Can You Drill Through Acrylic: Proven Essential Guide

Yes, you can drill through acrylic! With the right tools and techniques, drilling plastic sheets like acrylic is straightforward and safe. This guide will show you how to achieve clean, crack-free holes every time, even if you’ve never drilled plastic before. Get ready to tackle your acrylic projects with confidence!

Working with materials like acrylic can sometimes feel a bit intimidating, especially when you need to make a hole. Many beginners worry about cracking or damaging the plastic. If you’ve ever wondered, “Can you drill through acrylic?” you’re in the right place. It’s a common question, and the good news is, the answer is a resounding yes! With a few simple adjustments to your usual drilling habits, you can create perfect holes without any fuss. This guide is designed to walk you through everything you need to know, from picking the right drill bit to the best way to make that first pilot hole. We’ll make sure your acrylic projects turn out smooth and professional. Let’s dive into making those holes!

Why Drilling Acrylic Can Seem Tricky (But Doesn’t Have To Be)

Acrylic, often known by brand names like Plexiglas, is a fantastic material. It’s clear, lightweight, and more impact-resistant than glass. However, it’s also softer and more prone to melting than wood or metal. This can make drilling seem like a challenge. If you use the wrong drill bit or push too hard, the heat generated from friction can melt the acrylic, gumming up your bit and potentially causing cracks. The material can also chip or break if not supported correctly. But don’t let that stop you! Understanding these properties is the first step to overcoming them and drilling acrylic with ease.

Essential Tools and Materials for Drilling Acrylic

Getting the right gear makes all the difference. You don’t need a professional workshop for this; most of what you need is probably already in your toolbox, or easily accessible. With these items, you’ll be well-prepared to drill clean holes in acrylic safely and effectively.

What You’ll Need:

- Safety Glasses: Always protect your eyes! Acrylic chips can fly.

- Drill Bits: More on this below, but specialized bits are best.

- Drill: ACordless drill or drill press works well.

- Masking Tape or Painter’s Tape: To help prevent scratches and guide your drill.

- Soft Jaws for Vise (Optional): If you need to secure the acrylic.

- Wood Blocks or Scrap Material: For support and to prevent blowout.

- Marking Tool: A fine-tip marker or pencil.

- Vacuum or Brush: To clean up dust.

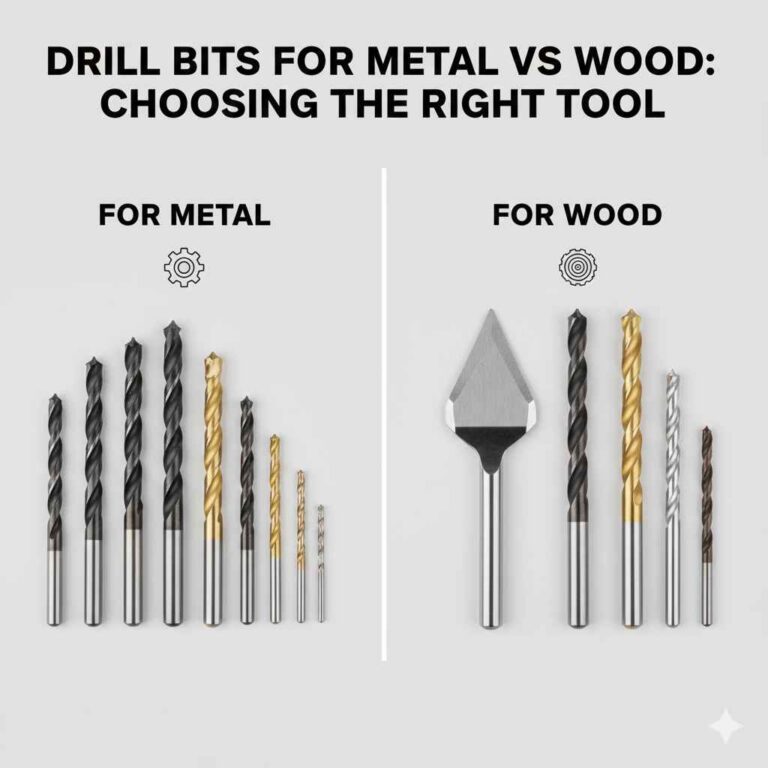

Choosing the Right Drill Bit for Acrylic

This is perhaps the most critical step. Using a standard drill bit designed for wood or metal can lead to problems. The key is to find a bit that cuts cleanly without generating excessive heat or push. Here are the best options:

Types of Drill Bits for Acrylic:

- Specialty Plastic Drill Bits: These are your best friends! They have a reduced angle rake and a sharper point designed to shear the plastic rather than push it. This minimizes heat and prevents the plastic from melting. You can often find these at hardware stores or online. Look for bits labeled for plastic or acrylic.

- Brad-Point Drill Bits: These are common for woodworking but can work well for acrylic too. Their sharp center spur helps to keep the bit from wandering, and they create a cleaner entrance hole than standard bits. They still require a slower speed and lighter pressure.

- Hole Saws: For larger diameter holes, a hole saw (especially one designed for plastic or a bi-metal type) can be effective. Use a slow speed and steady pressure, and withdraw the saw periodically to clear debris and cool the area.

- Standard Bits (with Caution): If you absolutely must use a standard bit (like a twist bit for metal), choose a sharp one and significantly reduce your drill speed. You’ll need to be extra careful about heat buildup and may want to experiment on scrap pieces first. A lower flute angle bit will also perform better.

Avoid using standard auger bits or bits designed for masonry, as these will almost certainly cause damage. The goal is to cut, not to bore a wide opening with brute force.

Step-by-Step Guide: Drilling Your First Hole in Acrylic

Now that you have your tools and know about the right drill bits, let’s get drilling! Follow these steps carefully to ensure a smooth process and a perfect result.

Step 1: Preparation and Safety First

Before you even pick up the drill, put on your safety glasses. Ensure your workspace is clean and well-lit. If you’re drilling a sheet of acrylic, it’s crucial to support it properly. Place the acrylic sheet on a flat surface with a piece of scrap wood or a sacrificial board underneath. This prevents the drill bit from “blowing out” the back of the hole as it exits, which can cause chipping or cracking. Avoid drilling unsupported edges.

Step 2: Mark Your Hole

Use a fine-tip marker or pencil to mark the exact center of your desired hole. For extra precision, you can create a small ‘X’ mark. If you’re worried about the marker potentially smearing or being hard to remove from the acrylic surface, you can try marking the tape itself before applying it.

Step 3: Apply Masking Tape

Place a layer or two of masking tape or painter’s tape over the area where you will be drilling. This tape serves a few purposes: it helps prevent the drill bit from scratching the shiny acrylic surface, and the tape (along with your mark) provides a stable point for the drill bit to start on, reducing the chance of it slipping.

Step 4: Secure the Acrylic

This is vital for preventing the acrylic from shifting or cracking. If you’re drilling a small piece, you can hold it firmly with your hand (while wearing gloves if desired for grip). However, for most projects, clamping it down is much safer and more effective. Use clamps to secure the acrylic to your workbench. If you’re using a drill press, ensure the acrylic is firmly clamped to the table. If you have soft jaws for your vise, use them to grip the acrylic securely without marring the surface. Remember to use your scrap wood underneath for support.

Step 5: Set Your Drill Settings

Drilling acrylic requires a different approach than drilling wood. You need to drill slowly and with minimal pressure.

- Speed: Set your drill to a slow speed setting. If your drill has a variable speed trigger, use it to maintain very low RPMs. Think of it as a gentle cut, not a high-speed abrasion.

- Drilling Mode: Ensure your drill is set to ‘drill’ mode, not ‘hammer’ or ‘impact’ mode, as this can easily shatter the acrylic.

Step 6: Start Drilling

Position the tip of your drill bit directly on your marked spot on the tape. Begin drilling at a slow speed. Let the drill bit do the work; don’t force it. Apply steady, light pressure. As the bit starts to cut, you may see a small amount of plastic shavings. Periodically withdraw the drill bit slightly from the hole. This helps to clear away the plastic shavings and allows air to cool the bit and the material, preventing heat buildup.

Tip: If you drill a pilot hole first with a very small bit, it can help guide a larger bit and reduce the chance of the larger bit from wandering.

Step 7: Exiting the Hole

As you feel the drill bit is about to break through the other side, reduce your pressure even further. If you’re using a drill press, you might stop drilling before the bit completely passes through the acrylic, then finish from the backside. This helps to prevent chipping or “blowout” on the exit side. Once the hole is complete, let the drill bit stop spinning completely before pulling it out of the hole. This prevents the bit from scraping the edges as it comes out.

Step 8: Clean Up

Carefully remove the clamps. Peel off the masking tape. Use a soft brush or a vacuum cleaner to remove any residual plastic dust or chips from the acrylic surface and around the hole. You can use a plastic cleaner or a damp cloth to wipe down the area and remove any marks from your marker.

Drilling a Series of Holes or a Pattern

If your project involves creating multiple holes, the same principles apply. Consistency is key.

- Spacing: Use a ruler or a jig to ensure your holes are evenly spaced.

- Alignment: If you need to drill holes that must align perfectly, consider using a drill press. It offers much greater accuracy and stability for repetitive drilling.

- Template: For complex patterns, you can create a template out of thin plywood or even sturdy cardstock. Drill holes in the template and use it to guide your bit on the acrylic.

Troubleshooting Common Drilling Issues

Even with the best preparation, you might run into a few snags. Here’s how to tackle them:

Issue: Melting or Gumming Up

Cause: Too much heat from excessive speed or pressure.

Solution: Slow down your drill speed, use lighter pressure, and intermittently withdraw the bit to clear shavings and cool. Ensure you are using an appropriate drill bit type.

Issue: Cracking or Chipping

Cause: Inadequate support, sudden pressure changes, or using the wrong bit.

Solution: Ensure the acrylic is fully supported by scrap wood. Drill slowly and steadily. Avoid drilling right up to the edge of the sheet. If cracking persists, try a slower speed and even lighter pressure.

Issue: Drill Bit Slipping

Cause: The drill bit is not starting on a stable surface; the material might be too smooth.

Solution: Use masking tape over the drill point. Ensure the drill bit tip is sharp and properly aligned with your mark. A brad-point bit also helps prevent slipping.

Issue: Poor Hole Quality (Rough Edges)

Cause: Dull drill bit, wrong bit type, or too much force.

Solution: Use a sharp, appropriate drill bit for plastic. Ensure you are drilling at a slow speed with gentle, consistent pressure. Finish the hole from the backside if possible.

When Might You Not Want to Drill Acrylic?

While drilling acrylic is generally safe and effective, there are a few scenarios where you might want to reconsider or proceed with extreme caution.

- Very Thin Acrylic: If your acrylic sheet is extremely thin (less than 1/8 inch or 3mm), it becomes much more fragile. Even with the best techniques, it can be prone to cracking. Consider adhesive techniques or laser cutting for very thin applications.

- Edge Drilling: Drilling too close to the edge of an acrylic piece significantly increases the risk of it breaking or cracking. The general rule is to keep your hole from being closer than 1-2 times the diameter of the hole to the edge.

- Structural Loads: If the drilled hole is intended to bear significant structural weight or stress, you might need to consult with an engineer or a specialist fabricator. Acrylic can be strong, but holes can become stress points.

Choosing Between a Drill Press and a Handheld Drill

Both a drill press and a handheld drill can be used to drill acrylic, but they offer different advantages:

| Feature | Drill Press | Handheld Drill |

|---|---|---|

| Accuracy & Consistency | Excellent. Provides a perfectly vertical hole every time. Ideal for multiple holes or precise work. | Good, requires skill and a steady hand. Can be challenging for perfectly perpendicular holes. |

| Stability | Superior. The workpiece is typically clamped, and the drill is mounted, offering maximum stability. | Requires user to provide stability by holding the drill and workpiece securely. |

| Heat Control | Better control due to stable, consistent pressure application. Easier to withdraw the bit for cooling. | More challenging to maintain consistent, light pressure, potentially leading to heat buildup. Variable speed is crucial. |

| Portability | Stationary, requires a dedicated space. | Highly portable, can be used anywhere. |

| Best For | Projects needing precision, multiple identical holes, or larger pieces that can be safely secured. | Smaller projects, on-site work, or when a drill press isn’t available. Requires more user attention. |

For beginners, a drill press offers a significant advantage in ease of use and achieving clean results, especially for critical measurements. However, a good quality handheld drill, used with care and the right techniques, can absolutely get the job done.

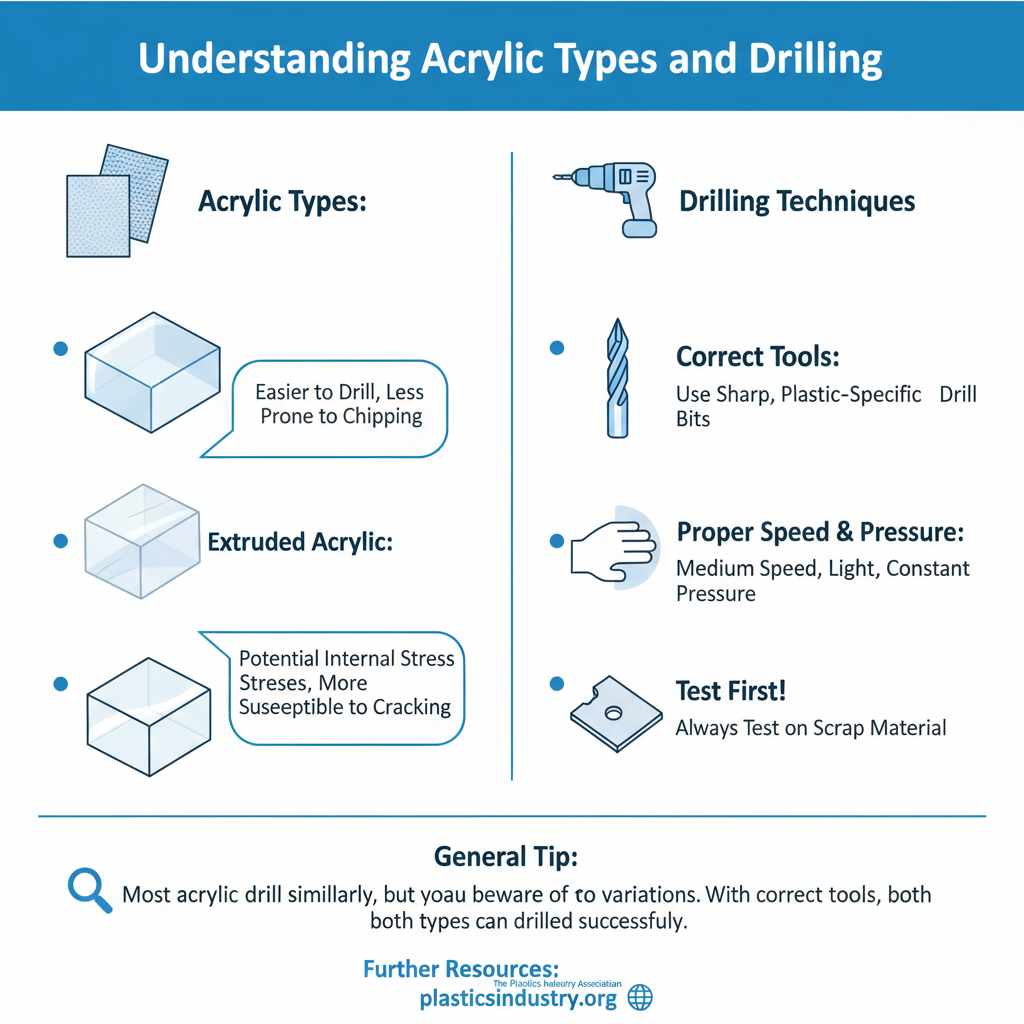

Understanding Acrylic Types and Drilling

While most acrylics drill similarly, there are a few variations to be aware of. Cast acrylic is generally considered easier to drill and less prone to chipping than extruded acrylic. Extruded acrylic is made through an extrusion process, which can sometimes create internal stresses that might be more susceptible to cracking. However, with the correct tools and techniques described in this guide, you should be able to successfully drill both types. If you are unsure about your specific material, it’s always a good idea to test your drilling method on a scrap piece first. For more detailed information on different types of plastics and their properties, resources like The Plastics Industry Association offer valuable insights.

Frequently Asked Questions (FAQ) About Drilling Acrylic

Q1: What is the best drill bit to use for acrylic?

The best drill bit is a specialty plastic or acrylic drill bit. These have a sharper point and a specific flute design to cut plastic cleanly without excessive heat. Brad-point bits are a good second choice.

Q2: Do I need to drill holes slowly in acrylic?

Yes, absolutely. Always use a slow drill speed. High speeds generate more heat, which can melt and damage the acrylic.

Q3: Can I use my regular metal drill bits?

You can, but with extreme caution. Use a very sharp bit, set your drill to its slowest speed, and apply minimal pressure. It’s much better to use bits designed for plastic if possible.

Q4: How do I prevent acrylic from cracking when drilling?

Support the acrylic properly with scrap wood underneath, use calm, steady pressure, and drill at a slow speed. Periodically withdraw the bit to cool. Do not force the drill.

Q5: What kind of drill should I use?

Either a handheld drill or a drill press can work. A drill press offers more stability and accuracy, making it easier for beginners to get clean results. For handheld drills, ensure it has a variable speed setting.

Q6: What if I need to drill a large hole?

For large holes, a hole saw designed for plastic or bi-metal is the best option. Use slow speeds and withdraw the saw frequently to clear material and cool the bit.

Q7: How do I keep the acrylic from scratching?

Apply masking tape or painter’s tape to the surface where you will be drilling. This protects the shiny finish. Always remove the tape gently after drilling.

Conclusion: Drill Acrylic with Confidence!

As you can see, asking “can you drill through acrylic?” has a clear and encouraging answer: yes! With the right knowledge, a few specific tools, and a deliberate approach, drilling through acrylic is a perfectly achievable task for any DIYer. The key takeaways are to use the correct drill bit, set your drill to a slow speed, apply gentle and consistent pressure, and always support your material properly. By following the steps we’ve outlined and keeping safety in mind, you can confidently create precise holes for all your acrylic projects, from custom enclosures and furniture to artistic displays and household fixes. Don’t hesitate to practice on scrap pieces first. The more you do it, the more comfortable and skilled you’ll become, unlocking a whole new world of possibilities with this versatile material. Happy drilling!