What Temp to Apply Polyurethane: Best Practices

The ideal temperature to apply polyurethane is between 70°F and 80°F (21°C to 27°C). Avoid applying it in temperatures below 50°F (10°C) or above 90°F (32°C).

Applying polyurethane requires careful attention to temperature for optimal results. The right temperature ensures proper adhesion and drying time, which affects the finish quality. Working in temperatures between 70°F and 80°F allows the product to flow smoothly and cure effectively.

Humidity also plays a crucial role; high humidity can prolong drying time. Always check the manufacturer’s guidelines for specific recommendations. Proper preparation and environmental conditions lead to a durable, beautiful finish on your wood surfaces. Understanding these factors can make a significant difference in your project’s success.

Introduction To Polyurethane Finishes

Polyurethane finishes are popular for protecting wood surfaces. They provide a tough, durable layer that resists scratches and water damage. Many people use them for furniture, floors, and cabinetry. Understanding how to apply polyurethane correctly is essential for achieving the best results.

Basics Of Polyurethane

Polyurethane is a type of synthetic resin. It comes in two main forms:

- Oil-based: This type dries slowly. It offers a warm, amber tone.

- Water-based: This dries quickly. It remains clear and is easier to clean up.

Both types provide excellent protection. They enhance the natural beauty of wood. Each has unique properties that suit different projects.

Importance Of Proper Application

Proper application of polyurethane is crucial. This ensures a smooth and even finish. Follow these steps for best results:

- Choose the right temperature. Ideal application temperature is between 50°F to 90°F.

- Ensure humidity levels are low. High humidity can affect drying time.

- Use high-quality brushes or applicators. This helps avoid bubbles and streaks.

Applying polyurethane under the right conditions is key. This prevents issues like bubbling or uneven drying. Always read the manufacturer’s instructions for best practices.

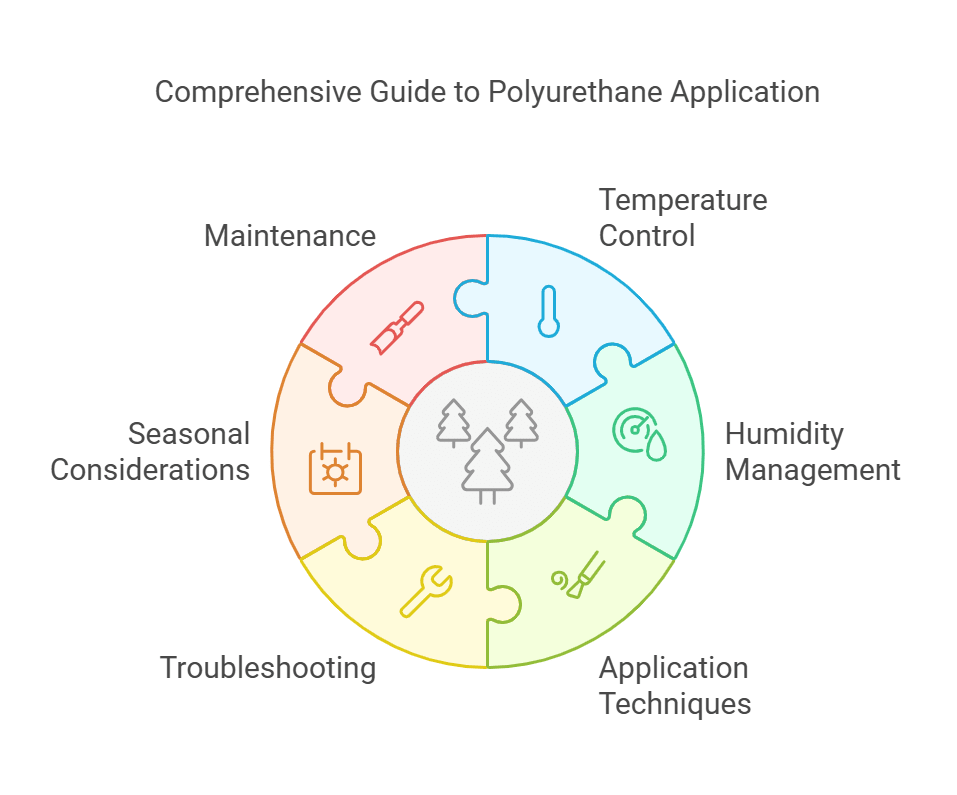

Ideal Temperature For Applying Polyurethane

Applying polyurethane at the right temperature is crucial for the best results. It affects drying time, finish quality, and adhesion. Understanding the ideal conditions can lead to a perfect finish.

Optimal Temperature Range

The best temperature range for applying polyurethane is between 65°F and 85°F (18°C to 29°C). This range allows the product to flow smoothly and dry evenly. Here’s a quick reference:

| Temperature Range | Effect on Polyurethane |

|---|---|

| Below 65°F | Slower drying time; increased risk of runs. |

| 65°F – 85°F | Optimal drying and curing; ideal finish. |

| Above 85°F | Faster drying; risk of bubbles and uneven finish. |

Effects Of Temperature On Polyurethane

Temperature significantly influences polyurethane performance. Here are key effects:

- Drying Time: High temperatures speed up drying. Low temperatures slow it down.

- Flow and Leveling: Warm conditions help polyurethane level out. Cold conditions can cause it to be lumpy.

- Adhesion: Proper temperatures enhance adhesion to surfaces. Extreme temperatures can lead to peeling.

For the best results, always check the weather. Avoid applying polyurethane in extreme temperatures.

Humidity’s Role In Polyurethane Application

Humidity significantly impacts the application of polyurethane. Understanding how it affects the process can lead to better results. High humidity can cause issues with drying and curing. Low humidity may also pose challenges. Knowing the right conditions ensures a smooth finish.

Understanding Humidity Levels

Humidity is the amount of moisture in the air. It affects how polyurethane dries and adheres. Here’s a quick guide to humidity levels:

| Humidity Level | Effect on Polyurethane |

|---|---|

| Low (0-30%) | Fast drying, may cause cracks |

| Moderate (30-60%) | Ideal for application and drying |

| High (60%+) | Slower drying, risk of bubbles |

Optimal humidity for applying polyurethane is between 30% and 60%. This range promotes proper curing and adhesion.

Mitigating Humidity Issues

High humidity can lead to several problems. Here are some tips to mitigate these issues:

- Use a dehumidifier: Lower moisture levels in the room.

- Choose the right time: Apply on dry days.

- Ventilate: Open windows to improve air circulation.

For low humidity, consider these actions:

- Use a slower-drying product: Look for formulas designed for low humidity.

- Apply in thin coats: This helps prevent cracks.

- Keep the area warm: Heat can help with curing.

By managing humidity levels, you ensure a successful polyurethane application.

Preparing The Environment For Application

Getting the environment right is crucial for applying polyurethane. Proper temperature and humidity levels enhance the finish quality. Follow these steps to prepare your space effectively.

Temperature And Humidity Control

Maintaining the right temperature and humidity is key. The ideal conditions are:

| Condition | Ideal Range |

|---|---|

| Temperature | 60°F to 80°F (15°C to 27°C) |

| Humidity | 30% to 50% |

Extreme temperatures can affect drying times. High humidity leads to bubbles in the finish. Use a thermometer and hygrometer to monitor conditions.

Preparing The Surface

Surface preparation is vital for a smooth application. Follow these steps:

- Clean: Remove dust, dirt, and grease.

- Sand: Smooth the surface with fine-grit sandpaper.

- Remove Dust: Wipe off sanding residue with a damp cloth.

- Dry: Ensure the surface is completely dry before applying.

Properly prepared surfaces allow for better adhesion. This results in a longer-lasting finish. Follow these steps closely for the best results.

Application Techniques For Different Conditions

Understanding the right application techniques is crucial for achieving a perfect finish with polyurethane. Different temperatures and conditions require specific approaches. This section will guide you through adjusting your technique based on temperature, and provide essential tools and tips for a smooth application.

Adjusting Technique By Temperature

Temperature affects how polyurethane dries and adheres. Here’s how to adjust your technique:

| Temperature Range | Recommended Technique |

|---|---|

| Below 50°F (10°C) | Use a slow-drying formula. Apply thin coats. |

| 50°F – 70°F (10°C – 21°C) | Standard application. Use regular drying time. |

| Above 70°F (21°C) | Work quickly. Use a fast-drying formula. |

Always check the manufacturer’s instructions for specific temperature guidelines. This ensures the best results.

Tools And Tips For A Smooth Finish

Using the right tools can make a big difference. Here are some tips for a smooth finish:

- Brush: Use a high-quality, synthetic brush.

- Roller: For large areas, use a smooth roller.

- Sanding: Lightly sand between coats for better adhesion.

- Temperature Control: Keep the area warm and well-ventilated.

Follow these steps for a flawless application:

- Prepare the surface by cleaning and sanding.

- Choose the right temperature and technique.

- Apply the first coat evenly.

- Allow proper drying time.

- Sand lightly before applying the next coat.

These simple techniques ensure a smooth, durable finish with polyurethane.

Troubleshooting Common Issues

Applying polyurethane can lead to various problems. Understanding these issues helps achieve a smooth finish. Below are common problems and their solutions.

Bubbles And Brush Marks

Bubbles and brush marks can ruin your finish. They often appear due to incorrect application techniques. Here are some reasons and solutions:

- Fast Application: Applying too quickly creates bubbles.

- Wrong Brush: Use a high-quality brush or foam applicator.

- Humidity: High humidity can cause bubbles. Aim for 50% humidity.

To fix bubbles:

- Wait for the finish to dry.

- Sand the area lightly.

- Reapply a thin coat.

Tackiness And Drying Problems

Some finishes may feel tacky or take too long to dry. This can be frustrating. Common causes include:

- High Humidity: Excess moisture slows drying time.

- Low Temperature: Cold temperatures can prevent proper curing.

- Thick Coats: Applying too much polyurethane can cause tackiness.

To resolve tackiness:

- Check room temperature (ideal: 70-75°F).

- Ensure good air circulation.

- Consider using a thinner coat next time.

By knowing how to troubleshoot, you can achieve a perfect finish every time.

Seasonal Considerations For Polyurethane Application

Applying polyurethane requires attention to seasonal changes. Different temperatures and humidity levels affect how the finish cures. Understanding these factors helps achieve the best results.

Summer And Winter Differences

Summer and winter bring unique challenges for polyurethane application:

| Season | Temperature (°F) | Humidity Level | Application Tips |

|---|---|---|---|

| Summer | 70-90 | 30-70% |

|

| Winter | 50-70 | 20-50% |

|

Adjustments For Spring And Fall

Spring and fall also require specific adjustments:

- Spring:

- Watch for rain and moisture.

- Temperature can fluctuate, so check often.

- Use a dehumidifier if necessary.

- Fall:

- Cooler temperatures may slow drying.

- Check humidity levels regularly.

- Plan for unpredictable weather changes.

Paying attention to these seasonal factors ensures a smooth application. Proper conditions lead to a durable and beautiful finish.

Maintaining The Finish Over Time

To keep your polyurethane finish looking great, regular care is essential. Proper maintenance extends the life of the finish. Knowing how to care for it ensures it stays vibrant and durable.

Long-term Care Tips

- Clean Regularly: Dust surfaces often to prevent buildup.

- Avoid Harsh Chemicals: Use mild cleaners for safe cleaning.

- Use Soft Cloths: Avoid abrasive materials that can scratch.

- Control Humidity: Maintain a stable humidity level indoors.

- Protect from Sunlight: Use curtains to block direct sunlight.

When To Reapply Polyurethane

Reapplying polyurethane helps maintain its protective layer. Look for signs that indicate it’s time to reapply:

- Visible Wear: Noticeable scratches or dullness appear.

- Water Damage: Water beads less on the surface.

- Fading Color: The original color looks washed out.

- Frequent Cleaning: You need to clean more often.

Reapply every 3 to 5 years, depending on use. High-traffic areas may need more frequent attention.

Frequently Asked Questions

What Is The Ideal Temperature For Applying Polyurethane?

The ideal temperature for applying polyurethane ranges from 70°F to 80°F (21°C to 27°C). This temperature ensures proper drying and curing. Temperatures below 60°F (15°C) can slow down the process, while above 90°F (32°C) may lead to bubbles or uneven finishes.

Can I Apply Polyurethane In Cold Weather?

Applying polyurethane in cold weather is not recommended. Low temperatures can cause the finish to become tacky and take longer to dry. If you must apply it in colder conditions, use a space heater to maintain an optimal temperature range.

Does Humidity Affect Polyurethane Application?

Yes, humidity significantly impacts polyurethane application. High humidity can extend drying times and lead to a cloudy finish. Aim for humidity levels below 70% for best results. Consider using a dehumidifier if you’re working in a humid environment.

How Long Does Polyurethane Take To Cure?

Polyurethane typically takes 24 to 48 hours to dry, depending on temperature and humidity. Full curing can take up to 30 days. It’s essential to avoid heavy use during this period to achieve the best durability and finish.

Conclusion

Understanding the right temperature for applying polyurethane is crucial for achieving the best finish. Aim for a controlled environment between 70°F and 80°F. This ensures optimal drying and adhesion. Following these guidelines will help you avoid common pitfalls and enhance your project’s overall quality.

Happy finishing!