Cut Aluminum With Circular Saw: Expert Tips for Precision

To cut aluminum with a circular saw, use a non-ferrous circular saw blade or a wood blade with a carbide tip. Ensure the blade is suitable for metal cutting.

When using a circular saw, it’s crucial to prioritize safety measures and wear appropriate protective gear. Now, let’s delve into the best practices for cutting aluminum with a circular saw. Cutting aluminum with a circular saw requires the right blade and technique.

Whether you’re a DIY enthusiast or a professional, understanding the proper approach is essential for achieving precise and clean cuts. In this comprehensive guide, we’ll explore the necessary tools, techniques, and safety precautions for cutting aluminum with a circular saw. By the end, you’ll have the knowledge and confidence to tackle your aluminum cutting projects effectively and safely.

Introduction To Cutting Aluminum

To cut aluminum with a circular saw, use a non-ferrous circular saw blade or a wood blade with a carbide tip. It is the appropriate tool for this task and delivers precise results. You can also employ a jigsaw with metal cutting blades for this purpose.

Safety First: Preparing To Work With Aluminum

Before you begin cutting aluminum with a circular saw, it is crucial to prioritize safety. Taking the necessary precautions will ensure a smooth and accident-free experience. Here are some essential steps to follow:

- Wear safety goggles to protect your eyes from any flying debris.

- Put on ear protection to shield your ears from the loud noise produced by the saw.

- Wear gloves to safeguard your hands from sharp edges and potential cuts.

- Secure your workpiece using clamps or a vise to prevent it from moving during the cutting process.

- Ensure you have a clear working area, free from any obstructions or hazards.

- Keep a fire extinguisher nearby in case of any unexpected accidents.

By following these safety measures, you can minimize the risk of injuries and create a safe working environment.

The Right Tool: Choosing A Circular Saw

When it comes to cutting aluminum, choosing the right circular saw is crucial for achieving precise and efficient cuts. Here are some factors to consider:

- Blade Type: Opt for a non-ferrous circular saw blade specifically designed for cutting aluminum. These blades have a higher tooth count and are made from carbide or diamond-tipped materials.

- Blade Size: Select a blade size that matches the thickness of the aluminum you intend to cut. A larger blade diameter will allow for deeper cuts.

- Saw Power: Ensure that your circular saw has enough power to handle the demands of cutting aluminum. A higher amperage or wattage will provide smoother and more efficient cuts.

- Adjustability: Look for a circular saw with adjustable cutting angles and depth settings. This versatility will enable you to make precise and customized cuts.

- Additional Features: Consider features such as a laser guide or LED light that can enhance cutting accuracy.

By carefully selecting the right circular saw for cutting aluminum, you can achieve clean and accurate cuts while maximizing efficiency.

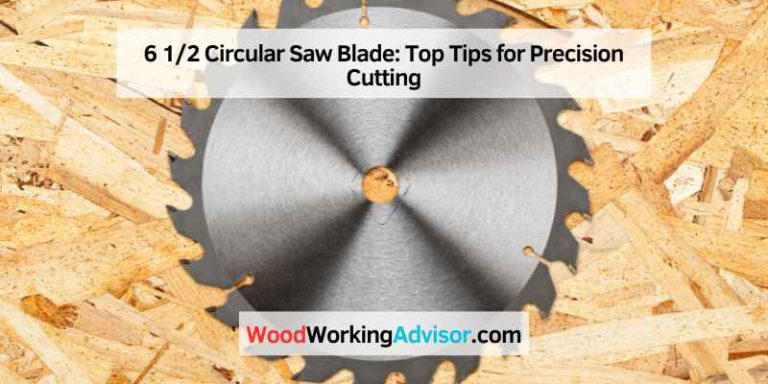

Selecting The Perfect Blade

When it comes to cutting aluminum with a circular saw, selecting the perfect blade is crucial for achieving clean and precise cuts. The right blade will ensure smooth operation and minimize the risk of damage or accidents. In this section, we will discuss the various aspects to consider when choosing a blade for cutting aluminum.

Blade Types For Aluminum Cutting

There are different types of blades available for cutting aluminum with a circular saw. The two main types are non-ferrous blades and wood blades with carbide tips. Non-ferrous blades are specifically designed for cutting soft metals like aluminum, while wood blades with carbide tips can also be used effectively.

Non-ferrous blades have a special coating that prevents the aluminum from sticking to the blade, reducing friction and heat buildup. This helps to prolong the blade’s lifespan and maintain cutting efficiency. Wood blades with carbide tips can be a more affordable option, but they may wear out faster when cutting aluminum.

Tooth Count And Blade Dimensions

The tooth count and blade dimensions are important factors to consider when selecting a blade for cutting aluminum. Higher tooth count blades are generally recommended for smoother cuts, as they produce smaller chips and reduce the chance of the material getting caught in the blade. Blades with 80 to 100 teeth are commonly used for cutting aluminum.

Additionally, the dimensions of the blade, such as its diameter and arbor size, should be compatible with your circular saw. It’s essential to ensure that the blade fits securely on the saw and is aligned properly for accurate cuts.

Summary

- Choose a non-ferrous blade or a wood blade with carbide tips for cutting aluminum with a circular saw.

- Consider the tooth count of the blade, with higher tooth counts recommended for smoother cuts.

- Ensure the blade dimensions, such as diameter and arbor size, are compatible with your circular saw.

By selecting the perfect blade for cutting aluminum, you can achieve clean, precise, and efficient cuts. Remember to prioritize safety by wearing appropriate protective gear and following the manufacturer’s instructions for your circular saw and blade.

Preparing Your Aluminum

Before cutting aluminum with a circular saw, it’s essential to prepare the material properly to ensure a clean and precise cut. This involves surface cleaning and securing the aluminum in place to prevent any movement during the cutting process.

Surface Cleaning

Start by thoroughly cleaning the surface of the aluminum to remove any dirt, grease, or debris that could affect the cutting process. Use a mild detergent and water to clean the surface, and then dry it thoroughly with a clean cloth to ensure a smooth and uniform cutting experience.

Securing The Aluminum

Once the surface is clean, it’s important to secure the aluminum firmly in place before making any cuts. This can be achieved by using clamps or a sturdy workbench to hold the aluminum securely and prevent any movement that could lead to inaccuracies in the cutting process.

Setting Up Your Workspace

To cut aluminum with a circular saw, use a non-ferrous blade or a wood blade with a carbide tip. Ensure the blade has a higher tooth count for smoother cuts. Secure the aluminum firmly and use light pressure to prevent binding.

Lubricating the blade with wax can also help improve the cutting process.

Workspace Requirements

Before cutting aluminum with a circular saw, it’s crucial to set up your workspace with the right requirements. You’ll need a sturdy workbench or table to support the material, ensuring stability and safety during the cutting process. Additionally, a clamp or vice can secure the aluminum in place, preventing any movement that could lead to inaccurate cuts or potential hazards.

Lighting And Accessibility

Proper lighting is essential for clear visibility while working with a circular saw. Position your workspace near a well-lit area or use additional lighting sources to eliminate shadows and enhance accuracy. Accessibility to power outlets is also important, ensuring that the circular saw can be easily connected without any obstructions.

Cutting Techniques

For cutting aluminum, a circular saw with a non-ferrous blade or a carbide-tipped wood blade can be used. It’s important to use the appropriate blade to ensure clean and precise cuts. Lubrication with wax or oil can also aid in the cutting process.

Straight Cuts

When it comes to cutting aluminum with a circular saw, straight cuts are the easiest to make. It is recommended to use a non-ferrous blade or a wood blade with carbide tips. Make sure to clamp the aluminum securely to prevent it from moving and causing injuries. Set the blade depth to a maximum of 1/8 inch deeper than the aluminum’s thickness to avoid binding the blade. Additionally, wear safety glasses, hearing protection, and a dust mask for safety.Miter And Bevel Cuts

Miter and bevel cuts are a bit more challenging to make than straight cuts. When making miter cuts, angle the saw table to the desired angle and adjust the blade angle accordingly. For bevel cuts, adjust the saw blade angle and tilt the saw table to the desired angle. It is essential to use a blade with a high tooth count to achieve a clean and precise cut. Take extra precautions when making these cuts as the blade may bind, causing kickback.Cutting Tips

– Always wear appropriate safety gear when cutting aluminum with a circular saw. – Choose the right blade for the job. Non-ferrous blades or wood blades with carbide tips are ideal for cutting aluminum. – Clamp the aluminum securely to prevent it from moving and causing injuries. – Set the blade depth to a maximum of 1/8 inch deeper than the aluminum’s thickness. – Use a high tooth count blade for clean and precise cuts. – Take extra precautions when making miter and bevel cuts to avoid blade binding and kickback. In conclusion, cutting aluminum with a circular saw is an easy process as long as you follow the right techniques and precautions. Always prioritize safety and use the right blade for the job to achieve the desired results.Speed And Feed Rate

Cutting aluminum with a circular saw requires the use of a non-ferrous circular saw blade or a wood blade with a carbide tip. It is important to choose the appropriate tool and blade for clean and efficient cuts.

Optimal Speed For Aluminum

When it comes to cutting aluminum with a circular saw, speed is a crucial factor. The optimal speed for cutting aluminum with a circular saw is between 1000 and 3000 RPM. If the saw is spinning too fast, the blade can overheat, which can result in warping or melting of the aluminum. Conversely, if the saw is spinning too slow, the blade can become dull, which can lead to poor cutting performance.Feed Rate Adjustments

In addition to speed, feed rate is another critical factor that affects the cutting performance when cutting aluminum with a circular saw. The feed rate refers to the speed at which the saw is moved through the material. The optimal feed rate for cutting aluminum with a circular saw is between 0.005 and 0.015 inches per tooth. If the feed rate is too slow, the blade can become clogged with aluminum chips, which can lead to poor cutting performance. On the other hand, if the feed rate is too fast, the blade can become overloaded, which can lead to warping or melting of the aluminum. To achieve the optimal feed rate, it’s essential to adjust the saw’s cutting depth, the number of teeth on the blade, and the saw’s speed. By making these adjustments, you can ensure that the saw cuts through the aluminum cleanly and efficiently, without causing any damage to the material or the blade. In conclusion, cutting aluminum with a circular saw requires careful consideration of both speed and feed rate. By following the guidelines outlined above, you can achieve optimal cutting performance and ensure that your saw cuts cleanly and efficiently through the material.Lubrication And Cooling

Cutting aluminum with a circular saw requires effective lubrication and cooling to ensure smooth and efficient operations. These measures are crucial for maintaining the integrity of the material and the saw blade, ultimately impacting the quality of the finished cuts and the overall safety of the process.

Importance Of Lubrication

Lubrication plays a vital role in the cutting process as it minimizes friction between the blade and the aluminum, reducing heat build-up and preventing the material from sticking to the blade. This results in cleaner cuts and extends the lifespan of the saw blade.

Methods Of Cooling During Cuts

Cooling methods are essential for dissipating the heat generated during the cutting process, preventing the aluminum from overheating and potentially warping. There are several effective cooling methods to consider, including:

- Using a lubricant specifically designed for aluminum cutting, such as a coolant or cutting oil, to reduce friction and heat.

- Applying compressed air or a steady stream of water to the cutting area to maintain a lower operating temperature and facilitate smooth cutting.

- Utilizing saw blades with built-in cooling features, such as expansion slots or heat-dissipating coatings, to enhance heat management during cuts.

Post-cut Processing

Once you have cut the aluminum with a circular saw, it’s essential to carry out post-cut processing to ensure smooth and precise edges. The post-cut processing involves deburring edges and adding finishing touches to the aluminum.

Deburring Edges

Deburring the edges of the aluminum is crucial to remove any rough or sharp protrusions. This can be achieved using a deburring tool or a file to smooth out the edges and eliminate any burrs that may have formed during the cutting process.

Finishing Touches

After deburring the edges, applying finishing touches to the aluminum can enhance its appearance and functionality. This may involve sanding the edges to create a smooth finish, or using a metal polish to add a lustrous shine to the surface of the aluminum.

Maintenance And Blade Care

Cutting aluminum with a circular saw can be done using a non-ferrous circular saw blade or a delicate wood blade with a carbide tip. It’s important to choose the appropriate tool for the job to ensure clean cuts and avoid any safety risks.

Cleaning The Blade

Maintenance and blade care are essential to ensure the longevity and efficiency of your circular saw when cutting aluminum. One crucial aspect of maintenance is keeping the blade clean. Over time, aluminum debris can build up on the blade, affecting its performance and cutting ability.

To clean the blade, follow these steps:

- Disconnect the saw from the power source and remove the blade from the saw.

- Using a stiff-bristle brush or an old toothbrush, gently scrub the blade to remove any built-up aluminum residue.

- If there are stubborn deposits, you can use a blade cleaner specifically designed for removing pitch and resin.

- Rinse the blade with water and dry it thoroughly before reattaching it to the saw.

Storage And Handling

Proper storage and handling of your circular saw and its blade are crucial to maintain their performance and prevent any damage. Here are some tips:

- Always store the saw in a dry and clean environment to prevent rust or corrosion.

- When not in use, cover the blade with a blade guard or sheath to protect it from dust and moisture.

- Avoid placing heavy objects on top of the saw, as it can cause the blade to warp or bend.

- Handle the saw and blade with care, avoiding any rough or aggressive movements that can cause damage.

- Before using the saw, inspect the blade for any signs of wear or damage. If the blade is dull or damaged, replace it before cutting aluminum.

By following these maintenance and blade care practices, you can ensure that your circular saw performs optimally when cutting aluminum. Regular cleaning and proper storage will not only extend the lifespan of your saw and blade but also ensure accurate and efficient cuts every time.

Troubleshooting Common Issues

When it comes to cutting aluminum with a circular saw, there are some common issues that you may encounter. Understanding these issues and how to troubleshoot them can help you achieve accurate cuts and prevent any potential problems. In this section, we will discuss two common issues that you may face when cutting aluminum with a circular saw: blade wobble and inaccurate cuts.

Blade Wobble

Blade wobble is a common issue that can affect the quality of your cuts when working with aluminum. This can result in uneven edges and a rough finish. Fortunately, there are a few steps you can take to troubleshoot and resolve this problem.

- Check the blade for any signs of damage or wear. A dull or damaged blade can cause wobbling. If necessary, replace the blade with a new one.

- Ensure that the blade is properly tightened. Loose blade screws can cause wobbling. Use a wrench to tighten the screws securely.

- Inspect the arbor of the saw for any debris or obstructions. Clean the arbor thoroughly to ensure smooth rotation.

- Make sure that the saw’s motor is running smoothly. Any issues with the motor can contribute to blade wobble. Consult the manufacturer’s instructions for troubleshooting motor problems.

Inaccurate Cuts

If you are experiencing inaccurate cuts when cutting aluminum with a circular saw, there are a few possible causes and solutions to consider.

- Check the alignment of the saw’s base plate. A misaligned base plate can result in cuts that are not straight. Use a square to ensure that the base plate is properly aligned.

- Verify that the fence or guide is properly positioned and secured. A loose or misaligned fence can lead to inaccurate cuts. Adjust and tighten the fence as needed.

- Inspect the blade for any buildup of aluminum chips or debris. Clean the blade regularly to prevent buildup that can affect the cutting accuracy.

- Ensure that the blade is suitable for cutting aluminum. Using a blade designed for wood or other materials may result in inaccurate cuts. Invest in a high-quality blade specifically designed for cutting aluminum.

By troubleshooting these common issues, you can improve the accuracy and quality of your cuts when working with aluminum using a circular saw. Remember to always prioritize safety and consult the manufacturer’s instructions for your specific saw model.

Advanced Tips And Tricks

Cutting aluminum with a circular saw can be easily achieved using a non-ferrous circular saw blade or a delicate wood blade with a carbide tip. This tool is ideal for thicker cuts or larger projects that require multiple cuts. Be sure to use appropriate lubrication for smoother operation.

When it comes to cutting aluminum with a circular saw, there are some advanced tips and tricks that can help you achieve the best results. Whether you’re cutting complex shapes or using stack cutting techniques, these strategies can make the process easier and more efficient.

Cutting Complex Shapes

Cutting complex shapes in aluminum can be challenging, but with the right techniques, it can be done successfully. Here are some tips to consider:

- Use a fine-toothed blade: A fine-toothed blade with carbide tips is ideal for cutting intricate shapes in aluminum. It provides clean and precise cuts, minimizing the risk of chipping or damaging the material.

- Secure the aluminum: To prevent the material from moving or vibrating during the cutting process, ensure it is properly clamped or secured to a stable surface. This will help maintain accuracy and reduce the chance of errors.

- Take your time: Cutting complex shapes requires patience and precision. Slowly guide the saw along the desired path, allowing the blade to do the work. Avoid rushing or forcing the saw, as this can lead to mistakes or uneven cuts.

Stack Cutting

Stack cutting is a technique commonly used when cutting multiple pieces of aluminum simultaneously. Here are some tips to help you achieve clean and efficient stack cuts:

- Choose the right blade: When stack cutting, it’s important to use a blade specifically designed for multi-layer cutting. These blades have a special tooth geometry that allows them to cut through multiple layers of aluminum with ease.

- Secure the stack: To ensure precise and even cuts, it’s crucial to secure the stack of aluminum sheets tightly together. This can be done using clamps or a vise, depending on the size and shape of the stack.

- Adjust the saw’s speed: When stack cutting, it’s recommended to reduce the saw’s speed to avoid overheating the blade. Lowering the speed will also help maintain control and accuracy throughout the cutting process.

By following these advanced tips and tricks, you can enhance your cutting skills and achieve excellent results when working with aluminum and a circular saw. Remember to prioritize safety, wear appropriate protective gear, and always double-check your measurements before making any cuts.

Safety Recap And Best Practices

To safely cut aluminum with a circular saw, use a non-ferrous circular saw blade or a carbide-tipped wood blade. Ensure the blade has a high tooth count and consider using a little wax for lubrication. Proceed with caution and always wear appropriate safety gear to prevent injury.

Review Of Safety Measures

Cutting aluminum with a circular saw can be a daunting task, especially if you are not well-versed in the safety measures to take. Here are some essential safety tips to keep in mind when using a circular saw:- Always wear safety glasses or goggles to protect your eyes from flying debris.

- Wear earplugs or earmuffs to protect your hearing from the loud noise of the saw.

- Wear gloves to protect your hands from sharp edges.

- Wear a dust mask to avoid inhaling aluminum dust that may cause respiratory problems.

- Ensure that the saw is unplugged before changing the blade or adjusting the blade depth.

- Secure the aluminum material to prevent it from moving during the cutting process.

- Ensure that the saw blade is sharp and in good working condition.

- Never force the saw through the material, let the blade do the work.

Creating A Cutting Routine

In addition to following safety measures, it’s also crucial to create a cutting routine that ensures precision and accuracy. Here are some tips to help you create an efficient cutting routine:- Measure the aluminum material and mark it where you want to cut.

- Set the depth of the saw blade to the thickness of the aluminum material.

- Start the saw and let it reach full speed before making contact with the material.

- Slowly guide the saw along the marked line, keeping your hands steady and at a safe distance from the blade.

- Once you’ve completed the cut, turn off the saw and wait for the blade to come to a complete stop before removing the material.

Frequently Asked Questions

Can You Cut Aluminium With A Circular Saw?

Yes, you can cut aluminum with a circular saw using a non-ferrous or carbide-tipped wood blade.

What Type Of Circular Saw Blade To Cut Aluminum?

For cutting aluminum, it is best to use a non-ferrous circular saw blade or a wood blade with carbide tips. These blades are specifically designed to cut through aluminum without damaging the material. It is important to avoid using standard metal cutting blades as they can cause chipping and rough edges.

What Saw Is Best For Cutting Aluminium?

A circular saw with a non-ferrous or carbide-tipped wood blade is the best saw for cutting aluminum. For thicker cuts or larger projects, a circular saw is the ideal choice. It’s important to use the appropriate blade and lubrication for smooth and accurate cuts.

What Speed Circular Saw For Cutting Aluminum?

For cutting aluminum, use a circular saw with a non-ferrous blade or a wood blade with a carbide tip. The recommended speed for cutting aluminum is around 1,000 to 3,000 RPM.

Conclusion

To conclude, cutting aluminum with a circular saw is possible, but it requires the appropriate blade and technique. Using a non-ferrous circular saw blade or a delicate wood blade with a carbide tip, along with proper lubrication, can result in clean and precise cuts.

It’s important to take safety precautions and use protective gear when handling the saw and aluminum material. With the right tools and knowledge, cutting aluminum with a circular saw can be a simple and efficient process.