What is 8/4 Wood: Unlocking the Secrets of Lumber Sizes

**What is 8 4 Wood? ** 8 4 Wood refers to a specific type of lumber that measures 8 feet in length and 4 inches in width.

This wood is often used in construction and DIY projects. **Introduction** Understanding lumber dimensions is crucial for both professionals and DIY enthusiasts. The term “8 4 Wood” indicates a piece of lumber that is 8 feet long and 4 inches wide.

This size is commonly utilized for framing, decking, and various structural applications. Knowing the dimensions helps in planning and executing projects efficiently. Many people choose this type of wood for its versatility and ease of use. Whether you are building a deck or crafting furniture, 8 4 Wood provides a solid foundation. Familiarity with different wood types and sizes can significantly enhance your construction skills and project outcomes.

The Basics Of Lumber Measurement

8/4 wood refers to lumber that is 2 inches thick. The term “8/4” means it is 8 quarters of an inch thick. This lumber is often used for heavy-duty projects.</p

Understanding lumber dimensions is important for builders. Sizes are usually given in inches. Common dimensions include width and length. For example, a board can be 2 inches wide and 4 feet long.

| Measurement | Equivalent in Inches |

|---|---|

| 8/4 wood | 2 inches |

| 4/4 wood | 1 inch |

| 1/2 inch | 0.5 inches |

Decoding The ‘8/4’ In Lumber Sizes

The term ‘8/4’ refers to lumber that is two inches thick. This thickness is common for hardwoods. It is often used in furniture and cabinetry. Understanding lumber sizes helps in selecting the right material.

Other common lumber sizes include 4/4, which is one inch thick. 6/4 lumber is one and a half inches thick. Each size serves different purposes in woodworking. Here’s a quick comparison:

| Lumber Size | Thickness (inches) | Common Uses |

|---|---|---|

| 4/4 | 1 | Cabinet doors, panels |

| 6/4 | 1.5 | Table tops, thicker shelves |

| 8/4 | 2 | Heavy furniture, workbenches |

The Significance Of 8/4 Wood In Woodworking

8/4 wood is a popular choice in woodworking. This thickness offers great strength and stability. Many projects benefit from its durability.

Common projects for 8/4 wood include:

- Furniture: Tables and benches made from 8/4 wood last long.

- Cabinetry: Use it for sturdy cabinets that can hold weight.

- Doors: Thick doors provide better insulation and security.

- Wooden Beams: Great for structural support in buildings.

Strength and durability are crucial in woodworking. 8/4 wood provides excellent resistance to wear. It can handle heavy loads well, making it ideal for various applications.

How Lumber Is Milled To Size

The milling process transforms rough logs into finished lumber. It begins with cutting large logs into smaller pieces. These pieces are then dried to reduce moisture content. This step helps prevent warping or cracking later.

Next, the lumber is planed to achieve a smooth surface. Different machines are used to cut the wood to specific sizes. Common sizes include 8 by 4 feet for easy handling. Finally, the wood is graded based on its quality. High-quality lumber is more valuable in the market.

Selecting The Right 8/4 Wood For Your Project

Selecting the right 8/4 wood can enhance your project. Different wood species offer unique characteristics. Understanding these helps in making the best choice. Here are some common wood species and their traits:

| Wood Species | Grain Pattern | Aesthetics |

|---|---|---|

| Oak | Straight with visible rays | Warm, classic look |

| Maple | Fine, even grain | Bright, modern appearance |

| Cherry | Straight, smooth grain | Rich, deep color |

| Pine | Knots and swirls | Rustic, homey feel |

Choosing the right wood species affects both function and look. Consider grain patterns for added beauty. Aesthetic appeal can enhance any project.

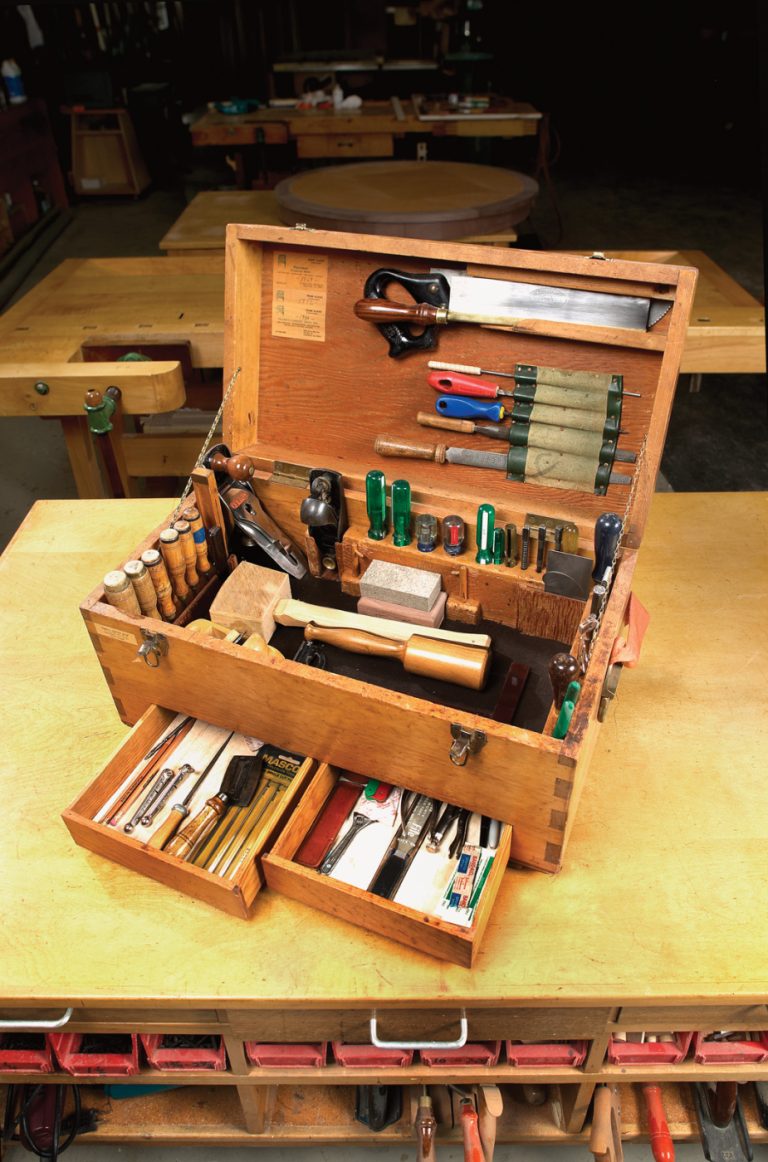

Working With 8/4 Wood: Tips And Techniques

Cutting and shaping 8/4 wood requires special tools and techniques. Use a table saw for straight cuts. A band saw works well for curves. Make sure to measure twice before cutting.

Thicker wood can be heavy. Use clamps to hold pieces securely. This helps prevent slips and accidents.

For joinery, choose mortise and tenon joints. They provide strong connections. Dovetail joints are also excellent for drawers and boxes. Use a router for precise cuts.

Sand the edges smooth. This improves the overall look of your project. Finish with stain or sealant for protection.

Finishing 8/4 Wood: Achieving The Best Results

Surface preparation is essential for 8/4 wood. Start by sanding the wood with fine-grit sandpaper. This helps to remove any rough spots and creates a smooth surface.

Use a vacuum or cloth to remove dust after sanding. This ensures a clean area for finishing. Sealing the wood is a good step. It protects against moisture and enhances the final look.

Choosing the right finish is important. Oil-based finishes provide a rich color and durability. Water-based finishes are easy to clean and dry quickly. Select based on your project needs.

Test the finish on a small area first. This helps see how the wood reacts. Always follow the manufacturer’s instructions for the best results.

Purchasing And Storing 8/4 Lumber

Finding quality 8/4 lumber is important for any project. Check local hardware stores and lumber yards. Online retailers often have a wide selection. Compare prices to get the best deal.

Storing lumber correctly helps maintain its quality. Keep lumber in a dry area to prevent moisture damage. Use stacks or racks to elevate the wood off the ground. Ensure good air circulation around the wood. Cover the lumber with a tarpaulin if storing outside.

| Best Practices for Lumber Storage | Details |

|---|---|

| Location | Store in a dry area |

| Elevation | Use stacks or racks |

| Airflow | Ensure good air circulation |

| Protection | Cover with a tarpaulin |

Frequently Asked Questions

What Is 8 4 Wood Used For?

8 4 wood is primarily used in construction and woodworking. Its dimensions, typically 8 inches wide by 4 inches thick, make it ideal for structural beams and heavy-duty applications. Additionally, it’s popular for crafting furniture and outdoor projects due to its strength and durability.

How Is 8 4 Wood Measured?

8 4 wood is measured in inches, referring to its thickness and width. The “8” indicates the width is 8 inches, while the “4” signifies the thickness of 4 inches. It’s important to note that lumber is often sold in nominal sizes, meaning actual dimensions may vary slightly.

Is 8 4 Wood Expensive?

The cost of 8 4 wood can vary based on wood type and market demand. Generally, hardwoods like oak or maple are pricier than softwoods like pine. Prices may also fluctuate based on supply chain factors. Always check local suppliers for accurate pricing.

Where Can I Buy 8 4 Wood?

You can purchase 8 4 wood at local lumberyards or home improvement stores. Many retailers offer a variety of wood types and sizes. Online marketplaces also provide options, allowing you to compare prices and availability easily. Always consider shipping costs when buying online.

Conclusion

Understanding what 8 4 wood is can enhance your woodworking projects. This type of lumber offers versatility and durability. Whether you are a seasoned craftsman or a beginner, knowing its properties helps you make informed choices. Embrace the benefits of 8 4 wood for your next project to achieve excellent results.