Ash Wood: Hard or Soft? Proven Essential Guide

Is ash wood considered hard or soft? Ash wood is decidedly a hard wood. Renowned for its strength, durability, and attractive grain, it’s a fantastic choice for a wide range of woodworking projects. You can confidently use ash for furniture, tool handles, and more, knowing it will stand the test of time.

Hey there, fellow DIY enthusiasts and aspiring woodworkers! Md Meraj here, ready to demystify another common question that pops up when you’re picking out wood for your next project: “Is ash wood hard or soft?” It’s a super important question because the type of wood you choose can make or break your project, affecting how easy it is to work with, how it looks, and how long it lasts. Many beginners feel a bit lost when faced with different wood types, wondering if ash will be too tough to handle or not sturdy enough for their needs. Don’t worry, I’ve got your back! We’re going to break down exactly what ash wood is, whether it’s a hardwood or softwood, and why it’s such a popular choice among woodworkers. Stick with me, and by the end of this guide, you’ll feel confident about choosing and using ash wood for all your creative endeavors!

Understanding Wood Hardness: A Quick Primer

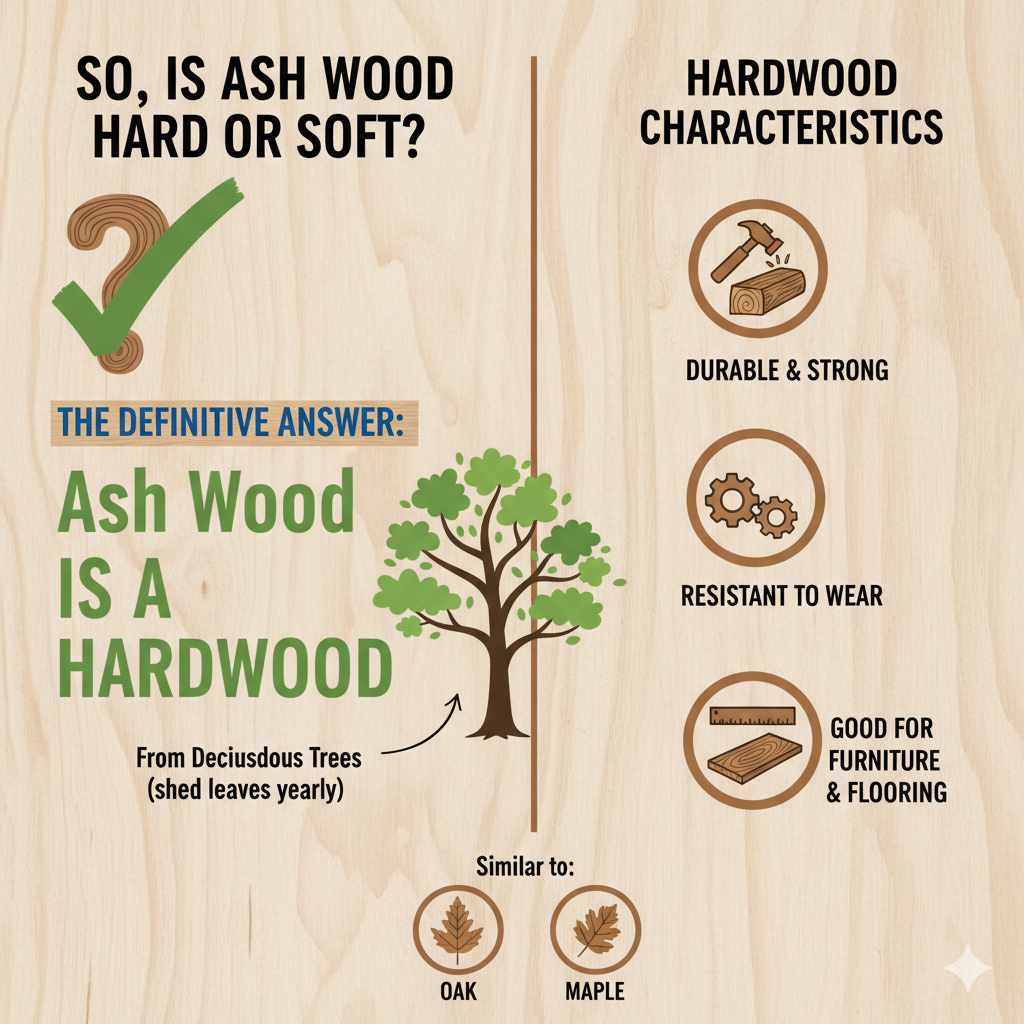

Before we dive deep into ash, let’s quickly understand what makes wood “hard” or “soft.” This isn’t about how easy it is to dent with your fingernail, as you might imagine! In the timber world, “hardwood” and “softwood” refer to the botanical classification of the trees the wood comes from.

Hardwoods come from deciduous trees (trees that lose their leaves annually), like oak, cherry, maple, and, you guessed it, ash. These trees typically have broader leaves and grow slower, which generally results in a denser, stronger wood.

Softwoods come from coniferous trees (evergreens with needles and cones), like pine, spruce, and fir. These trees often grow faster and have simpler structures, leading to a lighter, less dense wood.

So, right off the bat, when we talk about ash, we’re talking about a hardwood. This classification gives us a clue about its properties, but let’s explore those in more detail!

So, Is Ash Wood Hard or Soft? The Definitive Answer

To put it simply and directly: Ash wood is a hardwood.

This means it comes from deciduous trees (trees that shed their leaves each year) and shares many characteristics with other well-known hardwoods like oak and maple. This “hardwood” classification is your first key piece of information about its performance and behavior in your workshop.

The Amazing Properties of Ash Wood

Why is ash so popular, then? It’s not just its hardness; ash wood boasts a fantastic combination of strength, flexibility, and beauty that makes it a go-to choice for a wide array of applications.

Here are some of its standout properties:

Excellent Strength-to-Weight Ratio: Ash is remarkably strong for its weight. This makes it ideal when you need durability without unnecessary bulk.

Shock Resistance: This is a big one! Ash is known for its ability to absorb shock. Think tool handles – hammers, axes, and shovels often use ash because it can withstand significant impact without breaking.

Good Workability: Despite being a hardwood, ash is generally considered good to work with. It machines well, planes smoothly, and can be bent using steam. This makes it versatile for various crafting techniques.

Bending Strength: Its natural elasticity means ash can be bent effectively, which is crucial for creating curved furniture pieces or components.

Attractive Grain Pattern: Ash typically features a straight, prominent grain with a coarse texture. It often has a beautiful, natural luster and can range in color from creamy white to light brown, sometimes with pinkish or grayish hues. This makes for visually appealing furniture and decorative items.

Finishing Qualities: Ash takes stains, paints, and finishes very well. Whether you want to showcase its natural beauty or give it a specific color, it accepts finishes evenly and reliably.

Common Types of Ash Trees and Their Wood

While “ash” is a general term, there are over 40 species of ash trees, and the wood from different types can have subtle variations. However, for most woodworking purposes, a few types are more common and widely used.

1. White Ash (Fraxinus americana)

This is perhaps the most commercially important ash species in North America.

Characteristics: Known for its strength, ability to absorb shock, and good bending properties. It’s the classic ash wood most woodworkers think of.

Color: Typically ranges from light brown to pale yellow, with a white sapwood.

Uses: Excellent for tool handles, baseball bats, furniture, flooring, cabinetry, and sporting goods.

2. Green Ash (Fraxinus pennsylvanica)

Also known as Red Ash, this species is common throughout North America.

Characteristics: Similar to White Ash in many respects, though sometimes slightly less dense and may have a slightly coarser texture. Still offers good strength and shock resistance.

Color: Light brown to yellowish-brown, with darker heartwood and lighter sapwood.

Uses: Often used for pallets, crates, furniture, and general utility lumber where high-end appearance isn’t the primary concern.

3. European Ash (Fraxinus excelsior)

This is the primary ash species found in Europe.

Characteristics: Highly valued for its strength, toughness, and elasticity. It’s considered one of Europe’s finest hardwoods.

Color: Pale creamy white to light yellowish-brown.

Uses: Famous for bentwood furniture (like Thonet chairs), tool handles, sports equipment, and decorative veneers.

A Note on the Emerald Ash Borer: It is important to be aware that the Emerald Ash Borer (EAB), an invasive insect, has devastated ash tree populations in North America. This has significantly impacted the availability and cost of ash lumber, especially from affected regions. Resources like the Emerald Ash Borer Information Network (EABIN) provide detailed information on this issue.

Ash Wood: A Comparison with Other Popular Woods

To truly appreciate ash, let’s see how it stacks up against some other common woods you might encounter. This will help you make informed decisions for your projects.

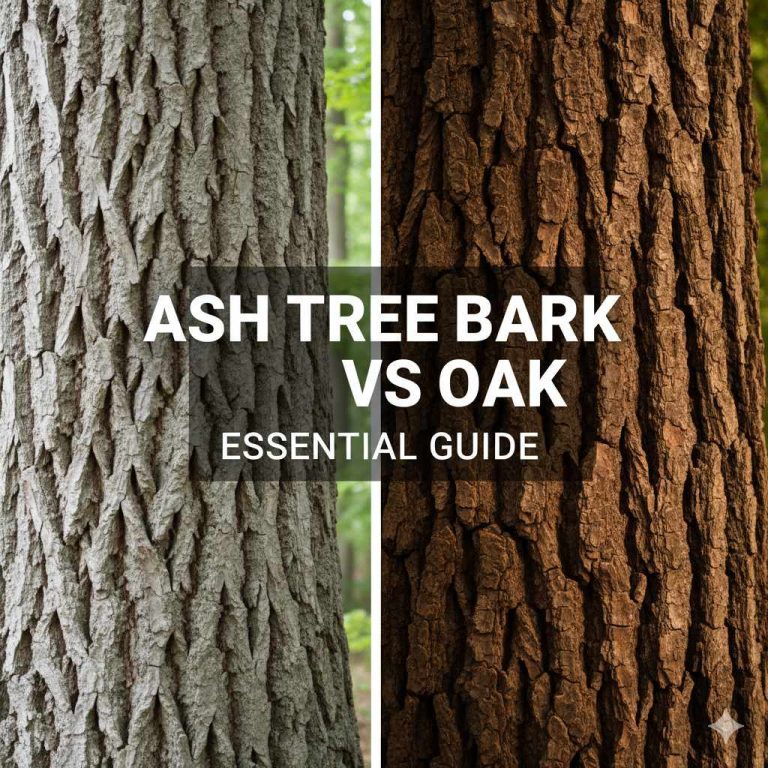

Ash vs. Oak

| Feature | Ash Wood | Oak Wood (Red or White) |

| :————— | :———————————————— | :—————————————————- |

| Hardness | Hardwood | Hardwood |

| Density | Moderately dense, good strength-to-weight ratio | Denser than ash, very strong |

| Grain | Straight, prominent, coarse texture, often lighter | Straight, prominent, can be coarser than ash, prominent rays in quarter-sawn |

| Color | Creamy white to light brown, sometimes with pink/gray | Light to medium brown, can have reddish (Red Oak) or grayish (White Oak) tones |

| Workability | Excellent; machines, bends, and finishes well | Good; can be a bit denser and harder to work than ash |

| Shock Resistance | Excellent | Good, but ash is generally superior |

| Cost | Generally less expensive than oak | Moderately expensive |

| Typical Uses | Tool handles, furniture, baseball bats, flooring | Furniture, flooring, cabinetry, construction, barrels |

Ash often has a bit more “spring” or elasticity than oak, making it better for items that need to flex or absorb impact.

Ash vs. Maple

| Feature | Ash Wood | Maple Wood (Hard Maple) |

| :————— | :———————————————— | :—————————————————- |

| Hardness | Hardwood | Hardwood (often harder than ash) |

| Density | Moderately dense | Very dense and strong |

| Grain | Straight, prominent, coarse texture | Straight, fine, sometimes wavy or figured (birdseye, flame) |

| Color | Creamy white to light brown | Creamy white to light brown, can be very pale |

| Workability | Excellent; machines, bends, and finishes well | Can be tougher due to density; glues well, can burn during routing |

| Shock Resistance | Excellent | Good, but ash is usually preferred for high-impact uses |

| Cost | Generally less expensive than hard maple | Moderately expensive |

| Typical Uses | Tool handles, furniture, baseball bats, flooring | Butcher blocks, flooring, furniture, musical instruments |

Hard maple is famously dense and often used for surfaces that need to withstand heavy wear, like butcher blocks. Ash offers a similar workability with lighter weight and better shock absorption.

Ash vs. Pine (a Softwood)

| Feature | Ash Wood | Pine Wood (e.g., White Pine, Yellow Pine) |

| :————— | :———————————————— | :—————————————————- |

| Hardness | Hardwood | Softwood |

| Density | Moderately dense | Less dense, lighter |

| Grain | Straight, prominent, coarse texture | Can be straight or irregular, knots are common |

| Color | Creamy white to light brown | Varies widely, often yellowish or reddish-brown |

| Workability | Excellent; machines well, durable | Very easy to cut and shape, but dents and scratches easily |

| Shock Resistance | Excellent | Poor; dents and splinters easily |

| Cost | Moderately priced | Generally less expensive |

| Typical Uses | Furniture, tool handles, flooring, cabinetry | Construction framing, DIY projects, furniture, trim |

This comparison highlights why ash is chosen for durability. Pine is much easier to work with and cheaper, making it great for quick DIY projects or framing, but it simply can’t match ash’s resilience.

Working with Ash Wood: Tips for Beginners

Since ash is a hardwood, you might be thinking it’s difficult to work with. While it does require a bit more care than a soft pine, it’s very manageable, especially with the right approach.

Cutting and Shaping

Sharp Tools are Key: Always use sharp chisels, saw blades, and planer knives. Dull tools will tear the grain and make your work much harder.

Cross-Cutting: When cutting across the grain, use a fine-toothed saw or a sharp blade with a good number of teeth to minimize tear-out.

Planing: Ash planes beautifully, but take lighter passes rather than trying to remove a lot of material at once, especially if your tools aren’t razor-sharp.

Drilling: Use sharp drill bits and consider backing boards to prevent blowout on the exit side of the hole.

Sanding Ash

Ash has a relatively coarse texture. You’ll likely need to sand through a few grits to achieve a smooth finish. Start with something like 80 or 100 grit to remove any milling marks or heavy imperfections. Then move up through 120, 150, and finish with 180 or 220 grit for most projects. If you’re aiming for a piano-like finish, you might go higher.

Gluing and Fastening

Ash glues well. Just ensure your surfaces are clean and free of dust. For fasteners, pre-drilling pilot holes is highly recommended to prevent splitting, especially near edges.

Finishing Ash

This is where ash really shines!

Natural Finish: If you love the natural color and grain, a clear coat of polyurethane, lacquer, or a natural oil finish like tung or linseed oil will bring out its beauty and provide protection.

Staining: Ash accepts stains very evenly. You can achieve a wide range of colors. If you want a more uniform color, especially on pieces with a lot of sapwood and heartwood variation, consider using a pre-stain wood conditioner first. This helps the stain penetrate more evenly, preventing blotchiness.

Painting: Ash provides a good surface for paint. Ensure it’s properly sanded and primed for the best results.

Projects Best Suited for Ash Wood

Given its properties, ash wood is perfect for projects where strength, durability, and a good appearance are important.

Furniture: Tables, chairs, bed frames, dressers, and cabinets. Its strength makes it ideal for structural components, and its attractive grain adds visual appeal.

Tool Handles: As mentioned, this is a classic application. Hammer handles, axe helves, shovel handles, and other tools that endure impact and leverage.

Sporting Goods: Baseball bats, hockey sticks, and oars. Its combination of strength, flexibility, and shock resistance is unmatched here.

Flooring and Decking: Ash can be used for hardwood flooring due to its durability, though it might be more susceptible to dents than some other hardwoods.

Bows: Traditional archery bows are often made from ash for its flexibility and strength.

Cabinetry and Millwork: Its straight grain and good finishing properties make it a solid choice for high-quality cabinets and trim work.

Turning: For woodturners, ash is a good material for bowls, spindles, and other turned items, though its coarser grain might require a bit more finishing effort.

Here’s a quick rundown of why ash is a great choice for a beginner project like a small workbench or a set of sturdy shelves:

Durability: It won’t easily dent or scratch, meaning your project will look good for years.

Strength: It can handle weight and stress without problems.

Availability: While impacted by the EAB, ash is still relatively accessible from lumber yards.

Workability: It’s forgiving enough for those learning new tools and techniques.

Safety First in Your Workshop!

Working with any kind of wood, including ash, means prioritizing safety. Here are a few key points:

Eye Protection: Always wear safety glasses. Wood dust and chips can cause serious eye injuries.

Hearing Protection: Power tools are loud. Earplugs or earmuffs are essential for protecting your hearing.

Dust Mask/Respirator: Wood dust, especially fine dust, can be harmful to your lungs. Wear a dust mask rated for fine particles. Consider a respirator for more involved work.

Tool Safety: Read your tool manuals! Understand how to use each tool safely and correctly. Keep your fingers away from moving blades and bits.

Ventilation: Work in a well-ventilated area to help clear dust and fumes from finishes.

Frequently Asked Questions About Ash Wood

Here are some common questions beginners have about ash wood.

Frequently Asked Questions

Is ash wood good for outdoor furniture?

Ash is a hardwood with good durability, but it’s not naturally rot-resistant like some other woods (e.g., cedar or redwood). If you plan to use ash for outdoor furniture, you must take extra precautions. This includes careful sealing and finishing with outdoor-specific protective coatings, and ensuring the furniture is not in constant contact with moisture on the ground. For humid or wet climates, other woods might be a more carefree choice for outdoor use.

How does ash wood compare to poplar for furniture?

Ash is significantly harder, denser, and stronger than poplar. Poplar is a hardwood, but it’s on the softer side and dents easily. Ash has a more prominent grain and is much more durable, making it better suited for high-wear furniture like tabletops or chairs that see a lot of use. Poplar is lighter, easier to work with, and often more affordable, making it a good choice for painted furniture components or less demanding applications.

Can I use ash wood for a cutting board?

While ash is a hardwood and strong, it’s not typically the first choice for high-quality cutting boards. Its grain can be a bit too coarse, making it harder to clean effectively. Furthermore, it doesn’t have the same natural antibacterial properties as some woods like maple or walnut that are commonly recommended for food contact surfaces. For the best and most hygienic cutting board, consider hard maple, walnut, or cherry.

Is ash wood more expensive than pine?

Generally, yes. Ash, being a hardwood, is typically more expensive than pine, which is a softwood. The cost difference reflects the tree’s growth rate, wood density, and its properties like durability and workability. Pine is often chosen for budget-friendly projects or where extreme durability isn’t the main concern.

What is the main drawback of using ash wood?

The primary drawback, especially in North America, is the threat and impact of the Emerald Ash Borer (EAB). This invasive insect has killed millions of ash trees, leading to reduced availability and increased prices for ash lumber in affected regions. This makes sourcing consistent and affordable ash more challenging than it used to be. Beyond that, if not finished properly, its coarse texture can sometimes trap dirt.

What kind of finish looks best on ash wood?

Ash wood looks fantastic with a variety of finishes. A clear or Danish oil finish really highlights its natural grain and light color. Stains can be used effectively to achieve different looks, from a rich, dark tone to a more contemporary gray. If you want a very smooth, modern look, it takes well to clear coats of polyurethane or lacquer, especially after careful sanding.