Can You Use PVA Primer On Wood? Proven Essential

Yes, you absolutely can use PVA primer (like basic white wood glue diluted with water) on wood! It’s a fantastic, cost-effective DIY sealer that blocks stain bleed-through, prevents blotching on raw wood, and provides excellent adhesion for your topcoat. This guide shows you exactly how to use it correctly for smooth, durable finishes.

Welcome to the workshop! I’m Md Meraj, and if you’ve ever stood in front of a shelf full of expensive primers feeling overwhelmed, you are not alone. We often assume the only way to get a professional paint finish on wood is by buying specialty products. However, many professional painters rely on a secret weapon found right in their own glue stash: PVA primer.

PVA stands for Polyvinyl Acetate—that’s just a fancy name for common white wood glue, like Elmer’s or Titebond, when used as a sealer. Can you use PVA primer on wood? The short answer is a resounding yes, and it’s surprisingly effective for raw wood.

If you struggle with wood soaking up paint unevenly, causing that frustrating blotchy look, or you just want a budget-friendly way to prep wood, this method is for you. We are going to walk through exactly why this works, how to mix it, and the simple steps to get stunning, uniform results on your next DIY project. Let’s get started building that confidence!

Why Wood Needs Primer: Understanding the Problem

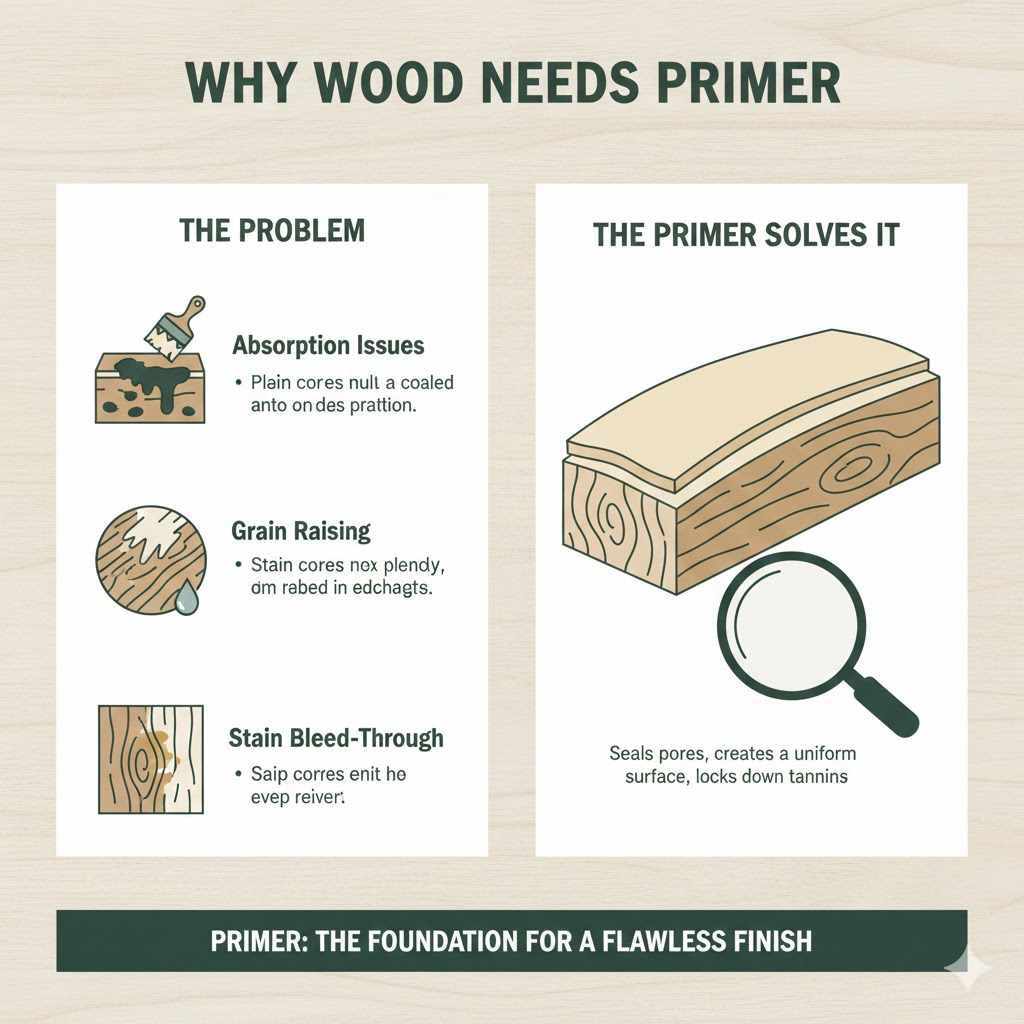

Before diving into the PVA method, let’s quickly talk about why wood demands primer in the first place. Wood is naturally porous, meaning it has tiny gaps and openings, much like a sponge. When you try to paint directly onto raw wood, a few problems pop up:

- Absorption Issues: The wood soaks up the liquid (the binder) in your paint much faster than the pigment (the color). This leads to uneven coverage—areas soak up more than others—resulting in blotchy or streaky finishes, even after several coats.

- Grain Raising: Water-based paints and stains introduce moisture. This moisture causes the wood fibers on the surface to swell and lift, creating a rough, fuzzy texture once dry. Sanding afterwards often doesn’t fully solve this.

- Stain Bleed-Through: If your wood has sap, tannins (natural wood oils), or knots, these materials can eventually bleed through your new paint job, causing yellow or brown spots to reappear over time.

A good primer solves all of this. It seals the pores, creates a uniform surface for the paint to stick to, and locks down any problematic natural substances in the wood. Now, let’s see how simple PVA glue steps in to do this job perfectly.

What Exactly is PVA Primer? The Simple Truth

When we talk about using PVA primer on wood, we aren’t talking about buying a can labeled “PVA Primer.” We are talking about mixing common wood glue (which is a type of PVA adhesive) with water. This dilution transforms the glue into an excellent, basic sanding sealer or first-coat primer.

PVA Glue vs. Traditional Primer

It’s helpful to know the difference so you choose the right product for the right job. PVA glue is fundamentally an adhesive, but when thinned, its high concentration of binders acts just like a penetrating primer.

| Feature | PVA Glue Primer (DIY) | Standard Wood Primer (Purchased) |

|---|---|---|

| Cost | Very low (uses existing supplies) | Moderate to high |

| Best Use | Sealing bare wood, blocking tannins, affordable topcoats | Heavy stain blocking, exterior projects, rapid dry times |

| Water Resistance | Fair (Water-soluble once cured) | Good to excellent (Epoxy or Alkyd formulas) |

| Application | Slightly thicker, requires careful thinning | Ready-to-use consistency |

For most indoor furniture, shelving, or trim projects where durability against water isn’t the number one concern, PVA is an unbeatable beginner choice. It offers great grain control without the hefty price tag.

Essential Materials Needed for Your PVA Primer Project

One of the best parts about this method is that you likely already have most of what you need in your garage or shed! Keep your safety in mind; ventilation is key, even with non-toxic glue.

Tools and Supplies Checklist:

- PVA Wood Glue: Any standard interior PVA wood adhesive works (Titebond I or II, Elmer’s Wood Glue, etc.).

- Clean Water: Tap water is fine.

- Mixing Container: A clean plastic cup or small bucket.

- Stirring Stick: A craft stick or disposable plastic knife.

- Applicator: A cheap chip brush, foam brush, or roller cover dedicated just for this job.

- Safety Gear: Safety glasses and appropriate gloves.

- Sanding Supplies: Fine-grit sandpaper (180 or 220 grit) for light touch-ups.

Before mixing, take a moment to ensure your wood surface is clean. Wipe down any dust or debris. If the wood has old finishes or grease, a light sanding or a wipe with mineral spirits might be necessary for the PVA to adhere properly.

Step-by-Step Guide: How to Mix PVA Primer

Getting the ratio right is the most crucial step. Too much glue, and it dries gummy and impossible to sand. Too much water, and it won’t seal the wood effectively. We are aiming for a consistency thinner than whole milk but thicker than water.

The Magic Ratio: 1 Part Glue to 1 Part Water (1:1)

This is the standard starting point that most seasoned DIYers recommend for bare, porous wood. It seals beautifully without being too heavy.

Follow these mixing steps carefully:

- Measure Your Water: Pour exactly 1 unit of clean water into your mixing container. For example, if you use a half-cup measure, pour in a half cup of water.

- Measure Your Glue: Pour the exact same amount of PVA wood glue into the container with the water. (If you used a half-cup of water, add a half-cup of glue.)

- Mix Thoroughly: Stir the mixture slowly but completely. You want a smooth, uniform liquid with no visible streaks of thick glue. This may take a minute or two of stirring. Do not over-mix or whip air into the mixture, as this causes bubbles.

- Test the Consistency: Dip your stir stick in the mix and let it drip back into the bucket. It should flow easily off the stick, almost like thin syrup. If it drags like thick honey, add a tiny splash more water and re-stir.

Pro Tip: Mix only what you think you will use in the next hour or two. Once the PVA starts curing, you can’t reuse the excess.

Applying the PVA Primer to Your Wood Surface

Now that your DIY primer is ready, the application is similar to applying a thin coat of stain. Work quickly, follow the grain, and don’t try to overwork the coat. The goal is just to penetrate the wood surface.

Application Steps for a Perfect Seal:

- Load Your Brush: Dip your foam or chip brush into the PVA mixture, shaking off any large drips. Don’t load the brush heavily; you want a steady flow, not a glob of liquid.

- Apply in One Direction: Brush the mixture onto a section of the wood, always following the direction of the wood grain. Work in manageable sections, like one board at a time.

- Wipe Off Excess (Crucial Step!): This is the step beginners often skip, leading to sticky, gummy patches. About 15–30 seconds after application, take a clean, lint-free cloth or rag and wipe off any remaining excess material sitting on the surface. You are essentially wiping the liquid in, allowing the primer to soak deeply into the wood pores, but removing the thick layer that prevents drying and sanding.

- Allow Thorough Drying: Let the surface dry completely. Depending on humidity and how heavily you applied it, this can take anywhere from 30 minutes to 2 hours. It should feel dry to the touch and no longer sticky.

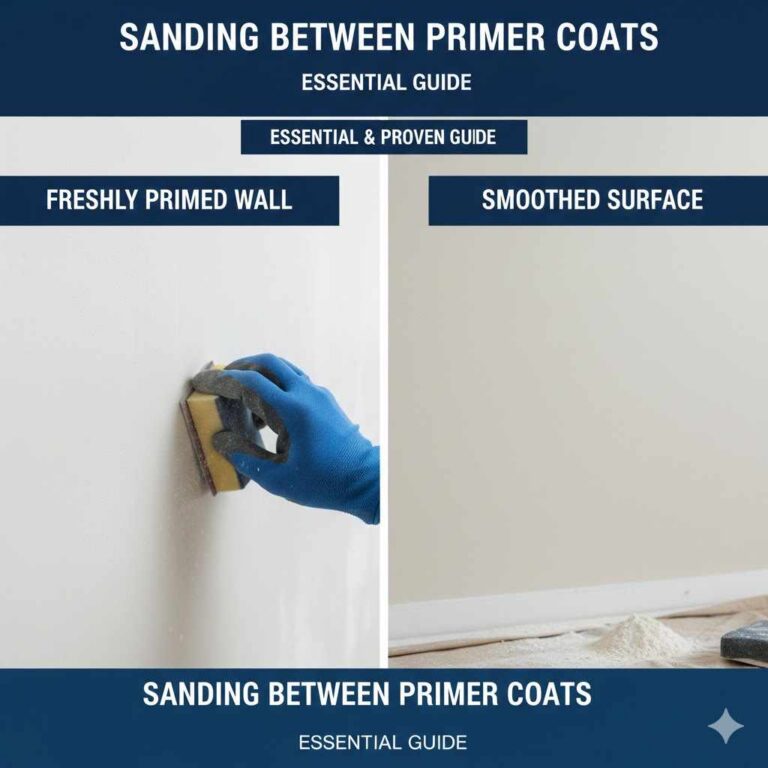

- Light Sanding: Once fully dry, the surface will likely feel slightly rough because the raised wood fibers have swelled (grain raising). Very lightly sand the entire surface with 180-grit or 220-grit sandpaper until it feels smooth again. Use light pressure—you are only knocking down the fuzz, not trying to remove the primer itself.

- Clean and Topcoat: Wipe off all sanding dust with a tack cloth or damp cloth. Your wood surface is now sealed, hardened, and ready for your chosen paint or topcoat.

If you are working on very soft, blotchy woods (like pine or maple), you may apply a second thin coat of the PVA primer after sanding, followed by another light sanding pass, before painting.

When Should You Use PVA Primer (And When to Avoid It)?

PVA primer is brilliant for certain jobs, but it’s not a one-size-fits-all solution. Knowing the limitations helps you achieve long-lasting craftsmanship.

Ideal Uses for PVA Sealer:

- Raw, Bare Wood: Perfect for sealing fresh-cut lumber or sanded-down surfaces that have never been finished.

- Controlling Grain Raising: It excels at stiffening those soft fibers, leading to a much smoother final topcoat.

- Sealing Soft Woods: Excellent on woods that typically drink up paint quickly, like pine or MDF (Medium Density Fiberboard).

- Budget Projects: When you need to prime many items and cost is a factor, this is a huge money saver.

Situations Where You Should Use Commercial Primer Instead:

While powerful, PVA is essentially diluted glue. It doesn’t perform well when faced with harsh chemicals or extreme moisture.

- Exterior Applications: PVA is not rated for continuous outdoor exposure. For outside projects, you must use a proper exterior-grade, moisture-resistant primer (often alkyd or specialized acrylic). You can look into recommended exterior preparation standards from organizations like the This Old House experts for guidance on durable exterior finishes.

- Heavy Tannin Staining: Woods like cedar or redwood have strong tannins that can sometimes bleed through PVA after a few months. For these, a specialty stain-blocking primer (like a shellac-based primer) is superior.

- Water Exposure: If the piece will sit in water (like a bathtub surround or a very humid basement), PVA may soften over time. Choose an oil-based or high-quality acrylic primer for maximum water resistance.

- Over Existing Finishes: If you are painting over existing oil paint, a dedicated bonding primer is usually necessary. PVA works best when penetrating raw material.

If you stick to interior, furniture-grade projects, your PVA primer will serve you reliably.

Troubleshooting Common PVA Application Mistakes

Don’t worry if your first coat isn’t perfect. Woodworking is a process of learning how the material reacts. Here are the most common issues beginners face with DIY PVA primer and how to fix them.

Issue 1: The Wood Feels Gummy or Sticky After Hours

This is the #1 mistake. It almost always means you did not wipe off the excess surface material after applying the mix.

- The Fix: Patience is required. If it’s only slightly sticky, increase ventilation (use fans) and wait longer. If it’s very gummy, you may need to gently scrape the thick spots with a plastic scraper and then scrub lightly with a damp cloth before sanding very lightly once mostly dry. Moving forward, be much more aggressive in wiping off the excess primer from the surface layer.

Issue 2: The Wood Still Looks Blotchy After Painting

This suggests the primer coat was too thin or absorbed too fast, meaning it didn’t create a uniform surface barrier.

- The Fix: Your PVA mixture was likely too watery, or you wiped off too much primer. Repeat the process: apply a slightly less diluted coat (perhaps leaning toward 1 part water to 1.5 parts glue) and wipe off less vigorously on the surface. Seal, dry, lightly sand, and apply your paint again.

Issue 3: Paint Adhesion is Poor

This happens if the surface wasn’t prepped well or you sanded incorrectly.

- The Fix: Check for contaminants like wax or silicone residue. If the surface is clean, ensure you used at least a 180-grit paper for sanding after the primer dried. You need a slightly rough, toothy surface for the topcoat paint to grab onto. A coat of good quality, general-purpose primer (like a specific sanded primer, not PVA) applied after the PVA seal can sometimes help “tie” the surface together better if this issue persists.

Exploring Other Affordable Sealer Options

While PVA is excellent, it’s smart DIY knowledge to know what else works similarly, especially if you don’t have wood glue on hand. Other household items can serve as basic primers.

DIY Primer Alternatives:

| Alternative Sealer | Mixing Ratio (Approximate) | Notes for Beginners |

|---|---|---|

| Shellac Flakes (Sanded or De-waxed) | 1 part flakes to 4–5 parts denatured alcohol | Best stain blocker available, dries fast, but requires proper ventilation (alcohol fumes). |

| Milk Paint (Pre-mixed) | Usually used straight or slightly watered down | Acts as a very traditional primer/sealer. Natural option, good adhesion to raw surfaces. |

| Shellac Spray/Primer | None needed (ready to use) | Zinsser B-I-N Shellac is a professional favorite for knots and stain blocking. More expensive than PVA. |

For the beginner looking for maximum utility and safety with the lowest cost, the PVA glue method remains the reigning champion. It lets you control the seal perfectly for your specific piece of wood.

Long-Term Care and When to Re-Prime

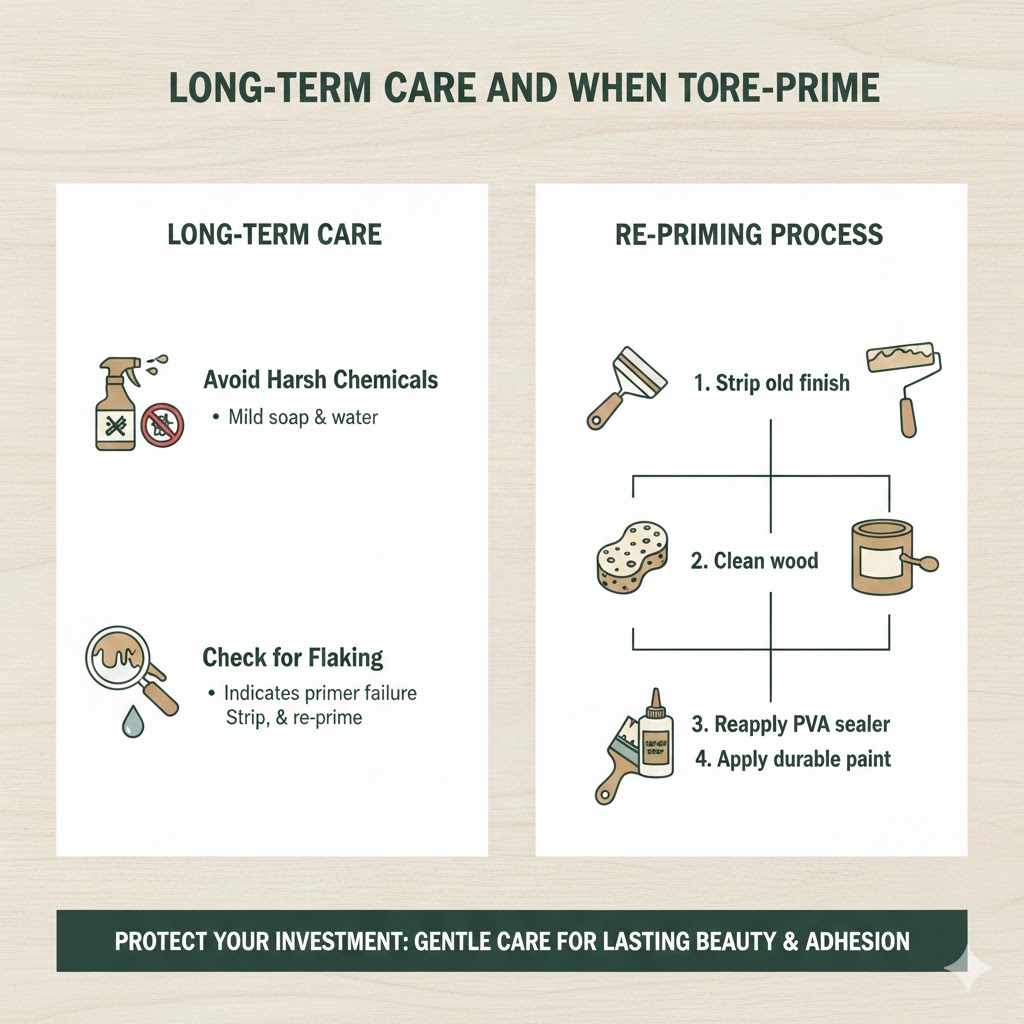

Once you’ve sealed and painted your wood item, you want it to last! Since PVA is water-based and slightly more delicate than an oil-based primer, you should be mindful of its environment.

- Avoid Harsh Chemicals: Cleaning products containing strong solvents or high concentrations of alcohol can potentially break down the PVA sealant beneath your paint over many years of aggressive scrubbing. Stick to mild soap and water for cleaning your finished pieces.

- Check for Flaking: If the paint begins to peel or flake years down the road, it often indicates the original primer failed due to moisture ingress or poor preparation. If you need to repaint, strip the old finish, clean the wood, and reapply the PVA sealer, followed by a high-quality paint formulated for durability.

Remember, a primer is meant to create the perfect substrate. Treat the primer coat gently during sanding, and you give your topcoat the best possible foundation for long-term beauty and adhesion. You’ve taken the first big step toward professional-looking finishes simply by prepping the surface correctly!

Frequently Asked Questions (FAQ) About PVA Primer on Wood

Q1: Is it okay if the PVA mixture dries slightly yellow?

A: Yes, that is normal. Most PVA glues have a slight yellowish tint. As long as it dries completely hard (not tacky) and you sand off the texture, this color will be fully covered by your chosen paint or stain.

Q2: Can I use the PVA primer recipe on painted wood?

A: It is generally not recommended. PVA is designed to soak into raw wood fibers. If you apply it over existing glossy paint, it will likely just sit on top, cure very slowly, and peel off later along with your new paint layer. Always use a dedicated bonding primer over existing paint.

Q3: How long do I need to wait before painting over the PVA primer?

A: Wait until the surface is completely dry and no longer feels cool or tacky to the touch. This is usually 1 to 2 hours, but in cool, humid weather, it might take up to 4 hours. If you can see any dampness, wait longer before sanding or painting.

Q4: Does this work for sealing particleboard or MDF?

A: Absolutely! PVA is excellent for MDF and particleboard. These materials are essentially wood fibers pressed together, and they soak up liquid aggressively. The PVA seal is fantastic for preventing the severe swelling and pitting common with these engineered materials.

Q5: What is the best ratio if the wood is very dense, like oak?

A: Denser woods absorb less quickly. If you are working with dense hardwood like Oak or Maple, you might need a slightly more watery mix, perhaps 1 part glue to 1.5 parts water. The key is making sure it still adheres and hardens quickly after wiping the excess.

Q6: If I am staining the wood, can I use PVA primer first?

A: No, you should not. Primer is designed to prevent penetration. If you use PVA primer, the subsequent wood stain will just sit on top of the sealer and likely wipe right off. If you need to seal tannins before staining, use a clear shellac sealer specifically designed for stain-blocking, not diluted PVA glue.

Conclusion: Confidence in Your Prep Work

See? You didn’t need to spend a fortune or buy complex chemicals to tackle basic wood prepping. Understanding the core function of a primer—to seal the surface and create a unified substrate—allows you to use affordable household items like PVA glue effectively.

By mastering this simple 1:1 mixing ratio, wiping off that excess material, and giving it a light sanding, you have successfully locked down that raw wood grain. This preparation step ensures your topcoat looks even, professional, and will last for years to come. Now grab your chosen paint and get to the fun part! With this solid foundation beneath you, you can tackle any home painting project with confidence. Happy crafting!