue Withstand High Temperatures?

Standard super glues may not withstand high temperatures effectively. They typically have a temperature tolerance of up to 180°F (82°C). For applications involving heat, consider using high-temperature adhesives or specific metal adhesives designed for such conditions. Always verify the temperature rating before application.

Conclusion

Choosing the right super glue for metal bonding can make all the difference. With the right product, you can achieve a strong, lasting hold. Remember to follow application guidelines for the best results. Whether for repairs or crafts, super glue is an effective solution for metal-to-metal bonding projects.