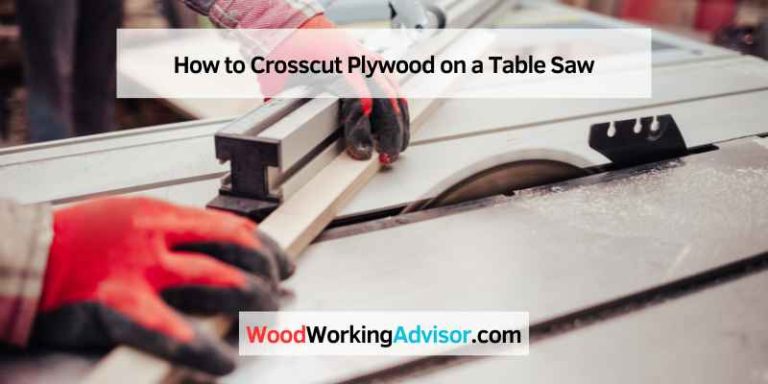

Table Saw Retractable Casters: Boost Your Workshop Efficiency

Imagine transforming your cluttered workspace into a safer, more efficient haven with just one simple addition. If you’ve ever found yourself struggling to move your table saw around your workshop, you know how frustrating and time-consuming it can be.

This is where table saw retractable casters come into play. By investing in these nifty tools, you not only enhance your workflow but also gain the flexibility to rearrange your space with ease. Curious about how these casters can revolutionize your woodworking experience?

Stay with us as we delve into everything you need to know about table saw retractable casters and how they can be a game-changer for you.

Credit: www.woodcraft.com

Why Retractable Casters Matter

Retractable casters make moving heavy tools easy. They help to move table saws. You can roll them to where you need. Casters save your back from lifting. Safety is important too. Casters stop the saw from moving. This makes cutting safer. They also help keep your workspace tidy. No more cluttered floors. Retractable casters are strong. They last long and work well. Installation is simple. Most can do it at home. Tools need to be stable. Casters make them stable. You can work better. Casters are a smart choice for any workshop. They fit most table saws. Upgrade your tools with casters. Your work will be safer and easier. Casters are not just wheels. They are helpers.

Credit: www.youtube.com

Choosing The Right Casters

Load capacity is key when picking casters. Heavy saws need strong casters. Each caster should hold enough weight. Total load must be split evenly. For a saw weighing 200 pounds, each caster should support 50 pounds. This ensures safe movement. Check caster ratings before buying. A safe choice saves time and trouble. Safety is always important.

Casters come in many materials. Rubber wheels are quiet and protect floors. Steel casters are strong but can scratch surfaces. Plastic ones are light and cheap. Choose based on your needs. Think about your work area. Hardwood floors might need rubber casters. Concrete floors can handle steel. Material choice affects durability and performance.

Installation Tips

Gather these tools before starting. A wrench is needed for tightening bolts. A drill helps make holes in the wood. Screws and a screwdriver are also necessary. A measuring tape ensures accurate measurements. Don’t forget a pencil for marking spots.

Begin by marking the caster positions. Use the measuring tape for this. Next, drill holes where the marks are. Attach the casters using screws. Tighten each screw with the screwdriver. Finally, check that each caster is secure. Ensure the table moves smoothly.

Safety Precautions

Locking mechanisms keep the table saw stable. This prevents accidents. Check locks before use. Ensure they are tight and secure. Loose locks can cause wobbling. This is unsafe. Always test the locking system. Press down on the saw. It should not move. If it moves, fix it. Locking mechanisms need regular checks. This is important for safety.

Proper weight distribution is vital. It keeps the saw from tipping. Balance the saw evenly. Use retractable casters wisely. They help in moving. Ensure weight is centered. This avoids falls. Heavy sides can tilt the saw. Check the balance often. Adjust if needed. Proper weight distribution prevents mishaps. Keep all sides equal.

Benefits Of Mobility

Retractable casters make your table saw easy to move. You can push it into a corner when not using it. This helps save space in small workshops. More room means less clutter. Working becomes easier and safer. Moving heavy tools is simple now. No more lifting or dragging.

With mobile tools, you can change the setup fast. You can start new projects without delay. This means you spend more time building and less time organizing. Easier movement saves your energy. You can work longer without getting tired. It makes your work fun and efficient.

Credit: www.woodcraft.com

Maintenance Advice

Check bolts and nuts every month. Ensure they are tight. Loose parts can cause problems. Inspect wheels for wear and tear. Replace if damaged. Lubricate casters regularly. It makes them last longer. Examine locking mechanisms. They must hold firm. Ensure brakes work properly. Safety first!

Caster won’t roll smoothly? Check for debris. Remove any dirt. Wheels squeak? Add a drop of oil. Wipe off extra oil. Caster doesn’t lock? Test and adjust the lock. If broken, replace it. Caster gets stuck? Look for bent parts. Fix or replace them. Keep checking regularly. Simple steps keep your saw safe.

Comparing Brands And Models

Choosing the right table saw casters can be tricky. Cost and quality often don’t match. Some brands offer affordable options. But, they may lack durability. Others focus on premium materials. Their price might be higher. But they last longer.

It’s important to balance both aspects. A cheap caster might break quickly. A costly one should perform better. Always read the product details. Check the materials and construction. This helps in making the best choice.

Listening to other users helps a lot. Many people share their experiences. Positive reviews often highlight smooth movement. Negative reviews might mention issues. Look for comments on ease of use. This can save you from regrets.

Also, check if installation was easy. Some casters are hard to fit. Others glide on smoothly. Users often share if they would buy again. A repeat purchase is a good sign. Pay attention to such details.

Frequently Asked Questions

What Are Retractable Casters For Table Saws?

Retractable casters allow easy mobility for heavy table saws. They provide stability during use and flexibility for movement. By retracting, they keep the saw stationary when needed, offering convenience for workshop setups.

How Do Retractable Casters Improve Saw Mobility?

These casters make moving your table saw effortless. They lift the saw off the ground, enabling smooth transport across your workspace. This ensures efficient rearrangement and storage without heavy lifting.

Are Retractable Casters Easy To Install?

Yes, retractable casters are generally straightforward to install. Most come with simple mounting instructions. You can attach them using common tools, making it a quick enhancement for your table saw.

Do Retractable Casters Affect Saw Stability?

When locked in place, retractable casters maintain the saw’s stability. They secure the saw firmly on the ground, preventing movement during operation. This ensures safety and precision while working on projects.

Conclusion

Table saw retractable casters make workshop tasks easier. They allow easy movement and storage. No more heavy lifting or dragging around. Safety improves with stable positioning. Casters lock securely when needed. Setup becomes quicker and more efficient. These tools offer great convenience for any woodworker.

Consider adding them to your workspace. Enhance your productivity and comfort. Better tool management leads to better projects. They’re a smart investment for any DIY enthusiast. Simplify your workshop experience today. Enjoy smoother, hassle-free woodworking sessions.