Wood Screws Vs Deck Screws: Choosing the Right Fastener

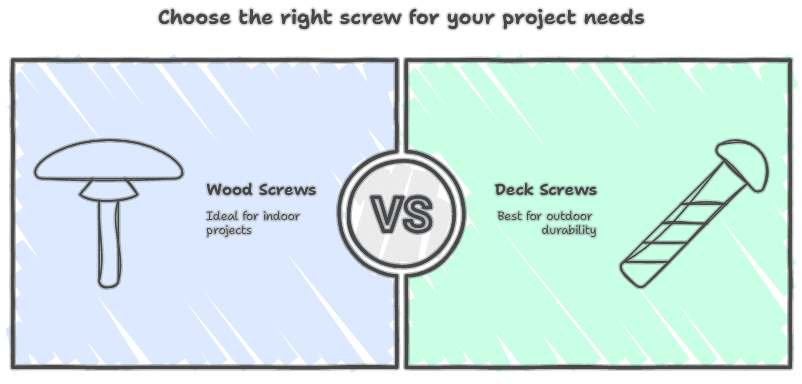

When you’re in the midst of a project, choosing the right screws can make all the difference. You might be wondering whether wood screws or deck screws are the better option for your needs.

This decision can impact the strength, longevity, and appearance of your work. Imagine the satisfaction of knowing you’ve selected the perfect screw, ensuring your project not only stands the test of time but also looks impeccable. We’ll dive deep into the differences between wood screws and deck screws, helping you make an informed choice.

Are you ready to enhance your DIY skills and avoid common pitfalls? Let’s get started!

Types Of Screws

Wood screws are strong and reliable. They have a sharp point. This helps them go into the wood easily. The threads are coarse. This gives a better hold. The head is usually flat. It sits well on the wood. Wood screws come in many sizes. Choose the right size for your project. Use a screwdriver for tight fitting. These screws are used for making furniture. Also for fixing wooden frames.

Deck screws are made for outdoor use. They resist rust and corrosion. These screws are longer. This ensures a firm grip in wood. The head is larger. It prevents the screw from slipping. Deck screws are durable. They withstand harsh weather. Perfect for decks and patios. Always use the right drill bit. Choose deck screws for outdoor projects. They are strong and reliable.

Material Composition

Wood screws are often made from steel. This makes them strong. Sometimes, they use brass. This makes them look nice. But brass is not as strong as steel. Deck screws are usually made of steel too. They are strong and tough. These screws can handle weather changes.

Some screws have special coatings. These coatings stop rust. For example, wood screws might have a coating. This keeps them from rusting. Deck screws have even better coatings. They resist water and sun damage. A special treatment makes them last longer.

Design Features

Wood screws have coarse threads. These threads grip wood tightly. They prevent slipping. Deck screws have finer threads. They are designed for outdoor use. They resist weather effects. Both screws have different purposes. Choose wisely based on need. Wood screws are for indoor projects. Deck screws are for outdoor decks.

Wood screws often have flat heads. These heads allow for a smooth surface. Ideal for furniture and cabinets. Deck screws usually have bugle heads. They fit snugly into wood. Prevent splitting and cracking. Head styles affect installation. Flat heads sit flush. Bugle heads provide extra hold. Think about your project needs.

Application Areas

Wood screws are often used indoors. They are great for furniture making. You can use them for shelves too. These screws work well with soft woods. They hold materials together tightly. Their sharp tips make them easy to insert. They are ideal for small repairs. You can use them for cabinet assembly. They are also good for picture frames.

Deck screws are best for outdoor tasks. They resist rust and weather. Use them for building decks and fences. They hold up in rain and sun. Their coating keeps them strong. Deck screws are great for patio furniture. They are strong and durable. These screws last a long time. They are good for garden projects too.

Durability And Strength

Wood screws are not very good against water. They can rust easily. This makes them less durable. Deck screws are better. They have a special coating. This helps them resist rust. They stay strong in wet areas. Deck screws are great for outdoor projects. They last longer.

Wood screws can hold weight. But they are not very strong. They might break under heavy loads. Deck screws are tougher. They can carry more weight. They are made for heavy-duty jobs. Deck screws are perfect for building decks. They keep things secure.

Credit: woodgears.ca

Installation Techniques

Choosing between wood screws and deck screws depends on the project. Wood screws are ideal for indoor tasks, offering a firm grip. Deck screws resist rust, making them perfect for outdoor use. Each type serves a specific purpose, ensuring durability and strength in different environments.

Pre-drilling Requirements

Wood screws often need pre-drilling to prevent wood from splitting. This step helps the screw go in smoothly. Deck screws usually don’t need pre-drilling. They have a special tip that makes holes as they turn. This feature saves time and effort. It’s important to know the type of wood. Hardwoods may need pre-drilling even for deck screws. Softwoods are less likely to split. Always check the screw instructions for best results.

Driving Methods

Wood screws are driven using a screwdriver or drill. The tool matches the screw head type. Deck screws often use a power drill with a special bit. This helps them go in faster. The drill bit grips the screw tightly. Using a power drill requires care. Keep your hand steady while drilling. Don’t rush the process. Fast driving can damage the wood. Practice makes perfect with driving methods.

Cost Considerations

Wood screws are usually cheaper. They are easy to find. Most hardware stores have them. Deck screws cost more. They have extra features. These features help them last longer. Sometimes, you get what you pay for. So, think about what you need. You might save money with wood screws. But for outdoor projects, deck screws are better. They stop rust and are strong.

Deck screws offer better long-term value. They last longer in bad weather. You won’t need to replace them often. That saves money over time. Wood screws might wear out. You may need to buy new ones sooner. Think about the project. If it’s outside, deck screws are a smart choice. They might cost more at first. But they save money later.

Credit: monsterbolts.com

Choosing The Right Fastener

Wood screws are perfect for wood projects. They have a sharp tip. This makes them easy to drive into wood. Deck screws are best for outdoor use. They resist rust and corrosion. This keeps your deck strong and safe. Choose wood screws for indoor furniture. Deck screws are better for outdoor decks.

Weather affects screw choice. Rain and moisture cause rust. Deck screws resist this better. Wood screws may rust in wet conditions. Choose deck screws for rainy areas. Dry places are fine for wood screws. Temperature changes can weaken screws. Deck screws handle temperature changes better. Wood screws might crack. Always consider the weather for your project.

Credit: www.nachi.org

Frequently Asked Questions

Are Deck Screws As Strong As Wood Screws?

Deck screws are generally stronger than wood screws. They are designed for outdoor use, offering corrosion resistance and durability. Wood screws are suitable for indoor projects and may lack the strength and protective coating of deck screws. Choose deck screws for structural integrity and longevity in outdoor settings.

Can I Use Wood Screws For Decking?

Using wood screws for decking is not recommended. Deck screws are specifically designed for outdoor durability. They resist corrosion and provide better strength. For a safe and lasting deck, always use high-quality deck screws.

Can I Use Deck Screws For Everything?

Deck screws are not suitable for every task. Use them for outdoor wooden projects. For metal or drywall, use appropriate screws.

What Is The Difference Between Decking Screws And Normal Screws?

Decking screws resist corrosion, ideal for outdoor use. Normal screws lack weather resistance, suited for indoor projects. Decking screws have sharper threads for wood, ensuring firm grip. Normal screws often have flat heads, varying thread styles for different materials. Choose based on environment and material requirements.

Conclusion

Choosing the right screw matters for your project. Wood screws are perfect for indoor tasks. They work best in furniture or cabinetry. Deck screws hold strong in outdoor settings. They resist rust and weather well. Each type has its own strengths.

Consider your environment and project needs. Match screws with the right materials. This ensures a sturdy and lasting result. Picking wisely saves time and trouble. Happy building!