SYP vs SPF Lumber: The Essential Proven Differences

SYP (Southern Yellow Pine) is a strong, dense, and heavy wood perfect for structural framing and outdoor projects that need strength. SPF (Spruce-Pine-Fir) is lighter, more affordable, and easier to work with, making it ideal for interior walls, DIY furniture, and general-purpose construction where high load-bearing capacity isn’t required.

Walking into the lumber aisle can feel overwhelming. You see stacks of wood, and many look the same. Two labels you’ll see everywhere are “SYP” and “SPF.” What’s the difference? Choosing the wrong one can make your project harder, weaker, or more expensive than it needs to be. Don’t worry, this is a common point of confusion for every beginner.

I’m here to clear it all up for you. In this guide, I’ll break down the simple, proven differences between SYP and SPF lumber. By the end, you’ll walk into any home center with confidence, ready to pick the perfect wood for your next project.

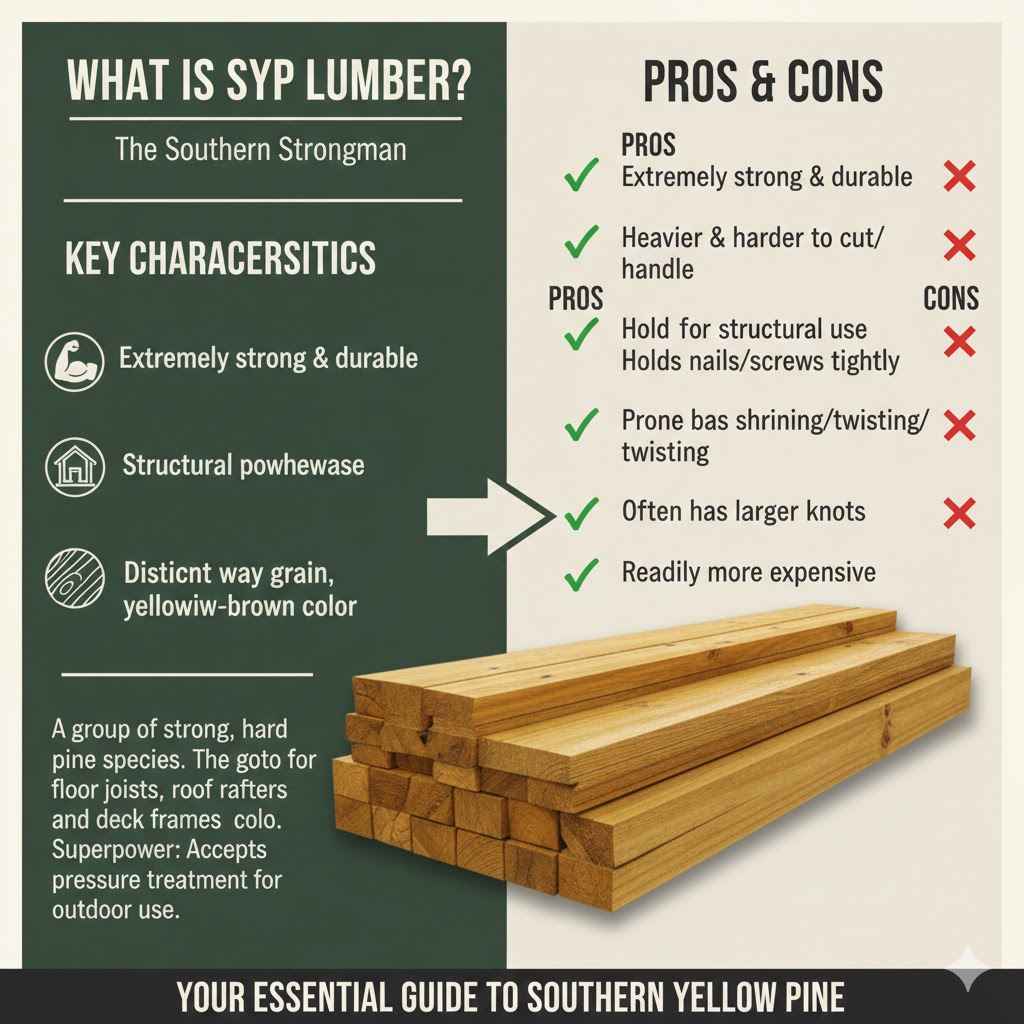

What is SYP Lumber? (The Southern Strongman)

SYP stands for Southern Yellow Pine. It isn’t just one type of tree. It’s a group of strong, hard pine species that grow in the Southern United States. Think of it as the powerhouse of the construction world. When builders need wood that can hold up a house, this is often their first choice.

You’ll recognize SYP by its distinct, often wavy grain pattern and its characteristic yellowish, sometimes brownish, color. It feels heavy and dense in your hands. This density is what gives it incredible strength. It’s tough enough to handle heavy loads, which is why it’s a favorite for floor joists, roof rafters, and deck frames.

One of SYP’s biggest superpowers is how well it accepts pressure treatment. Its cell structure easily soaks up the chemicals that protect wood from rot, decay, and insects. This makes pressure-treated SYP the go-to material for almost any outdoor project, from fences to pergolas.

Pros and Cons of SYP Lumber

Pros:

Extremely strong and durable

Excellent for structural, load-bearing applications

Holds nails and screws very tightly

Ideal for pressure treating for outdoor use

Readily available, especially in the Southern and Eastern U.S.

Cons:

Heavier and harder to handle than SPF

Can be more difficult to cut and drill through

Prone to shrinking or twisting if not properly dried

Often has larger, more noticeable knots

Can be slightly more expensive than SPF

What is SPF Lumber? (The Versatile Lightweight)

SPF is also a group of woods, not a single tree. It stands for Spruce, Pine, and Fir. These trees grow in the cooler climates of Canada and the northern United States. If SYP is the strongman, SPF is the versatile all-around player. It’s a fantastic, budget-friendly choice for a huge range of projects.

SPF is much lighter in color, often appearing white or pale yellow with a subtle grain pattern. It feels significantly lighter than a piece of SYP of the same size. This makes it a dream for DIYers—it’s easy to carry, lift into place, and cut with basic tools. Its softer nature also means it’s less likely to split when you drive a nail or screw into it.

While not as mighty as SYP, SPF is still plenty strong for most residential construction, especially for framing interior walls that don’t carry the weight of a roof or upper floor. It’s also a popular choice for woodworking projects like building shelves, simple cabinets, or workbenches because its smooth surface takes paint beautifully.

Pros and Cons of SPF Lumber

Pros:

Lightweight and very easy to work with

Generally more affordable than SYP

Cuts, drills, and fastens with ease

Fine, straight grain provides a clean look

Takes paint and primer very well

Cons:

Not as strong or dense as SYP

Not suitable for heavy load-bearing uses

Doesn’t hold up well outdoors unless protected from weather

Does not accept pressure treatment as effectively as SYP

Can dent and scratch more easily due to its softness

SYP vs. SPF: A Head-to-Head Comparison

Now that you know the players, let’s put them side-by-side. Understanding these key differences will help you make the right choice every time you’re at the lumber yard.

Strength and Density

This is the most significant difference. SYP is the clear winner in the strength department. It has a higher density, which means there is more wood fiber packed into the same amount of space. This makes it incredibly stiff and strong, capable of supporting heavy loads without bending or breaking.

SPF is softer and less dense. It’s still strong enough for many applications, like wall studs, but you wouldn’t want to use it for a long-span floor joist or a critical roof rafter. The American Wood Council provides span tables that show just how much farther SYP can span under the same load compared to SPF.

Appearance and Texture

Visually, the two are quite different. SYP has a bold, prominent grain pattern that can be quite attractive if you’re looking for a rustic feel. Its color is a warm, golden yellow. SPF, on the other hand, has a much subtler, straighter grain and a brighter, whiter appearance. This makes SPF a great “blank canvas” for projects you plan to paint.

Knots are another point of difference. SYP tends to have larger, darker, and more distinct knots. SPF usually has smaller, tighter knots that are less obtrusive. For projects where appearance matters, choosing a higher grade of lumber with fewer knots is always a good idea for both types.

Weight and Workability

For a beginner, workability is huge. This is where SPF shines. An 8-foot-long 2×4 made of SPF is noticeably lighter than its SYP counterpart. This makes it easier to carry a stack, lift boards into place, and hold them steady while you work. Its softer wood is also much easier on your saw blades and drill bits.

SYP’s density makes it a bit more of a workout. It’s heavy, and cutting through it requires a bit more effort from you and your tools. The upside is that its hardness means it resists dings and dents better than SPF.

Durability and Rot Resistance

In their natural, untreated state, neither SYP nor SPF is particularly resistant to rot or insects when exposed to moisture. However, the story changes completely with pressure treatment. SYP’s porous cellular structure allows it to absorb preservatives deep into the wood. This makes treated SYP incredibly durable for outdoor use.

SPF does not accept treatment nearly as well. You will rarely find pressure-treated SPF at a home center because it’s simply not as effective. For any project that will be exposed to the elements, treated SYP is the safe and reliable choice.

Cost and Availability

Price is often a deciding factor. Generally, SPF is less expensive than SYP. This is due to several factors, including faster growth cycles for the trees and lower shipping weights, which reduce transportation costs. Its widespread availability, especially in the northern half of North America, also helps keep prices competitive.

SYP is king in the South and East but may cost a little more in other regions due to shipping. However, for structural jobs where its strength is required, the slight extra cost is well worth the performance and peace of mind.

Quick Comparison Table: SYP vs. SPF

| Feature | SYP (Southern Yellow Pine) | SPF (Spruce-Pine-Fir) |

|---|---|---|

| Strength | Very High | Moderate |

| Weight | Heavy and Dense | Lightweight |

| Appearance | Yellowish color, prominent wavy grain | White/pale color, subtle straight grain |

| Workability | Harder to cut, requires more effort | Easy to cut, nail, and handle |

| Pressure Treatment | Excellent absorption, ideal for outdoors | Poor absorption, not used for outdoors |

| Cost | Moderate to High | Low to Moderate |

| Common Uses | Deck frames, floor joists, rafters, subfloors | Interior wall studs, furniture, shelving, hobbies |

When Should You Choose SYP Lumber?

Think “Strength and Structure.” SYP is your go-to lumber when the project needs to be strong and stand the test of time, especially against weight and weather.

Structural Framing: If you are building anything that holds up a significant weight—like floor joists, roof rafters, or beams—SYP is the right choice. Its strength ensures your structure will be safe and sound.

Outdoor Projects: For decks, fences, pergolas, playground sets, or retaining walls, you must use pressure-treated wood. Pressure-treated SYP is the industry standard for this. It will resist rot and insects for many years.

Subflooring: The layer of wood under your main flooring needs to be stiff and strong. SYP provides a solid, unbending base.

Stairs: The stringers—the saw-toothed pieces that support the steps—are another critical structural component where SYP is the preferred choice for its strength.

When is SPF Lumber the Right Choice?

Think “Interior, Lightweight, and Appearance.” SPF is perfect for projects where ease of use is more important than raw strength.

Interior Wall Framing: For non-load-bearing walls (walls that just divide a room and don’t hold up a ceiling or roof), SPF is perfect. It’s inexpensive, straight, and easy to assemble.

DIY Furniture and Shelving: Building a simple bookshelf, a small cabinet, or some storage shelves for the garage? SPF is a fantastic choice. It’s affordable, easy to cut accurately, and its smooth surface is great for painting.

Workshop Projects: SPF is the wood of choice for creating jigs, simple workbenches, or organizing systems in your shop.

Hobby and Craft Projects: Because it’s soft and easy to shape, SPF is great for smaller crafts and hobbyist creations.

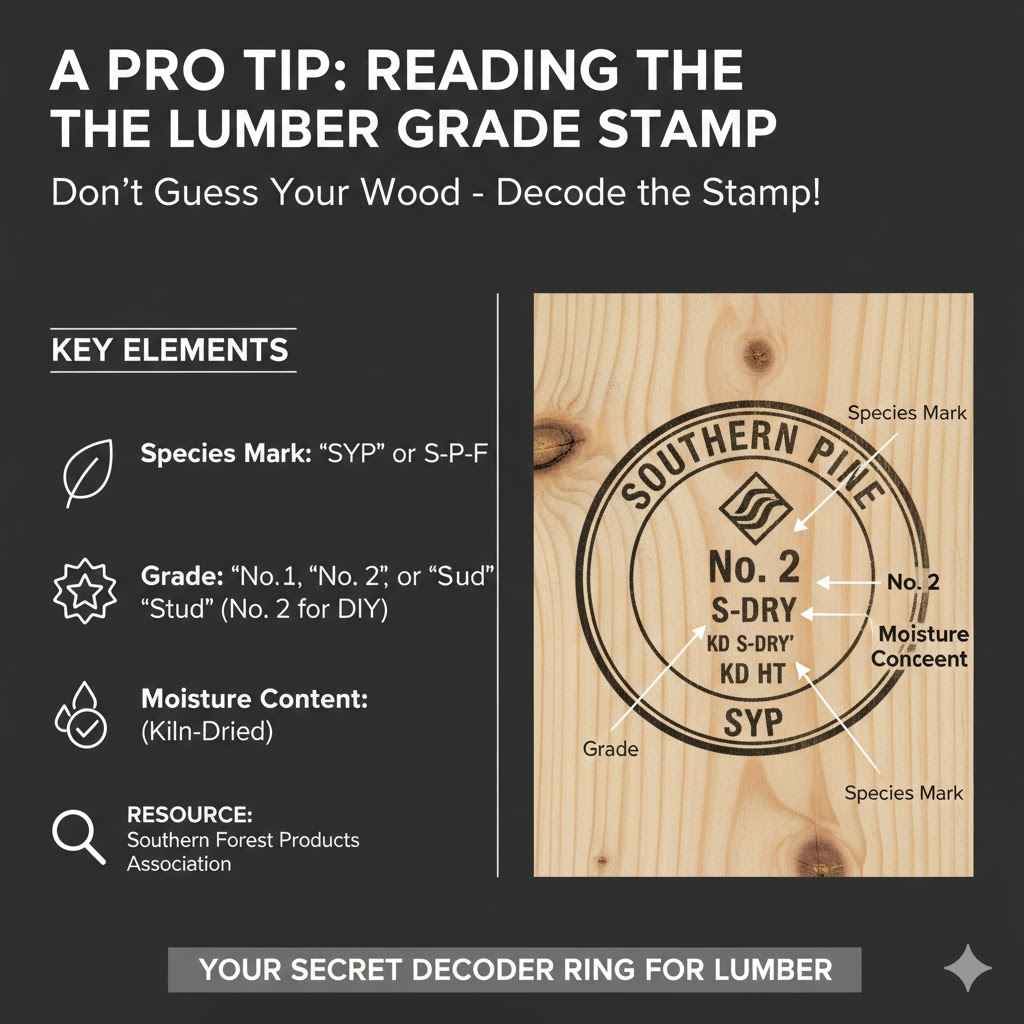

A Pro Tip: Reading the Lumber Grade Stamp

Don’t just guess which wood is which! Every piece of structural lumber has a stamp on it that tells you exactly what you’re buying. Learning to read it is like having a secret decoder ring.

Look for a stamp that includes:

Species Mark: This will clearly say “SYP” or “S-P-F”. This is your first and most important clue!

Grade: This tells you the quality of the wood. You’ll see things like “No. 1,” “No. 2,” or “Stud.” For most DIY and construction projects, No. 2 grade is the perfect balance of strength and affordability.

Moisture Content: You want to see “KD” or “S-DRY.” This means the wood has been kiln-dried to reduce moisture, making it more stable and less likely to warp. The Southern Forest Products Association offers great guides on how to interpret these stamps.

Looking at the stamp removes all guesswork and ensures you’re buying the right material for your job.

Frequently Asked Questions (FAQ)

Can I use SPF for an outdoor deck?

No, you should never use untreated SPF for any part of a deck. The structural frame (posts, joists, and beams) must be made from pressure-treated SYP for strength and resistance to rot. Using SPF would be unsafe and violate building codes.

Is SYP always better because it’s stronger?

Not at all! “Better” depends entirely on the project. For building a heavy-duty workbench, SYP is better. But for building a lightweight painted bookshelf for a kid’s room, SPF is better because it’s lighter, cheaper, and easier to work with.

Why is SPF lumber cheaper than SYP?

SPF is often cheaper for a few reasons. The trees (spruce, pine, and fir) grow relatively quickly. More importantly, SPF lumber is much lighter, which significantly reduces the cost of shipping it from the forest to the store.

Can I paint or stain both types of wood?

Yes, you can paint or stain both. SPF’s fine, uniform grain typically provides a smoother surface for painting. SYP has a more pronounced grain that can show through paint and stain, which can be a beautiful, rustic look if that’s what you want. Always use a good quality primer first, especially on SYP, to prevent knots from bleeding through the paint.

Which wood is easier for a beginner to work with?

For a true beginner, SPF is definitely easier to work with. It’s lighter to carry, softer to cut with a handsaw or power saw, and more forgiving when driving nails and screws. It’s a great material to learn on.

What does the “Fir” in SPF actually mean?

The “Fir” in the SPF combination usually refers to either Douglas Fir or Balsam Fir. These species share similar characteristics of strength, weight, and appearance with spruce and certain pines, so they are harvested and milled together as a single group.

How can I tell SYP and SPF apart at the store if the stamp is hard to read?

First, always try to find the stamp. If you can’t, use your other senses. Lift a board of each—the SYP will feel noticeably heavier. Look at the color and grain. SYP will be more yellow with a bold, swirly grain pattern. SPF will be paler, almost white, with a much straighter, fainter grain.

Conclusion: Choosing the Right Lumber with Confidence

The choice between SYP and SPF lumber doesn’t have to be complicated. Now you know the secret: it’s all about matching the wood to the job. Think of them as two different tools in your workshop. You wouldn’t use a hammer to drive a screw, and you wouldn’t use SPF for a job that needs the raw power of SYP.

To put it simply:

- For strength, structure, and anything outdoors, grab SYP.

- For lightweight interior projects, furniture, and easy handling, choose SPF.

Understanding this fundamental difference is a huge step in your woodworking and DIY journey. It will save you time, money, and frustration. The next time you walk down that lumber aisle, you can look at those stacks of wood not with confusion, but with the confidence of someone who knows exactly what they need to build something great.