When was Plywood First Made?: Unveiling its Origins

Plywood was first made in 1797. It is a type of engineered wood product.

The invention of plywood revolutionized the woodworking industry. Before plywood, solid wood planks were used for sub-flooring and exterior wall sheathing. Today, plywood is a popular choice for various construction and woodworking projects due to its strength, versatility, and cost-effectiveness.

This engineered wood product is made by gluing together thin layers of wood veneer, known as plies, to create a strong and durable sheet material. Plywood has become an essential material in modern construction and furniture making, and its production process has evolved over the years to meet the growing demand for this versatile wood product.

Tracing Back To The Origins

Plywood, a versatile building material, has been around for centuries. Its origins can be traced back to 1797 when it was first invented. Before plywood, solid wood planks were commonly used in construction. Today, plywood is widely used in various applications due to its strength, durability, and cost-effectiveness.

Ancient Beginnings

Plywood may seem like a modern invention, but its origins can be traced back to ancient times. The ancient Egyptians, for instance, used thin pieces of wood glued together to make furniture and sarcophagi. Additionally, the Greeks and Romans used laminated wood to create curved furniture pieces.

Industrial Revolution Innovations

It wasn’t until the 19th century that plywood as we know it today began to emerge. In the mid-1800s, rotary veneer cutting was invented, allowing for the production of thin, uniform veneers. This, combined with the discovery of synthetic adhesives, made it possible to create plywood on a large scale.

During the Industrial Revolution, plywood was used for a variety of applications, such as building materials, furniture, and even airplanes. In fact, the Wright brothers used plywood to construct their famous aircraft, the Wright Flyer.

Today, plywood remains a popular building material due to its strength, versatility, and affordability. From home construction to furniture making, plywood continues to be a staple in many industries.

Sources:

– “A Short History of Plywood in Ten-ish Objects” – Victoria and Albert Museum

– “Plywood” – Wikipedia

– “The Origins of Wholesale Plywood in the United States” – USply

– “The History of Plywood” – Fomex Group

The Evolution Of Plywood Manufacturing

Plywood has a long history dating back to ancient Egypt, but it wasn’t until the 19th century that the modern process of manufacturing plywood was developed. The first patent for plywood was issued in the United States in 1865, and since then, plywood has become a popular building material due to its strength and versatility.

Early Techniques

Plywood has a long and fascinating history, dating back to ancient Egypt and China. Early techniques of plywood manufacturing involved manually cutting thin layers of wood, known as veneers, from logs using a knife or saw. These veneers were then glued together with animal-based adhesives, such as bone glue, to create a strong and durable panel. The process required skilled craftsmen who carefully selected and arranged the veneers to ensure optimal strength and stability.

Modern Advancements

Over time, advancements in technology and manufacturing processes revolutionized the plywood industry. In the late 18th century, the invention of the rotary lathe made it possible to produce veneers more efficiently. This innovation allowed for the production of larger and more uniform sheets of plywood.

Another significant advancement came with the introduction of synthetic adhesives in the early 20th century. These adhesives, such as phenol-formaldehyde and urea-formaldehyde, provided stronger and more durable bonds between the veneers. This made plywood even more resistant to moisture, heat, and chemicals.

Today, plywood manufacturing involves highly automated processes that ensure precision and consistency. Computer-controlled machines are used to cut, patch, and stack the veneers, resulting in high-quality plywood boards. Advanced adhesives, such as melamine-urea-formaldehyde and phenol-resorcinol-formaldehyde, are now commonly used, further enhancing the durability and performance of plywood.

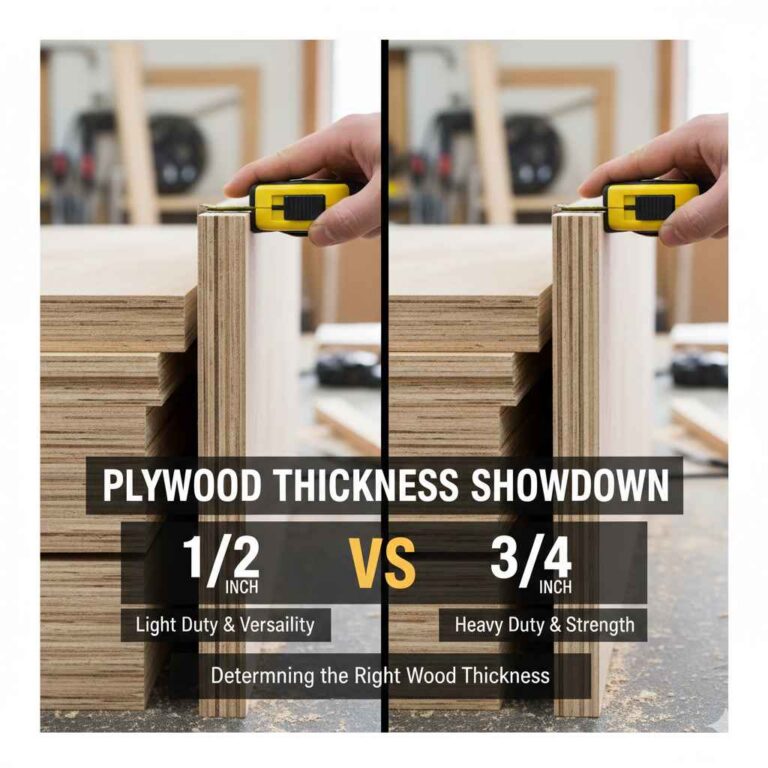

Moreover, the availability of various wood species and the ability to produce plywood with different thicknesses and grades have expanded the range of applications for this versatile material. From construction and furniture to packaging and automotive industries, plywood continues to be a popular choice due to its strength, durability, and cost-effectiveness.

Plywood In Construction: A Historical Overview

When it comes to construction materials, plywood has become an integral part of the industry. Its versatility, durability, and cost-effectiveness have made it a popular choice for builders and architects alike. But when was plywood first made? Let’s take a closer look at the history of plywood in construction.

First Uses In Building

Before plywood became widely used, builders relied on solid wood planks for sub-flooring and exterior wall sheathing. While these materials provided strength and stability, they had limitations. Solid wood planks were prone to warping, splitting, and were often expensive. However, everything changed with the invention of plywood in the late 18th century.

Plywood, as we know it today, was first invented in 1797. It was initially used in the construction of boats, providing a lightweight yet sturdy material that could withstand the harsh conditions of the sea. The use of plywood quickly expanded beyond the maritime industry and found its way into various construction applications.

Plywood On Roofs And Walls

As builders discovered the benefits of plywood, its usage extended to roofs and walls. Plywood proved to be an excellent material for these applications due to its structural integrity and resistance to moisture. Its layered composition, with alternating grain directions, provided enhanced strength and stability.

By the early 20th century, plywood had become a common choice for roofing and wall sheathing in residential and commercial buildings. Its use revolutionized construction practices, making it easier, faster, and more cost-effective to build structures.

Manufacturing Process

The manufacturing process of plywood has also evolved over time. Today, it involves the use of advanced machinery and technology to produce high-quality plywood boards. Here is a simplified overview of the modern manufacturing process:

- Douglas fir trees are felled for plywood manufacture.

- The bark is removed to make a smooth surface for cutting.

- A knife held against the length of the log unpeels it into a single sheet of veneer.

- The cut veneers are sorted into stacks according to their size and quality.

- Dried veneers are removed at the other end.

- Glue is evenly applied to the veneers by the glue spreader.

- The stacks of layered-up veneers are loaded into the hot press.

- The plywood boards are removed from the press.

- Veneers are cut on a rotary lathe, scanned for imperfections, and patched by computer-controlled machines.

This modern manufacturing process ensures the production of high-quality plywood that meets the demands of the construction industry.

In conclusion, plywood has a rich history in construction, starting from its invention in 1797. It has proven to be a game-changer in the industry, providing builders with a reliable and versatile material. From its early uses in boat construction to its widespread adoption in roofs and walls, plywood continues to play a vital role in modern construction practices.

Plywood In The Furniture Industry

Plywood, a versatile material widely used in the furniture industry, was first made in the 1860s. Its invention revolutionized furniture construction, offering strength and stability. Today, plywood remains a popular choice for furniture makers due to its durability and cost-effectiveness.

Initial Applications

Plywood, a versatile and cost-effective building material, has had a significant impact on the furniture industry. In its early days, plywood was primarily used for construction purposes due to its strength and durability. However, its potential in the furniture industry was soon realized, and it began to revolutionize the way furniture was designed and manufactured.

Revolutionizing Modern Furniture

With its unique properties, plywood opened up endless possibilities for designers and manufacturers in the furniture industry. Its strength and stability allowed for the creation of innovative and intricate designs that were previously difficult to achieve with traditional solid wood. The ability to bend and shape plywood into various forms expanded the range of furniture styles and added a touch of creativity to modern interior designs.

Plywood also offered advantages in terms of cost and efficiency. Its availability in large sheets allowed for the production of furniture pieces with fewer joints, resulting in reduced labor and material costs. Additionally, the uniformity of plywood sheets ensured consistent quality and minimized the risk of warping or splitting, making it a reliable choice for furniture manufacturers.

Furthermore, plywood’s lightweight nature made it easier to handle and transport furniture, while still maintaining its structural integrity. This made it a popular choice for both commercial and residential furniture, as it offered durability without sacrificing convenience.

As the furniture industry continues to evolve, plywood remains a go-to material for designers and manufacturers alike. Its versatility, durability, and cost-effectiveness make it an ideal choice for creating modern and stylish furniture pieces that meet the demands of today’s consumers.

Plywood Across The Globe

Plywood has a rich history dating back to ancient Egypt, where it was first made by gluing thin layers of wood together. However, the modern plywood we know today was invented in the early 20th century, revolutionizing the construction and furniture industries.

Introduction In The United States

Plywood was first made in the early 20th century, and the United States played a significant role in its development. In 1928, a company called the United States Plywood Corporation was formed, and it quickly became one of the largest producers of plywood in the world. The popularity of plywood in the U.S. grew rapidly, and it became a standard material for use in construction, furniture making, and other industries.

Spread To Other Regions

As the use of plywood became more widespread in the United States, it began to spread to other regions of the world. Today, plywood is produced in many countries and is used in a variety of ways. In Europe, for example, plywood is commonly used in the construction of buildings and bridges, while in Asia, it is often used in furniture making.

Manufacturing methods have also evolved over time. In the past, plywood was made by gluing thin sheets of wood together, but today, it is often made using more advanced techniques, such as cross-laminating the wood to create a stronger and more durable material.

Overall, the history of plywood is a fascinating one that spans continents and centuries. From its humble beginnings in the United States to its widespread use around the world today, plywood has proven to be a versatile and valuable material that continues to play an important role in many industries.

Before Plywood: Alternatives And Predecessors

Before plywood, solid wood planks were used for sub-flooring and exterior wall sheathing. Plywood was first made in 1797, and it revolutionized construction and furniture making. Today, plywood is a widely used material known for its strength and versatility.

Before the invention of plywood, solid wood was the most common material used in construction. However, solid wood had its drawbacks, such as warping and splitting, which led to the development of alternative materials. One of the earliest alternatives was the use of veneers, which are thin slices of wood that are glued together to form a thicker sheet. Another alternative was the use of particleboard, which is made by compressing wood particles together with glue. Both of these materials had their limitations, and it wasn’t until the invention of plywood that a truly superior material was available.

Solid Wood

Solid wood has been used in construction for thousands of years, and it is still used today in many applications. However, solid wood has its limitations. It is prone to warping, splitting, and cracking, which makes it unsuitable for certain applications. In addition, solid wood is often expensive and difficult to work with.

Other Materials

Veneers and particleboard were two of the earliest alternatives to solid wood. Veneers are thin slices of wood that are glued together to form a thicker sheet. While veneers can be used to create decorative finishes, they are not very strong and are prone to splitting and warping. Particleboard, on the other hand, is made by compressing wood particles together with glue. While particleboard is stronger than veneers, it is still prone to warping and is not very durable.

Transition To Plywood

The invention of plywood was a game-changer for the construction industry. Plywood is made by gluing together multiple thin layers of wood, with the grain of each layer running perpendicular to the previous layer. This cross-grain construction gives plywood its strength and durability, while also reducing its tendency to warp and split. Plywood is also relatively inexpensive and easy to work with, making it a popular choice for many applications.

Overall, the development of plywood was a significant milestone in the history of construction materials. It provided a strong and durable alternative to solid wood, as well as to earlier alternatives such as veneers and particleboard. Today, plywood is used in a wide range of applications, from subflooring and roofing to furniture and cabinetry.

Understanding Plywood’s Manufacturing Process

Plywood was first made in the 18th century. Before the advent of plywood, solid wood planks were used for sub-flooring and exterior wall sheathing. The manufacturing process involves peeling, drying, gluing, and pressing the veneers to create plywood boards.

Plywood is a versatile building material that is widely used in construction, furniture manufacturing, and various other applications. To fully comprehend the value and quality of plywood, it is essential to understand its manufacturing process. In this section, we will explore the journey of logs transforming into layers, the technological innovations involved, and the final production of plywood boards.

From Logs To Layers

The process of manufacturing plywood starts with the selection of suitable logs. High-quality logs, typically sourced from softwood trees like Douglas fir, are chosen for their strength and durability. These logs are then felled and prepared for further processing.

After the logs have been felled, the bark is removed to ensure a smooth surface for cutting. This step is crucial as it helps in achieving uniform and consistent veneer sheets. The logs are then fed into a machine called a rotary lathe, where a knife is held against the length of the log. This action unpeels the log into a single sheet of veneer.

Once the veneers are cut, they are sorted into stacks based on their size and quality. This meticulous sorting process ensures that each plywood board is made up of veneers that are similar in thickness and appearance. The veneers are then dried and prepared for the next stage of production.

Technological Innovations

Over the years, technological advancements have greatly improved the manufacturing process of plywood. Computer-controlled machines play a significant role in enhancing the quality and efficiency of production.

After the veneers have been cut and sorted, they are scanned for imperfections and patched by computer-controlled machines. This step ensures that any defects or irregularities in the veneers are addressed, resulting in a higher-quality final product. The use of these machines also minimizes human error and increases the precision of the manufacturing process.

Another technological innovation in plywood production is the glue spreader. Glue is evenly applied to the veneers by this machine, ensuring a strong and reliable bond between the layers. The even distribution of glue is crucial for the structural integrity of the plywood boards.

Final Production Of Plywood Boards

After the veneers have been sorted, patched, and glued, they are loaded into a hot press. The hot press applies heat and pressure to the stacks of layered-up veneers, resulting in the consolidation of the layers and the formation of plywood boards.

Once the boards have been pressed and cooled, they are removed from the press and undergo a final inspection. Any boards that do not meet the required standards are discarded, ensuring that only high-quality plywood boards are released into the market.

In conclusion, understanding the manufacturing process of plywood gives us insights into the meticulous steps involved in creating this versatile building material. From logs to layers, and with the aid of technological innovations, plywood production has evolved to meet the demands of modern construction and design.

Plywood’s Role In Antique Furniture

Plywood has played a significant role in antique furniture since its invention in the 18th century. The first known use of plywood dates back to 1797, and it has since been a popular choice for crafting durable and intricate furniture pieces.

Historical Significance

Plywood has played a significant role in the creation of antique furniture throughout history. Its invention revolutionized the furniture-making industry, offering craftsmen a versatile and cost-effective material to work with. By understanding the historical significance of plywood, we can gain a deeper appreciation for the craftsmanship and design of antique furniture.

Identification And Preservation

Identifying and preserving antique furniture made with plywood requires a keen eye and knowledge of the material’s characteristics. Plywood, with its distinct layering and grain patterns, can be easily identified when examining antique pieces. Preservation techniques, such as proper cleaning and maintenance, ensure that the plywood remains in good condition for years to come.

When it comes to identifying plywood in antique furniture, there are a few key factors to consider:

- Layering: Plywood is composed of several layers of thin wood veneers glued together. These layers can often be seen at the edges of furniture pieces, providing a telltale sign of plywood construction.

- Grain Patterns: Each layer of plywood has a distinct grain pattern, resulting in a unique appearance. Examining the grain patterns can help determine if plywood was used in the construction of antique furniture.

- Manufacturing Techniques: Antique furniture made with plywood may exhibit specific manufacturing techniques, such as curved or molded plywood components. These techniques were often employed to take advantage of plywood’s flexibility and strength.

Preserving antique furniture made with plywood involves taking certain precautions:

- Cleaning: Regular dusting and gentle cleaning using non-abrasive materials help maintain the beauty of antique plywood furniture.

- Humidity Control: Plywood is sensitive to changes in humidity, which can cause warping or delamination. Keeping antique furniture in a stable humidity environment helps prevent damage.

- Protection: Using protective covers or pads can safeguard plywood surfaces from scratches and other physical damage.

By understanding the historical significance of plywood and implementing proper identification and preservation techniques, we can appreciate and enjoy the beauty of antique furniture for generations to come.

Frequently Asked Questions

When Did We Start Using Plywood?

Plywood was first used in 1797, and it became popular for construction and furniture making in the 20th century.

When Was 4×8 Plywood Invented?

Plywood was first invented in 1797, but it wasn’t until 1928 that the 4×8 size was introduced. Before plywood, solid wood planks were used for sub-flooring and exterior wall sheathing. Plywood is now commonly used in furniture, houses, and roofs, and is made by layering and gluing thin sheets of wood veneer together.

When Did Carpenters Start Using Plywood?

Carpenters started using plywood in 1865. Before plywood, solid wood planks were used for sub-flooring and exterior wall sheathing. Plywood was invented as a more cost-effective and versatile alternative. It is made by layering thin sheets of wood veneer and bonding them together with adhesive.

Plywood became popular for its strength, durability, and ease of use in construction and furniture making.

What Did Builders Use Before Plywood?

Before plywood, builders used solid wood planks as sub-flooring and exterior wall sheathing. This provided strength and stability to the structures. However, with the advent of plywood and particleboard, these materials became popular alternatives due to their cost-effectiveness and ease of use.

Plywood, in particular, gained popularity for its versatility and strength.

Conclusion

The history of plywood dates back to the 18th century, with its modern production methods evolving over time. Plywood has revolutionized construction and woodworking, offering a durable and versatile material. Its usage has become widespread in various applications, contributing to the development of innovative and sustainable building practices.