Do Drive Links Matter on Chainsaw? Essential Insights

Drive links do matter on chainsaws for optimal performance. Chainsaw chains with more drive links provide better cutting efficiency and smoother operation.

Chainsaws are powerful tools that are used for various purposes, including cutting down trees, pruning branches, and trimming hedges. To ensure that your chainsaw functions at its best, it is important to consider the number of drive links on your chainsaw chain.

Drive links are the small metal links that attach the chain to the chainsaw’s bar, and they play a crucial role in determining the efficiency and smoothness of the cutting process. Chainsaw chains with more drive links have a greater cutting surface area, resulting in improved cutting efficiency and smoother operation. In this blog post, we will explore the importance of drive links in chainsaws and how they can impact the performance of your tool.

The Role Of Drive Links In Chainsaw Performance

When it comes to chainsaw performance, many factors play a vital role in determining the efficiency and effectiveness of the tool. One of the most critical components of a chainsaw is the drive links. These links play a crucial role in determining how well the chainsaw cuts through wood and other materials. In this blog post, we will explore the role of drive links in chainsaw performance, defining drive links and their function, and the impact of drive links on cutting efficiency.

Defining Drive Links And Their Function

Drive links are the small metal links that protrude from the underside of a chainsaw chain. They are responsible for transmitting power from the chainsaw’s engine to the cutting chain, allowing it to cut through wood and other materials. The number of drive links on a chainsaw chain can vary depending on the size and type of chainsaw.

The function of drive links is to engage with the chainsaw’s drive sprocket, which is connected to the engine. As the engine turns the drive sprocket, the drive links pull the cutting chain around the guide bar, allowing it to cut through the material being worked on.

Impact On Cutting Efficiency

The number of drive links on a chainsaw chain can impact the cutting efficiency of the tool. Chains with more drive links will generally have more cutting teeth and will cut through materials more quickly. However, more drive links can also make the chainsaw chain heavier, which can impact the user’s ability to control the tool.

The material used to manufacture the drive links can also impact cutting efficiency. Chains with drive links made from high-quality steel will generally have a longer lifespan and will maintain their sharpness for longer periods. This can result in a more efficient and effective cutting experience.

It is essential to consider the number of drive links and the quality of the material when selecting a chainsaw chain. Choosing the right chain for the job can result in a more efficient and effective cutting experience while also extending the lifespan of the tool.

Comparing Chains: Drive Link Variations

When it comes to chainsaw chains, one crucial aspect to consider is the drive link variations. Drive links are the teeth-like components that fit into the guide bar and propel the chain along the bar. Understanding the different types of chains and their drive link differences is essential in selecting the right chain for your chainsaw.

Chain Types And Drive Link Differences

There are several chain types available for chainsaws, each designed for specific cutting tasks. The most common chain types include:

- Skip Chain

- Semi-Skip Chain

- Full Chisel Chain

- Semi Chisel Chain

- Low-Profile Chain

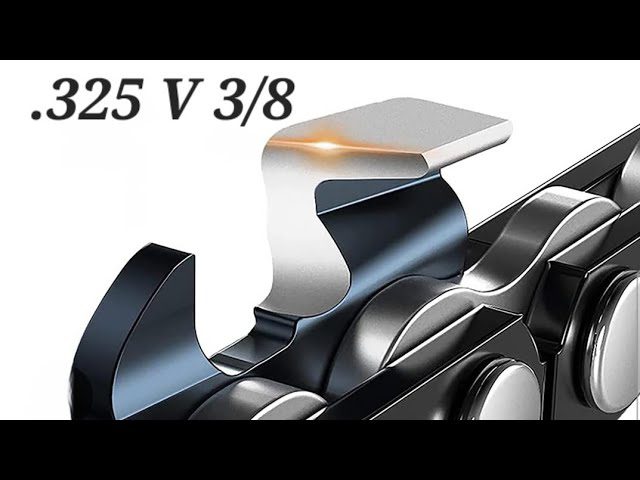

While each chain type has its unique characteristics, the drive link differences play a crucial role in their performance. Drive link variations can include:

- Shape of the Drive Link: Some chains feature square-cornered drive links, while others have rounded-cornered ones. The shape of the drive link affects the cutting efficiency and durability of the chain.

- Depth Gauge Configuration: The depth gauge helps control the depth of the cut. Different chains may have varying depth gauge configurations, which affect the aggressiveness and smoothness of the cutting action.

- Drive Link Thickness: Drive links can vary in thickness, impacting the overall strength and performance of the chain. Thicker drive links are generally more durable and suitable for heavy-duty cutting tasks.

Selecting the right chain for your saw depends on the specific requirements of your cutting job. Consider the type of wood you’ll be cutting, the desired cutting speed, and the level of precision needed. Understanding the drive link variations will help you make an informed decision and ensure optimal performance from your chainsaw.

Drive Link Count: Matching Your Chainsaw’s Guide Bar

Matching the drive link count to your chainsaw’s guide bar is crucial for optimal performance. Ensuring the correct number of drive links is essential for safe and efficient cutting operations with your chainsaw. Proper matching of drive links enhances the overall functionality and longevity of your chainsaw equipment.

Importance Of Accurate Drive Link Count

Matching the drive link count of your chainsaw to the guide bar is crucial for optimal performance and safety. The drive link count refers to the number of links on the chain that fit into the guide bar’s groove. When the drive link count is accurate, it ensures smooth operation and prevents potential issues that could arise from a mismatch.

Using a chainsaw with an incorrect drive link count can have various negative consequences. It’s essential to understand these consequences to avoid any potential problems while operating your chainsaw.

Consequences Of Mismatched Drive Links And Guide Bars

A mismatch between the drive link count and guide bar size can lead to several issues that affect the performance and longevity of your chainsaw. It’s important to be aware of these consequences to ensure you have the right combination of drive links and guide bars.

- Poor Cutting Performance: When the drive link count doesn’t match the guide bar, the chainsaw may not cut efficiently. This can result in slower cutting speeds, uneven cuts, and increased strain on the chainsaw’s engine.

- Increased Wear and Tear: Mismatched drive links and guide bars can cause excessive wear and tear on both components. This can lead to premature chain and guide bar wear, reducing their overall lifespan.

- Reduced Safety: Using a chainsaw with mismatched drive links and guide bars can compromise safety. It can result in chain derailment, kickback, or other unpredictable behaviors, increasing the risk of accidents.

- Overloading the Chainsaw: A mismatched combination can put unnecessary stress on the chainsaw’s engine, causing it to work harder than intended. This can lead to overheating, decreased performance, and potential damage to the chainsaw.

It’s crucial to ensure that the drive link count matches the guide bar size recommended by the chainsaw manufacturer. This information is usually provided in the chainsaw’s user manual or specifications. By using the correct drive link count, you can optimize the chainsaw’s performance, prolong its lifespan, and ensure safe operation.

Maintenance Tips For Optimal Drive Link Performance

For optimal chainsaw performance, drive links play a crucial role. Regular maintenance ensures smooth operation and extends the lifespan of your chainsaw. Keep drive links sharp and well-lubricated to enhance cutting efficiency and prevent wear and tear.

Regular Cleaning and Inspection

Regular cleaning and inspection ensure optimal drive link performance. Remove debris and dirt from the drive links using a brush. Inspect for any signs of wear and tear, such as bent or damaged links. Replace any worn or damaged drive links promptly.

Lubrication: Ensuring Smooth Operation

Lubricate the drive links to ensure smooth operation. Apply a high-quality chainsaw bar and chain oil to the drive links. This minimizes friction and reduces wear, extending the life of the drive links. Check the oil level regularly and top up as needed to maintain proper lubrication.

By following these maintenance tips, you can ensure that your chainsaw’s drive links operate at their best, prolonging the life of your chainsaw and maintaining optimal performance.

Troubleshooting Common Drive Link Issues

When it comes to chainsaw maintenance, one crucial aspect to consider is the condition of the drive links. The drive links are responsible for the chainsaw’s cutting performance, and any wear or damage can affect its efficiency. In this section, we will discuss how to identify wear and damage in drive links and provide step-by-step instructions for their replacement.

Identifying Wear And Damage

Regular inspection of the drive links is necessary to ensure optimal chainsaw performance. Here are some signs of wear and damage to look out for:

- Worn or rounded edges: Check the edges of the drive links for any signs of excessive wear or rounding. This can indicate that the chain has been used extensively and may need replacement.

- Cracks or breaks: Inspect the drive links for any visible cracks or breaks. These can weaken the chain and pose a safety risk during operation.

- Bent or twisted links: If you notice any bent or twisted links, it is essential to address the issue promptly. Bent links can affect the chain’s alignment, leading to poor cutting performance.

- Excessive elongation: Over time, the drive links may stretch, causing an increase in the chain’s length. Measure the chain’s pitch regularly to identify any excessive elongation, which can affect the chain’s tension and overall performance.

Steps For Drive Link Replacement

If you encounter any wear or damage in the drive links, it is crucial to replace them promptly. Follow these steps for a seamless drive link replacement process:

- Step 1: Ensure the chainsaw is turned off and disconnected from any power source for safety.

- Step 2: Use a suitable tool to remove the chain from the chainsaw’s guide bar.

- Step 3: Identify the damaged drive links by inspecting the chain closely.

- Step 4: Using a drive link removal tool, carefully detach the damaged links from the chain.

- Step 5: Take the replacement drive links and insert them into the chain, ensuring they fit securely.

- Step 6: Reattach the chain to the guide bar, making sure it is properly tensioned.

- Step 7: Test the chainsaw’s cutting performance to ensure the new drive links are functioning correctly.

By following these troubleshooting steps and replacing worn or damaged drive links, you can maintain your chainsaw’s efficiency and extend its lifespan. Regular inspection and timely replacement are crucial for optimal cutting performance and safe operation.

Drive Link Quality: Material And Manufacturing

When it comes to the performance and durability of a chainsaw, the quality of the drive link – the part of the chainsaw chain that engages with the sprocket – plays a crucial role. In this section, we will delve into the key factors that determine drive link quality, specifically focusing on the materials used in construction and how manufacturing processes impact durability.

Materials Used In Drive Link Construction

The materials utilized in the construction of drive links significantly influence their strength and longevity. High-carbon steel is the most commonly used material for drive links due to its exceptional strength and resistance to wear. It offers the necessary toughness to withstand the rigors of cutting through tough wood and other challenging materials.

Additionally, some advanced chainsaw models incorporate titanium-reinforced drive links to further enhance their durability and performance. Titanium imparts exceptional strength and corrosion resistance, making it an ideal material for drive link construction.

How Manufacturing Processes Affect Durability

The manufacturing processes employed in the production of drive links have a direct impact on their durability and performance. Precision heat treatment is a critical aspect of drive link manufacturing, as it enhances the hardness and toughness of the steel, ensuring that the drive links maintain their sharpness and integrity over prolonged use.

Furthermore, advanced manufacturing techniques such as laser cutting and precision stamping enable the creation of drive links with precise dimensions and smooth surfaces, which are essential for seamless engagement with the chainsaw’s sprocket.

Safety Considerations: The Critical Role Of Drive Links

In chainsaw operation, ensuring safety is paramount. Safety Considerations: The Critical Role of Drive Links emphasizes the importance of drive links in maintaining a safe chainsaw operation.

Preventing Chain Failure With Reliable Drive Links

Drive links play a crucial role in preventing chain failure, ensuring the chainsaw operates smoothly.

Drive Link Inspections As A Safety Measure

Regular drive link inspections are essential for maintaining a safe chainsaw operation.

Advancements In Drive Link Technology

The advancements in drive link technology play a crucial role in the performance of chainsaws. The drive links are vital for maintaining smooth and efficient operation, impacting the overall cutting performance and longevity of the chainsaw. Understanding the significance of drive links can lead to improved chainsaw functionality and durability.

Innovations In Drive Link Design

Recent innovations have revolutionized drive link design in chainsaws.

New materials and shapes enhance cutting efficiency and durability.

Advanced coatings reduce friction and enhance corrosion resistance.

Future Trends In Chainsaw Drive Links

Future drive links will focus on enhancing performance and longevity.

Integration with smart technology for real-time performance monitoring.

Increased focus on sustainability with eco-friendly materials and production methods.

Frequently Asked Questions

Do Drive Links Affect The Chainsaw’s Performance?

Drive links play a crucial role in a chainsaw’s performance. They ensure smooth cutting by transferring power efficiently.

How To Determine The Right Drive Link Count?

To find the correct drive link count for your chainsaw, consult the manufacturer’s manual or check the old chain for information.

Can I Replace A Chainsaw Chain With A Different Drive Link Count?

It is essential to match the drive link count when replacing a chainsaw chain to ensure proper functionality and safety.

Conclusion

Drive links play a crucial role in the performance and safety of chainsaws. Ensuring that the chainsaw has the right drive links is essential for optimal functionality and longevity. By understanding the significance of drive links, users can make informed decisions when selecting and maintaining their chainsaw equipment.