What is the Difference between Pneumatic and Electric Drills?

Are you on the hunt for the perfect drill to tackle your next big project? Choosing the right tool can be a bit daunting, especially with so many options available.

You might have heard about pneumatic drills and electric drills, but what’s the real difference between them? Understanding these differences can save you time, money, and effort, ensuring you pick the right drill for your specific needs. Imagine making a confident choice that boosts your productivity and gets the job done efficiently.

Isn’t that what you want? Before you make your decision, it’s crucial to know how each type of drill operates and what advantages they offer. This article will guide you through the key differences between pneumatic and electric drills, helping you make an informed choice that suits your projects perfectly. Ready to dive in and discover the ideal tool for you? Let’s get started!

Basics Of Drills

Pneumatic drills use compressed airto work. They are also known as air drills. These drills are often found in construction sites. Workers use them to break hard surfaces. They are good for heavy-duty tasks. Pneumatic drills can be noisy. They need an air compressorto run. This can make them less portable. But, they are very powerful.

Electric drills use electricityto power their motors. They plug into a wall or run on batteries. These drills are common in homes and workshops. They are used for lighter taskslike drilling holes or screwing. Electric drills are usually quieter. They are easy to carry around. Many people like them for their convenienceand ease of use.

Credit: axatool.com

Power Source

Pneumatic drills use air pressureto work. An air compressormakes this pressure. The compressor is often large. It connects to the drill with a hose. Air pressuremoves parts inside the drill. This makes the drill spin. Pneumatic drills are strongand can work in wet places. They are often used for big jobs.

Electric drills use electricityto work. They plug into a power outlet. Some have batteriesinstead. Electricity powers a motorinside the drill. The motor makes the drill spin. Electric drills are easyto carry. They can be used in small spaces. They are often used for simple tasksat home.

Performance And Efficiency

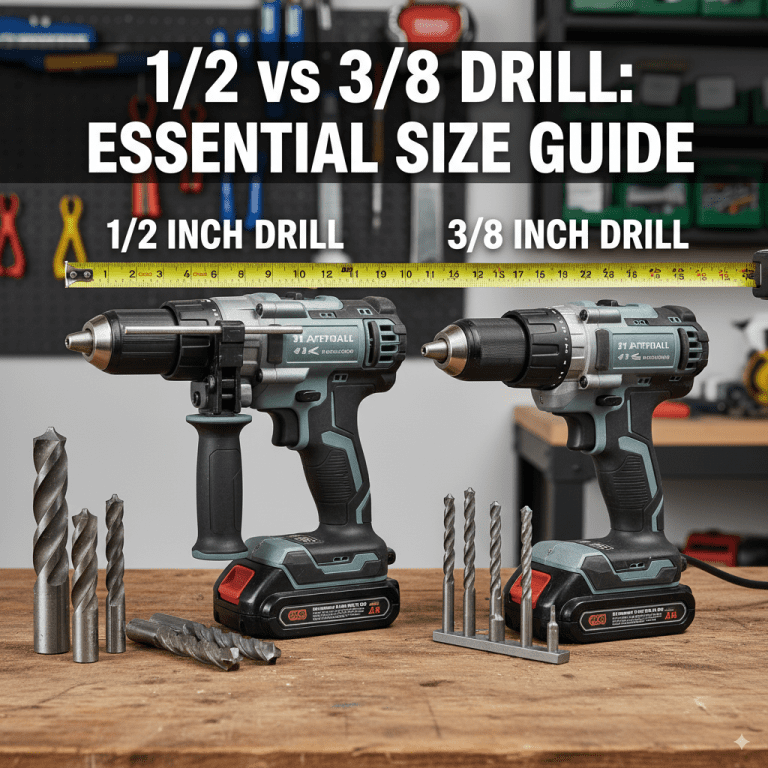

Pneumatic drills are known for high torque. They work well with hard materials. Electric drills offer better speed control. They are good for delicate tasks. Pneumatic drills are powerful. They are often used in industries. Electric drills are lighter and easier to use. They are perfect for home projects. Both tools have their own strengths. Choosing the right one depends on the job.

Pneumatic drills use compressed air. They need a lot of energy. Electric drills use electricity. They are more energy-efficient. Pneumatic drills require an air compressor. This makes them less portable. Electric drills are easy to carry. They can be used anywhere with a power source. Energy use affects costs. Electric drills usually save on energy bills.

Durability And Maintenance

Pneumatic drills are known for their strength. They are often used in tough jobs. The parts can handle heavy use. But they still face wear and tear. Air pressure helps run the drill. Over time, parts might wear out. Regular checks are a must. This keeps the drill working well. An air compressor is needed. It also needs care to avoid problems.

Electric drills are easy to use. They have simple parts. But they need care too. Overuse can cause overheating. This might damage the drill. Keep the drill clean. Dust can block air vents. This can cause the drill to overheat. Check wires often. Frayed wires can be dangerous. Proper care makes them last longer.

Safety Considerations

Pneumatic drills are powered by compressed air. They can be heavyand vibratea lot. Always use protective glovesto keep hands safe. Keep your body balancedwhile using the drill. Make sure the air hoseis not twisted or tangled. Check for leaksin the hose. Always stand in a safe position. Keep the work area cleanand freefrom clutter. Ensure the drill is turned offwhen not in use.

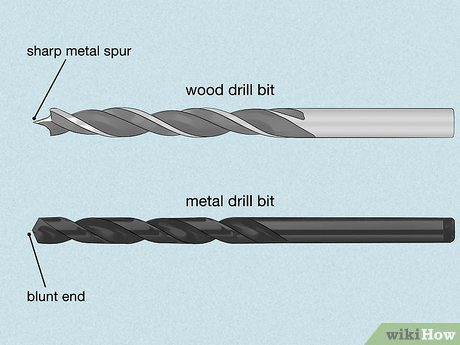

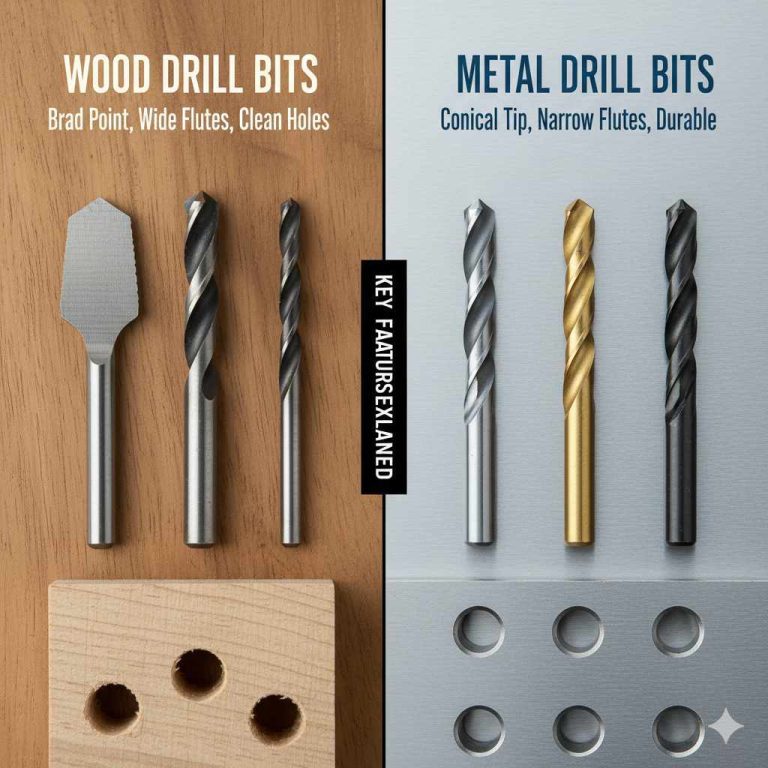

Electric drills use electricityto work. Check the cordfor damage before use. Avoid using near waterto prevent shocks. Always use the right drill bitfor the job. Hold the drill firmlyto avoid slipping. Keep fingers away from the drill bit. Wear eye protectionto shield eyes from debris. Unplug the drill when changing bits or cleaning. Never leave the drill unattendedwhile plugged in.

Cost And Availability

Pneumatic drills often cost more than electric drills. They need air compressors. This adds to the cost. Prices can start from $100. Some can go over $500. Professionals use them. They are not always in regular stores. Specialized shops sell them. Online stores also have them. Look for deals there.

Electric drills are less expensive. Many choices available. Prices start around $50. Some models can be over $200. Hardware stores stock them. Easy to find in most places. They are very popular. Sales and discounts often happen. Good deals are out there. Keep searching for the best price.

Environmental Impact

Pneumatic drillsare often seen as more eco-friendly. They use air pressure. No need for electricity. This means less energy consumption. Lower energy use is better for our planet. They also produce less heat. Less heat means less damage to the environment.

Electric drillshave some environmental concerns. They need electricity to work. This can lead to higher energy use. More energy use can harm nature. Electric drills can also get hot. Heat can affect the surroundings. It’s important to think about these issues.

Credit: www.woodsmith.com

Application And Usage

Pneumatic drills are commonly used in factories. They are powerful and can handle heavy-duty tasks. These drills are perfect for long hours of work. They don’t overheat easily. Pneumatic drills are also used in construction sites. They can break concrete and rock. Workers rely on them for tough jobs. Electric drills are less common in factories. They are better for lighter tasks. They can drill through metal and wood. They are ideal for quick jobs. Flexibility is their strong point. They are easy to move around.

Electric drills are popular at home. They are easy to use and carry. Many people choose them for DIY projects. They can drill holes in walls and furniture. They work well for small repairs. Pneumatic drills are rare at home. They need special air to work. Most people don’t have this air. Electric drills are handy for home projects. Simple and efficient.

Frequently Asked Questions

What Are Pneumatic Drills Used For?

Pneumatic drills are typically used in construction and demolition. They are ideal for breaking up concrete, asphalt, and other hard materials. Their power comes from compressed air, making them suitable for heavy-duty tasks. They are often preferred for their durability and ability to work in challenging environments.

How Do Electric Drills Work?

Electric drills operate using an electric motor powered by electricity. They are versatile tools used for drilling holes and driving screws. They’re suitable for various materials such as wood, metal, and plastic. Electric drills are popular for their convenience and ease of use in household and professional tasks.

Which Drill Is More Powerful?

Pneumatic drills are generally more powerful than electric drills. They derive their power from compressed air, enabling them to handle tough materials. This makes them ideal for demanding tasks like demolition. Electric drills, while versatile, are better suited for lighter tasks that require precision and control.

Are Electric Drills More Portable?

Yes, electric drills are more portable than pneumatic drills. They are compact and lightweight, making them easy to carry and use. Cordless models enhance portability, allowing use without a power outlet. This makes electric drills suitable for various locations, including remote or hard-to-reach places.

Conclusion

Choosing between pneumatic and electric drills depends on your needs. Pneumatic drills work well in heavy-duty settings. They offer consistent power and reliability. Electric drills are versatile and easy to use. They are great for home projects and lighter tasks.

Consider the availability of power sources. Also, think about your specific project requirements. Both types have unique benefits. Understanding these differences helps you make an informed decision. Select the drill that best fits your work environment. Make sure it meets your requirements.

Achieve efficiency and success in your drilling tasks.