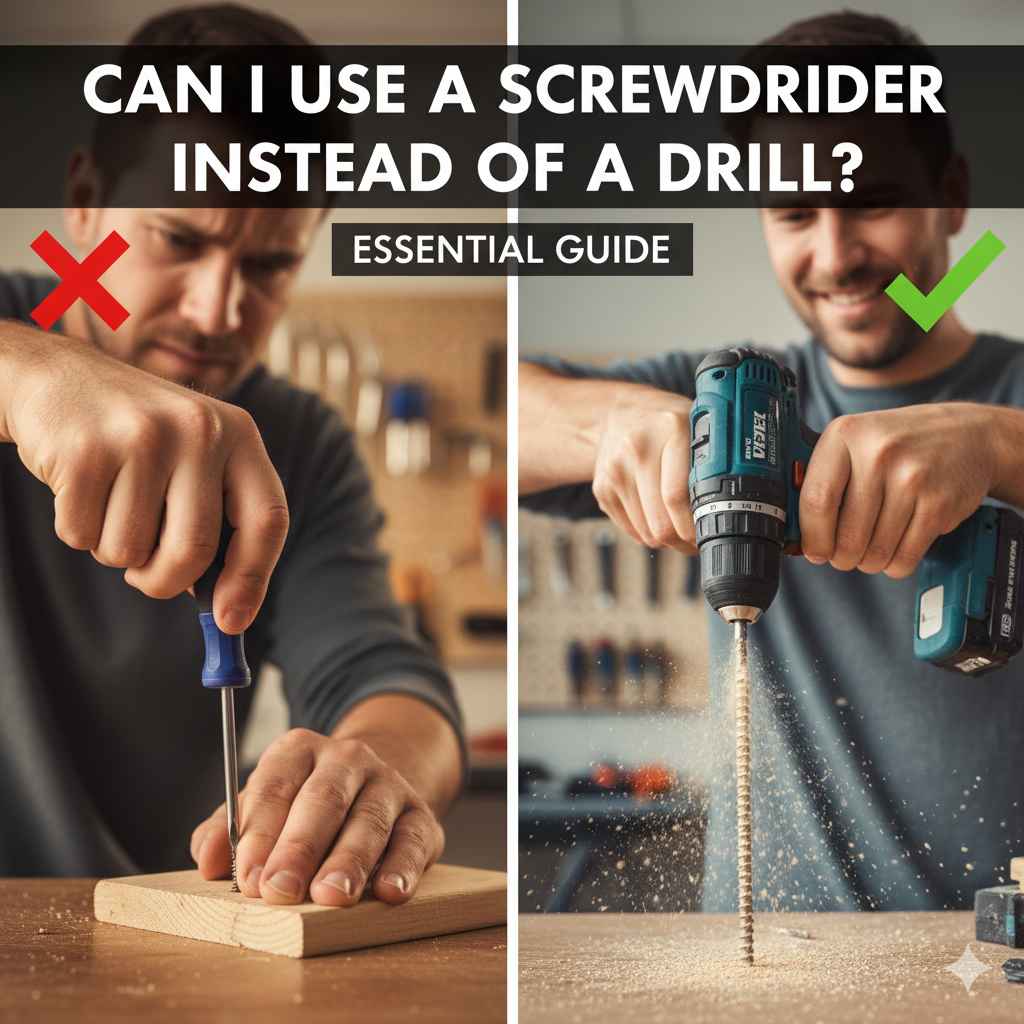

Can I Use Screwdriver Instead of Drill? Essential Guide

Can I use a screwdriver instead of a drill? Yes, for many smaller jobs! A manual screwdriver is perfect for light-duty tasks like assembling furniture or hanging small decor where a drill might be overkill. For tougher jobs, an electric screwdriver offers a middle ground, providing power without the bulk of a full drill. This guide will help you decide when each tool is best.

Ever found yourself staring at a task that needs a screw driven in, but your trusty drill seems like a bit too much? Maybe it’s tucked away, or perhaps the project is so small, a big power tool feels unnecessary. It’s a common dilemma among DIYers and homeowners! You might wonder, “Can I use a screwdriver instead of a drill?” The good news is, yes, you absolutely can, for many situations. But knowing when and how is key to making your DIY projects smooth sailing. Let’s explore how your good old manual screwdriver, and its powered cousin, the electric screwdriver, can save the day and help you get the job done right.

Screwdriver vs. Drill: Understanding the Basics

Before we dive into when you can use a screwdriver, let’s quickly touch on what makes these tools different. This understanding will help you pick the right tool for your job and avoid frustration.

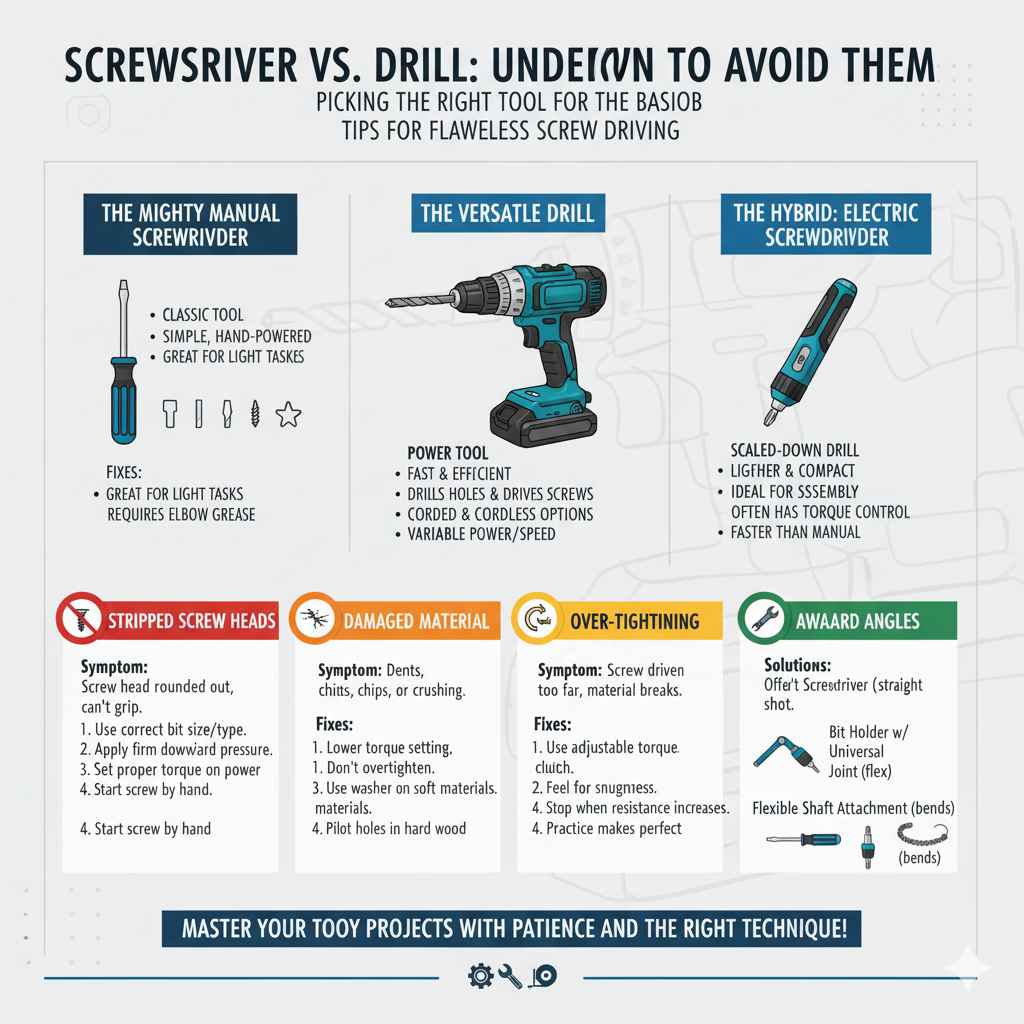

The Mighty Manual Screwdriver

This is the classic tool you likely have in your junk drawer. It’s simple: a handle and a metal shaft with a shaped tip. The tip is designed to fit into the head of a screw – think Phillips (cross shape), flathead (slot), Torx (star shape), etc. You provide the power by turning the handle.

The Versatile Drill

A drill, on the other hand, is a power tool. Its primary job is to spin a bit at high speed. This bit can be for drilling holes or, with the right attachment, for driving screws. Drills come in different forms, like corded and cordless models, and offer varying levels of power and control.

The Hybrid: Electric Screwdriver

Think of an electric screwdriver as a scaled-down drill, designed specifically for driving screws. It’s lighter than a full-sized drill and often much faster than a manual screwdriver. Many have torque control to prevent over-tightening.

When Can You Use a Screwdriver Instead of a Drill?

The short answer is: for tasks that don’t require a lot of force, repetitive screwing, or drilling holes. Here’s a breakdown of situations where a manual or electric screwdriver shines:

1. Assembling Flat-Pack Furniture

This is probably the most common scenario. Those IKEA shelves or office desks often come with dozens of screws.

- Manual Screwdriver: Perfectly capable for small batches of screws or if you have plenty of time and want to work out your arm! It gives you precise control, so you’re less likely to strip a screw head or damage the material.

- Electric Screwdriver: An absolute game-changer for furniture assembly. It dramatically speeds up the process and reduces fatigue. Look for one with adjustable torque settings to avoid overtightening.

2. Hanging Light Decor and Pictures

For lightweight items like a framed photo, a small mirror, or a coat hook, a screwdriver is usually all you need.

- Manual Screwdriver: Ideal for pre-drilled holes or soft materials like drywall. Just ensure you’re using the correct type and size of screw for the wall anchor (if needed) and the item.

- Electric Screwdriver: Makes quick work of multiple hanging points. Again, torque control is your friend here to avoid damaging delicate wall anchors.

3. Tightening Loose Screws on Appliances and Fixtures

Does your cabinet door hinge need adjusting? Is a light switch plate loose? A screwdriver is your go-to for quick fixes.

- Manual Screwdriver: Excellent for these minor adjustments where precise feel is important. You can easily stop as soon as the screw is snug.

- Electric Screwdriver: Works well too, just be mindful of the torque. You don’t want to crush a plastic fixture by over-tightening a screw.

4. Small DIY Projects and Crafts

Projects involving small wood pieces, attaching hardware to craft items, or building simple models often only require a screwdriver.

- Manual Screwdriver: Offers the best feel and control for delicate materials or intricate work.

- Electric Screwdriver: Can be great if you’re making many similar connections in a craft project.

5. When Noise is a Concern

A manual screwdriver is silent. An electric screwdriver is much quieter than a drill. If you need to work early in the morning, late at night, or in shared living spaces, these are better options.

When You Really Need a Drill

While screwdrivers are versatile, there are definitely times when a drill is essential. Trying to force a screw with a manual screwdriver in these situations can lead to stripped screws, damaged materials, and a lot of frustration.

1. Drilling Holes

This is the drill’s primary function. If you need to create a pilot hole for a larger screw, make a hole for a dowel, or pass a wire through a stud, only a drill can do this efficiently. You can find a great resource on properly drilling holes from the U.S. Consumer Product Safety Commission: CPSC Home DIY Construction Safety.

2. Driving Large Screws or Lag Bolts

For screws that are long, thick, or made of hard metal, a drill provides the necessary torque and speed to drive them without excessive effort. This is crucial for structural work, like building decks or framing.

3. Working with Hard Materials

Drilling into hardwoods, metal, masonry, or concrete requires the power and capabilities of a drill, often with specialized bits.

4. Repetitive Screw Driving in Construction or Large Projects

If you’re building a fence, assembling multiple pieces of furniture, or undertaking any project with a high volume of screws, a drill will save you immense time and energy.

5. Driving Screws into Dense Materials

Even if the screw isn’t unusually large, if the material is very dense (like solid oak or certain plastics), a drill can make the process much easier and prevent damage.

Choosing the Right Screwdriver for the Job

Now that we know when to use them, let’s make sure you’re picking the right kind of screwdriver.

Manual Screwdrivers: The Essentials

A basic set of manual screwdrivers is a must-have for any toolkit. They come in various sizes and tip types.

- Phillips Head: Identified by a cross shape. Most common for general use.

- Flathead (Slotted) Head: Has a single slot. Less common now but still found in older hardware and some specific applications like electrical outlets.

- Torx Head: Star-shaped. Found in electronics, bicycles, and modern appliances.

- Robertson (Square) Head: Square-shaped. Popular in Canada and some woodworking applications due to its resistance to cam-out (slipping).

For convenience, consider multi-bit screwdrivers that store interchangeable bits in the handle. This saves space and ensures you have the right tip on hand.

Electric Screwdrivers: Power and Precision

Electric screwdrivers offer a powered assist for screw driving. They are generally smaller and lighter than full-size drills.

- Corded Electric Screwdrivers: Offer consistent power but are tethered by a cord. Great for tasks where you’re near an outlet and need sustained performance.

- Cordless Electric Screwdrivers: Battery-powered for ultimate portability. Ideal for furniture assembly, quick fixes, and projects away from power sources. They vary in battery size, torque, and features.

Key features to look for in an electric screwdriver:

- Torque Settings: Essential for preventing over-tightening and stripping screws. Higher torque means more power.

- Speed Settings: Can offer more control, especially at lower speeds.

- Forward/Reverse Switch: For driving screws in and backing them out.

- LED Light: Handy for illuminating your work area.

- Ergonomics: A comfortable grip is important for usability.

Screwdriver vs. Electric Screwdriver vs. Drill: at a Glance

To help you visualize when each tool is best, here’s a quick comparison:

| Feature | Manual Screwdriver | Electric Screwdriver | Drill (with screwdriver bit) |

|---|---|---|---|

| Primary Use | Manual screw driving, light-duty tasks | Powered screw driving, furniture assembly, quick fixes | Drilling holes, driving screws (especially large/hard ones), heavy-duty tasks |

| Power Source | Human strength | Battery or corded electricity | Battery or corded electricity |

| Speed | Slow, depends on user | Moderate to fast | Fast, variable |

| Torque/Power | Limited (user dependent) | Moderate, often adjustable | High, often adjustable |

| Portability | Excellent | Very good (cordless) | Good to very good (cordless) |

| Best For | Delicate work, small jobs, quiet operation | Speed, reduced fatigue, repetitive tasks where a drill is overkill | Hard materials, large screws, drilling holes, heavy construction |

| Risk of Stripping Screw | Moderate (user dependent) | Lower to moderate (with torque control) | Lower (with torque control), but higher without it or if set too high |

How to Use a Screwdriver (Manual & Electric) Safely and Effectively

Using any tool safely is paramount. Here are some tips whether you’re wielding a manual screwdriver or an electric one.

Using a Manual Screwdriver:

- Select the Right Size and Type: This is crucial! Using a Phillips bit on a flathead screw or a bit that’s too small or too large will damage the screw head and make it hard to drive. The better the fit, the easier the job.

- Ensure a Firm Grip: Stabilize the object you’re working on. Hold the screwdriver firmly so the tip is seated squarely in the screw head.

- Apply Downward Pressure: Push straight into the screw head. This is vital to prevent the screwdriver from slipping out and potentially injuring yourself or damaging the material.

- Turn Slowly and Steadily: Rotate the handle in the direction needed to tighten (usually clockwise, “righty-tighty”) or loosen (counter-clockwise, “lefty-loosey”). Feel the screw engage and drive.

- Know When to Stop: For manual screwdrivers, you’ll feel when the screw is snug. Don’t force it excessively.

Using an Electric Screwdriver:

- Charge Your Battery: Ensure your cordless electric screwdriver is fully charged.

- Select the Correct Bit: Just like with a manual screwdriver, the right bit fit is critical.

- Set the Torque (if available): For delicate materials or small screws, start with a low torque setting. You can always increase it if needed. For larger screws or denser materials, you’ll need a higher setting. Many manufacturers recommend specific bit types for certain materials to ensure optimal performance and longevity. You can often find helpful guides like this one on screw installation from the Wood Magazine website.

- Position the Bit: Place the screwdriver head squarely onto the screw.

- Engage the Trigger: Apply slight downward pressure and squeeze the trigger. Let the tool do the work.

- Observe and Stop: Watch the screw head. If you’re using torque control, the clutch will likely disengage when the set torque is reached, preventing over-tightening. If not, release the trigger as soon as the screw feels snug.

- Use Forward/Reverse Switch Correctly: Make sure the switch is in the correct position before you start driving or loosening.

- Control the Speed: If your screwdriver has speed settings, use a lower speed for better control when starting a screw, and higher speeds for faster driving once it’s engaged.

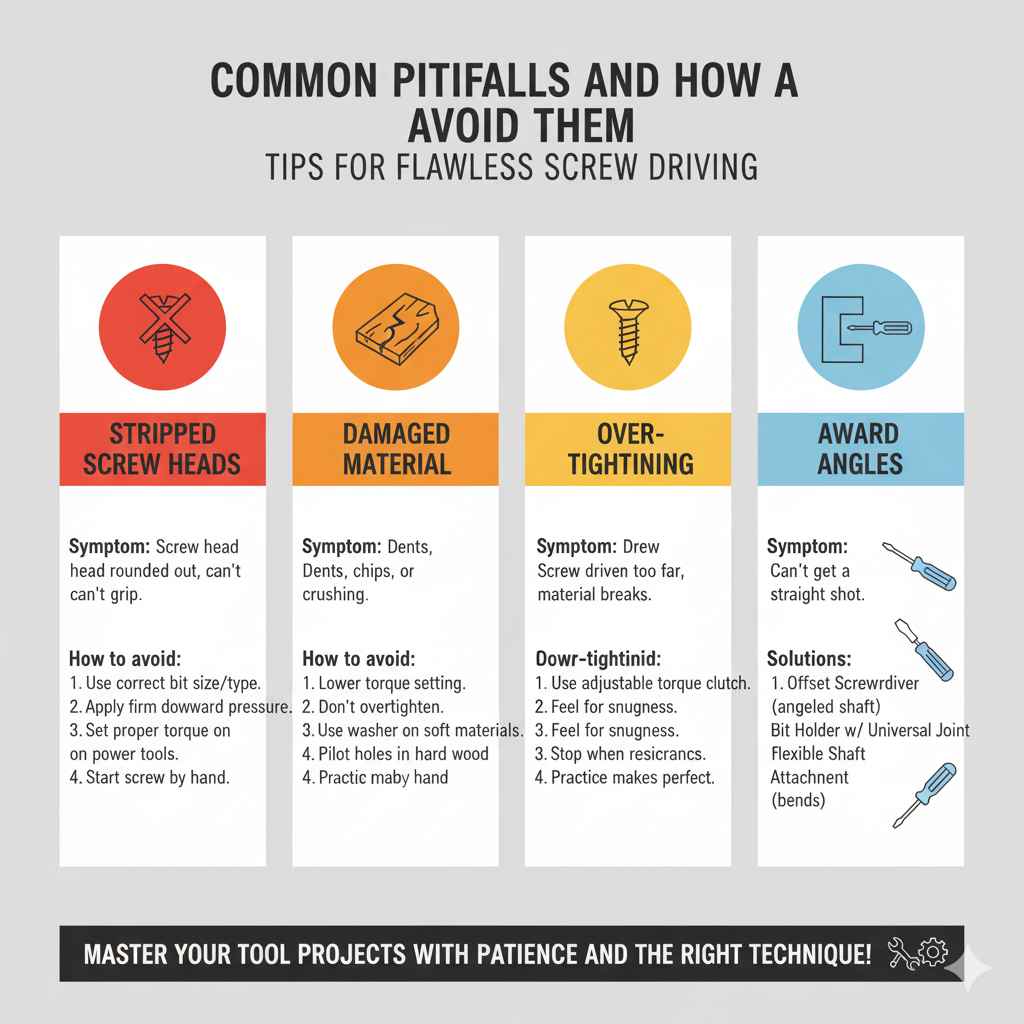

Common Pitfalls and How to Avoid Them

Even with the right tool, mistakes can happen. Here are common issues and how to sidestep them:

Stripped Screw Heads

What it is: The tip of the screw head becomes rounded out, making it impossible for the screwdriver or drill bit to grip and turn it.

How to avoid:

- Always use the correct type and size of screwdriver bit.

- Apply firm downward pressure to keep the bit engaged.

- Use the right torque setting on power tools.

- If starting a screw by hand, drive it in a few turns to seat it properly before using power.

Damaged Material

What it is: The surrounding material (wood, drywall, plastic) gets dented, chipped, or crushed.

How to avoid:

- Use a lower torque setting on power tools.

- Don’t overtighten screws.

- For very soft materials, consider using a screw with a larger head or placing a washer under the screw head.

Over-tightening

What it is: Screws driven in too far, which can strip the head, damage the material, or even break the screw.

How to avoid:

- Use a drill or electric screwdriver with an adjustable torque clutch and set it appropriately.

- Learn to feel when a screw is snug.

- Stop turning as soon as resistance increases significantly.

Working in Awkward Angles

Sometimes, you just can’t get a straight shot at the screw. This is where specialized tools can help.

Solutions:

- Offset Screwdriver: These have an angled or offset shaft for tight spots.

- Screwdriver Bit Holder with Universal Joint: Allows the bit to flex slightly, giving you better access and angle.

- Flexible Shaft Screwdriver Attachment: A bendable shaft that connects to your drill or electric screwdriver for very tight or recessed areas.

FAQ: Your Screwdriver Questions Answered

Q1: Can I use a screwdriver for all IKEA furniture assembly?

A1: For most IKEA furniture, yes you can. A manual screwdriver works for a few screws, but an electric screwdriver is highly recommended to save time and effort, especially if there are many screws. Just be mindful of the torque settings to avoid damaging the particleboard.

Q2: Is it okay to use a screwdriver to hang a heavy mirror?

A2: For a heavy mirror, you’ll likely need a drill. Heavy items require secure mounting into wall studs or using robust wall anchors, which are best installed with a pilot hole drilled by a drill. A screwdriver might suffice for lighter pictures, but not for significant weight.

Q3: What happens if I use the wrong size screwdriver bit?

A3: Using the wrong size bit is a common cause of stripped screw heads. It also means less grip, making it harder to turn the screw and increasing the chance of the screwdriver slipping, which can damage the screw head or the surrounding material.

Q4: Are electric screwdrivers as powerful as drills?

A4: Generally, no. Electric screwdrivers are designed for driving screws efficiently with moderate power. Drills, especially hammer drills, have much more power and are designed for far more demanding tasks like drilling through concrete or driving large lag bolts.

Q5: How do I know when to stop tightening a screw with a manual screwdriver?

A5: You’ll feel resistance increase significantly as the screw becomes fully seated. Stop applying turning force at that point. Pushing harder can strip the screw head or damage the material. It comes with practice and feeling the connection.