Bench Saw Vs Table Saw: The Essential Choice

A bench saw is a lightweight, portable saw perfect for small workshops, job sites, and basic DIY tasks. A table saw is a larger, stationary tool that offers more power, stability, and precision for serious woodworking and cutting large materials. Your choice depends on your space, budget, and the types of projects you plan to tackle.

Hello there! I’m Md Meraj. Stepping into the world of woodworking is exciting, but choosing your first major saw can feel a little overwhelming. You’ve likely heard the terms “bench saw” and “table saw” used, sometimes even interchangeably. This can be confusing! What’s the real difference? And more importantly, which one is the right partner for your projects?

Don’t you worry. We’re going to clear this up together. Think of me as your friendly guide in the workshop. In this article, we’ll break down everything you need to know about bench saws and table saws in simple, easy-to-understand terms. By the end, you’ll feel confident and ready to make the perfect choice for your needs. Let’s get started!

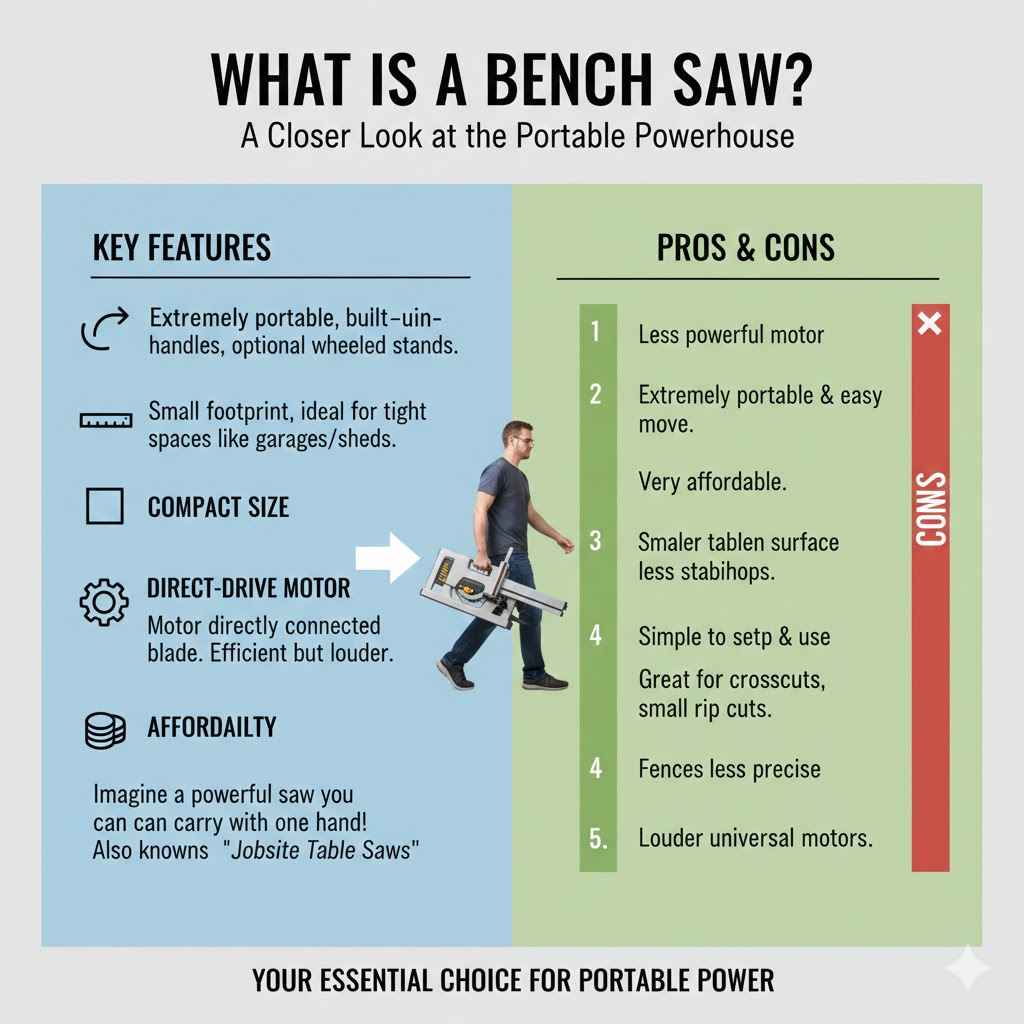

What is a Bench Saw? A Closer Look at the Portable Powerhouse

Imagine a powerful saw that you can carry with one hand and set up on a workbench or a sturdy stand. That’s a bench saw! These saws are also commonly known as “jobsite table saws” because they are designed for portability.

They are the most compact type of table saw available. The entire unit—motor, blade, and table surface—is a single, self-contained piece. They are generally made from lighter materials like aluminum and plastic to keep the weight down, making them easy to move from your garage to the backyard or even to a friend’s house to help with a project.

Key Features of a Bench Saw

- Portability: This is their number one advantage. Most have built-in handles, and many come with folding stands that have wheels.

- Compact Size: They have a small footprint, making them ideal for garages, sheds, or basements where space is tight.

- Direct-Drive Motor: The motor is directly connected to the blade. This design is compact and efficient, but it can be louder and less powerful than the motors on larger saws.

- Affordability: Bench saws are the most budget-friendly entry point into the world of table saws.

Pros and Cons of a Bench Saw

Like any tool, bench saws have their strengths and weaknesses. It’s important to know both before you decide.

| Pros (The Good Stuff) | Cons (The Challenges) |

|---|---|

| ✅ Extremely portable and easy to move. | ❌ Less powerful motor can struggle with thick hardwoods. |

| ✅ Very affordable for beginners and DIYers. | ❌ Smaller table surface makes cutting large sheets difficult. |

| ✅ Perfect for small workshops and garages. | ❌ Lighter weight means more vibration and less stability. |

| ✅ Simple to set up and use right out of the box. | ❌ Fences and miter gauges are often less precise than on larger saws. |

| ✅ Great for crosscuts, small rip cuts, and general home repairs. | ❌ Louder universal motors. |

What is a Table Saw? Understanding the Workshop Staple

When experienced woodworkers talk about a “table saw,” they are usually referring to a larger, more permanent fixture in the workshop. Unlike a bench saw, these are not designed to be moved around often. They are the heart of many woodworking shops for a reason: they are powerful, stable, and incredibly precise.

Table saws come in a few main types, each bigger and more powerful than the last:

Contractor Saws: These are a step up from bench saws. The motor hangs off the back of the saw, and they are often on a wheeled base, offering some mobility.

Hybrid Saws: A mix between contractor and cabinet saws, they offer many features of the bigger saws but in a more compact and affordable package. The motor is housed inside the cabinet.

Cabinet Saws: These are the biggest, most powerful, and most accurate of them all. Made almost entirely of cast iron and steel, they are extremely heavy and designed for professional workshops.

For our comparison, we’ll focus on the general category of these larger, stationary saws.

Key Features of a Table Saw

Stability and Weight: Built with heavy materials like cast iron, they are incredibly stable. This reduces vibration and leads to cleaner, more accurate cuts.

Powerful Motors: They use quiet, powerful induction motors (belt-drive) that can slice through the thickest, densest hardwoods with ease.

Large Table Surface: A large cast-iron table provides excellent support for big pieces of wood, like full sheets of plywood.

Precision Fences: The rip fences are robust and highly accurate, locking down securely for perfectly straight cuts every time.

Excellent Dust Collection: They are designed with better dust ports and shrouds to help keep your workshop clean.

Pros and Cons of a Table Saw

These powerful machines are fantastic, but they aren’t the right fit for everyone.

| Pros (The Good Stuff) | Cons (The Challenges) |

|---|---|

| ✅ Extremely powerful and cuts all types of wood easily. | ❌ Very heavy and difficult, if not impossible, to move. |

| ✅ Highly accurate and precise for fine woodworking. | ❌ Requires a significant amount of dedicated workshop space. |

| ✅ Low vibration results in smoother cuts. | ❌ A much higher initial cost. |

| ✅ Can handle large sheets of wood and big projects. | ❌ Can require more complex setup and electrical wiring (240v for some models). |

| ✅ Quieter and more durable induction motors. | ❌ Not suitable for job site work or temporary setups. |

Head-to-Head Comparison: Bench Saw vs Table Saw

Let’s put them side-by-side to make the differences crystal clear. This is where you’ll really see which one aligns with your goals.

| Feature | Bench Saw (Jobsite Saw) | Table Saw (Contractor/Cabinet) |

|---|---|---|

| Portability | High. Lightweight and designed to be moved easily. | Low. Very heavy and intended to be stationary. |

| Power | Moderate. Direct-drive motor is good for softwoods and most hardwoods up to 2 inches. | High. Belt-drive induction motors cut through thick, dense wood with ease. |

| Precision & Accuracy | Good. Can make accurate cuts, but lighter fence and more vibration can be a factor. | Excellent. Heavy cast-iron tops and robust fences provide superior accuracy. |

| Capacity (Rip Capacity) | Limited. Typically up to 24 inches, enough for half a sheet of plywood. | Large. Can be 30, 36, or even over 50 inches, allowing for full sheet breakdown. |

| Dust Collection | Basic. Usually a single small port at the back. Can be messy. | Advanced. Better internal shrouds and larger ports for connecting to a dust collector. |

| Price | $300 – $700 | $800 – $5,000+ |

| Ideal User | DIYers, homeowners, contractors who need portability, beginners with small spaces. | Serious hobbyists, furniture makers, professional woodworkers with a dedicated shop. |

Safety Features: Protecting Your Most Important Tools (Your Hands!)

Safety is the most important topic in any workshop. Both types of saws come with essential safety gear, and you should never operate one without them. According to the U.S. Occupational Safety and Health Administration (OSHA), proper guarding is critical.

Look for these key features on any saw you consider:

Blade Guard: A plastic shield that covers the blade to prevent accidental contact.

Riving Knife: A metal fin behind the blade that moves with it. It prevents the wood from pinching the blade, which is a primary cause of dangerous kickback.

Anti-Kickback Pawls: These are small, toothed arms that grab the wood and stop it from shooting back toward you if a kickback begins.

Push Stick: Not part of the saw, but essential! Always use one to guide wood near the blade, keeping your hands safely away.

Larger table saws often have better-integrated and more robust safety systems, but modern bench saws have come a long way and include these critical features as well. Some advanced saws even have flesh-sensing technology that stops the blade instantly on contact with skin.

Which Saw is Right for YOU? A Practical Guide

Okay, we’ve covered a lot of ground. Now it’s time to bring it all back to you and your workshop. The answer to “bench saw vs table saw” is not about which is better overall, but which is better for you. Let’s break it down into simple scenarios.

Choose a Bench Saw If…

You have a small workspace. If your “workshop” is a corner of the garage or a basement that you share with the laundry, a compact bench saw is a perfect fit. You can fold it up and put it away when you’re done.

You need to move your saw around. If you plan to work on projects in the driveway, in the backyard, or at a different location, the portability of a bench saw is a game-changer.

You are on a tight budget. A bench saw offers incredible capability for a much lower price, making it the most accessible option for getting started.

Your projects are mainly for home repair and simple DIY. Building shelves, making picture frames, cutting trim, or breaking down smaller boards for a project are all tasks a bench saw handles beautifully.

Choose a Table Saw If…

You have a dedicated workshop. If you have a permanent space for your tools, the size and weight of a stationary table saw become a huge advantage in stability and performance.

You are a serious woodworker (or want to be). If you dream of building fine furniture, cabinetry, or other large-scale projects, you will appreciate the power and precision of a larger table saw.

You frequently cut large materials. If your projects involve breaking down full 4×8 sheets of plywood or MDF, the large table and high rip capacity of a table saw are essential.

Precision is your top priority. For joinery that needs to be perfect and cuts that are flawless, the stability and superior fence systems of cabinet and hybrid saws are unmatched.

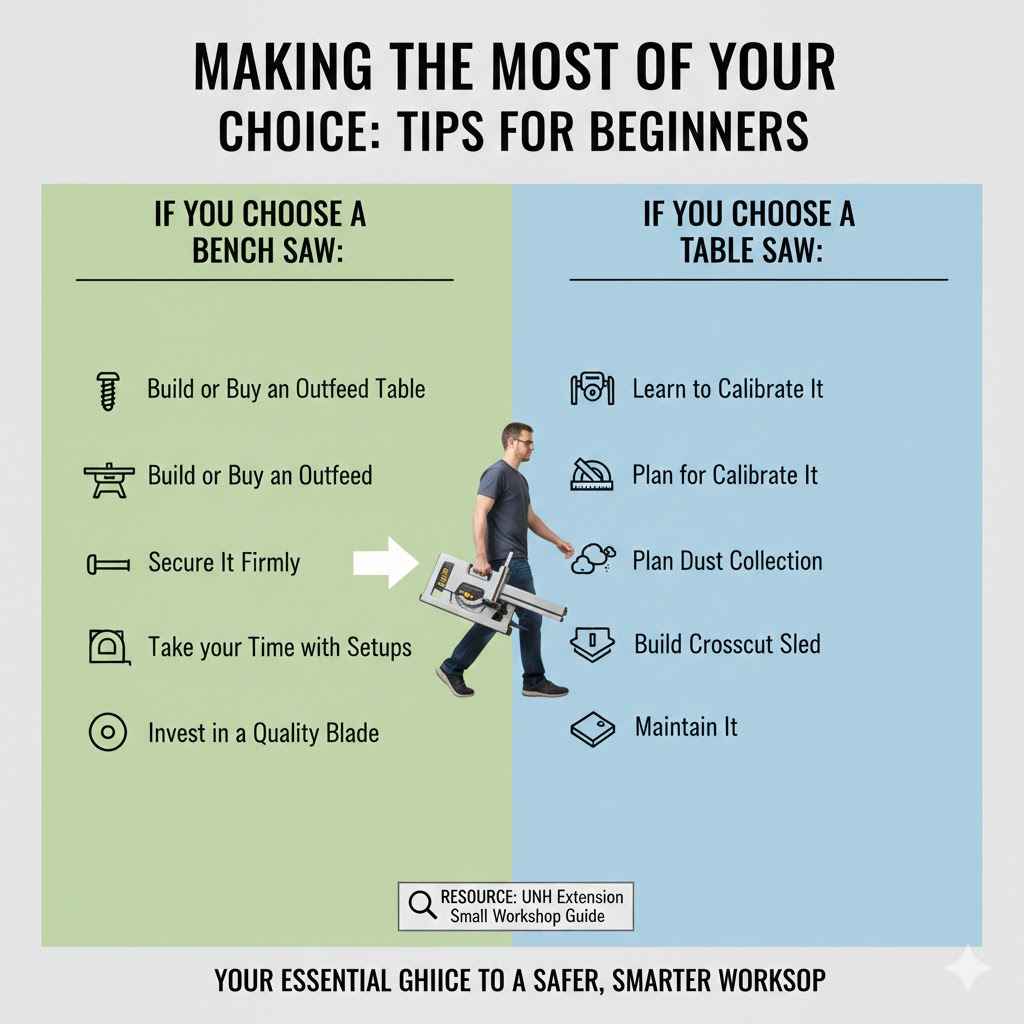

Making the Most of Your Choice: Tips for Beginners

Congratulations on getting closer to a decision! Whichever saw you choose, there are ways to maximize its potential and ensure you’re working safely and effectively.

For a fantastic resource on setting up a safe and efficient small workshop, check out this guide from the University of New Hampshire Extension. It’s full of practical tips.

If You Choose a Bench Saw:

Build or Buy an Outfeed Table: The biggest challenge with a small saw is supporting long pieces of wood after they pass the blade. A simple, portable outfeed stand or table will make your cuts safer and more accurate.

Secure It Firmly: Whether it’s on its stand or a workbench, make sure your saw is stable and doesn’t wobble before you turn it on.

Take Your Time with Setups: Double-check that your fence is parallel to the blade and your miter gauge is set to a perfect 90 degrees. A little extra time here pays off with great results.

Invest in a Quality Blade: The blade that comes with the saw is usually very basic. Upgrading to a good quality combination or rip blade will make a world of difference in your cut quality.

If You Choose a Table Saw:

Learn to Calibrate It: Take the time to learn how to align your saw perfectly. This includes the blade, the fence, and the miter slots. This process, known as “tuning up” your saw, is the key to its precision.

Plan for Dust Collection: These saws can produce a huge amount of sawdust. Connect it to a shop vac at a minimum, or ideally, a dedicated dust collector, to keep your air and your shop clean.

Build a Crosscut Sled: A crosscut sled is a shop-made jig that will allow you to make incredibly accurate and repeatable crosscuts, which is something the standard miter gauge struggles with on larger pieces.

Maintain It: Keep the cast-iron top clean and protected from rust with a coat of paste wax. This also helps wood slide smoothly across the surface.

Conclusion: Building Your Confidence, One Cut at a Time

So, there you have it. The great debate of bench saw vs table saw is really a simple conversation about your personal needs. It’s not about one being “good” and the other “bad.” Both are amazing tools that can help you bring your ideas to life.

A bench saw is your portable, space-saving, and budget-friendly friend, perfect for getting started and tackling a huge range of DIY projects. A stationary table saw is the powerful, precise heart of a dedicated workshop, ready for the biggest challenges and the finest details.

The most important thing is to choose the saw that fits your space, your budget, and your woodworking dreams. Once you make your choice, learn it inside and out, always prioritize safety, and start building. Every project you complete will build your skills and your confidence. Happy woodworking!

Frequently Asked Questions (FAQ)

1. Is a bench saw just a small table saw?

Yes, that’s a great way to think about it! A bench saw (or jobsite saw) is the smallest, most portable category of table saw. They perform the same basic functions—making rip cuts and crosscuts—but on a smaller scale with less power and precision than their larger, stationary cousins.

2. Can I cut a full 4×8 sheet of plywood on a bench saw?

It’s very difficult and not recommended for beginners. A bench saw’s rip capacity is usually not wide enough to cut a 4-foot-wide sheet down the middle. Plus, the small table makes it unstable and unsafe to handle such a large sheet. It’s much safer to break down large sheets with a circular saw first, then make finer cuts on the bench saw.

3. Are table saws really as dangerous as people say?

Any power tool demands respect and safe practices. Table saws are powerful and can be dangerous if used improperly. However, modern saws are equipped with excellent safety features like riving knives and blade guards. If you learn and always follow basic safety rules—like using a push stick, never cutting freehand, and ensuring your guards are in place—you can operate one safely and confidently.

4. Do I need to buy special blades for my saw?

Your saw will come with a basic blade, but upgrading is one of the best investments you can make. You don’t need dozens of blades to start. A good quality 40-tooth or 50-tooth “Combination Blade” is very versatile and will give you much cleaner cuts in plywood and solid wood for both ripping and crosscutting.

5. Can I build my own table to make my bench saw more like a stationary saw?

Absolutely! This is a very popular project for woodworkers. Many people build a “workbench station” around their bench saw. This creates a large, stable surface and allows you to add features like a better fence system and outfeed support. It’s a fantastic way to upgrade the capabilities of a portable saw without buying a whole new machine.

6. What does “rip capacity” mean?

Rip capacity is the maximum distance you can set the fence from the blade. This measurement tells you the widest piece of wood you can cut (or “rip”) on the saw. For example, a rip capacity of 24 inches means you can cut a 4×8 sheet of plywood in half, into two 2×8 pieces.

7. Which type of saw motor is better: direct-drive or belt-drive?

Each has its advantages. Direct-drive motors (found in bench saws) are compact and transfer power efficiently but are very loud and can’t handle heavy, continuous work as well. Belt-drive induction motors (in larger table saws) are much quieter, more powerful, and more durable. They are better for cutting thick hardwoods and for all-day use in a busy shop.