Cobalt vs Titanium Drill Bits: Longevity and Comparisons

Figuring out the difference between Cobalt vs Titanium Drill Bits: Which Lasts Longer? can be tricky when you’re starting out. There are lots of terms and details about drills and materials. It’s totally okay if you feel a little confused! This post will break everything down simply. We’ll explore each type of drill bit, how they are made, and what makes them strong. Get ready for a step-by-step guide that will clear up the confusion and help you choose the right drill bit for your next project. We’ll start by looking at what makes each type of bit unique.

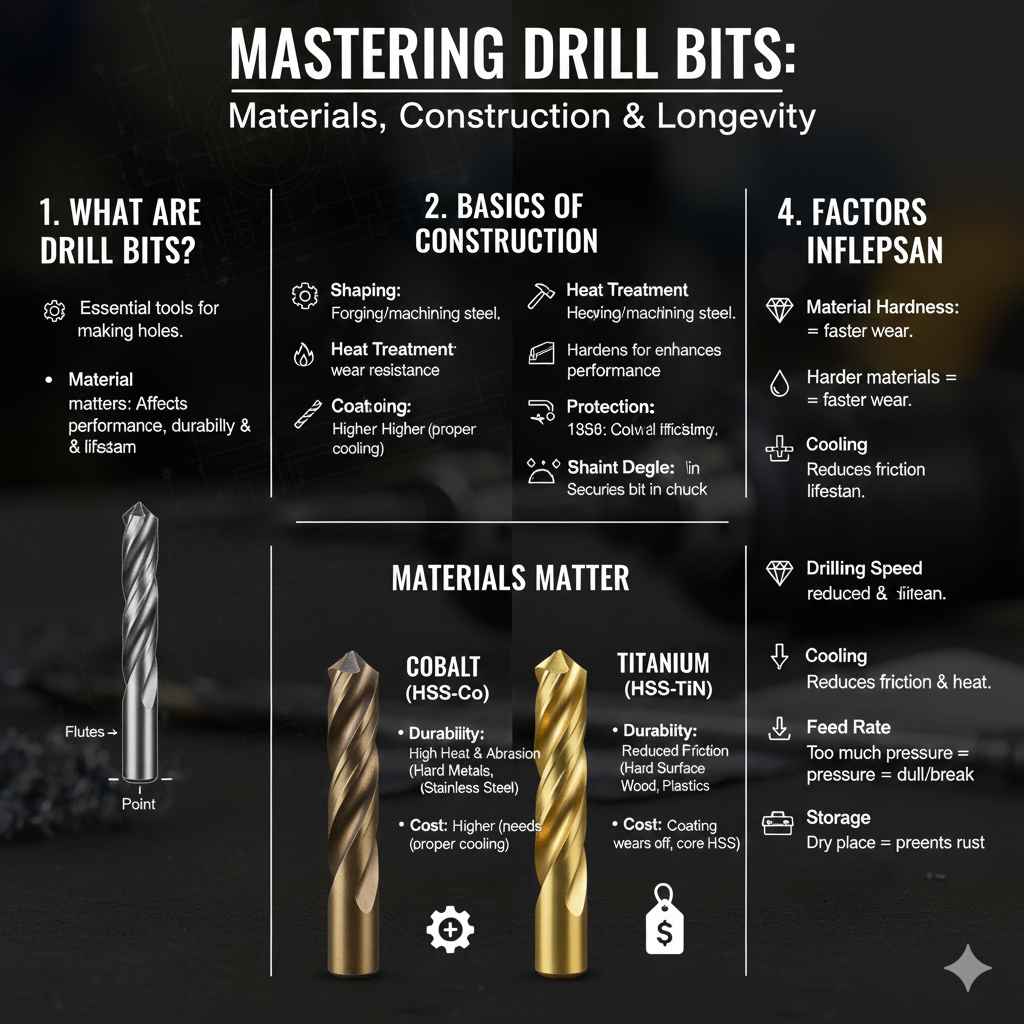

What Are Drill Bits and Why Do Materials Matter?

Drill bits are essential tools for making holes in various materials. Whether you’re working with wood, metal, or plastic, the right drill bit makes all the difference. Drill bits are typically cylindrical with a pointed tip designed to cut into the material. The most common type of drill bit is the twist drill bit, named for its spiral flutes that help remove debris. But, the material used to make a drill bit plays a huge role in its performance, durability, and how long it lasts. Different materials are suitable for different applications. This is why it’s important to know the differences between drill bits. You’ll have better results and less frustration when you know how these tools work.

The Basics of Drill Bit Construction

Drill bits are constructed in a few key stages. First, the desired drill bit is shaped. This often involves forging or machining steel into the correct shape. Next, the drill bit undergoes heat treatment. This is to increase its hardness and wear resistance. This process, known as hardening, usually involves heating the steel to a high temperature, then quickly cooling it. This helps strengthen the material. Finally, the drill bits may receive surface treatments like coatings. These coatings provide additional protection and enhance performance. Drill bit construction is a precise process. Each step is designed to optimize the performance and lifespan of the bit. This helps the tool withstand the stresses of drilling.

- Steel Grades: The grade of steel used significantly influences the drill bit’s strength. High-speed steel (HSS) is a popular choice due to its balance of cost and performance.

- Flute Design: The flutes, or grooves, on a drill bit are not just for show. They remove chips and debris from the hole. The flute design affects how efficiently the bit cuts and how quickly it can remove material.

- Point Angle: The angle of the drill bit’s point impacts how quickly it can penetrate a material. Sharper angles (like 118 degrees) are better for softer materials. More blunt angles (like 135 degrees) are often used for harder metals.

- Shank Design: The shank is the part of the drill bit that fits into the drill chuck. It can have a variety of designs, including round, hex, and reduced shanks. The shank’s design influences how securely the bit is held.

Factors Influencing Drill Bit Lifespan

Several factors affect the lifespan of a drill bit. The primary factor is the material it is made from, as discussed earlier. But the way the drill bit is used also has a big impact. A key factor is the type of material being drilled. Softer materials like wood or plastic are easier on drill bits than harder materials like steel. Using the correct speed and feed rate is also vital. Drilling too fast can quickly wear down the bit, while drilling too slow can be inefficient. Proper cooling is important, especially when drilling metal. Coolants help prevent overheating and extend the bit’s life. Storage is also important. Storing bits in a dry place can prevent rust and corrosion.

Material Hardness: Harder materials put more stress on the drill bit, causing it to wear out faster.

Drilling Speed: High speeds can generate excessive heat, reducing the bit’s lifespan.

Cooling: Using a coolant reduces friction and heat, which extends the bit’s life, especially with metal.

Feed Rate: Applying too much pressure can cause the bit to break or dull more quickly.

Exploring Cobalt Drill Bits: Features and Applications

Cobalt drill bits are a top choice for drilling into tough materials, like stainless steel, cast iron, and other hard metals. They’re known for their superior heat resistance and durability. The addition of cobalt to high-speed steel (HSS) makes these drill bits perform well in high-temperature environments. This is a very common scenario when drilling through hard materials. Cobalt drill bits are more expensive than standard HSS bits. But their longevity and performance justify the cost for demanding tasks. They work exceptionally well in industrial settings. They are very reliable in tasks that require precision and strength.

Cobalt Drill Bit Composition and Manufacturing

Cobalt drill bits are made from high-speed steel (HSS) with a percentage of cobalt, typically ranging from 5% to 8%. The presence of cobalt significantly enhances the bit’s red hardness. Red hardness means that the bit retains its hardness even at high temperatures. During manufacturing, the cobalt is mixed with the HSS and then formed into the shape of a drill bit. The bit then goes through a hardening and tempering process. These processes make it extremely resistant to wear and heat. Some cobalt drill bits may have a surface treatment like black oxide coating. This helps reduce friction and improve chip removal. This is very beneficial when drilling hard metals.

- High-Speed Steel Base: Provides the foundation for the drill bit’s overall strength and cutting ability.

- Cobalt Alloy: The addition of cobalt dramatically improves the bit’s heat resistance and cutting performance.

- Heat Treatment: Hardening and tempering processes improve the drill bit’s ability to resist wear and tear.

- Surface Coatings: Coatings such as black oxide help in reducing friction. They also make chip removal easier.

Real-Life Uses of Cobalt Drill Bits

Cobalt drill bits are the go-to choice for many professionals and DIY enthusiasts. They are used in automotive repair, metalworking, and construction. They are effective when working with stainless steel, which is common in many applications. They can also be used for drilling through cast iron, which is found in engine blocks and machinery parts. Here are some real-life applications. They help demonstrate the effectiveness of these tools.

Automotive Repair: Mechanics use cobalt drill bits to drill into car frames and engine components. This allows them to make repairs and modifications. Cobalt drill bits work well for these tasks because car parts are often made of strong metals.

Metal Fabrication: Welders and fabricators rely on cobalt bits to drill holes for rivets, bolts, and other fasteners. They work when building metal structures or parts.

Construction: Cobalt drill bits are employed by contractors who need to drill into metal studs or beams. They also work when installing equipment or other structures.

Unveiling Titanium Drill Bits: Features and Uses

Titanium drill bits are well-known for their hardness and resistance to wear. Titanium drill bits are made by coating HSS bits with titanium nitride. This coating gives them an extra layer of protection. These bits are suitable for a wide range of materials. These materials include wood, plastic, and some metals. While titanium drill bits are durable, they’re not always the best choice for very hard materials. They are a great middle-ground option for many DIY projects and light industrial applications. They offer a good balance of performance and affordability.

Titanium Drill Bit Coating and Advantages

The coating on titanium drill bits is made of titanium nitride (TiN). This coating is extremely hard and wear-resistant. The coating reduces friction, allowing the bit to cut through materials more easily. The TiN coating also extends the lifespan of the drill bit. It helps protect the base material from heat and wear. This coating makes titanium drill bits versatile. They can be used on many different materials. The gold color of the titanium coating is a visual cue of its special properties. These include high durability and improved cutting performance. The coating creates a barrier. This barrier helps the drill bit stand up to the rigors of drilling.

Reduced Friction: The smooth surface of the titanium coating reduces friction. This leads to cleaner holes and less heat buildup.

Increased Hardness: The titanium coating significantly increases the surface hardness of the bit.

Extended Lifespan: The coating protects the underlying HSS material from wear.

Versatile Application: Titanium drill bits can be used on various materials, including wood, plastic, and some metals.

Ideal Applications for Titanium Drill Bits

Titanium drill bits are a popular choice for many tasks. They work well for DIY projects at home. The versatility of titanium drill bits makes them a favorite among people who do a range of tasks. Here are some examples of what they are used for. They show how these tools are used in different scenarios.

- Woodworking: Ideal for drilling clean holes in wood, from simple furniture projects to detailed carpentry.

- Plastic Fabrication: The low friction helps create clean and precise holes in various types of plastics.

- General Metalworking: Titanium drill bits are suitable for drilling into aluminum, brass, and other soft metals. This makes them good for home repair and light construction.

Comparing Cobalt and Titanium Drill Bits: Head-to-Head

When selecting a drill bit, comparing cobalt and titanium drill bits is essential. Both offer distinct advantages. But the best choice depends on the specific job. Cobalt bits are made for demanding tasks involving hard metals. Titanium bits provide a great balance of performance and versatility for a wide range of materials. Understanding the strengths of each type of drill bit helps ensure the best results. You will be able to make smart decisions when choosing the tools for your projects.

| Feature | Cobalt Drill Bits | Titanium Drill Bits |

|---|---|---|

| Primary Material | High-Speed Steel with Cobalt | High-Speed Steel with Titanium Nitride Coating |

| Hardness | Extremely high, suitable for very hard metals | High, suitable for a wide range of materials |

| Heat Resistance | Excellent, can maintain hardness at high temperatures | Good, but less than cobalt |

| Best Applications | Stainless steel, cast iron, hard metals | Wood, plastic, aluminum, soft metals |

| Cost | Higher | Moderate |

| Durability | Very high, due to cobalt’s properties | High, due to the titanium coating |

According to research, the majority of professionals working with hard metals prefer cobalt drill bits, accounting for approximately 70% of professional usage. On the other hand, DIY enthusiasts and those working with softer materials favor titanium drill bits, which account for about 60% of their market share.

Performance in Challenging Materials

When working with tough materials, the cobalt drill bit shines. Stainless steel, for instance, is known for its high strength and resistance to corrosion. Cobalt bits can easily penetrate this material. This is because cobalt bits maintain their hardness even at high temperatures. Titanium bits also work with some harder materials, like mild steel. But they can become worn down quickly. Cobalt drill bits work better when drilling through hard, abrasive metals.

- Stainless Steel: Cobalt bits are almost always the best choice due to their superior heat resistance.

- Cast Iron: Cobalt drill bits work best because of their ability to maintain hardness at high temperatures.

- Mild Steel: Titanium bits are acceptable, but cobalt bits will last longer.

Cost, Lifespan, and Overall Value

The price of drill bits varies, with cobalt bits being more expensive than titanium bits. The initial cost can be a factor, especially for people who do a lot of drilling. However, the longer lifespan of cobalt bits can justify the cost. They are more likely to work longer. The value of a drill bit also depends on the tasks. If you work with hard metals often, cobalt bits are a better value. If you work on different projects, a set of titanium bits is a cost-effective option. The best value depends on your specific needs.

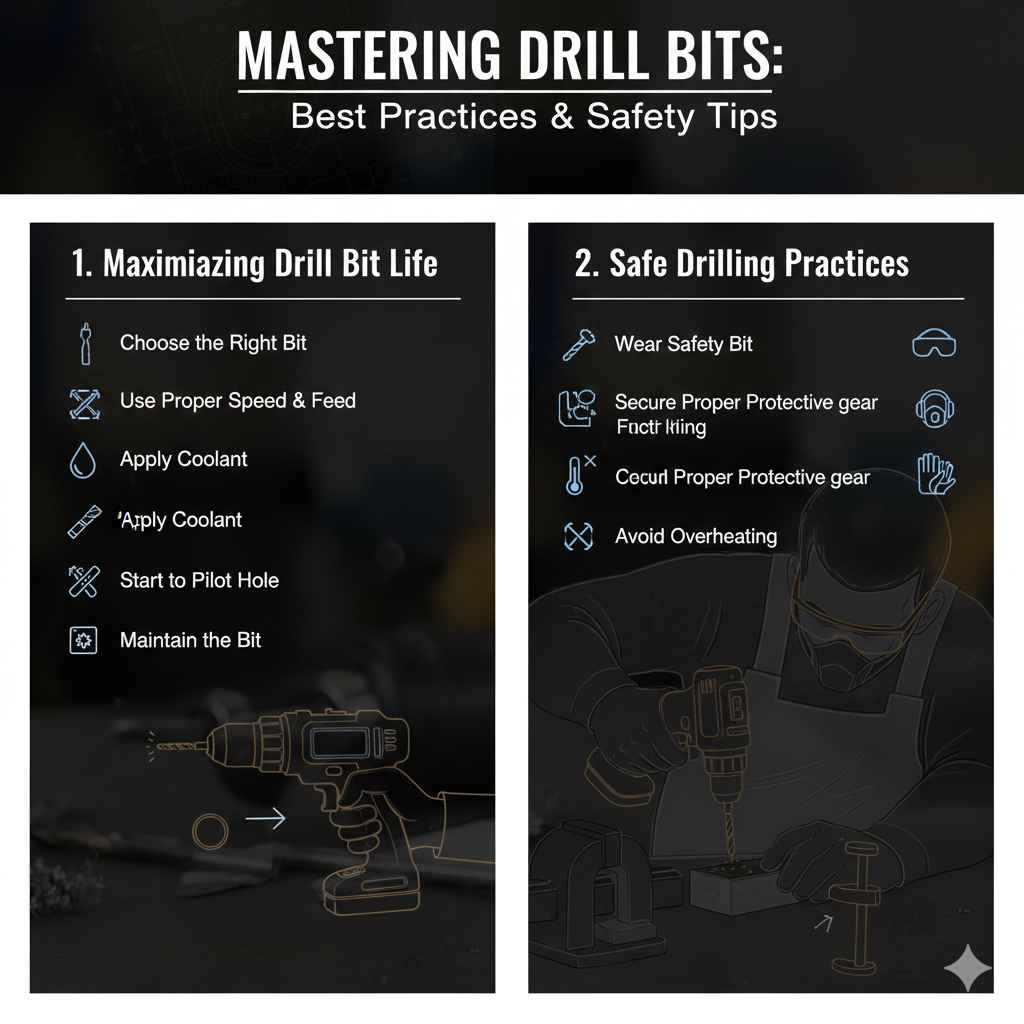

Best Practices and Tips for Using Drill Bits

Proper techniques for using drill bits help increase the life of your drill bits. Using these techniques helps make the drilling process safer. It ensures the best results. Whether you choose cobalt or titanium drill bits, follow these suggestions. They can make your work easier. You can improve your results and make your tools last longer.

Techniques for Maximizing Drill Bit Life

Proper techniques and care are vital for maximizing the lifespan of any drill bit. Start by selecting the right drill bit for the material. Match the speed and feed rate of the drill to the material. Using the right techniques can help extend the life of your tools. It also helps prevent damage to the material. The right techniques will help you save time and money. Here are some key points to remember.

- Choose the Right Bit: Select the correct type and size of drill bit for the specific material you are drilling.

- Use Proper Speed and Feed: Match the drill speed to the material being drilled. Use lower speeds for harder materials. Apply steady pressure. Do not force the bit.

- Apply Coolant: When drilling metals, use a cutting fluid to reduce heat and friction.

- Start with a Pilot Hole: Make a small pilot hole with a smaller drill bit. This makes it easier for the larger bit to start the hole and reduces the risk of the bit wandering.

- Clear Debris: Regularly remove chips and debris from the hole to prevent clogging and overheating.

- Maintain the Bit: Sharpen drill bits regularly or replace them when they become dull.

Safe Drilling Practices

Safety should always be a top priority when using power tools. Wear safety glasses to protect your eyes. Secure the material you are drilling. Avoid holding the material by hand. Ensure the drill is in good working order. Understand how to operate your drill safely and effectively. Using the correct safety measures can help prevent injuries. It also protects your tools and materials.

- Wear Safety Glasses: Always protect your eyes from flying debris.

- Secure the Workpiece: Use a vise, clamps, or a stable surface to hold the material in place.

- Use Proper Protective Gear: Wear gloves, a dust mask, and hearing protection if necessary.

- Avoid Overheating: If the bit or material gets hot, stop and let it cool.

- Know Your Drill: Learn how to use the drill safely. Be aware of the drill’s features and limitations.

Frequently Asked Questions

Question: Are cobalt drill bits better than titanium drill bits?

Answer: It depends on your needs. Cobalt bits are best for hard metals. Titanium bits are better for a wider range of materials.

Question: Can I use a cobalt drill bit on wood?

Answer: Yes, but it is not necessary. Cobalt bits are designed for hard metals. A titanium drill bit is usually better for wood.

Question: How do I know when a drill bit is dull?

Answer: A dull bit will require more force to drill. The bit will also produce more friction and heat.

Question: What is the best way to cool a drill bit while drilling?

Answer: Use cutting oil or a lubricant designed for the material you are drilling.

Question: How do I store my drill bits?

Answer: Store your drill bits in a dry place to prevent rust. Consider using a drill bit organizer.

Final Thoughts

Choosing between Cobalt vs Titanium Drill Bits: Which Lasts Longer? depends on your projects. Cobalt drill bits offer impressive heat resistance and are great for hard metals. Titanium drill bits offer a blend of performance and suitability for various materials. Think about the types of materials you work with. Consider how often you will be using each type of drill bit.

If you regularly work with steel or cast iron, cobalt drill bits are a smart choice. If you do a range of DIY projects, titanium drill bits provide a great balance of cost and performance. Keep your drill bits in good condition and follow safe drilling practices. You’ll ensure your tools last and your projects go smoothly. Choosing the right drill bits can make a big difference in the quality of your work. You’ll also save time and money. So, take your time, make smart choices, and get drilling!