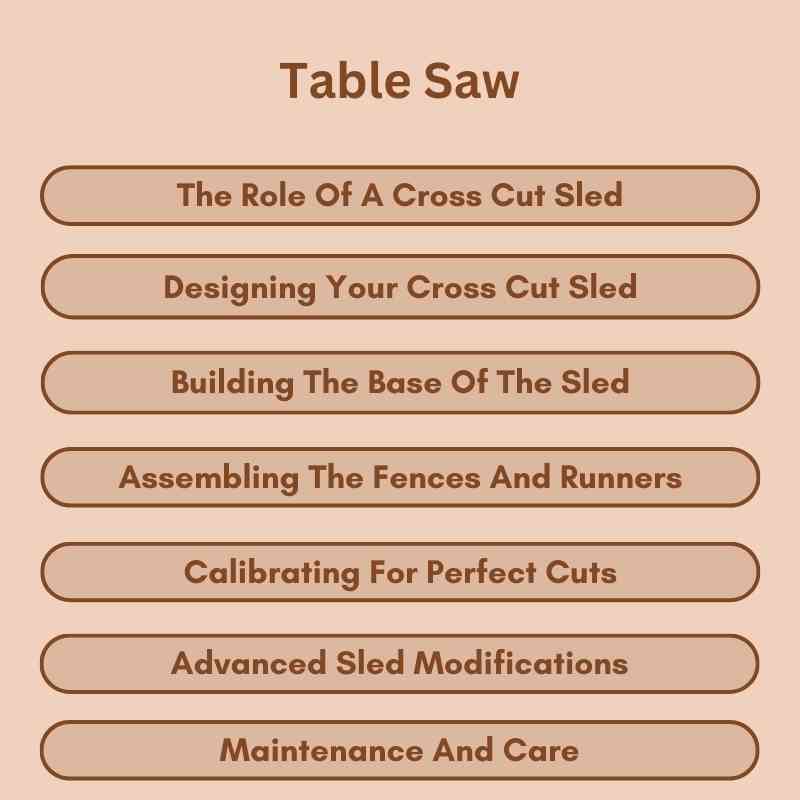

Table Saw: Cross Cut Sled for Precision Woodworking Projects

A cross cut sled for a table saw is a specialized tool designed for precise crosscuts. It improves accuracy and safety compared to traditional miter gauges.

A cross cut sled is essential for woodworkers aiming for precision and efficiency. This tool allows users to make straight cuts across the grain, ensuring consistency in size and shape. Unlike standard miter gauges, a sled provides better support for larger pieces, reducing the risk of kickback.

It consists of a sturdy base with adjustable fences that hold the workpiece securely in place. With a well-built cross cut sled, woodworkers can achieve cleaner edges and minimize measuring errors. Using this tool not only enhances the quality of your projects but also boosts confidence in your cutting skills. Investing in a cross cut sled is a smart choice for any serious woodworker.

The Role Of A Cross Cut Sled

A cross cut sled is a vital tool for woodworkers. It enhances the precision of cuts. This tool provides stability and safety during operations. Understanding its role can boost your woodworking skills significantly.

Enhancing Accuracy In Woodworking

Accuracy is crucial in woodworking. A cross cut sled ensures straight, clean cuts every time. Here are some key benefits:

- Perfect Angles: Cuts are always at precise angles.

- Consistent Lengths: Repeated cuts are uniform in size.

- Stable Support: Material stays in place during cutting.

The sled helps eliminate errors. It supports larger pieces easily. This makes it ideal for all projects.

Safety Benefits Over Traditional Methods

Safety is paramount in woodworking. A cross cut sled enhances safety in several ways:

- Reduced Kickback: Less chance of wood being thrown back.

- Hands-Free Operation: Keeps hands away from the blade.

- Stable Cutting: Less movement means fewer accidents.

Using a sled minimizes risks. It allows for safer operation with larger materials. Woodworkers can focus on their craft, not on hazards.

Designing Your Cross Cut Sled

Creating a cross cut sled enhances accuracy and safety. A well-designed sled makes cross cuts easier and faster. It is essential for any woodworking project.

Key Dimensions And Materials

Choosing the right dimensions and materials is crucial. Here are some key factors to consider:

| Dimension | Recommended Size |

|---|---|

| Base Width | 24 inches |

| Base Length | 30 inches |

| Fence Height | 3 inches |

Use these materials for durability:

- Plywood for the base.

- Hardwood for the fence.

- Metal for runners.

Custom Features For Versatility

Adding custom features enhances functionality. Here are some ideas:

- Adjustable Fence: Allows for precise cuts.

- Stop Blocks: Ensure repeatable cuts.

- Built-in Measuring Tape: For quick measurements.

Consider adding:

- Insert Plates: For different blade sizes.

- Storage Compartment: Keep tools organized.

Custom features make your sled versatile and user-friendly.

Building The Base Of The Sled

Creating a solid base for your cross cut sled is essential. A sturdy base ensures accuracy and stability. Follow these steps to build an effective sled base.

Selecting The Right Plywood

Choosing the right plywood is crucial for your sled’s durability. Here are some tips to consider:

- Thickness: Use at least ¾ inch plywood for strength.

- Grade: Opt for high-grade plywood for a smooth surface.

- Type: Birch or maple plywood works best for stability.

Good plywood prevents warping and ensures even cuts. Avoid cheap options that can compromise your sled’s performance.

Cutting To Size And Squaring The Edges

Accurate cutting is key to a successful sled. Follow these steps:

- Measure your desired sled dimensions carefully.

- Mark the measurements clearly on the plywood.

- Use a straight edge for a clean cut.

- Cut the plywood using a table saw.

After cutting, check the edges:

- Use a square to ensure all corners are 90 degrees.

- Trim any uneven edges for a perfect fit.

A well-cut base leads to better accuracy in your woodworking projects. Take your time during this step for the best results.

Assembling The Fences And Runners

Building a cross cut sled involves careful assembly of fences and runners. These components ensure precise cuts and enhance the sled’s functionality. Proper alignment is crucial for accuracy and safety.

Attaching The Front And Back Fences

The front and back fences provide support for your workpieces. Follow these steps to attach them correctly:

- Measure the sled’s width. Ensure the fences are straight.

- Use a square to check the alignment. Adjust as needed.

- Secure the front fence with screws. Ensure it is tight.

- Attach the back fence. Check for parallel alignment with the front.

Use wood glue for extra stability. This helps reduce movement during cuts.

Choosing And Fixing The Runners

Runners allow the sled to glide smoothly on the table saw. Selecting the right material is vital. Here are some options:

| Material | Benefits |

|---|---|

| Wood | Easy to cut and adjust |

| Metal | Durable and long-lasting |

| Plastic | Lightweight and low-friction |

To fix the runners:

- Cut the runners to fit the sled base.

- Attach them with screws or glue.

- Test the sled’s movement on the table saw.

Ensure the runners slide smoothly. This enhances the sled’s performance.

Calibrating For Perfect Cuts

Calibrating your table saw’s cross cut sled is crucial. It ensures that every cut is accurate and clean. Proper calibration saves time and materials. Here’s how to do it effectively.

Squaring The Fence To The Blade

Start by squaring the fence. A square fence aligns with the blade. Follow these steps:

- Place a square against the blade.

- Adjust the fence until it touches the square.

- Lock the fence in place.

Check the alignment again. Repeat the process if necessary. A squared fence leads to precise cuts.

Adjusting For Blade Kerf

Blade kerf is the width of the cut the blade makes. This measurement affects the final piece size. Here’s how to adjust for it:

- Measure the kerf width with calipers.

- Set the sled’s stop block accordingly.

- Make a test cut on scrap wood.

Check the width of the cut. Adjust the stop block if needed. Correct adjustments lead to perfect results.

| Step | Action |

|---|---|

| 1 | Measure blade kerf width. |

| 2 | Adjust the sled’s stop block. |

| 3 | Perform a test cut. |

| 4 | Check the cut width. |

| 5 | Make final adjustments as needed. |

Proper calibration of your cross cut sled enhances your woodworking projects. Take time to measure accurately and adjust correctly.

Advanced Sled Modifications

Modifying your table saw’s cross cut sled enhances its versatility. Advanced sled modifications make your cuts more precise. These upgrades can save time and improve accuracy.

Adding A Stop Block For Repeated Cuts

A stop block allows for accurate, repeated cuts. It ensures each piece is the same length. Here’s how to add one:

- Choose a sturdy piece of wood.

- Attach it to the sled’s fence using screws.

- Mark the desired length on the stop block.

- Test the length with a piece of scrap wood.

Benefits of using a stop block:

- Ensures uniform cut lengths.

- Reduces measuring time.

- Improves workflow efficiency.

Incorporating A T-track For Clamps And Jigs

A T-track adds flexibility to your cross cut sled. It allows for easy attachment of clamps and jigs. Follow these steps to install a T-track:

- Choose the right size T-track for your sled.

- Measure and mark where to place it on the sled.

- Cut a groove in the sled to fit the T-track.

- Secure the T-track with screws.

Advantages of a T-track:

- Versatile for various projects.

- Easy to adjust clamps and jigs.

- Enhances overall cutting precision.

With these modifications, your cross cut sled becomes a powerful tool. It will help you achieve better results in your woodworking projects.

Maintenance And Care

Proper maintenance ensures your cross cut sled lasts longer. Regular care keeps it performing at its best. Follow these tips to maintain your sled effectively.

Regular Cleaning For Longevity

Cleaning your cross cut sled is essential. Dust and debris can affect performance. Here are the steps for regular cleaning:

- Remove Saw Dust: Use a brush or a vacuum.

- Wipe Surfaces: Use a damp cloth to clean the top.

- Check for Residue: Remove any glue or pitch buildup.

Cleaning after each use will extend the sled’s life. A clean sled improves accuracy and safety.

Checking For Wear And Calibration

Regular checks for wear and calibration are vital. Follow these steps:

- Inspect Components: Look for cracks or damage.

- Check the Fence: Ensure it is square to the blade.

- Test Calibration: Use a square to verify alignment.

Replace worn parts immediately. Regular calibration ensures precise cuts. This keeps your projects accurate and safe.

Project Ideas Using A Cross Cut Sled

A cross cut sled is a versatile tool. It enhances precision for various woodworking projects. Here are some exciting project ideas to inspire your creativity.

Picture Frames And Small Boxes

Creating picture frames and small boxes is simple with a cross cut sled. This tool ensures clean, accurate cuts. Here are some steps to follow:

- Choose your wood type.

- Measure the desired dimensions.

- Set up the cross cut sled.

- Make precise cuts for frame pieces or box sides.

- Assemble using glue or nails.

Consider these tips:

- Use hardwood for durability.

- Sand edges for a smooth finish.

- Personalize with paint or stain.

Precision Joinery Techniques

Mastering precision joinery techniques is easy with a cross cut sled. Accurate cuts lead to strong joints. Here are popular joinery methods:

| Joinery Technique | Description |

|---|---|

| Butt Joint | Simple joint where two pieces meet at a right angle. |

| Miter Joint | Cut at an angle to create corners in frames. |

| Dado Joint | Groove cut into one piece to hold another. |

| Rabbet Joint | Notch cut along the edge for strong connections. |

Follow these steps for joinery:

- Measure and mark your cuts.

- Adjust the sled for angles.

- Make cuts slowly for accuracy.

Using a cross cut sled enhances your projects. Enjoy crafting beautiful picture frames and strong joints!

Frequently Asked Questions

What Is A Cross Cut Sled?

A cross cut sled is a table saw accessory that improves precision for cross cuts. It features a flat base and a guide fence. This setup enhances accuracy, making it easier to cut wood at exact angles. It’s ideal for repetitive cuts and ensures safety during operation.

How Do I Make A Cross Cut Sled?

To make a cross cut sled, gather materials like plywood and a fence. Cut the plywood to size and attach the fence parallel to the blade. Ensure the sled slides smoothly on the table saw’s miter slots. Test it with a scrap piece for accuracy before use.

Why Use A Cross Cut Sled?

Using a cross cut sled enhances your cutting accuracy significantly. It provides a stable platform for your workpiece. This tool reduces the risk of kickback and improves safety. It’s especially useful for making precise, repeatable cuts in woodworking projects.

What Materials Can I Cut With A Sled?

You can cut various materials with a cross cut sled, including hardwood, softwood, and plywood. It’s suitable for both thick and thin stock. However, avoid cutting materials that are excessively warped or twisted. Always ensure the material is securely positioned before cutting.

Conclusion

A cross cut sled enhances your table saw’s precision and safety. It simplifies making accurate cuts, saving time and reducing material waste. Investing in this tool boosts your woodworking skills significantly. Embrace the benefits of a cross cut sled and elevate your projects to a professional level.

Start creating with confidence today!