Table Saw Replacement Motors: Enhance Your Saw’s Performance

Imagine you’re in the middle of an important woodworking project, and suddenly, your table saw motor gives up on you. Frustrating, right?

But here’s the good news: finding the right replacement motor can not only get you back on track but also enhance your table saw’s performance like never before. You might wonder, “What should I look for in a table saw replacement motor?

” And that’s exactly what we’re here to explore. This guide will help you navigate the world of table saw motors, ensuring you make a choice that’s both efficient and cost-effective. With the right motor, you can transform your woodworking experience, making each cut smoother and each project more precise. So, are you ready to unlock the full potential of your table saw? Let’s dive in and discover the secrets to choosing the perfect replacement motor.

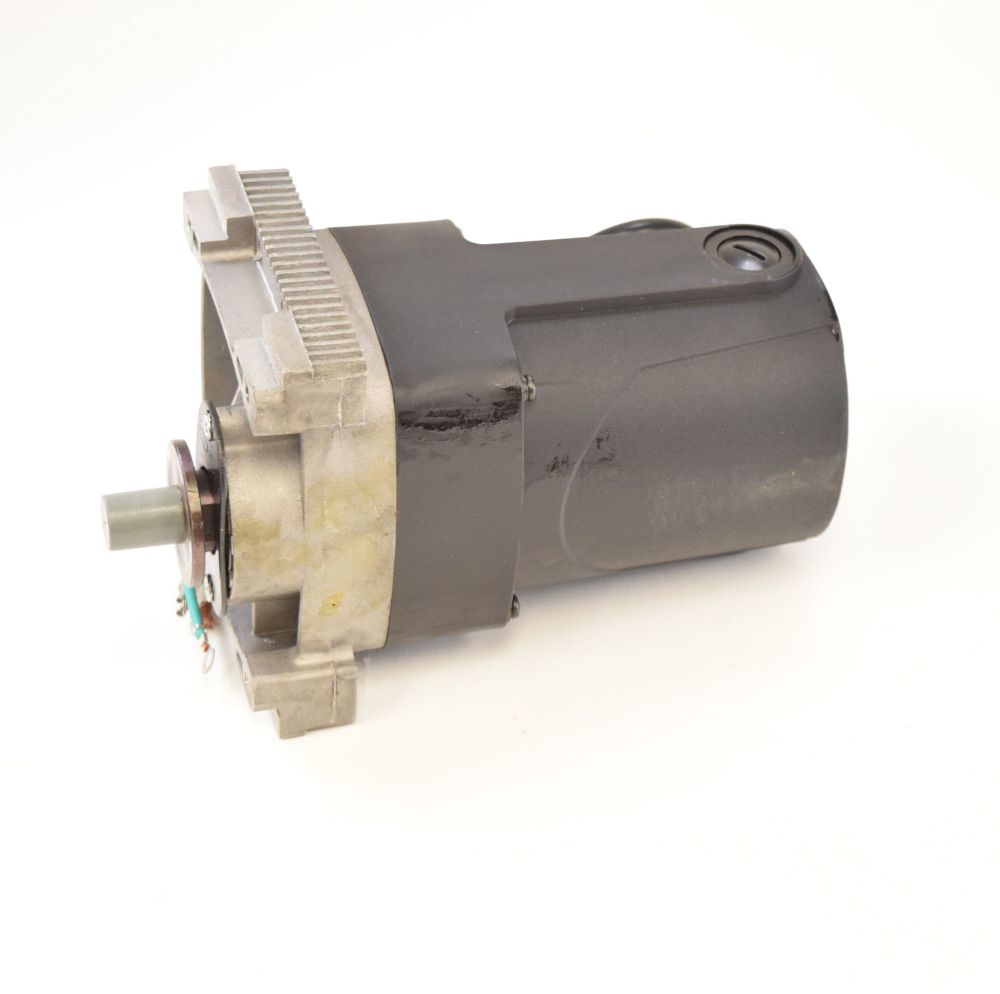

Credit: www.ebay.com

Choosing The Right Motor

Motor power is very important. You need to know how strong it is. A motor with more horsepower can cut through wood easily. But it might use more electricity. Voltage is another key factor. Most motors use either 110V or 220V. Check what your saw needs. Speed matters too. Faster motors can cut quickly. But sometimes, a slower motor is more precise. Always check the speed in RPM.

Size of the motor must fit your saw. It should not be too big. Mounting type is also crucial. Different saws have different mounts. Make sure the motor fits your saw’s mount. Wiring should match. If the wires are different, the motor won’t work. Weight of the motor can affect your saw. Too heavy can make it hard to move.

Types Of Replacement Motors

Induction motorsare quiet and reliable. They are good for long use. These motors do not have brushes. This makes them last longer. Less noise means a better work environment. They are also energy-efficient. This helps save power. Induction motors are best for heavy work. They handle tough tasks with ease.

Universal motorsare versatile. They work with both AC and DC power. These motors are lighter than induction motors. Universal motors can run at high speeds. This makes them suitable for small tasks. They are also cheaper to buy. But, they make more noise. Universal motors may wear out faster. They need regular maintenance.

Installation Process

Wear safety goggles to protect your eyes. Gloves keep your hands safe. Ensure the table saw is unplugged. Electric shock can be dangerous. Remove all jewelry. Loose items can catch in the motor. Keep the area clean and tidy. Tools should be in good condition. Inspect wires for damage. A damaged wire can cause accidents.

Start by removing the old motor. Unscrew the bolts carefully. Pull out the motor gently. Position the new motor in place. Align it with the saw base. Secure with bolts tightly. Check the alignment once more. Connect the wires properly. Ensure they are not loose. Test the motor briefly. Listen for unusual sounds. Adjust if necessary. Verify the saw blade spins correctly. Clean up the area after finishing.

Performance Benefits

New motors cut wood smoother and faster. Cutting efficiency increases with upgraded motors. Blades stay sharp longer. Less resistance means less wear. Precision improves, allowing for better finishes. Time-saving benefits are noticeable. Projects are completed quicker. Accuracy is enhanced, reducing mistakes.

Motors designed to last extend tool life. Durability increases with quality motors. Fewer breakdowns mean less repair costs. Longer lifespan saves money over time. Consistency in performance is ensured. Tools remain reliable for years. Investment in good motors pays off. Maintenance is less frequent. Efficiency of the tool remains stable.

Maintenance Tips

Keep your table saw motor in top shape with regular checks. Look for worn-out parts or loose connections. Tighten any loose screws or bolts. Check the power cord for any damage. It should not have cuts or cracks. A damaged cord can be dangerous. Make sure all safety guards are in place. These guards keep you safe while working. Inspect the motor’s brushes too. Replace them if they are worn down. Regular inspections can help you catch problems early.

Lubrication helps the motor run smoothly. Use the right oil for your motor. Not all oils are the same. Apply oil to the moving parts. This reduces friction and wear. Be careful not to over-lubricate. Too much oil can attract dust. Dust can harm the motor. Check the manual for lubrication guidelines. Follow the instructions for the best results. Proper lubrication keeps your motor healthy.

Cost Considerations

Buying a new motor can be expensive. It’s important to plan well. Budgeting helps avoid surprises. List all costs first. Include the motor price. Don’t forget shipping fees. Consider installation charges. Check for any extra tools needed. Add these to your list. It helps keep costs clear.

Investing in quality saves money later. A good motor lasts longer. Fewer repairs mean less spending. Quality motors run smoothly. They use less energy. This reduces power bills over time. Spending more now can save lots later. Think about the future. It’s not just about today’s cost.

Popular Brands And Models

Many people like the DeWalt DW745motor. It is strong and lasts long. Another choice is the Bosch 4100-09motor. It is known for smooth cuts. Makita 2705is also a good option. It is powerful and quiet. These motors fit many table saws. They work well for home and work use.

Users say DeWalt motors are reliable. They like the easy setup. Bosch motors get praise for smooth operation. Customers find them easy to use. Makita motors are loved for their quietness. Many users say they are very durable. People recommend these motors for their good performance.

Credit: www.searspartsdirect.com

Frequently Asked Questions

What Is A Table Saw Motor Replacement?

A table saw motor replacement involves changing the motor to restore or improve performance. It is necessary when the existing motor is damaged or underpowered. Replacing the motor can enhance cutting efficiency and extend the saw’s lifespan, ensuring reliable operation for various woodworking tasks.

How To Choose Table Saw Replacement Motors?

Choose a motor compatible with your saw’s specifications. Consider the horsepower, RPM, and voltage requirements. Select motors from reputable brands for reliability and durability. Ensure the motor fits the mounting and wiring configurations. Consulting the saw’s manual can help in making an informed decision.

Can I Install A Motor Myself?

Yes, you can install a motor yourself if you have basic skills. Ensure safety by disconnecting power and following the manual’s instructions. Use appropriate tools and check wiring connections carefully. If unsure, consult a professional to avoid potential hazards and ensure proper installation.

Why Replace A Table Saw Motor?

Replacing a table saw motor can enhance cutting power and efficiency. A new motor may offer better performance, especially if the old one is failing. It can extend the tool’s lifespan and improve safety. Upgrading the motor ensures optimal functionality for demanding woodworking tasks.

Conclusion

Choosing the right table saw motor ensures smooth, efficient cuts. Consider power needs and compatibility before buying. A motor upgrade boosts performance and extends your saw’s life. Research options carefully for your specific saw model. Look for reliable brands and read user reviews.

A good motor keeps your table saw running well. Enjoy safer woodworking and better results. Regular maintenance helps your motor last longer. Make informed choices to enhance your woodworking experience. Your table saw’s performance depends on a quality motor. Invest wisely for improved cutting and precision.