Do You Need a Hammer Drill for Concrete? A Simple Guide

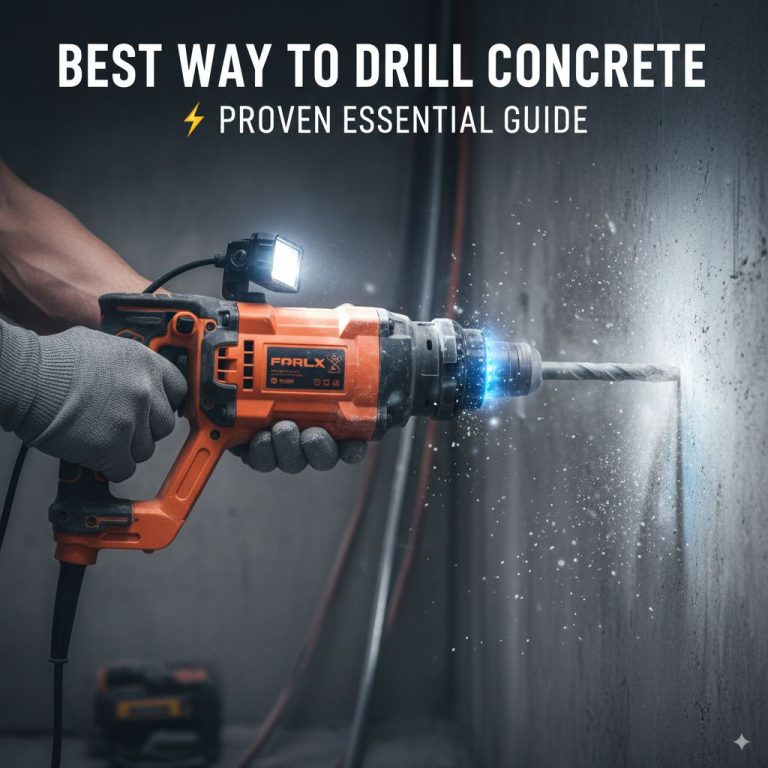

Figuring out if Do You Need a Hammer Drill for Concrete? is a common question, especially if you’re new to home improvement or construction. It can seem tricky to know if you really need a special tool for concrete. Don’t worry, this guide will make things easy. We’ll break down everything step-by-step so you can make the right choice. Next, we’ll look at the differences between standard drills and hammer drills and how they work on concrete.

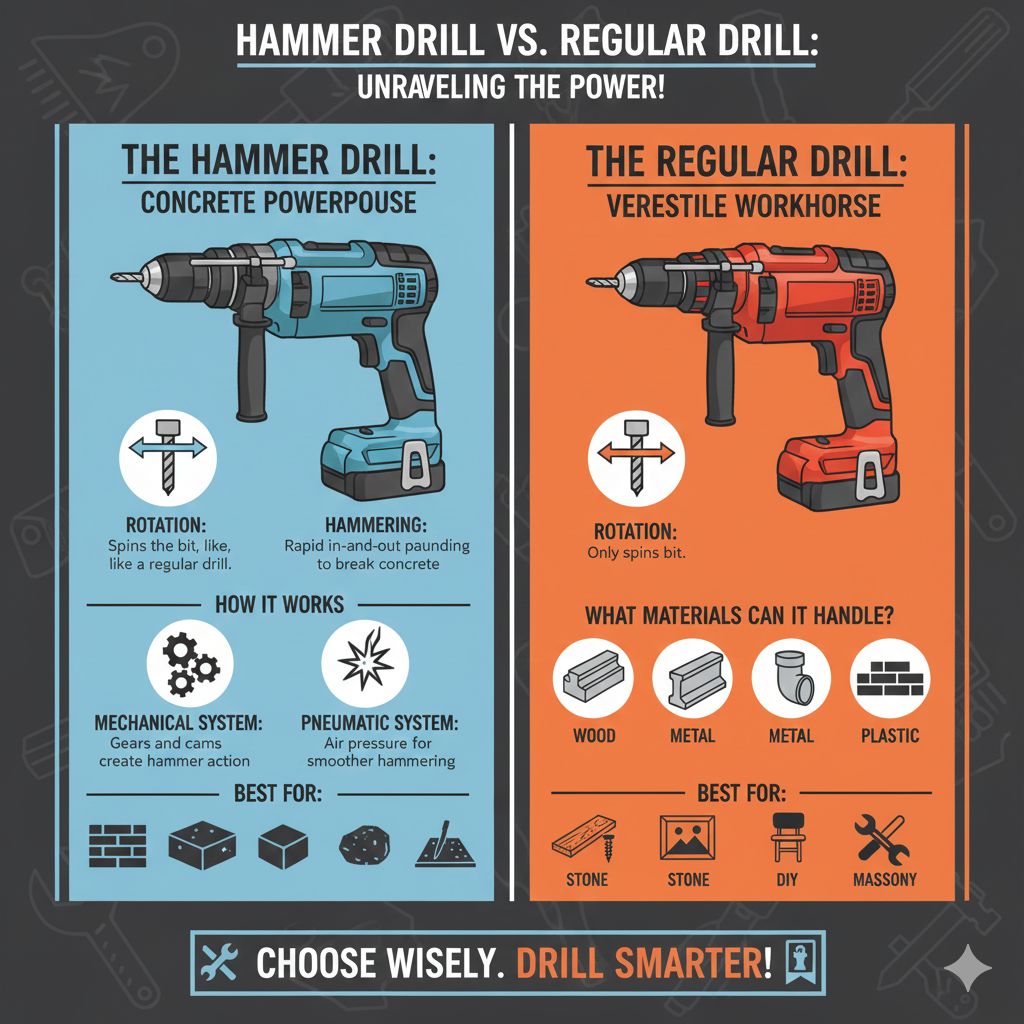

What is a Hammer Drill?

A hammer drill is a power tool designed specifically for drilling into hard materials like concrete, brick, and stone. Unlike a regular drill that only rotates the drill bit, a hammer drill also provides a hammering action, which helps to break up the material as the bit rotates. This hammering action is what allows the drill to penetrate concrete much more efficiently than a standard drill. The hammering action is typically measured in blows per minute (BPM), and the higher the BPM, the faster the drilling. The best hammer drills offer different modes to allow you to switch between hammer drilling, standard drilling, and sometimes even chiseling.

This section explores the core of hammer drills. It explains their unique ability to handle tough materials such as concrete due to the hammering mechanism. This includes a description of how this hammering action works and how it differs from a typical drill. Also, it discusses the significance of BPM in relation to hammer drill effectiveness and highlights the diverse functions of various hammer drills. The goal is to provide a solid foundation for grasping the core functionalities of this type of tool.

How a Hammer Drill Works

A hammer drill works by combining two actions: rotation and hammering. The rotation is what spins the drill bit, much like a regular drill. The hammering action is what truly sets it apart. Inside the drill, there’s a mechanism that quickly moves the drill bit back and forth while it rotates. This hammering action helps to break up the concrete, making it easier for the drill bit to penetrate. Different hammer drills use different methods to create this hammering action. Some use a mechanical system with gears and cams, while others use a pneumatic system, which relies on air pressure.

- Rotational Action: The drill bit spins, creating a hole. This action is similar to a regular drill, and it’s essential for getting the bit into the material.

- Hammering Action: This is where the magic happens. The drill bit moves in and out rapidly. This pounding motion breaks the concrete.

- Mechanical Systems: Some hammer drills use gears and cams to produce the hammering.

- Pneumatic Systems: These drills use compressed air to drive the hammering action, offering a smoother and more efficient performance.

The method of generating the hammering action has a big effect on a hammer drill’s performance. The mechanical system works by using gears and cams, providing a dependable and robust hammering action suitable for home use or smaller projects. On the other hand, the pneumatic system harnesses air pressure, offering smoother operation and greater efficiency, thus suitable for professional use or large-scale projects. Knowing these differences can help you pick the best tool for your job.

What Materials Can a Hammer Drill Handle?

The hammer drill’s design equips it to work effectively with tough, dense materials that regular drills can’t handle with ease. Concrete is its prime target. Brick and stone are other materials that become much simpler to deal with using this tool. Using a hammer drill helps reduce the effort and time needed for drilling in such materials. You can also use it with wood, metal, and plastic, but the hammering action isn’t needed here. The hammer drill’s main role is to simplify the task of working with hard, solid materials.

- Concrete: This is where the hammer drill shines. It makes drilling into concrete fast and easy.

- Brick: Hammer drills also work well on brick, allowing for easy anchoring and fastening.

- Stone: Hard stones, such as granite, are no match for the hammer drill.

- Wood, Metal, and Plastic: You can use a hammer drill for these materials, but the hammering action isn’t needed. Use the drill in the standard drill mode.

The materials a hammer drill can work with show its versatility. It’s really good at drilling into concrete, brick, and stone. Also, it’s capable of drilling into wood, metal, and plastic. In these cases, you don’t need the hammering feature. For those, you can simply use the drill mode. This flexibility makes it a must-have tool for different construction or home improvement projects.

Hammer Drill vs. Regular Drill: The Key Differences

The differences between a hammer drill and a regular drill are mainly in their design and functionality. A standard drill relies solely on rotation to create holes. It’s suitable for softer materials such as wood and plastic. A hammer drill adds a hammering action to rotation, which is key for hard materials like concrete. Hammer drills also tend to be more powerful. They have robust motors to provide the torque and force needed for the hammering action. The extra power is beneficial when working with difficult materials. If you often work with concrete or other hard materials, a hammer drill is the superior choice. If you primarily work with soft materials, a regular drill will likely meet your needs.

| Feature | Hammer Drill | Regular Drill |

|---|---|---|

| Action | Rotation and Hammering | Rotation Only |

| Suitable Materials | Concrete, Brick, Stone | Wood, Plastic, Metal |

| Power | Typically More Powerful | Typically Less Powerful |

| Use | For Hard Materials | For Softer Materials |

This comparison shows how different a hammer drill is from a normal drill. The main differences are the functions, material compatibility, and overall power. The hammer drill features rotation and hammering action, making it great for concrete and stone. On the other hand, regular drills only use rotation and are suitable for softer things, like wood and plastic. This table makes it easy to understand the core differences, which helps you choose the right tool for the job.

When Should You Consider a Hammer Drill?

Knowing when to use a hammer drill is very important to complete your projects efficiently. When you work with concrete, brick, or stone, a hammer drill is the tool of choice. It makes drilling into these materials much easier and faster. If you want to put up shelves on a concrete wall, hang pictures, or do any project that requires drilling into hard surfaces, a hammer drill is the right tool. If you are doing a lot of drilling in hard materials, a hammer drill is the better choice because it will save you time and energy. It will also help you get better, more precise results.

This section is focused on helping you recognize the situations where a hammer drill is essential. This includes knowing the ideal uses for the tool, specifically in concrete and brick projects. It also covers examples of scenarios where a hammer drill is extremely helpful, like when hanging things or doing construction work. The goal is to make sure you know when the advantages of using a hammer drill are most beneficial.

Projects Ideal for Hammer Drills

A hammer drill is ideal for a lot of projects, especially those that involve hard materials. If you are mounting a TV on a concrete wall, a hammer drill is going to be your best friend. It can make drilling the mounting holes quick and easy. When you’re renovating a bathroom and need to install fixtures on a tiled wall, a hammer drill will help. It allows you to drill without damaging the tile. For outdoor projects, if you need to build a deck or fence and need to attach posts to a concrete patio, a hammer drill is great. It can quickly drill the holes to fasten the posts.

- Mounting a TV on Concrete: A hammer drill is perfect for drilling holes to mount a TV on a concrete wall.

- Installing Fixtures on Tiled Walls: When renovating bathrooms and kitchens, hammer drills make drilling through tile a breeze.

- Outdoor Projects (Deck, Fence): For attaching posts to concrete, the hammer drill provides quick and effective results.

The projects listed show how useful a hammer drill is for different tasks. Whether you’re hanging a TV on a solid concrete wall, updating a bathroom, or building an outdoor space, this tool provides great performance. The examples prove that the hammer drill isn’t just good; it’s necessary for anyone who does these kinds of jobs.

Signs You Need a Hammer Drill for Concrete

There are several signs that show you’re going to need a hammer drill. If you’re struggling to drill into concrete with a standard drill, it’s time to switch. The standard drill will spin but won’t make much progress. Also, if you notice the drill bit is wearing down quickly, this is a clue. Concrete is very hard, and regular drill bits aren’t designed to handle this kind of force. If you feel excessive vibration, that’s another indication. The standard drill will vibrate a lot when it tries to penetrate concrete. When you are looking at concrete, brick, or stone, a hammer drill is the best option.

- Drill Bit Doesn’t Penetrate: If the drill bit won’t go into the material, you need a hammer drill.

- Rapid Bit Wear: Standard drill bits wear down quickly when used on concrete.

- Excessive Vibration: A regular drill will vibrate a lot when trying to drill into concrete.

These signs can help you identify when it’s time to switch from a regular drill to a hammer drill. If you run into problems trying to drill into concrete, like the drill not going in, the bit breaking, or heavy vibrations, you need a hammer drill. Knowing these signals can help you save time and effort. Also, it guarantees you get the job done properly.

Case Study: Installing a Fence on a Concrete Slab

Imagine you’re building a fence and need to secure the posts to a concrete slab. Using a regular drill would be a slow and frustrating process. The drill would struggle to penetrate the concrete, and you’d likely wear out multiple drill bits. In contrast, using a hammer drill makes this task simple. You’d quickly drill holes in the concrete and then insert anchors to attach the fence posts. The hammer drill would dramatically cut the time it takes to complete the job. It would also lead to cleaner, more accurate holes.

This example showcases the significant difference a hammer drill can make in practical situations. It contrasts the struggle of using a regular drill with the smooth, efficient results achievable with a hammer drill, like in the instance of building a fence. It emphasizes time efficiency and precision improvement, which makes the hammer drill a practical tool for similar construction projects.

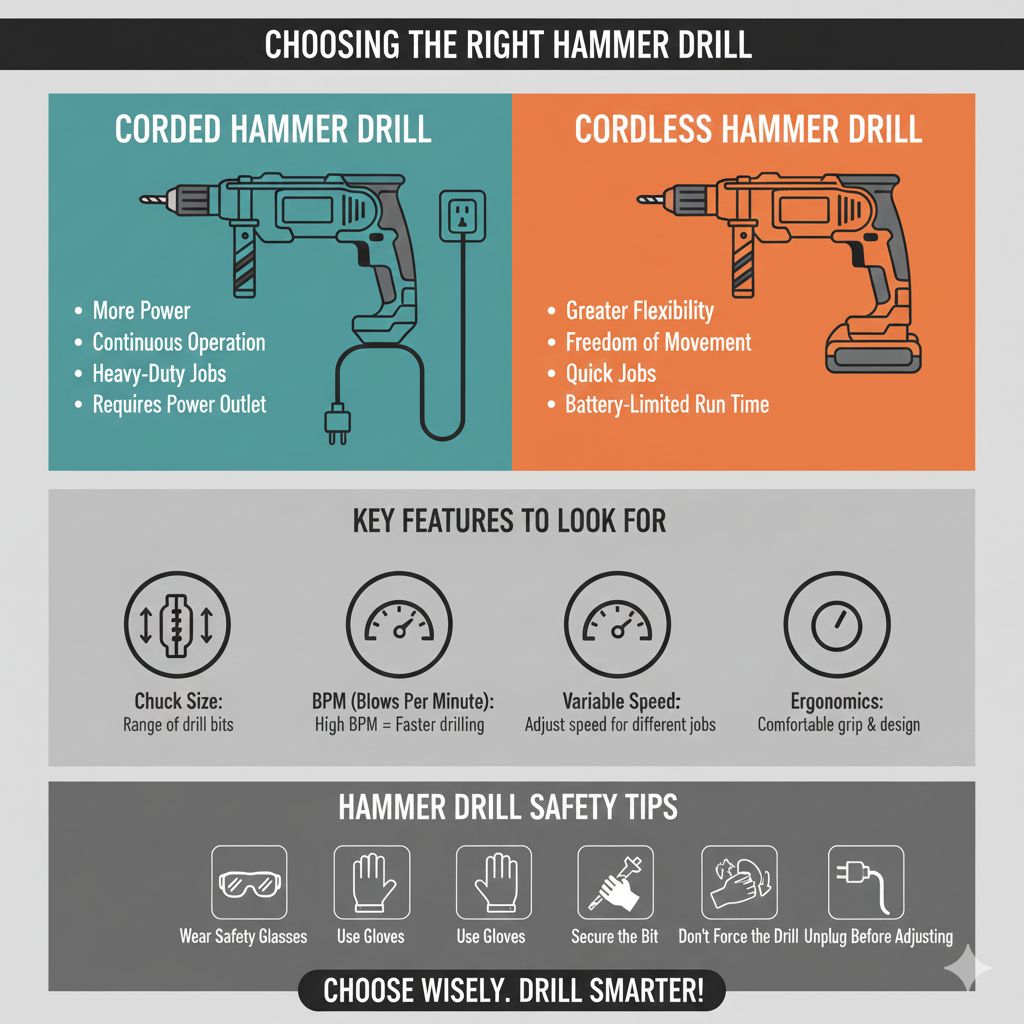

Choosing the Right Hammer Drill

There are different types of hammer drills, so it’s important to choose the right one for your needs. Corded hammer drills are powerful and reliable. They are great for demanding tasks, but they require a power outlet. Cordless hammer drills are convenient. They can be used anywhere, but their power and battery life can vary. The chuck size, which determines the bit sizes you can use, and the BPM, which indicates drilling speed, are also key considerations. Also, make sure to consider the ergonomics and features, such as variable speeds and different modes.

This section explores the various features and characteristics to consider when choosing a hammer drill. It gives a comparison of corded versus cordless models. It talks about the importance of chuck size and BPM. It also touches on how ergonomics and features affect the user experience and overall tool functionality. The goal is to provide a comprehensive look at how to find a hammer drill that meets your project requirements.

Corded vs. Cordless Hammer Drills

The choice between corded and cordless hammer drills often comes down to your project needs and preferences. Corded hammer drills are generally more powerful and offer continuous operation. They’re a great choice for heavy-duty jobs and when you need consistent power. The downside is that you have to be near a power outlet. Cordless hammer drills provide greater flexibility and freedom of movement. They are perfect for situations where you need to move around a lot or work in areas where power outlets are unavailable. They are great for quick jobs or smaller projects. However, the power and run time depend on the battery. Each has its pros and cons, so the decision depends on what is best for your project.

- Corded: More power, continuous operation, and suitable for heavy-duty jobs. Need a power outlet.

- Cordless: Offers more flexibility and freedom of movement. Run time is limited by the battery.

The comparison helps you figure out the best hammer drill option. Corded drills give constant power, good for heavy tasks, but they require a power outlet. Cordless drills have great mobility and are perfect for working in places without a power source. Consider the task type, mobility needs, and power access to choose the best one for your work.

Key Features to Look For

When choosing a hammer drill, several features can affect your experience. The chuck size is important because it dictates the range of drill bits you can use. The BPM rating determines how fast the hammer drill can break concrete. Higher BPM numbers mean faster drilling. Variable speed settings let you adjust the drill’s speed. This is perfect for different materials and tasks. A comfortable grip and good ergonomics will make it easier to work for longer periods. Features like an auxiliary handle can also improve control. Look for a hammer drill that has these features to ensure better performance and ease of use.

- Chuck Size: Impacts the range of drill bits you can use.

- BPM (Blows Per Minute): High BPM equals faster drilling.

- Variable Speed: Lets you change the drill’s speed for different jobs.

- Ergonomics: A comfortable grip and design are very important.

These key features can affect the effectiveness and ease of using a hammer drill. The chuck size and BPM are key for matching the drill to your project needs. Variable speed settings and a good design improve both control and comfort. By paying attention to these aspects, you can choose a hammer drill that suits your demands, increasing both productivity and user comfort.

Hammer Drill Safety Tips

Using a hammer drill safely is very important for your safety and the quality of your work. Always wear safety glasses to protect your eyes from debris. Also, use gloves to protect your hands from vibrations and potential injury. When drilling, make sure the drill bit is securely placed in the chuck. Don’t force the drill. Let the tool do the work. If it’s too difficult, check the bit and drill settings. Finally, always unplug the drill before you change bits or make any adjustments. By following these safety tips, you can reduce the risks while using a hammer drill and improve the safety of your work.

- Wear Safety Glasses: Always protect your eyes from flying debris.

- Use Gloves: Helps protect your hands.

- Secure the Bit: Make sure the drill bit is properly secured in the chuck.

- Don’t Force the Drill: Allow the tool to do its job and do not apply too much pressure.

- Unplug Before Adjusting: Always unplug the drill before changing bits.

Following these safety measures helps ensure a safe and effective working environment when using a hammer drill. Protecting your eyes with safety glasses and hands with gloves are essential for preventing injuries. Also, the tips on proper bit attachment and preventing excessive force are key for both safety and optimal performance. Making sure the drill is unplugged before adjustments is crucial for safety. By following these suggestions, you’ll be able to work more safely and effectively.

FAQ: Do You Need a Hammer Drill for Concrete?

Question: Can I use a regular drill for concrete?

Answer: No, it’s not recommended. Regular drills lack the hammering action needed to effectively drill into concrete.

Question: What’s the main difference between a hammer drill and a regular drill?

Answer: A hammer drill combines rotation with a hammering action, whereas a regular drill only rotates.

Question: Are hammer drills safe to use?

Answer: Yes, but you must follow the safety guidelines. Always wear safety glasses and gloves.

Question: What size drill bit should I use for concrete?

Answer: That depends on the project. Read the instructions for the anchors or screws you’re using for the exact size.

Question: Can I use a hammer drill for other materials besides concrete?

Answer: Yes, but turn off the hammer function when drilling in wood, metal, or plastic.

Final Thoughts

Determining if Do You Need a Hammer Drill for Concrete? is often the first step when you’re planning a project. If you are working with concrete, brick, or stone, a hammer drill is a must-have tool. The hammering action makes it possible to drill into these surfaces quickly and efficiently, making your jobs easier and producing better results. Selecting the best hammer drill involves considering the type (corded or cordless), the chuck size, and other features such as BPM and variable speed. Remember to follow safety precautions, such as using safety glasses and gloves, to keep yourself safe. With the right hammer drill and the proper techniques, you’ll be well-prepared to tackle any concrete project. So, explore different projects with your new hammer drill!